Primary Aluminium

Alloys for Pressure Die Casting

RHEINFELDEN ALLOYS

Table of contents RHEINFELDEN ALLOYS –

Aluminium Alloys for Pressure Die Casting

General

Alloys

Processing datasheets

Technical information

ALUMINIUM RHEINFELDEN Group

RHEINFELDEN FAST ALLOYS

Forms of delivery

Customer support and research and development

Aluminium casting alloys by RHEINFELDEN ALLOYS

Profile of the alloys for the die casters

Publications

Castasil

®

-37

– AlSi9MnMoZr

Castasil

®

-21

– AlSi9Sr

Silafont

®

-36

– AlSi10MnMg

Silafont

®

-38

– AlSi9MnMgZn

Castaman

®

-35

– AlSi10MnMg

Thermodur

®

-72/-73

– AlMg7Si3Mn – AlSi11Cu2Ni2Mg2Mn

Magsimal

®

-59

– AlMg5Si2Mn

Technical informations / Processing datasheets

Castasil

®

-37

Castasil

®

-21

Silafont

®

-36

Silafont

®

-38

Castaman

®

-35

Thermodur

®

-73

Thermodur

®

-72

Magsimal

®

-59

Surface coating

Joining techniques for die castings

Eight target levels for HPDC

2

3

4

5

6 – 7

8 – 9

10

11 – 20

21 – 24

25 – 38

39 – 40

41 – 42

43 – 44

45 – 55

56

57

58

59

60

61

62

63

64

65 – 66

67 –68

68

1

ALUMINIUM RHEINFELDEN Group

“Progress by tradition”

ALUMINIUM RHEINFELDEN Group: This history of aluminium

in Germany started at Rheinfelden. In 1898 Europe’s first

river power station brought about the establishment of the first

aluminium smelter in Germany, at Rheinfelden, Baden.

The company has always operated in three business segments

and in October 2008 restructuring turned ALUMINIUM

RHEINFELDEN GmbH into a holding company and the former

ALLOYS, SEMIS and CARBON divisions became independent

GmbH & Co. KGs.

www.rheinfelden-group.eu

RHEINFELDEN ALLOYS GmbH & Co. KG: Products of

RHEINFELDEN ALLOYS can be found wherever steel designs

or iron casts can be replaced by light aluminium casts.

RHEINFELDEN ALLOYS is a powerful partner, especially to

the automotive and mechanical engineering sectors in provid-

ing alloys designed to the process and cast part based on the

customer’s particular needs.

www.rheinfelden-alloys.eu · Tel. +49 7623 93 490

RHEINFELDEN SEMIS GmbH & Co. KG

www.rheinfelden-semis.eu

RHEINFELDEN CARBON GmbH & Co. KG

www.rheinfelden-carbon.eu

Our policy

Our

RHEINFELDEN ALLOYS GmbH & Co. KG innovative char-

acter is what allows us to adapt rapidly to fast changing market

needs. The agility of a private family owned operated company,

the central geographic location in the European cast metal

market, the know-how and experience of our team, are factors

making a difference for Customers looking for reliable tradition

and modern innovation. Efficient and effective use of cast alu-

minum is on the forefront of our new developments in materials.

It is RHEINFELDEN ALLOYS philosophy to fulfill also the newest

requested standards of quality, either ISO or VDA. Please ask for

our actual certificates or have a look at our homepage.

We offer customized alloys and new solutions for high perfor-

mance materials and light weight components with focus on low

carbon foot print products. Everywhere where steel construction,

cast iron or composites can be replaced by light-weight cast

aluminum, we’re at work !

2

RHEINFELDEN FAST ALLOYS

Panoramic view of the entire complex

Seven good reasons for RHEINFELDEN FAST ALLOYS

• No storage costs

• No finance costs

• No LME speculation

• No supply bottleneck

• Flexibility for your production

• Contemporary reaction to market change

• Higher flexibility close to your costumer’s request

Ordered today

Produced tomorrow

Ready for shipment one day later

3

Forms of delivery

RHEINFELDEN-Ingot: Since the new RHEINFELDEN Production System came on line, all our

materials have been supplied in the form of RHEINFELDEN ingots. This ingot form is replacing

the HSG ingot yet retains all the advantages of the old form of delivery.

Liquid metal: If you want us to deliver metal to go straight into production, we can also supply

liquid metal.

Chemical analysis: The delivery slip contains the average actual batch analysis.

Stack labelling: Each stack features an information box containing the brand name and/or alloy

group name, internal material number, stack weight and on request a colour marking. The batch

number consists of the year in the sequential production number and the number in the sequenze.

Machine-readable bar codes can be printed in this box.

RHEINFELDEN-Ingot

The stack of RHEINFELDEN ALLOYS is built

with 95 single ingots including the 4 base ingots;

here the stack with 13 layers of ingots.

Ingot

Weight 6 – 8 kg

Base area 716 × 108 mm

Height up to 52 mm

Stack of 13 layers

Stack weight up to 760 kg

Base area 716 × 716 mm

Stack height up to 780 mm

4

Customer support and research and development

When RHEINFELDEN ALLOYS develop new materials we always aim to achieve efficient and

specific use of aluminium cast. Through the use of materials tailored and refined to increase perfor-

mance, RHEINFELDEN ALLOYS is constantly striving to help reduce vehicle weight and therefore

cut fuel consumption and CO

2

-emissions.

Every product and every customer has individual requirements of the material. The Customer

Support team at RHEINFELDEN ALLOYS has the job of anticipating these needs and producing

tailored materials, fitting the casts and your requirements.

RHEINFELDEN Customer Support

Please contact our customer support team and use our TechCenter installations at RHEINFELDEN

ALLOYS also for your foundry concerns. We can advise on the use of aluminium cast, the design of

casts and the choice of alloy. Use our experience for your success.

RHEINFELDEN technical center

Time is increasingly of the essence when our customers experience casting technology problems.

It is therefore crucial that we have the facilities to allow us to quickly solve problems through

experimentation and immediately incorporate new findings into production. This technical support,

renowned throughout the industry, is available exclusively to RHEINFELDEN ALLOYS customers.

Goals of research and development

The technical center assists the customer support team and runs development projects with the

following goals:

• To optimise the mechanical and cast properties of our aluminium cast alloys

• To develop alloys under consideration of the appropriate casting method

• To collaborate with designers on use of our cast alloy most suited to their applications,

including testing mechanical properties

RHEINFELDEN sales service

The portfolio of RHEINFELDEN ALLOYS sales department is always adjusted to the request of

our costumer. RHEINFELDEN ALLOYS has the possibility to offer different commercial strategies.

RHEINFELDEN Internet portal www.rheinfelden-alloys.eu

We at RHEINFELDEN ALLOYS development use also phase

simulation software for calculations and optimization of our

wide range of cast alloys. Highlighted is here the solidification and

phase growing simulation of Magsimal-59.

5

Aluminium casting alloys by RHEINFELDEN ALLOYS

Get the spirit of RHEINFELDEN

Quick finder for selecting the right alloy

The following table provides an overview of RHEINFELDEN ALLOYS, which are used

in the car building industry either for structural and chassis parts or either for

heat conducting parts. Further on table presents some details of the alloy properties.

excellent

very good

good

all right

poor

— not applicable

Alloy

Chemical

denomination

Flangeability

Electrical conductivity

Suitable for technical anodising

Suitable for punch riveting

Strength in as-cast state

Elongation

Hardness

Corrosion resistance

For constructions with thin walls

Impact toughne ss / ductilit y

Machinability at F

Machinability following T6

Mechanical properties at elevated

temperatures (200 °C)

Weldability

Sand casting

Gravity die

HPDC

Appropriate

casting method

Conducting

parts

Structural and chassis parts

—

— —

— –

— —

—

— —

— —

— —

—

— —

—

—

—

— —

–

– –

– –

– – –

–

– –

– – – – –

– – – –

– –

– – – –

– – –

– – – – –

– – –

– – –

–

Anticorodal-70 AlSi7Mg0.3

Silafont-36 AlSi10MnMg

Silafont-38 AlSi9MnMgZn

Silafont-09 AlSi9

Silafont-20 AlSi11Mg

Castaman-35 AlSi10MnMg

Castasil-37 AlSi9MnMoZr

Unifont-94 AlZn10Si8Mg

Castadur-30 AlZn3Mg3Cr

Magsimal-59 AlMg5Si2Mn

Alufont-52 AlCu4Ti

Thermodur-72 AlMg7Si3Mn

Thermodur-73 AlSi11Cu2Ni2Mg2Mn

Anticorodal-71 AlSi7Mg0.3-E

Rotoren-Al 99.7 Al99.7-E

Castasil-21 AlSi9Sr

6

An alloy, produced for large high pressure die cast structural parts in the automotive con-

struction industry. In the meantime several OEMs recognised the advantages of these alloys

for car structural or electrical applications: high dimensional stability, can be used without

heat treatment, shape well and easy to weld, or by Castasil-21 with highest electrical or heat

conductivity.

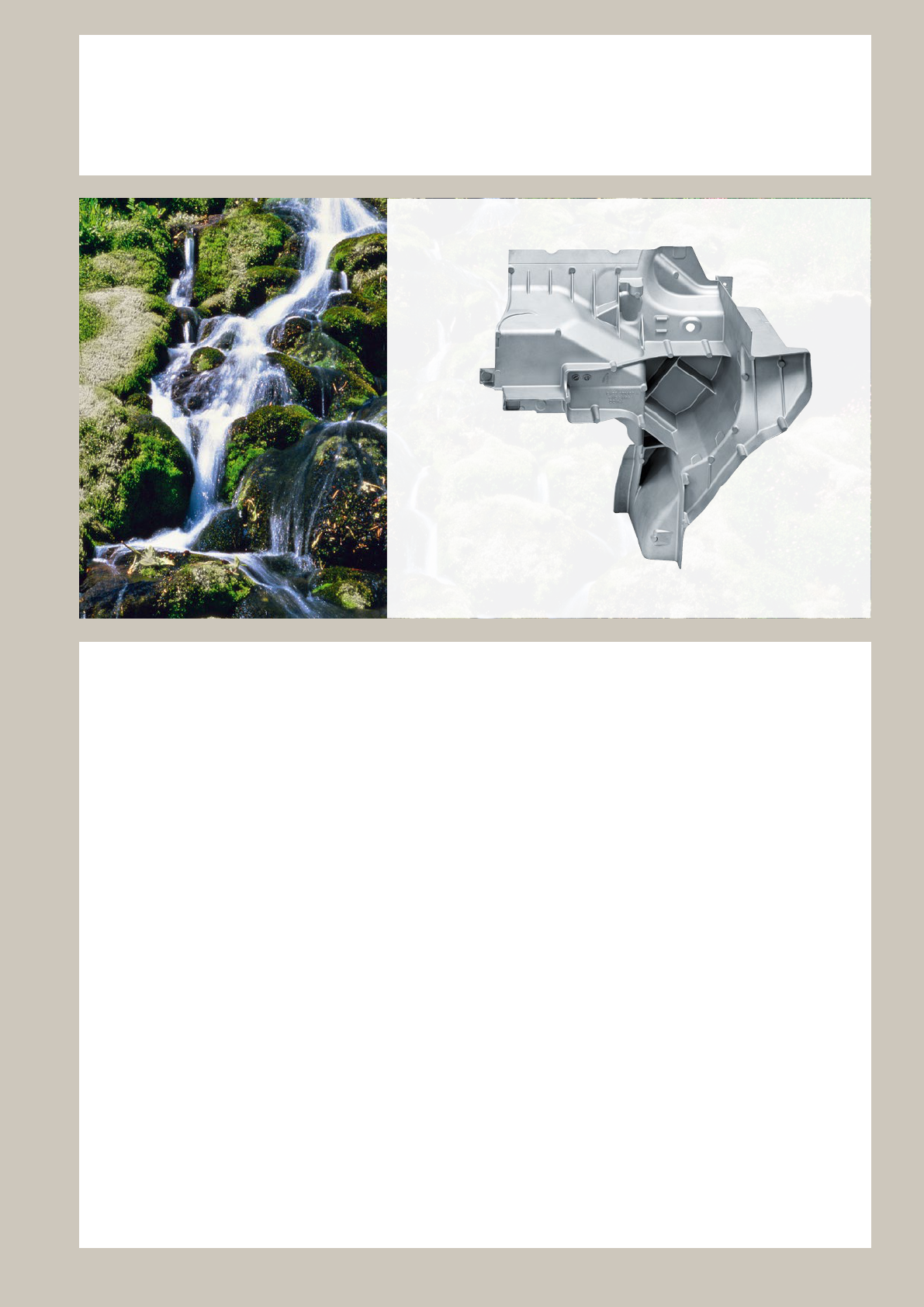

Nature’s equivalent: the vine branch which turns towards the sun, flexible, elastic and yet

incredibly tough and strong. > page 11

Castasil

®

– large surface, high dimensional stability, fantastic to cast

A family of materials which can be adapted to the part specifications and to the customer’s

individual production process with ultimate precision. Can be processed using any casting

procedure, outstanding flow properties, can be modified with sodium or strontium to further

enhance properties. Silafont is for complex, delicate components which have to satisfy precisely

defined requirements and, if they feature the right components, make maximum production

efficiency possible.

Silafont emulates flowing water,that flows around every stone and fills every cavity. > page 25

Silafont

®

– an infinite wealth of properties

An alloy family, that uses the possibilities of recycling, for a desired high sustainability –

represented in carbon footprint counter.

Nature’s role model: the lupine, growing from the humus of last year’s crop. > page 41

Castaman

®

– Reducing the Carbon-Footprint

A new material that withstands high temperatures like never before, allowing to play a key

role in increased efficiency in combustion engines: increased output, lower fuel consumption,

greater durability and lower emissions.

This alloy simulates the spider’s silk: outstanding mechanical properties, maximum strength,

stable, resilient and incredibly light. > page 43

Thermodur

®

– a glimpse into the future

An alloy for delicate parts which need to retain their strength and precise form over

a long period. Good weldability, high resilience, can be used in virtually any application.

Supreme corrosion resistance, even to salt water.

Parts which simulate the structure of the wings of a dragonfly: wafer thin, elastic and

yet offering incredible strength and resilience, they enable this dainty insect to fly

distances that never cease to amaze. > page 45

Magsimal

®

– of filigree lightness, but extremely resilient

7

Get the spirit of RHEINFELDEN

Profile of the alloys for the die casters

Silafont

®

- 36 [ AlSi10MnMg ]

• excellent castability

• applicable to thinnest wall designs

• magnesium content adjustable

to a wide range of requirements

• no heat treatment needed to

reach high elongation

• good die cast ejectability;

usable even for thinnest wall

thicknesses

• highest heat and electrical

conductivity compaired to AlSi

die casting alloys due to low

distorbing impurities

Castasil

®

- 21 [ AlSi9Sr ]

• good die cast ejectability

• heat treatable to highest

elongation and ductility

• very high corrosion resistance

• long-term stability

• high yield strength and excellent

elongation in the as-cast state

• very good corrosion resistance

• thin wall design possible

• good die cast ejectability

• long-term stability after

temper O

• high properties

• excellent weldability and machinability

• suitable for flanging, clinching or

self piercing

• high fatigue stress resistance;

highest compaired to AlSi-alloys

• excellent weldability; Suitable for

flanging, clinching or self piercing

• high yield strength and elongation in

the as-cast state or after temper O

• suitable to flanging, clinching or

self piercing, especially in temper O

Castasil

®

- 37 [ AlSi9MnMoZr ]

Treatment state R

p0.2

[ M Pa ] R

m

[ M Pa ] A [ % ] Hardness [ H BW ]

F 120 – 150 250 – 290 5 – 11 75 – 95

T7 120 – 170 200 – 240 15 – 2 0 60 – 75

Treatment state R

p0.2

[ M Pa ] R

m

[ M Pa ] A [ % ]

Conductibility [ M S /m ]

F 90 – 10 0 200 – 230 6 – 9 23 – 25

O 80 – 9 0 170 – 190 9 – 14 25 – 28

Treatment state Wall thickness [ mm ] R

p0.2

[ M Pa ] R

m

[ M Pa ] A [ % ]

F 2 – 3 120 – 150 260 – 300 10 – 14

F 3 – 5 100 – 130 230 – 280 10 – 14

8

Thermodur

®

- 73 [ AlSi11Cu2Ni2Mg2Mn ]

Magsimal

®

- 59 [ AlMg5Si2Mn ]

Thermodur

®

- 72 [ AlMg7Si3Mn ]

• usage in the as-cast state also for thick

wall HPDC

• low melt oxidation due to patented alloy addition

• no sticking to the die

• excellent castability, also for thick wall HPDC

• reducing distorsion is possible due to stabilising T5

• high corrosion resistance due to exact alloy limits

• high fatigue strength due to low iron content

• usage in the as-cast state for HPDC with

2 to 8 mm wall thickness

• low melt oxidation due to patented alloy addition

• no sticking to the die

• higher shrinkage in comparision to AlSi-alloys

• very high corrosion resistance,

no stress corrosion

• very high fatigue strength

• excellent weldability, suitable for flanging,

clinching and self piercing

• higher shrinkage in comparision to AlSi-alloys

• high elongation even at room temperature

• high temperature strength, especially at > 225 °C

• very high corrosion resistance

• excellent machinability

• very high hardness

• high temperature strength

Castaman

®

- 35 [ AlSi10MnMg ]

• outstanding castability, even for bigger

die casting designs

• magnesium content adjustable to a wide

range of requirements

• good die cast ejectability

• heat treatment T6 enables wide range of mechanical

properties

• very high corrosion resistance with high fatigue properties

• excellent weldability and machinability

• suitable to fit for flanging, clinching or self piercing

Treatment state R

p0.2

[ M Pa ] R

m

[ M Pa ] A [ % ] Hardness [ H BW ]

F 120 – 150 200 – 270 4 – 9 75 – 90

T6 18 0 – 26 0 250 – 320 6 – 12 80 – 110

Ageing R

p0.2

[ M Pa ] R

m

[ M Pa ] A [ % ] Hardness [ H BW ]

20 °C 190 – 20 0 350 – 380 7 – 10 80 – 100

225 °C / 500 h 150 – 175 180 – 205 < 20

Ageing R

p0.2

[ M Pa ] R

m

[ M Pa ] A [ % ] Hardness [ H BW ]

150 °C / 500 h 2 80 – 310 330 – 355 < 1 130 – 150

225 °C / 500 h 130 – 155 250 – 280 1 – 2

Treatment state Wall thickness [ mm ] R

p0.2

[ M Pa ] R

m

[ M Pa ] A [ % ]

F 2 – 4 160 – 2 20 310 – 340 12 – 18

F 4 – 6 140 – 170 250 – 320 9 – 14

9

Publications

Catalogues

Primary aluminium casting alloys Manual

Primary aluminium casting alloys Leporello

Manuals and processing data sheets Code

Silafont-36 Sf-36 518

Silafont-38 Sf-38 519

Silafont-09 Sf-09 516

Castasil-21 Ci-21 562

Castasil-37 Ci-37 561

Castaman-35 Cm-35 571

Thermodur-73 Td-73 562

Unifont-94 Uf-94 532

Magsimal-59 Ma-59 545

Rotoren -A luminium Al 9 9,7 - E 551

Reports based on real-life use and on the development of aluminium Code

Producing Low-iron Ductile Aluminium Die Casting in Silafont-36 630

Experiences of series production of high pressure die cast steering wheel frames in Magsimal-59 632

Melt testing in the aluminium foundry with a focus on quality 623

The possibilities of aluminium high pressure die casting – using this technology close to the limits; Sf-36 und Ma-59 635

Potentials of aluminium pressure die casting – application of this technology close to the limits; Sf-36 and Ma-59 636

31 reasons for using aluminium casting 629

Ductile high pressure die casting alloy with low iron content; Silafont-36 803

Recently developed high pressure die casting alloy with outstanding mechanical properties when cast; Magsimal-59 804

Non-ageing ductile high pressure die casting alloy for automotive construction; Castasil-37 806

http://rheinfelden-alloys.eu/en/downloads/

10

Castasil

®

-37

Large areas, high dimensional stability, fantastic to cast

Development by RHEINFELDEN ALLOYS Castasil-37

shows good mechanical properties, especially elongation,

which are superior to those of conventional AlSi-type alloys.

Out-standing castability and weldability enable the casting

of complex designs. Self-piercing riveting trials in the as-

cast state led for example to good results.

The properties are mainly influenced by alloying with silicon,

manganese, molybdenum and strontium. A low magnesium

content is essential for the excellent stability of long-term

stability of mechanical properties.

Specially chosen chemical composition enables the follow-

ing casting properties:

• excellent castability

• suitable for minimum wall thicknesses

• no sticking to the die

With increasing number of applications, mainly in car

manufacturing, other properties of Castasil-37 became

also important:

• high fatigue strength

• very good corrosion resistance

• excellent weldability

• excellent machinability

• suitable for self-piercing riveting and clinching

• suitable for glueing connections in car design

11

Physical composition

Processing properties compared to standard pressure die casting alloys

Chemical composition of Castasil - 37, AlSi9MnMoZr

Mechanical properties

Castasil

®

- 37 – Properties at a glance

Wall thickness

[ mm ]

YTS

R

p0.2

[ M Pa ]

UTS

R

m

[ M Pa ]

Elongation

A [ % ]

2 – 3 120 – 150 260 – 300 10 – 14

3 – 5 10 0 – 13 0 230 – 280 10 – 14

5 – 7 80 – 110 200 – 250 10 – 14

Unit Validity range

Solidification range 595 – 550 °C

Density 2.69 kg / dm

3

20 °C

Young’s modulus 68 – 75 GPa 20 °C

Linear thermal expansion coefficient 21 1 / K × 10

-6

20 – 200 °C

Thermal conductivity 1.3 W / (K × cm) 20 – 200 °C

Electrical conductivity 18 – 22

MS / m o r m / (Ω × mm

2

)

20 °C

Fatigue strength (r = -1); as-cast state (F);

form factor K

t

= 1.2

86 MPa 10

6

cycles

Alloy type Castasil-37 Silafont-36 AlSi9Cu3(Fe)

Stability of mechanical properties very good medium good

Hot crack tendency low low low

Sticking tendency low low low

Die life > 80 % > 80 % 100 %

Linear shrinkage 0.4 – 0.6 % 0.4 – 0.6 % 0.4 – 0.6 %

[%] Si Fe Cu Mn Mg Zn Mo Zr Ti Sr others

min. 8.5 0.35 0.1 0.1 0.006

max. 10.5 0.15 0.05 0.6 0.06 0.07 0.3 0.3 0.15 0.025 0.10

Note chapter “Technical Information”!

12

Castasil

®

- 37 [ AlSi9MnMoZr ]

Longitudinal carrier / Audi A8

Castasil-37; as-cast

1400 × 600 × 300 mm; weight: 10 kg

The extraordinary properties of Castasil-37 in the as-cast

state result together with a well running HPDC process

to the recommended high strength (YTS > 120 MPa) and

very high ductility (elongation > 10 %).

From one side these casted structural nodes reduced

the BIW weight by 200 kg. On the other side they are

reducing the “Carbon footprint” even during production

by energy low casting process and further on during

the long-term usage of the car.

Suspension-strut dome

Castasil-37; as-cast

Wall thickness 5 mm

430 × 330 × 340 mm; weight: 4.4 kg

More and more cars are designed with compact suspension

strut domes, produced in HPDC with vacuum application.

The showed suspension strut dome in Castasil-37 has several

integrated design elements and is used in the front BIW

without any additional heat treatment like T6/T7.

This is substituting a complex multi-part sheet design.

These die casted suspension strut domes have good weldability,

rivet deformability and are easy to glue. In addition they

have high dynamic strength and reduce weight and production

cost due to lower connecting areas and stiffer BIW structure.

13

Castasil

®

- 37 [ AlSi9MnMoZr ]

Crosswise reinforcement/sports car

Castasil-37; as-cast

370 × 70 × 60 mm; weight: 0.18 kg

Internal door parts for a sports car

Castasil-37; as-cast

620 × 340 × 170 mm; weight: 1.2 kg

700 × 340 × 170 mm; weight: 2.1 kg

Cover for switching electronics

Castasil-37; as-cast

365 × 270 × 45 – 65 mm; weight: 0.69 – 1.5 kg

A-pillar car / Audi

Castasil-37; as-cast; weldable

815 × 575 × 190 mm; weight: 6 kg

As part of the structural design for cars this

part is responsible for crash safety a lot

and has to implement or carry several other

elements. Also parts of the car electronic

are mounted, by using the quite high heat

transfer of this Castasil-37 cast.

14

Castasil

®

- 37 [ AlSi9MnMoZr ]

Rear connecting nodes of aluminium body / Lamborghini

Castasil-37; as-cast; weldable

320 × 210 × 200 mm; weight: 2.0 kg

Convertible soft-top lever / VW

Castasil-37; as-cast

510 × 100 × 80 mm; weight: 0.56 kg

In the event of a crash the hinged levers of the folding top

are particularly close to the passengers in the vehicles and

are therefore subject to especially high ductility require-

ments. These components must be prevented from breaking

off. Castasil-37 fulfils the particular requirements of this

folding top lever.

Reinforcement for convertible soft-top

Castasil-37; as-cast; weldable

260 × 220 × 60 mm; weight: 0.6 kg

Upper safety housing for high voltage plug connectors

Castasil-37; as-cast

210 × 330 × 140 mm; weight: 1.5 kg

In hybrid or electric cars the power electronic has to be

sheltered separately and is covered with a crash safe

housing to avoid unexpected contact. Additionally there is

a die casted cover, to avoid plug-off without intension

during a service run.

15

20 μm

Al

15

Mn

3

Si

4

Castasil

®

- 37 – Chemical composition

Table 1 shows the typical chemical composition. The silicon

content of 8.5 to 10.5 % enables good castability and outstand-

ing die filling capabilities. This is important for casting large

components and for filling complex designed structures. Silicon

growth during solidification leads to less shrinkage and hot

crack tendency of the alloy compared to other alloy systems.

Strontium modifies the eutectic silicon, which is very important

for ductility. The addition of strontium changes the morphology

of the silicon from lamellar or plate-like into a sponge-like coral

one. As strontium promotes hydrogen absorption, an effective

degassing of the melt with a rotating impeller is necessary.

This keeps the hydrogen content low and thus reduces poros-

ity and improves weldability. High elongation essentially results

from the high cooling rate of the pressure die casting process,

the modification with strontium and the very finely distributed

eutectic. These raise the elongation values up to more than 12 %.

The difference between a very fine Castasil-37 eutectic and a

modified, but coarser Silafont-36 eutectic is shown in figure 1

respectively figure 4 on page 32. The microstructures are taken

from 3 or 4 mm thick die cast sample plates.

An iron content below 0.15 % minimizes the formation of AlFeSi-

phases, which have a needlelike shape in the microstructure. Due

to their shape, these phases significantly influence the strength,

elongation and fatigue strength and promote crack formation

under load. Manganese is used instead of iron to avoid sticking to

the die. Manganese forms Al

12

Mn

3

Si

2

-phases, which can be seen

as globulitic particles in the microstructure, see figure 1a.

Magnesium is kept very low as it determines long-term ageing

behaviour.

Tab. 1: Chemical composition of Castasil-37, AlSi9MnMoZr in the ingot (weight in %)

Fig. 2: Yield strenght depending on the magnesium content in temper F, after

1000 h at 120 °C and after 3 h at 180 °C. Sample plate: 220 × 60 × 3 mm

180

Magnettafeln Roadshow

alter Katalog S.31

Yield strenght R

p0,2

[MPa]

Magnesium content [%]

120 °C

1000 h

0.040.003 0.08

170

160

150

140

130

120

0.120.100.060.02

Increasing

ageing

180 °C

3 h

As-cast state

Fig. 1: Microstructure of Castasil-37, AlSi9MnMoZr, in the as-cast state,

3 mm sample plate

[%] Si Fe Cu Mn Mg Zn Mo Zr Ti Sr others

min. 8.5 0.35 0.1 0.1 0.006

max. 10.5 0.15 0.05 0.6 0.06 0.07 0.3 0.3 0.15 0.025 0.10

16

Castasil

®

- 37 – Mechanical properties

Effect of magnesium on ageing behaviour

Figure 2 gives an overview of the properties of Castasil-37 in the

as-cast state, after 3 hours at 180 °C and after ageing at 120 °C

for 1000 hours (almost 6 weeks). The material properties change

during the course of time, whereby the effect of the magne-

sium on ageing behaviour becomes obvious. Artificial ageing is

necessary in order to avoid this natural ageing or to minimize its

effect. The following trials should indicate with which magnesium

contents no ageing occurs and how the mechanical properties

are influenced.

Table 3 shows the chemical analyses of the tested variants. Mag-

nesium was added in quantities between 0.003 % and 0.1 %.

The manganese content was maintained at an optimum level of

0.6 % and strontium at 120 ppm for a good modification of the

eutectic silicon. Sample plates 220 × 60 × 3 mm were cast in a

single-cavity die in order to determine the mechanical properties.

The test samples were cast on a 400 t Bühler B machine with

a forced venting system. The melt was cleaned and degassed

by means of a rotating impeller and the density was checked

by means of a low-pressure density sample. A density index

between 3 % and 5 % was established prior to degassing, there-

after below 2 %.

Samples were artificially aged at 120 °C for 1000 hours to simu-

late long-term ageing in the as-cast state.

Figure 2 shows the impact of magnesium content on the yield

strength in temper F (as-cast state), O (180 °C / 3 h) and O

(120 °C / 1000 h). If the samples are left at room temperature in

the as-cast state, the yield point remains approximately at the

same level with different magnesium contents. However, with

increased temperature the material properties change percep-

tibly with increasing magnesium content. Ageing starts from a

magnesium content between 0.04 % and 0.08 %. 0.06 % can

be assumed as the limit value. No significant dependence on

the magnesium content was established with regard to ultimate

tensile strength and elongation. Elongation values between 10 %

and 12 % were established in all tempers, which is rather high for

an AlSialloy without deep changes of the microstructure.

The mechanical properties of Castasil-37 depend to a slight

extent on the wall thickness and therefore on the solidification

conditions. The elongation values are impressive: 11.6 % with

2 mm wall thickness and even 14 % with wall thickness between

3 and 6 mm.

Yield strenght and ultimate tensile strenght react as known to

thicker walls and therefore longer solidification times.

Castasil-37 reached on our flat tensile samples a yield strenght

of 139 MPa with 2 mm wall thickness, falling down to 95 MPa

with 6 mm-thick samples (Fig. 3). The yield strenght is therefore

almost two times higher than the one of other magnesium-free

AlSi-pressure die casting alloys. At the same time elongation

remains steadily above 12 %, which reveals very important for

modern applications in crashrelevant bodywork manufacturing.

Tab. 2: Chemical compositions of trial series with different magnesium content in weight %

No. Si Fe Cu Mn Mg Zn Ti Sr

1 10.2 0.09 0.001 0.60 0.003 0.005 0.08 0.0126

2 10.1 0.09 0.001 0.60 0.020 0.005 0.08 0.0121

3 10.5 0.10 0.002 0.60 0.040 0.006 0.08 0.0150

4 10.3 0.09 0.002 0.59 0.082 0.005 0.08 0.0120

5 10.3 0.09 0.002 0.61 0.102 0.005 0.08 0.0120

17

Castasil

®

- 37 – Mechanical properties

Fig. 4: Stress-strain curve for Castasil-37, AlSi9MnMoZr, in the as-cast state (F)

Heat treatment

Castasil-37 can be annealed to temper O (without solutionizing)

in order to further increase its elongation. Figure 5 indicates the

mechanical properties for annealed states over different periods.

The yield point of 114 MPa in the as-cast state gradually falls to

93 MPa after 90 minutes at an annealing temperature of 350 °C.

The ultimate tensile strength behaves in a similar way. Yield

strength and ultimate tensile strength can be assumed to be stable

from a technical point of view! Elongation, on the other hand,

increases continuously from 14 % to 16,5 % after 90 minutes.

This means that elongation can be increased in Castasil-37 by

a single-step annealing to temper O.

Fatigue strength

In addition to the properties under static load, the designer

needs information on the dynamic load-bearing capacity of a

material. Samples were taken from temper F die cast plates with

4 mm wall thickness in order to determine the fatigue limit under

alternating loads. The sample geometry has a decisive influence

on the number of load alternations achieved. Form factor K

t

= 1.2

was selected in this case. The results of the fatigue test are

shown in figure 6. The progress of the curves in figure 6 is deter-

mined according to the common assessment method of 2007.

Wöhler curves show the fatigue strength under alternating

load with 5 %, 50 % and 95 % fracture probability. Castasil-37

endures one million loads alternations to an amplitude of 86 MPa

(5 % fracture probability) and the same number of cycles to an

amplitude of 103 MPa with 50 % fracture probability. This equals

39 % of the static notch-ultimate tensile strength in relation

to the sample shape used. Experience shows that cast samples

of conventional aluminium alloys in the heat-treated state only

achieve a far lower value.

High speed test for deformability

There is a difference in material performance either measuring

the tension test at high speed or with normal low speed with

0.02 mm/s. Therefor a tension test was run with 6 m/s similar to

the crash test velocity.

With Castasil-37 we measured a high positive effect for the yield

strength of 35 – 40 %, like demonstrated in figure 7.

Fig. 3: Mechanical properties of Castasil-37, AlSi9MnMoZr, in the as-cast

state (F), depending on the wall thickness

Wall thickness [mm]

Stress R [MPa]

1 72 3 4 5 6

0

2

16

14

12

10

8

6

4

R

p0.2

R

m

A

Elongation A [%]

Elongation A [%]

Stress R [MPa]

The extremely regular stress-strain curve in figure 4 results from

a finely modified microstructure with no strenghtening effect of

magnesium in solid solution.

One of the advantages of Castasil-37 are good mechanical

properties in the ascast state in order to save the time and costs

of heat treatments with solutionizing, which produces component

distortion and needs an additional straightening process.

Temper F

R

p0.2

= 125 MPa

R

m

= 277 MPa

A = 14.9 %

F

18

Castasil

®

- 37 – Mechanical properties

Fig. 5: Mechanical properties of Castasil-37 in the as-cast state (F) and various

annealed states. Test samples: 4 mm pressure die casting plate

Stress R [MPa]

Elo ngat ion A [ % ]

300

250

200

150

100

50

0

18

16

14

12

10

8

6

4

2

0

F

350 °C /

30 min .

350 °C /

60 min.

350 °C /

90 min.

R

p0.2

R

m

A

R

p0.2

R

m

A

R

p0.2

R

m

A

R

p0.2

R

m

A

Melting

Castasil-37 ingots can generally be processed into pressure die

castings in the foundry without special treatment. However, in

order to produce casts of high consistent quality, following points

must be noted.

The good properties of Castasil-37 are based essentially on the

production of this alloy from very pure electrolytic metal. Metallic

impurities in the melt like magnesium, iron zinc and copper should

be avoided. Rapid melting is important in order to avoid strong

oxidation of the melt and the formation of segregations. Oxides

have a negative impact on the casting behaviour and on the prop-

erties of the cast to a large extent. Melt cleaning, preferably

with an impeller, is necessary in order to avoid this with Castasil-37.

This cleaning of oxides and dissolved hydrogen should be car-

ried out in the melting furnace as far as possible, otherwise a

low-turbulence metal pouring is necessary in each step of the

process.

The strontium loss must be kept at a minimum in order to main-

tain good mechanical and technical properties. A strontium loss

of 0.004 % can normally be expected per melting procedure.

In practice, a minimum content of 60 ppm and an upper limit

of 250 ppm strontium in the melting furnace have proved to be

successful for a good strontium modification. Higher strontium

contents may possibly lead to increased hydrogen absorption in

the melt, which should however be avoided for weldable casts.

A reduction in elongation can be expected with lower contents

of strontium.

The melt temperature should not exceed 780 °C. Otherwise,

increased strontium loss and increased oxide formation are to

be expected. A casting temperature of 680 to 720 °C is recom-

mended. The casting temperature depends on the shape, flow

distance and wall thickness of the casts but also on the dosing

system from the melting furnace and on the eventual presence

of a shot sleeve heating device.

Casting

Common guidelines apply to the configuration and design of

pressure die castings with regard to wall thicknesses, avoidance

of material accumulations, radii of edges, corners and transi-

tion points, chamfers and undercuts. Some points are specified

below:

A linear shrinkage of 0,4 – 0,6 % is assumed for pressure die

casting dies designed for this AlSi-alloy with 9 % silicon.

Fig. 6: Wöhler’s diagram for Castasil-37, AlSi9MnMoZr, in the as-cast state (F)

Stress R [MPa]

Number of load cycles [n]

95 %

5 %

10

6

10

7

10

8

10

5

50 %

200

180

160

140

120

100

80

60

40

20

0

Wöhler's diagram for Castasil-37

Stress ratio r = -1

4 mm wall thickness, form factor K

t

= 1,2

5 %, 50 %, 95 % fracture probability

10

4

Fig. 7: Average strain velocity value for Castasil-37 as-cast state (F) at high speed

tension test

Stress R

[MPa]

Average strain velocity [m/s]

0.01 1000.0001 1

400

350

300

250

200

150

100

50

0

1000100.10.001

R

p0.2

40

35

30

25

20

15

10

5

0

A

A [%]

R

m

19

100 μm

100 μm

Castasil

®

- 37 – Application

The shrinkage depends locally on the die configuration, e. g.

when casts have varying rib patterns. Good ejection behaviour

enables draft angles starting from 1.0 °C. Lower draft angles shall

be defined with the die designer.

Conventional die-release agents and their mix ratios can be used.

The release agent quantity and its application must be adapted

to special cast requirements such as those of welded structural

parts, parts assembled by flanging or with a top-quality painting.

Pre-solidification

Deformation-intensive casts react sensitively to internal notches.

Pre-solidifications from the shot sleeve form defects such as

those shown in Figure 8a and thereby reduce the achievable de-

formation. Pre-solidifications can be metallographically detected

on the basis of the different solidification microstructure as

shown on an etched sample in Figure 8b. Investigations with

a thermoregulated shot sleeve on a 400 t pressure die casting

machine have demonstrated that pre-solidifications no longer oc-

cur in test plates starting from a sleeve temperature over 190 °C.

The lower the filling level of the chamber, the higher this tempera-

ture should be.

Fig. 8b: Micro of an etched pre-solidification

Joining technology

Also in chapter “Joining techniques for die casting” there are

details described for welding, riveting with glueing and flanging

of Castasil-37 casts.

Applications

Castasil-37 was developed for pressure die castings requiring

high elongation and a specific yield strength in the as-cast state.

These are, for example, structural components such as nodes for

SpaceFrame designs or pillars for car bodies. Today the majority

of these components are manufactured in AlSi-alloys and costin-

tensively heat treated in order to obtain the required properties.

Thin-walled components may distort during heat treatment with

solutionizing, calling for an additional process step to straighten

the component.

Castasil-37 with a yield strength of at least 120 MPa and elonga-

tion of more than 12 % provides in the as-cast state mechanical

properties which are adequate for many structural components

in cars. Elongation can be further increased with single-step

annealing at 350 °C for 30 to 90 minutes. In addition to the

good properties in the as-cast state, Castasil-37 is resistant to

long-term ageing thanks to the absence of magnesium. Long-

term trials at high temperatures (120 °C /1000 h) have shown

that mechanical properties remain at least at the high level of the

as-cast state.

Bibliography

Rheinfelden brochure Code 637, “Optimizing the Magnesium

and Manganese content for the structural part application”,

published for NADCA 2003, 10/2003.

Rheinfelden brochure Code 638, “Economic production of

ductile and weldable aluminium castings”, published

by Dr.-Ing. Stuart Wiesner, 02/2006 in CPT International.

Fig. 8a: Micro of a pressure die casting with crack along a pre-solidification

20

Castasil-21 is a HPDC alloy developed by RHEINFELDEN

ALLOYS for casts with outstanding requirements in terms

of electrical or thermal conductivity.

Aluminium 99,7 for rotors has indeed higher electrical

conductivity, but in praxis you need lower contraction for

huge casts, like with an alloy with more than 8 % silicon.

The application of Castasil-21 may help to lower the weight

of HPDC, especially for the light weight design of cars

with their additional casts like battery housing, conductor

plate for electronics, LED-lighting, but also for general

purposes of heating and cooling.

Chemical composition was optimized in order to have

high conductivity (up to 30 %) compare with usual HPDC

aluminium alloys.

The specially chosen chemical composition results in

following casting properties:

• excellent casting ability with good ejectability

• well usable for thin wall fins

More and more applications either in car design or in

telecommunication area need also following properties:

• very good corrosion resistance to weather

• good mechanical strength; excellent machinability

• flangeable or deformable to fix parts together

• suitable for glueing connections in car design

• electrical conductivity comes up to 45 % IACS,

to substitute Cu in the idea of light weight design or

Al 99,7 in rotors

Castasil

®

-21

Large areas, high dimensional stability, fantastic to cast

21

Physical composition

Processing properties compared to standard pressure die casting alloys

Chemical composition of Castasil-21, AlSi9Sr

Mechanical properties

Castasil

®

- 21 – Properties at a glance

Temper

YTS

R

p0.2

[ M Pa ]

UTS

R

m

[ M Pa ]

Elongation

A [ % ]

F 90 – 100 200 – 230 6 – 9

O 80 – 9 0 170 – 19 0 9 – 14

Unit Validity range

Solidification range 595 – 550 °C

Density 2.65 kg / dm

3

20 °C

Young’s modulus 62 – 78 GPa 20 °C

Linear thermal expansion coefficient 21 1 / K × 10

-6

20 – 200 °C

Thermal conductivity temper O < 1.7 W / (K × cm) 20 – 200 °C

Electrical conductivity temper F 23 – 25

MS / m o r m / (Ω × mm

2

)

20 °C

Electrical conductivity temper O 25– 28

MS / m o r m / (Ω × mm

2

)

20 °C

Alloy type Castasil-21 Silafont-36 Rotoren-Al 99.7

Stability of mechanical properties very good medium very good

Hot crack tendency very low very low high

Sticking tendency low low high

Die life 100 % 100 % 80 %

Linear shrinkage 0.4 – 0.6 % 0.4 – 0.6 % 0.8 – 1.2 %

Note chapter “Technical Information”!

[%] Si Fe Cu Mn Mg Zn Ti Sr others

min. 8,0 0,5 0,01

max. 9,0 0,7 0,02 0,01 0,03 0,07 0,01 0,03 0,10

22

Castasil

®

- 21 [ AlSi9Sr ]

Heatsink for electronic device

Castasil-21; temper O

170 × 70 × 70 mm; weight: 0.4 kg

This cast with fixed electrical divice has to diffuse

the hot spot of heat through the massive plate

and the casted fins and should lower the maximum

temperature ever.

Higher heat conductivity of the alloy results directly

in lower temperature. It is not necessary to design

longer fins or add forced air ventilation.

Heatsink for electronics box

Castasil-21; temper 0

460 × 160 × 65 mm; weight: 1.5 kg

Heat conducting housing for switching electronics in cars

Castasil-21; temper 0

160 × 200 × 55 mm; weight: 0.57 kg

23

Castasil

®

- 21 [ AlSi9Sr ] – Properties

Chemical composition

Table 1 shows the Castasil-21 composition with a silicon content

of 8 to 9 %. Thus, the processing temperature is 680 – 750 °C, an

area with typical thermal shock wear of die chamber and cavity.

Strontium causes a further lowering of the eutectic point, that is

the melting temperature, of about 6 – 8 °C. In die casting alloys

Strontium reduces the affinity of the melt to the die mold, i.e. the

tendency to stick on, although Castasil-21 is already alloyed with

an Fe content from 0.5 to 0.7 %.

As an impurity in this conductive alloy are magnesium and zinc

contents of more than 0.08 % and a copper content more than

0.02 %. While forming the conductivity disturbing solid solution

phases these elements are already at lower levels, but this is

negligible compared to the effects from the die casting process

(Fig. 1). Not so with the manganese and titanium content.

Here a value of only 0.01 % should not be exceeded in order to

keep the conductivity high. Because Castasil-21 is produced

with primary aluminum as base, further accompanying elements

are also kept very low.

Electrical conductivity

But more important is the modification of the silicon crystal during

solidification. The strontium addition causes a coralline

solidification structure of the Si crystal in the eutectic, the so

called modification. The relevant Castasil-21 advantage of this

modification is the higher conductivity of plus 2 – 4 MS /m.

Heat treatment

The processing in the die casting is characterized by a very rapid

solidification. Although this achieves higher strength and hard-

ness, this microstructure is negative for achieving high conductiv-

ity ! Castings out of Castasil-21 can even further be increased

in their conductivity by one-stage heat treatment, whereby

the internal stress of the cast structure is equalized than. In the

as-cast state a die cast with 6 mm wall thickness may reach

even 25 MS/m.

A heat treatment of 350 °C for 2 h or 250 °C for 3 h provides

superior conductivity of around 28 MS/m (Fig. 2). In this state,

the die casts have 83 % of the conductivity of Al 99.7. Upon

the cooling of the components after the stress-relieving may

only slowly air cooling to be made.

Handling instructions

Cleaning and processing the melt should result in a low achieved

oxide impurity. A strontium content of 100 to 350 ppm ensures

the modification. Ingate design and die cast parameters must be

optimized to result in a solid structure without pores, due to these

technically disturb the conductivity. Handling instructions for melt

preparation on page 56.

Electrical conductivity [ m/(Ω × mm

2

) ]

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

AlSi12(Fe) 170 °C 250 °C 350 °C Al for rotors

1h 2 h 3 hFF F 1h 2 h 3 h 1h 2 h 3 h

Castasil-21

Conductivity [MS/m]

Content of alloying element [%]

35

30

25

20

15

10

Cr

Mn

Zr

Ti

Cu

Fe

Zn

Si

0 0.2 0.4 0.6 0.8 1.0 1.2 1.4

37

Tab. 1: Chemical composition of Castasil-21, AlSi9Sr in the ingot (weight in %)

Fig. 1: Relationship between electrical conductivity of Al99,9 and added alloying

elements

Fig. 2: Electrical conductivity of Castasil-21 through heat treatment of the HPDC

Mg

[%] Si Fe Cu Mn Mg Zn Ti Sr others

min. 8,0 0,5 0,01

max. 9,0 0,7 0,02 0,01 0,03 0,07 0,01 0,03 0,10

24

Silafont

®

-36

An infinite wealth of properties

The pressure die casting alloy Silafont-36 was developed

by RHEINFELDEN ALLOYS in order to obtain maximum

elongation after heat treatment with average strength

values compared to standard pressure die casting alloys.

Mechanical properties at Silafont-36 can be further

improved by various heat treatments. Silafont-36 can thus

achieve elongation values over 15 % or yield strength

values around 260 MPa.

Besides these particular good mechanical properties,

Silafont-36 has also following properties required for

the pressure die casting process:

• excellent die cast castability

• no sticking to the die

• excellent machinability

In more and more applications, mainly in car manufac-

turing, other properties of Silafont-36 are of increasing

importance:

• very good corrosion resistance

• high fatigue strength

• excellent weldability for aluminium profil-cast designs

• suitable for self-piercing riveting and similar joining

processes

• suitable for glueing connections in car design

25

Physical composition

Processing properties compared to standard pressure die casting alloys

F: As-cast state

Heat treatment without solutionizing:

T5: Quenched directly after removal from the die

and artificially aged

Heat treatment with solutionizing:

T4: Solutionized, quenched and naturally aged for

more than 6 days

T6: Solutionized, quenched and artificially aged

T7: Solutionized, quenched and overaged

It should be taken into account that the magnesium

content must be tuned according to the required

property profile. Higher elongation values are linked to

lower values for yield strength and vice versa.

Elongation A [%]

Yield strength R

p0.2

[ MPa ]

Low

magnesium

T 5

F

T 7

T 4

High

magnesium

T 6

Mechanical properties

Yield strength and elongation in various heat treatment states and magnesium contents

Chemical composition of Silafont-36, AlSi10MnMg

Silafont

®

- 36 – Properties at a glance

Unit Validity range

Solidification range

590 – 550 °C

Density

2.64 kg / dm

3

20 °C

Young’s modulus

74 – 83 GPa 20 °C

Linear thermal expansion coefficient

21 1 / K × 10

-6

20 – 200 °C

Thermal conductivity temper O

1.5 W / (K × cm) 20 – 200 °C

Electrical conductivity temper F

21 – 26 MS / m o r m / (Ω × mm

2

) 20 °C

Fatigue strength (r = -1) in the as-cast state (F)

89 MPa 50 × 10

6

cycles

Alloy type Silafont-36 AlSi10Mg(Fe) AlSi9Cu3(Fe)

Heat treatment for property improvement very good good medium

Hot crack tendency low low low

Sticking tendency low low low

Joining potential high medium low

Die life > 80 % > 80 % 100 %

Linear shrinkage 0.4 – 0.6 % 0.4 – 0.6 % 0.4 – 0.6 %

Note chapter “Technical Information”!

[%] Si Fe Cu Mn Mg Zn Ti Sr P others

min. 9.5 0.5 0.1 0.04 0.010

max. 11. 5 0.15 0.03 0.8 0.5 0.07 0.15 0.025 0.001 0.10

26

Silafont

®

- 36 [ AlSi10MnMg ]

Cross member off-road vehicle

Silafont-36; as-cast

1020 × 690 × 280 mm; weight: 10.3 kg

Suspension strut dome

Silafont-36; as-cast

420 × 350 × 330 mm; weight: 4.3 kg

To cast a suspension dome reduce the overall produc-

tion effort a lot in comparision to a sheet design, and

give an weight reduction advantage too. In addition the

Silafont-36 with Mg 0,25 – 0,35 % is easy to cast

worldwide even with some integrated design elements.

Casting method Treatment state

YTS

R

p0.2

[ M Pa ]

UTS

R

m

[ M Pa ]

Elongation

A

[ % ]

Brinell hardness

HBW

HPDC F 120 – 150 250 – 290 5 – 11 75 – 95

HPDC T5 155 – 245 275 – 340 4 – 9 80 – 110

HPDC T4 95 – 140 210 – 260 15 – 22 60 – 75

HPDC T6 210 – 280 290 – 340 7 – 12 90 – 110

HPDC T7 120 – 170 200 – 240 15 – 20 60 – 75

Cross member / Porsche Cayman

Silafont-36; temper T6

610 × 830 × 80 mm; weight: 6.5 kg

Rear lid frame

Silafont 36; as-cast

710 × 1180 × 280 mm; weight 9.5 kg

Mechanical composition

27

Silafont

®

- 36 [ AlSi10MnMg ]

Engine Cradle / Daimler

Silafont-36; temper O

920 × 580 × 170 mm; weight: 10.0 kg

This pressure die casting replaces a heavier,

painted sheetsteel welded structure. As a cast

part, it integrates further functions at the same

time. The high deformation capability of this

Silafont-36 pressure die casting was achieved

by heat treatment in Temper O. This engine

cradle was-cast in a die-cavity provided with a

forced venting system in order to obtain high

product safety.

Frontplate, front bumper bar

Silafont-36; temper T7

195 × 145 × 55 mm; weight: 0.75 kg

Truck cab tilting joint / Lkw Renault

Silafont-36; temper T5

560 × 460 × 250 mm; weight: 9.5 kg

This 9,5 kg-pressure die cast replaces a

heat-treated gravity cast. This Silafont-36

component supports the driver’s cab and

locks the forward tilted driver’s cab when

the engine compartment is open.

Foot board for truck bumper, electron beam welded

Silafont-36; as-cast

190 × 640 × 110 mm; weight 2.8 kg

Extraordinary safety requirements and a life time over 20 years

in public cars can be fulfilled with this two casts design.

The single casts are produced in Silafont-36 with 0,35 % Mg

and welded together in the as-cast state.

Electron beam welding without any added material enables

a distortion free but heavy loadable design in best surface

shape.

Cross member / Fiat

Silafont-36; temper T5

450 × 930 × 220 mm; weight: 10.7 kg

28

Silafont

®

- 36 [ AlSi10MnMg ]

Front section frame / BMW 3 Series Cabrio

Silafont-36; as-cast

1250 × 350 × 250 mm; weight: 4.5 kg

As this cast is the top part of the car front section,

it must absorb as much kinetic energy as

possible through deformation. The torsional rigidity

of the component gives an additional advantage

during mounting into the convertible car.

This was made possible thanks to a strong rib pattern

design on the component underside and by the

material Silafont-36 with 0,24 % magnesium.

Steering column / Daimler

Silafont-36; as-cast

450 × 70 × 90 mm; weight: 0.96 kg

Filigree guide surfaces to be cast with high

dimensional accuracy, deformation with-

out fracture edges in the event of a crash and

maximum rip-out resistance strength in

the ignition lock area are the decisive require-

ments for Silafont-36 with a magnesium

content around 0,24 %.

Tailgate frame / BMW

Silafont-36; temper F

510 × 1130 × 320 mm; weight: 3.3 kg

Frame side rail, rear node / Alfa Giulia

Silafont-36; temper T5

210 × 550 × 340 mm; weight: 4.8 kg

Housing for rollover bar mechanism / Opel

Silafont-36; as-cast, crimped pipe

45 × 250 × 40 mm; weight: 0.37 kg

Integrated into the driver’s seat this mechanism device

has to push out and to fix the roll over savety bar in case

of a crash. A flangable edge of the pipe with the SRS

explosive and the high stability of the light weight cast

are the advantages of Silafont-36 with 0,20 % Mg.

29

Silafont

®

- 36 – Chemical composition

Silafont-36 is a pressure die casting AISi10MgMn-type alloy with

strontium, which is produced on the basis of aluminium metal

with 99.8 % purity. The alloy constituent elements (Tab.1) with

narrow tolerances produce constant good cast quality. Strontium

is included for modification, i.e. for the modification of the eutec-

tic silicon.

The magnesium content is further adjusted according to the

various applications. The cast composition can have a higher limit

for iron, copper and zinc. This results from the conditions in the

pressure die casting foundry, but is determined by the require-

ments on the component.

A silicon content of around 10.5 % enables an excellent die filling

capability, and therefore an excellent castability.

In order to ensure that the silicon phase is already finely distribut-

ed in the as-cast state, the aluminium-silicon eutectic is modified

by the addition of strontium. This leads to high elongation values

in the as-cast state and also helps the spheroidisation of silicon

in case of following heat treatments.

As high deformation values are required, the iron content was

kept as low as possible in order to keep the share of the plate-

type AIFeSi-phases occurring in the structure as low as possible.

These phases are the essential cause of low strength and elon-

gation values, as they act as the starting point for crack forma-

tion by reason of their morphology in case of a deformation and

especially in presence of dynamic loads.

The manganese content was increased to approximately 0.65 %

in order to reduce the sticking tendency and to increase the form

strength of the casts.

Manganese has the same effect as iron with regarding the

reduction of the sticking tendency to the die. However, in contrast

to iron, the precipitations occurring during solidification are

globulitic and not acicular.

Variation of magnesium

The required ductility and strength especially of this AlSiMg-

pressure die casting alloy can actually be adjusted with the

most appropriate magnesium content to meet the component

requirements, particularly if the casts are to be heat treated.

Fife alloy variants emerged for Silafont-36 with these focus:

0.13 – 0.19 % Mg for crash-relevant components and

flanging technology.

0.18 – 0.28 % Mg for rigid and even crash safety com-

ponents in presence of fatigue loads.

0.24 – 0.35 % Mg for components with high operating

strength against impact stress.

0.28 – 0.35 % Mg for heat-treated components with air

quenching after solutionizing; also

for T5 treatment.

0.35 – 0.45 % Mg for designs focused on strength in

as-cast state or after O, T4 or T6

Effect of manganese

From the literature it is well known that manganese should

reduce elongation in an AlSiMg-alloy, when its content exceeds

0.2 %. For this reason manganese is not recommended as an

addition to pressure die casting alloys as a substitute for or in

combination with iron. A series of tests was carried out with

manganese contents ranging between 0.04 % and 1.2 % in

order to better understand its effect on properties. At the same

time, the iron content was kept below 0.15 %. The magnesium

content was on average 0.19 %. The strontium content was

between 130 and 170 ppm in order to guarantee a good eutectic

modification.

Chemical composition of Silafont-36, AlSi10MnMg

[%] Si Fe Cu Mn Mg Zn Ti Sr P others

min. 9.5 0.5 0.1 0.04 0.010

max. 11. 5 0.15 0.03 0.8 0.5 0.07 0.15 0.025 0.001 0.10

Tab. 1: Chemical composition of Silafont-36, AlSi10MnMg in the ingot (weight in %)

30

Silafont

®

- 36 – Chemical properties

The test samples were cast on a 400 t Bühler B Machine with a

forced venting system. A four-cavity die was used with standard

machine conditions, i.e. melt temperature at 710 to 720 °C, melt

density index < 1 % (80 mbar low pressure density test), die tem-

perature 200 °C on both die halves, die lubricant dilution 1:180,

gate speed 30 to 40 m/s. The test bars had a cross-section of

3 × 10 mm in the gauge length according to DIN 50 125 Form E.

The tensile tests were carried out two days after casting in order

to ensure that the samples were in a stable condition. The tensile

tests were carried out in as-cast state (temper F) and in temper

T6 under the following conditions:

solutionizing at 520 °C for 1 hour, quenching in water and

artificial ageing at 160 °C for 6 hours. It was stated that in the

absence of manganese, the tendency of sticking to the die was

very pronounced, even if it was a simple die design. The stick-

ing tendency decreased with an increasing manganese content

and the required behaviour became apparent above content of

0.4 %. In the as-cast state it can be seen that there is only a

slight difference in ultimate tensile and yield strength with varying

manganese content as shown in figure 1a.

The same progression can be observed in temper T6 (Fig. 1b).

Only samples without manganese manifest different behaviour.

This might be caused by the strong sticking tendency as

described above. The components showed surface cracks and

the heat treatment may have caused surface damages leading

to poor results. The elongation, as seen in figure 1c, shows a

different progression in both conditions. In both cases, elonga-

tion is low without manganese by reason of the strong sticking

tendency. In the as-cast state, elongation increases steadily up

to a manganese content of 0.4 %. It is still above 8 % even with

high manganese contents. The optimum manganese content for

maximum elongation values in the as-cast state is between 0.5 %

and 0,8 % .

Elongation in temper T6 behaves differently. The highest value

was recorded with 0.2 % manganese. Elongation is approximately

at a level between 12 % and 14 % with 0.4 % to 1.0 % manga-

nese. On the other hand, the optimum range for a stable condi-

tion is between 0.5 % and 0.8 % manganese.

The different elongation values depending on the manganese

content may be caused by the T6 heat-treatment. During solution-

izing the intermetallic manganese phases tend to assume a

globulitic form. Surrounded by a ductile matrix, these globulitic

particles might increase elongation in comparison to the as-cast

state.

Fig. 1a: Mechanical properties depending on manganese content

in the as-cast state (F)

Fig. 1b: Mechanical properties depending on manganese content in temper T6

Fig. 1c: longation depending on manganese content in the as-cast state (F)

and in temper T6

R

m

As-cast state

R

p0.2

As-cast state

Sticking tendency

Manganese content [%]

Stre ss [ N/mm

2

]

R

m

Temper T6

R

p0.2

Temper T6

Sticking tendency

Manganese content [%]

Stre ss [ N/mm

2

]

A

Temper T6

A

As-cast state

Sticking tendency Loss of elongation

Manganese content [%]

Elongation [A]

31

100 μm

100 μm

10 μm

10 μm

10 μm

Silafont

®

- 36 – Mechanical properties

The microstructures (figures 3, 4 and 5) are taken from pressure die cast plates with

dimensions 220 × 60 × 4 mm (figure 2).

The eutectic aluminium-silicon matrix is almost globulitically modified alongside the

clearly recognizable bright α-aluminium dendrites. Al

12

Mn

3

Si

2

-phases also appear in

the eutectic as bright-gray phases in its globulitic shape.

At higher magnesium contents the Mg

2

Si-intermetallic phase is still present, light

optically hardly perceptible.

The rapid cooling rate in pressure die casting is by itself not enough to produce a

sufficiently fine cast microstructure and therefore the required high elongation

values. Only the modification with strontium produces a sufficiently fine eutectic

casting microstructure. Figure 5 shows the structure of a sample which was

produced from the same alloy type however without modification.

A comparison with figure 4 clearly shows that the eutectic silicon is considerably

finer thanks to modification. The achievable elongation to fracture increases from

5 % to 10 %. This effect is also visible with a solutionizing. Figures 6 and 7 show the

structure of a 6 mm pressure die casting sample after solutionizing for 3 hours at

490 °C. The silicon has coarsened somewhat but is still globulitically modified.

Further trials showed that the spheroidization of the eutectic silicon is achieved

already at 350 °C.

Fig. 3: Silafont-36, AlSi10MnMg, as-cast state

Fig. 4: Silafont-36, AlSi10MnMg, as-cast state

Fig. 5: AlSi10MnMg without strontium, as-cast state Fig. 2: HPDC test plate from the TechCenter

Fig. 6: Silafont-36, AlSi10MnMg, temper T4 Fig. 7: Silafont-36, AlSi10MnMg, temper T4

32

Mg-content

[%]

R

p0.2

[MPa]

R

m

[MPa]

A

[%]

Casting description

0.15 117 250 11. 2 Rear side members 2.5 mm

0.28 121 264 10.2 Rear side members 3 mm

0.30 133 279 8.1 Test plate (Fig. 2) 4 mm

0.33 141 261 6.3 Cylinder head cover 3.8 mm

0.42 146 286 5.8 Test plate (Fig. 2) 4 mm

Silafont

®

- 36 – Mechanical properties

Fig. 8: Stress-strain curve for Silafont-36, AlSi10MnMg, as-cast state, temper T5 and T7

Tab. 2: Mechanical properties of Silafont-36, AlSi10MnMg,

in the as-cast state depending on magnesium content

320

240

160

80

0

0 5 10 15 20

Elongation A [%]

Stress R [MPa]

T 5

F

T 7

Effect of magnesium content on

mechanical properties in the as-cast state

The extraordinarily high elongation amongst

AlSiMg-alloys is the distinguishing characteristic

of Silafont-36. Figure 8 shows the stress-strain

curve for Silafont-36 in the as-cast state.

The curves for T5 (artificially aged) and T7

(overaged) tempers, are also reported.

Yield strength rises with increasing magnesium

content, whereas elongation decreases. If high

yield strength is required, the magnesium content

should therefore be set in the upper range of

the alloy standards, i.e. at 0,3 – 0,4 %. If higher

elongation is required and yield strength does not

play a significant role, a low magnesium content

of 0.15 % is preferred.

Table 2 is a summary of mechanical properties

for various magnesium contents. The correspond-

ing trials were conducted with casts which were

produced in accordance with the parameters in

table 3.

Elongation drops from 11.2 to 5.8 % with increas-

ing magnesium contents, while yield strength

increases from 117 to 146 MPa. Ultimate tensile

strength is also increased from 250 to 286 MPa

by increasing magnesium contents.

Therefore, in the as-cast state a wide range of

mechanical properties can be fulfilled.

Magnesium contents above 0.5 % produce no

further increase in yield strength, as excess

magnesium precipitates as the Mg

2

Si-phase

and no longer contributes to the hardening of

the aluminium solid solution.

Temper F

R

p0.2

= 123 MPa

R

m

= 265 MPa

A = 11.4 %

Temper T5

R

p0.2

= 211 MPa

R

m

= 313 MPa

A = 8 .1 %

Temper T7

R

p0.2

= 148 MPa

R

m

= 206 MPa

A = 14.2 %

33

Tab. 3: Mechanical properties in temper T5, 0.30 % magnesium content;

test plate 4 mm

Tab. 4: Mechanical properties in temper T5, 0.33 % magnesium content;

test plate head cover 3.8 mm

Tab. 5: Mechanical properties in temper T5 with different storage times prior to

ageing at 200 °C for 1 hour, test plate 4 mm, 0.32 % magnesium content

Effect of heat treatment on mechanical properties

The mechanical properties of Silafont-36 can be targeted by

means of specific heat treatment, as well as with varying magne-

sium contents.

There are two completely different possibilities in the event of

heat treatment: with or without solutionizing.

The following heat treatments can be carried out with Silafont-36

without solutionizing:

• O: Annealed at low temperature

• T5: Quenched directly after removal from the die and

artificially aged

The desired spheroidisation of the eutectic silicon requires the

following heat treatments with solutionizing:

• T4: Solutionized, quenched, naturally aged for more than 6 days

• T6: Solutionized, quenched and artificially aged

• T7: Solutionized, quenched and overaged

Heat treatments without solutionizing

Temper O

An increase in yield strength or elongation can be achieved to

a slight extent with this heat treatment without risk of casting dis-

tortion. Two different variants for this temper are actually defined:

• O(I): annealed at lower temperature (320 °C / 30 – 60 min.)

• O(II): annealed at higher temperature (380 °C / 30 – 60 min.)

An increase in yield strength to 140 – 160 MPa with 8 – 12 %

elongation is achievable on thin samples with up to 3 mm wall

thickness and magnesium contents of 0,2 % in temper O(I).

Identical samples in temper O(II) achieve elongation of 12 – 16 %

with yield strength of 100 – 130 MPa.

Temper T5

The mechanical properties of Silafont-36 T5 are given in tables 4

and 5 for two different magnesium contents of the various casts.

Thanks to the T5 heat treatment, yield strength can be increased

by almost 100 MPa compared to the as-cast state.

It is particularly interesting to note that elongation does not de-

crease, but remains between 5 and 9 %. The highest increases

in yield strength are achieved with Silafont-36 with over 0.30 %

magnesium, if there are at least 10 hours storage time between

casting and ageing, as visible in table 5.

Silafont

®

- 36 – Mechanical properties

Ageing

temperature

[°C]

Ageing

time

[h]

R

p0.2

[MPa]

R

m

[MPa]

A

[%]

170 1.0 157 291 7.1

170 2.0 169 292 5.0

170 3.0 185 302 6.0

170 4.0 188 305 8.5

170 5.0 197 309 7.1

170 6.0 195 309 8.5

170 8.0 201 313 8.9

200 0.5 211 316 8.4

200 1.0 212 314 7.9

Ageing

temperature

[°C]

Ageing

time

[h]

R

p0.2

[MPa]

R

m

[MPa]

A

[%]

170 3.0 193 290 4.5

170 4.0 199 295 4.8

170 6.0 206 300 5.0

200 0.5 193 290 5.7

200 1.0 200 297 5.6

220 0.5 199 293 5.8

250 0.5 180 268 3.5

Interim storage time

[h]

R

p0.2

[MPa]

R

m

[MPa]

A

[%]

1 207 307 6.9

10 233 324 6.6

72 h or 3 days 232 324 6.8

34

Tab. 6 Mechanical properties of Silafont-36, AlSi10MnMg, in temper T4 depending

on magnesium content

Fig. 9: Mechanical properties of Silafont-36, AlSi10MnMg, with a magne-

sium content of 0.3 % as a function of the ageing time (solutionizing at

490 °C for 3 hours, quenching in water and ageing at 170 °C)

Heat treatments with solutionizing

Temper T4

Table 7 lists the mechanical properties after solutionizing

(490 °C / 3 h) with subsequent quenching in water.

The spheroidisation of the silicon and the other intermetallic

phases achieved in this way produce an increase in elongation

to 15 % and more, depending on magnesium content.

Yield strength increases to 141 MPa from 94 MPa of the

as-cast state. The ultimate tensile strength range of 206 to

259 MPa is somewhat lower than in the as-cast state.

Temper T6

Temper T6 produces maximum strength. For this purpose a

magnesium content above 0.3 % in the pressure die casting

should be aimed at, in order to exploit the hardening potential

of the alloy. Elongation settles to lower values. Figure 9 shows

graphically the mechanical properties over the ageing time

for a magnesium content of 0.3 %. The point of maximum

strength is at a yield strength of 240 MPa and ultimate tensile

strength of 310 MPa, however with an elongation of 7.1 %.

Single trials with higher magnesium contents have demon-

strated that yield strength can be increased to over 280 MPa,

whereby elongation is still above 3 % nevertheless.

Temper T7

The curve progression in figure 9 indicates that elongation

again increases with increasing ageing time, i.e. in an in-

creasingly overaged state. Trials with real casts have shown

that with targeted heat treatments, elongations up to 20 %

can be achieved; yield strength then reaches values of

120 – 130 M Pa .

Air quenching

Quenching with air instead of water is carried out after the

solutionizing in order to minimize the distortion of pressure

die castings. Yield strength of over 120 MPa can only be

achieved with a magnesium content of 0,3 %, if a subsequent

ageing for 2 hours at a temperature of 170 °C is performed.

320

280

240

200

160

120

0 1 2 3 4 5 6 7 8

Strenght [MPa]

Elongation A [%]

20

16

12

10

8

0

Ageing time [h]

R

m

R

p0.2

A

Silafont

®

- 36 – Mechanical properties

Mg-content

[%]

R

p0.2

[MPa]

R

m

[MPa]

A

[%]

Casting

description

0.15 94 206 20.6

Rear side members

2.5 mm

0.20 107 223 20.4

Rear side members

2.5 mm

0.25 119 229 17.3

Rear side members

2.5 mm

0.28 121 242 16.7

Rear side members

2.5 mm

0.42 141 259 15.0 Test plate 4 mm

35

Silafont

®

- 36 – Mechanical properties

Fatigue strength

Fatigue strengths for pressure die cast plates with 4 mm wall

thickness are shown in Figure 11 in the as-cast state accord-

ing to Wöhler’s curves. The trials were conducted on a high

frequency pulse generator with a frequency of around 117 Hz.

The stress ratio was r = -1 on a normal sample geometry.

Figure 10 shows that the fatigue strength reaches 89 MPa

under these test conditions; this equals approximately 66 % of

the yield strength.

Corrosion behaviour

The corrosion behaviour can be compared to an aluminium-

silicon primary alloy. Silafont-36 is not susceptible to corrosion

and does not manifest any tendency to stress corrosion cracking.

As visible in the application examples, the alloy is used,

among other things, for uncoated bodywork and car chassis

components.

Overview of mechanical properties

The figure on page 26 provides an overview of the ranges of mechanical properties which can be achieved with the various

heat treatments.

It should be taken into account that the magnesium content must be tuned according to the required property profile.

Higher elongation values are linked to lower values for yield strength and vice versa.

Fig. 10: Wöhler’s curve for Silafont-36, AlSi10MnMg, in the as-cast state

Stress R [MPa]

200

180

160

140

120

100

80

60

40

20

0

Number of load cycles [n]

0 10

5

10

6

10

7

10

8