Review study on Vacuum cleaners

Final report

Viegand Maagøe A/S

Van Holsteijn en Kemna B.V.

June 2019

The information and views set out in this study are

those of the author(s) and do not necessarily reflect

the official opinion of the European Commission

2

Prepared by

Study team:

Mette Rames, Peter Martin Skov Hansen, Annette Gydesen, Baijia Huang, Michelle Peled

and Larisa Maya-Drysdale (Viegand Maagøe A/S)

René Kemna and Roy van den Boorn (Van Holsteijn en Kemna B.V.)

Quality assurance:

Annette Gydesen (Viegand Maagøe A/S)

Contract managers:

Viegand Maagøe A/S

Project website: https://www.review-vacuumcleaners.eu/

Implements Framework Contract: ENER/C3/2015-619-LOT 2

Specific contract no.: ENER/C3/SER/FV 2017-438/03/FWC 2015-619 LOT2/05/SI2.757436

This study was ordered and paid for by the European Commission, Directorate-General for

Energy.

The information and views set out in this study are those of the author(s) and do not

necessarily reflect the official opinion of the Commission. The Commission does not

guarantee the accuracy of the data included in this study. Neither the Commission nor

any person acting on the Commission’s behalf may be held responsible for the use which

may be made of the information contained therein.

This report has been prepared by the authors to the best of their ability and knowledge.

The authors do not assume liability for any damage, material or immaterial, that may

arise from the use of the report or the information contained therein.

© European Union, June 2019.

Reproduction is authorised provided the source is acknowledged.

More information on the European Union is available on the internet (http://europa.eu).

1. Preface

This Final report for the review study of the Ecodesign Regulation

1

and the annulled Energy

Labelling Regulation

2

for vacuum cleaners is the final delivery of the specific contract. As

specified in the contract the Final report concerns all tasks of the MEErP methodology and

includes recommendations for the revision of these regulations.

Task 1 outlines the scope of the regulations and of the review study as well as the relevant

standards and legislation related to vacuum cleaner energy consumption, durability and

resource efficiency.

Task 2 gives an overview of the vacuum cleaner market including sales, stock and base

data on consumer costs, as well as an overview of market development trends and

production structures.

Task 3 regards the user behaviour, especially looking at robot and cordless vacuum

cleaners in order to suggest representative testing and energy consumption calculation at

later stages of the study. Furthermore, the end-user relevance of the current test standards

is discussed.

Task 4 reviews the technical aspects of vacuum cleaners as products, and outlines the

current technology levels in terms of average and best available technologies, on both

component and product level. Besides the energy consumption effect, the technologies are

also reviewed in terms of resource efficiency.

Task 5 defines the base cases and the environmental and economic impact of each of them.

The environmental impact is both the energy consumption in the use phase as well as the

material consumption and impact categories are given in the EcoReport tool. The

environmental impact is calculated as the product life cycle cost for the end-user for each

base case.

Task 6 outlines the design options for improving the environmental performance of the

base cases without causing excessive costs for the end-users. Design options are outlined

for both energy and resource efficiency improvements.

Task 7 defines policy options for each base case based on the viable design options and

presents the results on the scenario analyses that estimates the environmental and

economic impact of each of the policy options.

1

OJ L 192, 13.07.2013, p. 24-34, available at: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32013R0666

2

OJ L 192, 13.07.2013, p. 1-23, available at: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32013R0665

4

The specific aspects to review according to article 7 of the Ecodesign Regulation and of

the annulled Energy Labelling Regulation are:

• The review of the ecodesign regulation in light of technological progress;

• The review of verification tolerances to be used by Member State authorities for

market surveillance purposes;

• whether full size battery operated vacuum cleaners should be included in the scope

and

• whether it is feasible to use measurement methods for annual energy

consumption, dust pick-up and dust re-emission that are based on a partly loaded

rather than an empty receptacle.

It should be noted that this review study was begun before the General Court decision to

annul the Energy Labelling Regulation 665/2013

3

on November 8, 2018, which took effect

on 18 January 2019. The report therefore includes a review of this regulation, including

the evaluation of its effect according to the better regulation principles. Furthermore the

available market data and development observed in energy efficiency reflects the situation

as it has been with the energy label. Even though the Energy Label is now annulled, it was

in force from 2014 to January 2019, which is of course reflected in the data. Therefore the

text refers to “Regulations” in the plural, because it was in force during the period that was

studied.

3

https://curia.europa.eu/jcms/upload/docs/application/pdf/2018-11/cp180168en.pdf

5

2. Table of Contents

1. Preface .......................................................................................................... 3

2. Table of Contents ............................................................................................ 5

3. List of tables ..................................................................................................11

4. List of figures .................................................................................................16

5. List of abbreviations .......................................................................................20

6. Summary ......................................................................................................24

6.1 Background .............................................................................................24

6.2 Scope .....................................................................................................25

6.3 Standardisation and legislation...................................................................27

6.4 Market data .............................................................................................28

Energy and performance .....................................................................29

Product prices ....................................................................................33

6.5 Use patterns ............................................................................................34

Cordless vacuum cleaners ...................................................................35

Robot vacuum cleaners .......................................................................35

End of Life behaviour ..........................................................................36

Consumer relevant testing ..................................................................37

Uncertainties of test methods ..............................................................38

6.6 Technology overview ................................................................................38

Mains-operated household vacuum cleaners ..........................................39

Commercial vacuum cleaners...............................................................40

Cordless vacuum cleaners ...................................................................41

Robot vacuum cleaners .......................................................................42

6.7 Environmental and economic impacts .........................................................44

6.8 Design options .........................................................................................44

6.9 Scenarios ...............................................................................................45

Energy efficiency scenarios ..................................................................45

Energy label ......................................................................................48

Resource efficiency scenarios ...............................................................49

7. Task 1: Scope ................................................................................................52

7.1 Product scope ..........................................................................................52

Definitions from the regulations ...........................................................52

Definitions from preparatory study .......................................................54

Definitions from standards ..................................................................55

6

Description of products .......................................................................55

Bagged vs bagless vacuum cleaners .....................................................60

Alignment of definitions ......................................................................61

Recommendations ..............................................................................64

7.2 Review of relevant regulations ...................................................................66

Legislation and agreements at EU level .................................................66

Voluntary agreements at Member State level .........................................73

Legislation and agreements at third country level ...................................74

7.3 Review of relevant standards .....................................................................77

Mandate 540 .....................................................................................77

Safety standards ................................................................................78

Material efficiency standards ................................................................79

WEEE and RoHS standards ..................................................................80

Other relevant standards .....................................................................82

Consumer organizations ......................................................................89

8. Task 2: Market data: sales and stock ................................................................91

8.1 Production and trade ................................................................................91

8.2 Sales data ...............................................................................................94

Market values ....................................................................................97

8.3 Lifespan ..................................................................................................98

8.4 Stock .................................................................................................... 100

8.5 Energy and performance ......................................................................... 101

Energy ............................................................................................ 102

Cleaning performance ....................................................................... 104

Dust re-emission .............................................................................. 106

Sound power ................................................................................... 107

Cordless vacuum cleaners ................................................................. 108

Robot vacuum cleaners ..................................................................... 109

8.6 Market structure and -actors.................................................................... 110

Industry .......................................................................................... 110

Distribution structure ........................................................................ 112

Other actors .................................................................................... 112

7

8.7 Consumer expenditure base data ............................................................. 112

Interest and inflation rates ................................................................ 113

Consumer purchase price .................................................................. 113

Electricity cost ................................................................................. 114

Repair & maintenance costs ............................................................... 115

End of life costs ............................................................................... 116

9. Task 3: Users............................................................................................... 117

9.1 Use pattern of mains-operated household cleaners ..................................... 117

Formula for calculating annual energy consumption for mains-operated

cleaners 118

9.2 Use patterns for commercial vacuum cleaners ............................................ 121

Formula for calculating annual energy consumption for commercial cleaners

121

9.3 Use pattern of cordless vacuum cleaners ................................................... 124

Formula for calculating annual energy consumption for cordless vacuum

cleaners 125

9.4 Use pattern of robot vacuum cleaners ....................................................... 126

Formula for calculating annual energy consumption for robot vacuum cleaners

127

9.5 Alternative calculations methods .............................................................. 130

9.6 Consumer relevance – consumer survey results ......................................... 132

Ranking of important parameters ....................................................... 133

Floor types ...................................................................................... 134

Vacuum cleaner settings ................................................................... 135

9.7 Consumer relevance – testing .................................................................. 136

Carpet test ...................................................................................... 136

Hard floor test ................................................................................. 140

Specialised nozzles ........................................................................... 141

Commercial vacuum cleaner test ........................................................ 142

Definition of rated power input ........................................................... 142

Cordless and robot vacuum cleaner tests ............................................ 144

9.8 Testing with part load ............................................................................. 144

Dyson vs European Commission ......................................................... 145

Definition of part load ....................................................................... 146

8

Current part load definition ................................................................ 148

Part load of bagged vs bagless vacuum cleaners .................................. 149

Available data for part load testing ..................................................... 151

Possible options for considering part load testing ................................. 155

9.9 Verification tolerances ............................................................................. 158

9.10 Local infra-structure ............................................................................... 161

Electricity ........................................................................................ 161

9.11 Use of auxiliary products ......................................................................... 163

9.12 Repair practice ....................................................................................... 165

9.13 End of life behaviour ............................................................................... 168

Estimated second-hand use ............................................................... 168

Recyclability of vacuum cleaners ........................................................ 169

10. Task 4: Technical analysis ............................................................................. 171

10.1 Components .......................................................................................... 171

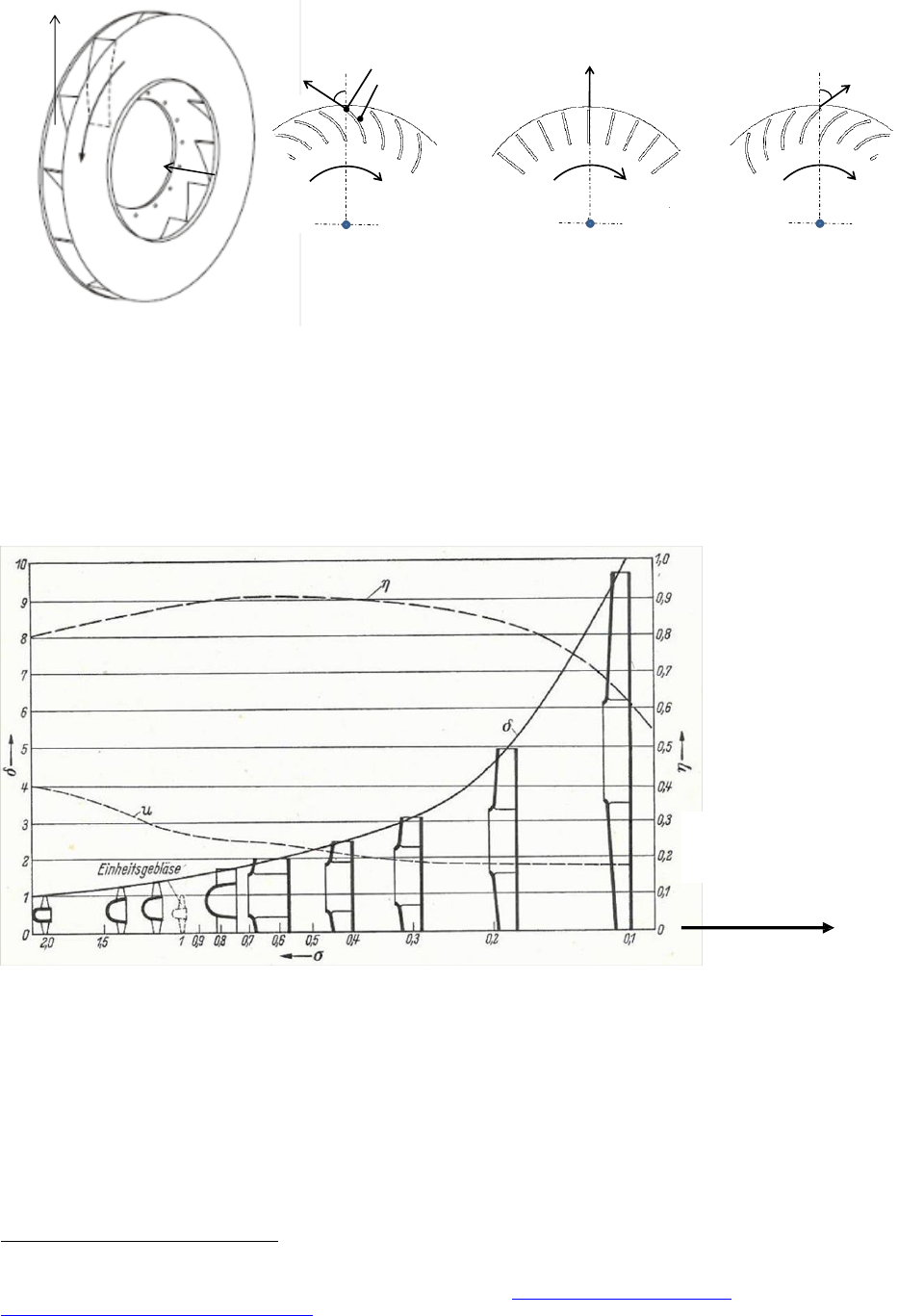

Motor.............................................................................................. 172

Fan ................................................................................................ 173

Receptacle ...................................................................................... 178

Filters ............................................................................................. 180

Hose ............................................................................................... 181

Nozzle ............................................................................................ 182

Batteries ......................................................................................... 183

Plug and power cord ......................................................................... 187

10.2 Materials and resource level .................................................................... 187

Material consumption in vacuum cleaners ............................................ 187

Critical materials and components ...................................................... 191

Manufacturing and distribution ........................................................... 193

Recycled content .............................................................................. 193

Use phase ....................................................................................... 194

End of life ....................................................................................... 194

Blue Angel requirements ................................................................... 197

10.3 Products ................................................................................................ 198

Mains-operated household vacuum cleaners ........................................ 199

9

Commercial vacuum cleaners............................................................. 201

Cordless handstick vacuum cleaners ................................................... 204

Robot vacuum cleaners ..................................................................... 207

11. Task 5: Environmental and economic impact ................................................... 217

5.1 Inputs for baseline calculations ................................................................ 217

11.1 Outputs from baseline calculations ........................................................... 220

Mains-operated household vacuum cleaners ........................................ 221

Commercial vacuum cleaners............................................................. 223

Cordless vacuum cleaners ................................................................. 224

Robot vacuum cleaners ..................................................................... 224

EU Totals – Environmental impacts ..................................................... 225

11.2 Consumption of critical raw materials and other materials of high importance 227

11.3 Life cycle cost ........................................................................................ 229

12. Task 6: Design options .................................................................................. 231

12.1 Household mains-operated vacuum cleaners (BC1) .................................... 231

Option 1: More stringent energy requirements ..................................... 232

Option 2: More realistic performance, indirectly better energy efficiency . 232

Option 3: Recycled content and/or light-weighting ............................... 234

Option 4: Increase product life ........................................................... 238

Option 5: Recycling .......................................................................... 243

12.2 Commercial mains-operated vacuum cleaners (BC2)................................... 244

12.3 Cordless vacuum cleaners (BC3) .............................................................. 244

12.4 Household robot vacuum cleaners ............................................................ 245

13. Task 7: Scenarios ......................................................................................... 246

13.1 Better Regulation evaluation .................................................................... 246

Description of the current regulations and their objectives ..................... 247

Baseline and point of comparison ....................................................... 248

Effectiveness ................................................................................... 250

Efficiency ........................................................................................ 257

Relevance ....................................................................................... 264

13.2 Policy analysis........................................................................................ 268

Stakeholders consultation ................................................................. 268

Policy measures ............................................................................... 268

13.3 Baseline scenario - BAU .......................................................................... 270

10

13.4 Policy scenarios for energy efficiency and performance ............................... 274

Requirements .................................................................................. 275

Energy saving potentials ................................................................... 280

Total consumer expenditure .............................................................. 283

Consumer health potentials ............................................................... 285

Conclusions ..................................................................................... 287

Label classes ................................................................................... 288

13.5 Policy scenario for resource efficiency ....................................................... 290

Material energy saving potentials ....................................................... 294

13.6 Parameters on the energy label ................................................................ 297

13.7 Sensitivity analysis ................................................................................. 298

13.8 Conclusions and recommendations ........................................................... 300

14. Annexes ...................................................................................................... 303

I. Annex A – Elaboration of standards ................................................................ 303

1. Durability of the hose and operational lifetime of the motor ......................... 304

2. Water filter vacuum cleaners ................................................................... 307

3. Full size battery operated vacuum cleaners................................................ 307

4. Robot vacuum cleaners ........................................................................... 307

5. Measurement with market-representative carpet(s) and hard floor(s) ........... 308

6. Consumer organization tests .................................................................... 311

II. Annex B – GfK data coverage ......................................................................... 315

III. Annex C - Sales and stock data ...................................................................... 316

IV. Annex D - Calculated collection rate ................................................................ 318

V. Annex E– Test results ................................................................................... 320

VI. Annex F - Impacts over a lifetime of vacuum cleaners calculated in the EcoReport Tool

327

11

3. List of tables

Table 1: Derived sales of each vacuum cleaner type from 1990 to 2030 ......................28

Table 2: Stock of different vacuum cleaner types in the EU ........................................29

Table 3: Unit retail prices in EUR vacuum cleaners, in 2018-prices for EU28 ................33

Table 4: Use pattern for cordless vacuum cleaners ...................................................35

Table 5: Use pattern for robot vacuum cleaners .......................................................36

Table 6: The top fault rates (above 10%) and causes for upright and cylinder vacuum

cleaners. .............................................................................................................36

Table 7: BAU, BAT and BNAT of household mains-operated vacuum cleaners in terms of

energy and performance (2018) .............................................................................39

Table 8: Household mains-operated vacuum cleaners’ materials (product-life 8 years) ..39

Table 9: BAU, BAT and BNAT of commercial vacuum cleaners in terms of energy and

performance ........................................................................................................40

Table 10: Commercial vacuum cleaners’ materials (product-life 5 years) .....................40

Table 11: BAU, BAT and BNAT of cordless vacuum cleaners in terms of energy and

performance ........................................................................................................41

Table 12: Cordless vacuum cleaners’ materials (product-life 6 years, package 0.05 m³) 41

Table 13: BAU, BAT and BNAT of Robot vacuum cleaners in terms of energy and

performance ........................................................................................................43

Table 14: Robot vacuum cleaners’ materials (product-life 6 years, package 0.05 m³) ...43

Table 15: Policy Option 1, 2 and 3: Energy and performance related requirements. ......45

Table 16: 2030 energy consumption and savings in PO1, PO2 and PO3 .......................47

Table 17: Expected market distribution of energy label classes with the rescaled label ..48

Table 18: Suggested performance classes ...............................................................49

Table 19: Requirements in Policy Options 4 .............................................................49

Table 20: Material energy savings for each base case in 2030 for PO4 and PO5 ............50

Table 21: Advantages and disadvantages for bagged and bagless vacuum cleaners ......60

Table 22: Vacuum cleaner product types from different sources .................................61

Table 23: Outline of Ecodesign requirements ...........................................................66

Table 24: Vacuum cleaner - the previous, annulled energy label classifications .............68

Table 25: PRODCOM and HS6 product codes and nomenclature ..................................91

Table 26: Eurostat, PRODCOM, Total vacuum cleaners with self-contained motor - codes

27512123+27512125. Trade data relates to extra-EU only ........................................92

Table 27: Value of EU production and selected Extra-EU trade data 2011-2017 in million

euros ..................................................................................................................93

Table 28: Market shares of household vacuum cleaners ............................................95

Table 29: Derived vacuum cleaner sales from 1990 to 2030 ......................................96

Table 30: Vacuum cleaner market values ................................................................97

12

Table 31: Average unit price for vacuum cleaner in EU according to GfK and Prodcom ..98

Table 32: Average expected lifetimes and assumed variations used in the stock model, in

years ..................................................................................................................99

Table 33: Stock of vacuum cleaners in EU 28 from 2005 to 2030.............................. 100

Table 34: APPLIA Database 2015-2016, Model count, average energy, power and sound

power ............................................................................................................... 101

Table 35: Average power (in W) of mains-operated household VCs EU in the year 2016

........................................................................................................................ 103

Table 36: Average power (in W) of mains-operated household VCs EU in the year 2018,

after tier 2 Ecodesign .......................................................................................... 104

Table 37: Sound power mains-operated household vacuum cleaners EU 2016 ............ 107

Table 38: Performance of cordless vacuum cleaners. Test results from GTT Laboratories

........................................................................................................................ 108

Table 39: Performance of robot vacuum cleaners than from separate sources, such as

consumer test organisations and products for sale online, ....................................... 109

Table 40: Unit retail prices in EUR for household vacuum cleaners, in 2016-prices for EU28

........................................................................................................................ 113

Table 41: Electricity prices with 2016 as base year will be used ................................ 114

Table 42: Vacuum cleaner spare part retail prices ................................................... 115

Table 43: Average total labour costs for repair services in euro per hour, in fixed 2016-

prices ................................................................................................................ 116

Table 44: Use pattern for mains-operated household vacuum cleaners ...................... 118

Table 45: Use pattern for commercial vacuum cleaners ........................................... 121

Table 46: use pattern for cordless vacuum cleaners ................................................ 125

Table 47: Average annual running hours in different modes for cordless vacuum cleaners.

........................................................................................................................ 125

Table 48: use pattern for robot vacuum cleaners .................................................... 127

Table 49: Average annual running hours in different modes for robot vacuum cleaners

........................................................................................................................ 127

Table 50: Percentage of consumers rating parameters important/very important in a

purchase situation .............................................................................................. 133

Table 51: Uncertainty of measuring MUV, results from RRT by CENELC TC59X WG6 ... 152

Table 52: Results on variation in DMT8 filling according to each of the three “bag full”

criteria. Range indicating largest minus lowest measured value ................................ 152

Table 53: suction power uncertainty for vacuum cleaner no. 1 (bagless, upright vacuum

cleaner) ............................................................................................................ 153

Table 54: suction power uncertainty for vacuum cleaner no. 2 (bagged, cylinder/barrel with

large bag) ......................................................................................................... 153

13

Table 55: suction power uncertainty for vacuum cleaner no. 3 (bagged, cylinder with small

bag) ................................................................................................................. 153

Table 56: Effect on dust pick-up (carpet) at part load (200g/25g) and full load (400g/50g)

compared to empty ............................................................................................ 154

Table 57: Effect on input power at part load (200g/25g) and full load (400g/50g) compared

to empty ........................................................................................................... 154

Table 58: Verification tolerances set out in the regulations and preliminary indication of

expanded uncertainties ....................................................................................... 159

Table 59: Global Energy Architecture Performance Index report – best performing countries

........................................................................................................................ 162

Table 60: Faults experienced with upright vacuum cleaners and cylinder vacuum cleaners

........................................................................................................................ 166

Table 61: Re-use, recycling, heat recovery, incineration and landfill rates assumed for the

End of life handling of vacuum cleaners ................................................................. 170

Table 62: Filter classes according to EN 1822:2009 ................................................ 180

Table 63: Comparison properties of Li-ion battery types (L =Low, M=Moderate, H=high)

........................................................................................................................ 186

Table 64: Cycle life of LI-ion batteries as a function of DoD. .................................... 186

Table 65: Bill-of-materials, Cylinder Vacuum Cleaner (source: JRC-IES 2015) ............ 188

Table 66: The assumed material composition in the current study. ........................... 190

Table 67: List of critical raw materials ................................................................... 191

Table 68. Base case 1: Household mains-operated vacuum cleaners’ energy, performance,

price ................................................................................................................. 201

Table 69. Base Case 1: Household mains-operated vacuum cleaners’ materials (product

life 8 years, package 0.08 m³) ............................................................................. 201

Table 70. Nilfisk commercial cylinder vacuum cleaner examples (source: Nilfisk.com, Sept.

2018)................................................................................................................ 202

Table 71. Base case 2: Commercial mains-operated vacuum cleaners (BC2) .............. 203

Table 72. Base Case 2: Commercial mains-operated vacuum cleaner materials (product-

life 5 years, package 0.1 m³) ............................................................................... 204

Table 73: Average data for cordless handstick cleaners collected from online retailers for

27 models from 16 brands. .................................................................................. 206

Table 74. Base case 3: Cordless vacuum cleaners’ energy, performance, price, 2018 data

........................................................................................................................ 206

Table 75. Base Case 3: Cordless vacuum cleaners’ materials (product-life 6 years, package

0.05 m³, dock/charger included) .......................................................................... 206

Table 76: characteristics of 6 robot vacuum cleaner models (source Stiftung Warentest

2017)................................................................................................................ 212

14

Table 77: Measurements of robot vacuum cleaner energy consumption when in use, energy

from battery ...................................................................................................... 214

Table 78: Measurements of energy consumption from electricity grid ........................ 214

Table 79. Base Case 4: Robot vacuum cleaners’ Energy and performance .................. 215

Table 80. Base Case 4: Robot vacuum cleaner materials (product-life 6 years, package

0.05 m³, dock/charger included) .......................................................................... 215

Table 81: Base case economic and market data for EcoReport, from task 2. All data is for

2016. ................................................................................................................ 218

Table 82: Average annual energy consumption (based on AE values) for each base case in

2016. ................................................................................................................ 219

Table 83: Inputs to calculate the environmental impacts and where they are presented

........................................................................................................................ 219

Table 84: Environmental impacts during the entire lifetime of vacuum cleaners sold in 2016

........................................................................................................................ 225

Table 85: Annual environmental impacts of vacuum cleaners (EU-28 stock) ............... 226

Table 86: The amount of cobalt, gold and copper and the derived impacts regarding energy,

emission of CO2-eq and market value in euros per product ...................................... 227

Table 87: The amount of cobalt, gold and copper and the derived impacts regarding energy,

emission of CO2-eq and market value in euros for the total stock of vacuum cleaners . 228

Table 88: The combined impact and value of gold and copper in all air conditioners (stock)

........................................................................................................................ 229

Table 89: Life cycle costs of the three base cases (VAT included) ............................. 230

Table 90: Annual consumer expenditure in EU28 .................................................... 230

Table 91 . Prices of plastic injection moulding grades .............................................. 235

Table 92: Comparison of results of this study to results from the 2013 Impact Assessment

regarding cumulative savings of key parameters .................................................... 250

Table 93: Coverage of the previous, annulled energy label data for each vacuum cleaner

type in scope of the regulations ............................................................................ 253

Table 94: Percentage of consumers rating parameters important/very important in a

purchase situation (Source: APPLiA 2018 consumer survey) .................................... 256

Table 95: Development of average AE values for household mains-operated and

commercial vacuum cleaners 2020-2030 ............................................................... 270

Table 96: Policy Option 1, 2 and 3: Energy and performance related requirements. .... 274

Table 97: Energy savings for each base case in 2030 for PO1, PO2 and PO3 in EU28 .. 282

Table 98: Energy consumption of cordless and robot vacuum cleaners in BAU and PO2,

kWH/year .......................................................................................................... 283

Table 99: EU User expenditure for each base case .................................................. 285

15

Table 100: Average noise levels of each vacuum cleaner type in 2018, 2025 and 2030 in

the policy scenarios ............................................................................................ 286

Table 101: Average dust re-emission levels of each vacuum cleaner type in 2018, 2025

and 2030 in the policy scenarios ........................................................................... 287

Table 102: Rescaling of the energy label and assumed distributions .......................... 289

Table 103: Suggested label classes for the performance parameters on the energy label

........................................................................................................................ 289

Table 104: Policy Option 4 and 5: resource efficiency requirements .......................... 290

Table 105: Material energy savings for each base case in 2030 for PO4 and PO5 in EU28

........................................................................................................................ 296

Table 106: EU Material end-user expenditures for each base case ............................ 297

Table 107: parameters suggested for the energy label in PO1, PO2 and PO4 .............. 298

Table 108: Change in robot vacuum cleaner sales and the effect in BAU, PO1, PO2 and PO3

........................................................................................................................ 298

Table 109: Change in cordless vacuum cleaner sales and the effect in BAU, PO1, PO2 and

PO3 .................................................................................................................. 299

Table 110: Change in the expected increase in lifetime in policy option 4 .................. 300

Table 111: CENELEC TC 59X WG 6 sub-working groups ........................................... 303

Table 112: IEC TC 59 SC 59F Working groups and advisory groups .......................... 303

Table 113: Calculated collection rate in EU 2014 .................................................... 318

Table 114: All impact categories for mains-operated household vacuum cleaners. The life

cycle phase with the highest impact for each of the categories is highlighted with red text.

........................................................................................................................ 327

Table 115: All impact categories for commercial vacuum cleaners. The life cycle phase with

the highest impact for each of the categories is highlighted with red text. ................. 327

Table 116: All impact categories for cordless vacuum cleaners. The life cycle phase with

the highest impact for each of the categories is highlighted with red text. ................. 328

Table 117: All impact categories for robot vacuum cleaners. The life cycle phase with the

highest impact for each of the categories is highlighted with red text. ....................... 329

16

4. List of figures

Figure 1: main types of vacuum cleaners included in the scope of the review study ......26

Figure 2: .............................................................................................................26

Figure 3: Annual sales and stock numbers for the total vacuum cleaner market 2005-2029

..........................................................................................................................29

Figure 4: The previous, annulled Energy Label classification energy 2015-2016 (sources:

APPLiA and GfK) ...................................................................................................30

Figure 5: The previous, annulled Energy Label classification hard floor cleaning 2015-2016

(sources: APPLiA and GfK) .....................................................................................31

Figure 6: The previous, annulled Energy Label classification carpet cleaning 2015-2016

(sources: APPLiA and GfK) .....................................................................................32

Figure 7: The previous, annulled Energy Label classification dust-re-emission 2015-2016

(sources: APPLiA and GfK) .....................................................................................33

Figure 8: Dust pick-up for an average cylinder cleaner and the three best robot cleaners

(source: Stiftung Warentest 2017)..........................................................................42

Figure 9: Annual energy consumption in each of the three policy scenarios compared to

BAU ....................................................................................................................47

Figure 10: Annual consumer costs in each of the three policy scenarios compared to BA

..........................................................................................................................48

Figure 11: GHG emissions in PO4 compared to BAU from 2018 to 2030 .......................50

Figure 12: End-user expenditure for all vacuum cleaners in EU each year from 2018-2030.

..........................................................................................................................51

Figure 13: Left: Barrel or tub form factor. Right: Sledge form factor ...........................56

Figure 14: Upright or Beat & Brush vacuum cleaner form factor (left) and roller brush

(right) .................................................................................................................57

Figure 15: Battery operated handstick vacuum cleaners ............................................58

Figure 16: two examples of 2-in-1 handstick vacuum cleaners and the detached handheld

vacuum cleaner ....................................................................................................59

Figure 17: Example of a robot vacuum cleaner .........................................................60

Figure 18: Overview of vacuum cleaner categories and the level to which they are defined

..........................................................................................................................62

Figure 19: main types of vacuum cleaners included in the scope of the review study ....63

Figure 20: scenario for sub-categorisation of the cordless vacuum cleaner category ......65

Figure 21: The previous, annulled Energy Label 1 (left) and label 2 (right) for vacuum

cleaners ..............................................................................................................68

Figure 22: Floor plan of test-box for cleaning, according to section 5 ..........................86

Figure 23: Floor plan of straight-line cleaning test according to section 6.....................86

Figure 24: Floor plan for testing autonomous coverage .............................................87

17

Figure 25: Apparent VC consumption 2010-2017 according to Eurostat PRODCOM, with

estimated fractions of products out of scope of the regulation ....................................93

Figure 26: Vacuum cleaner ≤1500W and <20L receptacle, EU 2017 imports by origin and

EU 2017 exports by destination ..............................................................................94

Figure 27: Vacuum cleaner ≤1500W and <20L receptacle, EU 2017 imports by origin and

EU 2017 exports by destination ..............................................................................97

Figure 28: Total annual sales and stock of all vacuum cleaner types in EU-28 ............ 101

Figure 29: The annulled Energy Label classification energy 2015-2016 (sources: APPLiA

and GfK) ........................................................................................................... 102

Figure 30: The previous, annulled Energy Label classification hard floor cleaning 2015-

2016 (sources: APPLiA and GfK) ........................................................................... 105

Figure 31: The previous, annulled Energy Label classification carpet cleaning 2015-2016

(sources: APPLiA and GfK) ................................................................................... 106

Figure 32: The previous, annulled Energy Label classification dust-re-emission 2015-2016

(sources: APPLiA and GfK) ................................................................................... 107

Figure 33: Types of rooms that more than 50% of the respondents in the APPLiA survey

have in their homes ............................................................................................ 134

Figure 34: Flooring types in the five most commonly occurring room types ................ 135

Figure 35: typical dirt types in the five most commonly occurring room types ............ 135

Figure 36: User behaviour regarding power settings, according to APPLiA consumer survey.

........................................................................................................................ 136

Figure 37: Typical bag-full indicator on bagged vacuum cleaner (left) and bagless vacuum

cleaner (right) .................................................................................................... 147

Figure 38: Net electricity generation, EU-28, 2015 (% of total, based on GWh) .......... 161

Figure 39: Hourly load values a random day in March ............................................. 163

Figure 40: Consumer habits regarding changing bags and filter of their main vacuum

cleaner, according to the APPLiA consumer survey .................................................. 164

Figure 41: Hourly labour cost in €, 2016 for European countries ............................... 166

Figure 42: Expected reprocessing of vacuum cleaners at End of life .......................... 169

Figure 43: Key components in a mains-operated vacuum cleaner ............................. 171

Figure 44: Sankey-diagram of energy flows in a mains-operated cylinder vacuum cleaner

(source: VHK 2017 graph on the basis of AEA Ricardo 2009 data) ............................ 172

Figure 45: Backwards curved centrifugal fan (left) and fan definitions using the centrifugal

........................................................................................................................ 175

Figure 46: Cordier diagram (Eurovent/EVIA 2016 citing Eck 2003) ........................... 175

Figure 47: Fan efficiency as a function of specific speed for industrial centrifugal fans in the

range up to 10 kW (source: Eurovent, EVIA. pers. comm.) ...................................... 177

18

Figure 48: The volume of the receptacle is between 1.3 and 3.4 litres. Average size in the

most recent tests is 2.2 litres ............................................................................... 179

Figure 49 The principle of a dry vacuum cleaner with a water filter (picture source: Kärcher

2018)................................................................................................................ 180

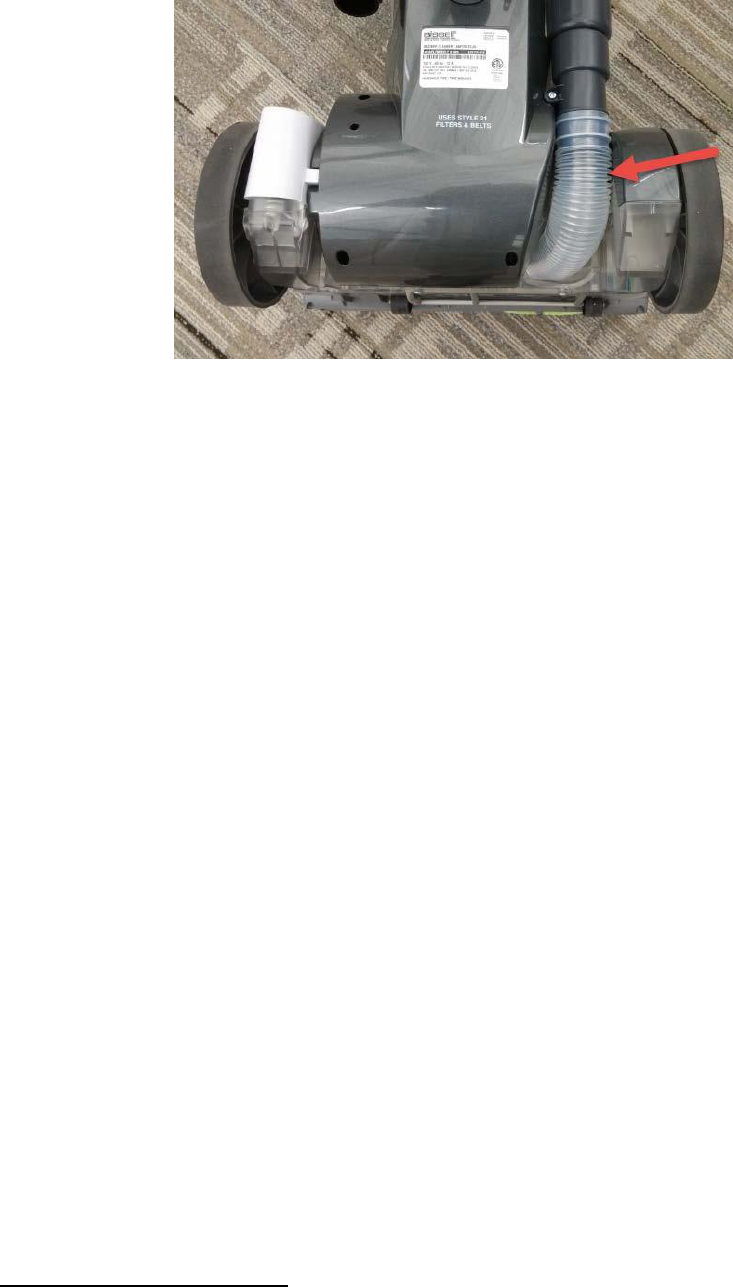

Figure 50: Example of an exploded drawing and spare parts listing for the canister (left)

and the nozzle plate (right) .................................................................................. 188

Figure 51. Commercial, cordless, backpack vacuum cleaner (source: Hoover) ............ 202

Figure 52. Examples of form factors for cordless stick models .................................. 205

Figure 53: Robot vacuum cleaner (illustrative only, VHK 2018) ................................ 209

Figure 54: Robot cleaner using a random bounce pattern to cover the surface ........... 210

Figure 55: Robot cleaner using a random + spiralling pattern to cover the surface ..... 210

Figure 56: Robot cleaner using SLAM technology to map the room ........................... 211

Figure 57: Dust pick-up for an average cylinder cleaner and the three best robot cleaners

on flat floor without crevice (source: Stiftung Warentest 2017). ............................... 212

Figure 58: Total energy consumption and emission of CO

2

-eq of mains-operated vacuum

cleaners – the impact of one vacuum cleaner over a lifetime .................................... 222

Figure 59: Total energy consumption and emission of CO

2

-eq of commercial vacuum

cleaners – the impact of one vacuum cleaner over a lifetime .................................... 223

Figure 60: Total energy consumption and emission of CO

2

-eq of cordless vacuum cleaners

– the impact of one vacuum cleaner over a lifetime ................................................ 224

Figure 61: Total energy consumption and emission of CO2-eq of robot vacuum cleaners –

the impact of one vacuum cleaner over a lifetime ................................................... 225

Figure 62: Pricing history of recycled injection grade PP (above) versus virgin PP (below).

Source: www.plasticsnews.com , extract 2018)................................................................. 236

Figure 63: Conceptual drawing of a recycling sign................................................... 238

Figure 64: LCC of the base-case (first column) and the durable scenario (second column)

(source: JRC-IES 2015) ....................................................................................... 241

Figure 65: Comparison of stock in 2013 Impact Assessment (IA) and the stock estimates

used in this study ............................................................................................... 249

Figure 66: Total energy consumption for various scenarios (based on stock) .............. 251

Figure 67: Greenhouse gas emissions related to electricity consumption in the use phase

........................................................................................................................ 251

Figure 68: Average annual energy consumption of household VC in stock and impact of

Ecodesign and Energy Labelling Regulations .......................................................... 252

Figure 69: Share of energy savings due to the Ecodesign regulation and the previous,

annulled Energy Labelling Regulation, based on average AE value of sales each year .. 253

Figure 70: percentage distribution of energy classes for each vacuum cleaner type in 2013,

label coverage 6% .............................................................................................. 254

19

Figure 71: Percentage distribution of energy classes for each vacuum cleaner type in 2016,

label coverage 85% ............................................................................................ 254

Figure 72: Share of people finding areas of the annulled label unclear, out of the 70%

finding at least one parameter unclear (source: APPLiA 2018 consumer survey) ......... 256

Figure 73: Average total costs of ownership for household users .............................. 258

Figure 74: Average total costs of ownership for commercial users ............................ 259

Figure 75: Manufacturers turnover without regulations (BAU0) and with the current

regulations (BAU). .............................................................................................. 260

Figure 76: Retailers turnover without regulations (BAU0) and with the current regulations

(BAU). .............................................................................................................. 261

Figure 77: Importance of the energy label for future vacuum cleaner purchases ......... 267

Figure 78: Expected energy consumption development in the BAU scenario, 2015-2030

........................................................................................................................ 272

Figure 79: Expected annual greenhouse gas emissions in the BAU scenario 2015-2030

........................................................................................................................ 272

Figure 80: Expected development in consumer life cycle costs in the BAU scenario from

2016 to 2030 ..................................................................................................... 273

Figure 81: Energy consumption in PO1, PO2 and PO3 compared to BAU from 2018 to 2030

........................................................................................................................ 281

Figure 82: GHG emissions in PO1, PO2 and PO3 compared to BAU from 2018 to 2030 281

Figure 83: Total end-user expenditure for all vacuum cleaners in EU28 each year from

2018-2030. ....................................................................................................... 284

Figure 84: Conceptual drawing of a recycling sign................................................... 294

Figure 85: Material energy in PO4 compared to BAU from 2018 to 2030 in EU 28 ....... 295

Figure 86: GHG emissions in PO4 and PO5 compared to BAU from 2018 to 2030 ........ 295

Figure 87: Material end-user expenditures for all vacuum cleaners in EU each year from

2018-2030. ....................................................................................................... 296

Figure 88: Total EU market for floor coverings in 2015, equalling 1900 million m2 and 15%

of global market ................................................................................................. 309

Figure 89: left: domestic loop pole, right: domestic cut pile ..................................... 309

Figure 90: left: Allura Vinyl Tile, right: Viva Cushion vinyl ........................................ 310

20

5. List of abbreviations

Abbreviation

Full name

ABS

Acrylic Butadiene Styrene

AC/DC

Alternating Current/Direct Current

ACD

Approved for Committee Draft

AE

Annual Energy Consumption (kWh/year)

ANEC

European consumer voice in

standardisation

ASE

Average Specific Energy (Wh/m

2

)

B2B

Business to Business

BAT

Best Available Technology

BAU

Business as Usual

BC

Base Case

BEP

Best Efficiency Point

BEUC

Bureau Européen des Unions de

Consommateurs

BNAT

Best Not Available Technology

GDP

Gross Domestic Product

BOM

Bill-of-Material

Brushless DC (BLDC)

Brushless Direct Current [motor]

CD

Committe Draft

CEN

European Committee for Standardization

CENELEC

European Committee for Electrotechnical

Standardization

CLC/TC

Technical Committe

Co

Cobalt

CO

2

-eq

Carbon Dioxide Equivalent

CPU

Central Processing Unit

CRM

Critical Raw Material

dB

Decibel

dB(A)

Decibel (Average)

DC

Direct Current

dm³

Cubic Decimetre

DoD

Depth of Discharge

dpu

Dust Pickup

dpu

c

Dust Pickup (carpet)

dpu

hf

Dust Pickup (Hard Floor)

dre

Dust Re-Emission

EC

European Commission

EC

Electronically Communicated [motors]

ECCP

European Climate Change Programme

ECOS

European Environmental Citizens

Organisation

EEB

European Environmental Bureau

EEE

Electrical and Electronic Equipment

EI

Energy Index

EMC

Electromagnetic Compatibility Directive

EoL

End of Life

EPA

Efficiency Particulate Air filter

21

EPS

Expanded Polystyrene

EPS

External Power Supply

ErP

Energy-related Product

EU

European Union

EuP

Energy-using Product

EUR

Euro

Eurostat

European Statistical Office

GfK

Growth from Knowledge

GHG

Greenhouse Gas

gp

General Purpose [50% c + 50% hf]

GPSD

General Product Safety Directive

GWP

Global Warming Potential

HEPA

High Efficiency Particulate Air filter

HPLV

High Pressure Low Volume

HREE

Heavy Rare Earth Elements

HS

Harmonized Commodity Description and

Coding Systems

HVAC

Heating, Ventilation, and Air Conditioning

IA

Impact Assessment

IC

Integrated Circuit

ICRT

The Consumer Test Institute

IEC

International Electrotechnical Commission

IR

Infrared

ISO

International Organization for

Standardization

JRC-IES

Joint Research Centre - Institute for

Environment and Sustainability

kg

Kilogram

kPa

Kilopascal

kt

Kiloton

L/s

Liters per Second

LCA

Life Cycle Assessment

LCC

Life Cycle Cost

LCI

Labour Cost Index

LD-PE

Low Density Polyethylene

Li-ion

Lithium-ion

LLCC

Least Life Cycle Cost

LREE

Light Rare Earth Elements

LVD

Low Voltage Directive

m

Meter

M

Mandatory

m/s

Meters per Seconnd

m

2

Square Meter

m³

Cubic Meter

MEErP

Methodology for Ecodesign of Energy-

related Products

MJ

Megajoule

mm

Millimeter

MPPS

Most Penetrating Particle Size

Mt

Megaton

22

N

Newton

NACE

Classification of economic activities issued

by the European Commission

[Nomenclature statistique des activités

économiques dans la Communauté

européenne]

NCA

Lithium nickel cobalt aluminum oxide (Li-

ion battery)

NiCd

Nickel–Cadmium [battery]

Ni-MH

Nickel Metal Hydride [battery]

NMC

Lithium Nickel Manganese Cobalt Oxide

[battery]

OE

Operating Expense

OEM

Original Equipment Manufacturer

PAH

Polycyclic Aromatic Hydrocarbons

[battery]

PAS

Publicly Available Specifications

PCB

Printed Circuit Board

PE

Polyethylen

PE-HD

Polyethylen High Density

PET

Polyetylentereftalat

PLF

Part Load Factor

PGM

Platinum Group Metal

PJ

Petajoule

PM

Permanent Magnet [motor]

PO

Power Output

PP

Polypropylene

PP

Purchase Price

PRIME Project

Power-efficient, Reliable, Many-core

Embedded systems

PRODCOM

PRODuction COMmunautaire

PS

Polystyren

PWF

Present Worth Factor

Qty

Quantity

RAM

Random Acces Memory

RCF

Room Coverage Factor

REACH

The Regulation on the Registration,

Evaluation, Authorisation and Restriction

of Chemicals

RoHS

The Restriction of Hazardous Substances

RPM

Rounds per Minute

RPS

Rounds per Second

RR

Round Robin

RRT

Round Robin Test

SDA

Small Domestic Appliance

SLAM

Simultaneous Localisation and Mapping

SME

Small and Medium-sized Enterprise

SoC

System-On-Chip

SRM

Switched Reluctance Motor

STM32 MCU

32-bit Microcontroller Unit

23

SVHC

Substances of Very High Concern

TWh

Terawatt Hour

UAP

Unique Acceptance Procedure

ULPA

Ultra Low Penetration Air Filter

UV

Ultraviolet

V

Voluntary

VAT

Value-added Tax

VC

Vacuum Cleaner

VTS

Visual Tracking System

W

Watt

WEEE

Waste Electrical and Electronic Equipment

WIFI

Wireless Fidelity

WOL

Wake-up On LAN

YTD

Year to Date

24

6. Summary

6.1 Background

The Commission’s Regulation

4

(EU) No 666/2013 on Ecodesign requirements for vacuum

cleaners and the annulled Regulation

5

(EU) No 665/2013 on Energy Labelling of vacuum

cleaners entered into force on 2 August 2013, with the first Ecodesign requirements and

energy label classes A to G applicable from 1 September 2014. The second tier of Ecodesign

requirements and the energy label classes A+++ to D were applicable from 1 September

2017. The Energy Labelling Regulation (EU) No 665/2013 was annulled with effect from 8

November 2018

6

.

The objective of the Regulations is to ensure the placing on the market of technologies that

reduce the life-cycle environmental impact, leading to estimated annual electricity savings

of 19 TWh by 2020, corresponding to 6 Mt CO

2

-eq, according to the Impact Assessment

7

.

The Ecodesign Regulation was amended by the horizontal Regulation (EU) 2016/2282 with

regard to the use of tolerances in verification procedures, while the annulled Energy

Labelling Regulation was amended by two horizontal regulations: Regulation (EU)

518/2014 regarding labelling of energy-related products on the internet and Regulation

(EU) 2017/254 regarding the use of tolerances in verification procedures. The horizontal

Regulations apply to all products covered at the time by Ecodesign and Energy Labelling

Regulations.

Reference to the harmonised standards for the Ecodesign Regulation and the Energy

Labelling Regulation was published in the Official Journal of the European Union, C 272, 20

August 2014

8

. In addition to the harmonised standard a standardisation request (M/540

9

)

was issued the European standardisation organisations to further develop the test

methods. Furthermore Guidelines accompanying the Regulations were published in

September 2014

10

.

A special review study was performed in 2016 by Van Holstein en Kemna (VHK) regarding

the specific Ecodesign requirements on the durability of the hose and the operational motor

lifetime, but without changing the content of the Regulation. Therefore, the results from

4

L 192 of 13.7.2013

5

OJ L 192 of 13.7.2013

6

https://curia.europa.eu/jcms/upload/docs/application/pdf/2018-11/cp180168en.pdf

7

COMMISSION STAFF WORKING DOCUMENT IMPACT ASSESSMENT (2013) with regard to Ecodesign requirements for vacuum

cleaners and the Energy Labelling of vacuum cleaners. http://ec.europa.eu/smart-

regulation/impact/ia_carried_out/docs/ia_2013/swd_2013_0240_en.pdf

8

OJ 2014/C 272/6, https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=OJ:C:2014:272:TOC

9

http://ec.europa.eu/growth/tools-databases/mandates/index.cfm?fuseaction=search.detail&id=561

10

https://ec.europa.eu/energy/sites/ener/files/documents/Manufacturer%20guide%20-%20vacuum%20cleaners.pdf

25

the special review study will be used in the present study when assessing the need for

revising the durability requirements in the Ecodesign Regulation.

The review study of the Ecodesign Regulation EU 666/2013 and the annulled Energy

Labelling Regulation EU 665/2913 with regard to vacuum cleaners was started in July 2017.

The study follows the MEErP methodology and reviews the scope and Ecodesign

requirements as well as the labelling classes, in light of current developments in the market

concerning technologies, energy efficiency levels and resource efficiency.

6.2 Scope

The scope of the review study follows the scope of the Ecodesign Regulation and the

annulled Energy Labelling Regulation for vacuum cleaners with the addition of cordless and

robot vacuum cleaners, as seen in Figure 1. In defining the scope, it was found that there

is a need for a redefinition of the current “full size battery operated vacuum cleaner” in

order to properly capture the current European market. It is therefore suggested to add a

definition for cordless vacuum cleaners and split it into two or three categories based on

the size and intended use. The following definitions are suggested:

Cordless vacuum cleaner means a vacuum cleaner powered only by batteries, other than

robot vacuum cleaners;

Cordless cleaners not intended for floor cleaning:

Handheld vacuum cleaner means a lightweight cordless vacuum cleaner with cleaning

head, dirt storage and vacuum generator integrated in a compact housing, allowing the

cleaner to held and operated whilst being held in one hand;

Cordless vacuum cleaners intended for floor cleaning:

Cordless floor vacuum cleaner means a cordless vacuum cleaner that can be used for

cleaning floors from an upright standing position, including handhelds fitted with any tubes,

aggregates or similar that makes it possible to use them for cleaning floor from an upright

standing position;

Some of the vacuum cleaner types shown in Figure 1, particularly upright and cylinder

types, can be either bagged or bagless, i.e. using a single-use bag to collect and store the

dust (bagged) or a reusable container (bagless). However, it is not suggested to change

the definitions of the vacuum cleaner types in the mains-operated group and thus not to

include definitions of bagged and bagless cleaners in the regulations, since the same

requirements should apply.

26

Figure 1: main types of vacuum cleaners included in the scope of the review study

Vacuum

cleaner

Mains

operated

and hybrid

CordlessRobot

CylinderUpright

Mains

handstick

Cordless

handstick

2-in-1

handstick

Handheld

Figure 2: Scope of the Commission Regulation (EU) 666/2013 regarding ecodesign for vacuum

cleaners. (Legend: CR=Commission Regulation, Vacs=Vacuum Cleaners)

Household and

commercial mains

operated and hybrid

vacs

CR (EU) 666/2013

Battery operated

cordless and 2-in-1

vacs

Handheld

vacs

Robot vacs

Robot vacs and floor

polishers/washeres

Wet and Wet&dry

vacs and floor

polishers

Central vacs

Industrial floor care

machines

Industrial outdoor

sweepers

Industrial vacs,

>50cm cleaning head

width

Outdoor vacs

Included in the

review study

Excluded

Excluded

27

6.3 Standardisation and legislation

New legislation has entered into force since the 2009 preparatory study for vacuum

cleaners, the most important in terms on influence on this study are the WEEE Directive

11

regarding management of electronic and electrical waste and the EPS (External Power

Supply)

12

and Standby Regulations

13

, which are important for battery operated vacuum

cleaners. Furthermore, the 2016 circular economy package

14

entails that an assessment of

resource efficiency should be included in Ecodesign and Energy Labelling studies.

Work is also ongoing to improve the standards developed in relation to the Ecodesign and

Energy Labelling

15

requirements for vacuum cleaners under standardisation request M/540

of 2015

16

. The improvement of existing standards regarding energy consumption, sound

power level and dust pick-up on market-representative hard floors and carpets are carried

out in CEN/CENELEC working group 6 (CLC TC59X/WG06).

Furthermore, new standards are under development at both IEC and CEN/CENELEC level

for robot and cordless vacuum cleaners. The development of a standard for robot vacuum

cleaners was started in 2009 and is handled in IEC SC 59F WG5, and is monitored by the

CENELEC working group. The first standard on “Cleaning robots for household use – dry

cleaning: methods for measuring performance” was published in July 2014. Work on the

next edition of the standard was started in 2015 under IEC 62885-7 with the name “surface

cleaning appliances – part 7: dry-cleaning robots for household use – methods for

measuring performance”, set to be published in July 2020

17

. The new standard will include

the following tests:

• Dust pick- up from carpets and hard floor in a straight-line movement;

• Autonomous navigation/coverage test in a test room;

• Obstacle overcome capability in a test room;

• Energy consumption;

• Debris and/or other coarse particles: Straight line;

• Fibre pickup.

In addition, work on a standard for noise measurement of robot vacuum cleaners has

begun in IEC 60704-2-17. Tests on corner/edge dust pick-up, multi zone navigation, and

dust re-emission have been postponed. A preliminary RRT (Round Robin Test) has been

conducted for the tests mentioned above, but the evaluation of the results is still ongoing.

11

http://ec.europa.eu/environment/waste/weee/legis_en.htm

12

OJ L 93, 7.4.2009, p. 3–10

13

OJ L 225, 23.8.2013, p. 1–12

14

http://www.europarl.europa.eu/EPRS/EPRS-Briefing-573936-Circular-economy-package-FINAL.pdf

15

The previous, annulled Energy Labelling Regulation

16

http://ec.europa.eu/growth/tools-databases/mandates/index.cfm?fuseaction=search.detail&id=561#

17

https://www.iec.ch/dyn/www/f?p=103:23:0::::FSP_ORG_ID:1395

28

For cordless vacuum cleaners the standardisation work is carried out at IEC level by IEC

SC 59F WG 7, “IEC 62885-4 ED1: Surface cleaning appliances - Part 4: Cordless dry

vacuum cleaners for household or similar use - Methods for measuring the performance”

18

.

and results are monitored by the European working group. The test parameters in the new

standard include:

• Energy consumption of the batteries; and

• Run time while maintaining reasonable suction power.

6.4 Market data

Vacuum cleaner market data was purchased for the review study from GfK, which included

sales data for the years 2006-2016, as well as performance data based on the annulled

energy label for the years 2013-2018. From the sales and expected lifespans, the stock

was calculated.

Since the market shares of the different vacuum cleaner types are only available for the

years 2013 to 2018, the market split was extrapolated to 2030. Assumptions were made

for the continued development of the market shares for 2025 and 2030 based on

stakeholder inputs, with linear interpolation of market shares in the years between. This

yielded the market shares shown in Table 1. The 2005 market split was calculated from

the preparatory study data

19

, and is assumed unchanged for all years prior to 2005.

Table 1: Derived sales of each vacuum cleaner type from 1990 to 2030

Sales in millions

1990

2000

2005

2010

2015

2018

2020

2025

2030

Cylinder domestic

14.81

16.92

25.01

25.28

25.07

23.43

22.06

17.88

12.07

Cylinder

commercial

1.78

2.03

3.00

3.03

3.01

2.95

2.95

2.95

2.95

Upright Domestic

2.61

2.99

4.41

3.44

2.91

2.60

2.56

2.38

2.01

Upright

Commercial

0.31

0.36

0.53

0.41

0.35

0.31

0.31

0.31

0.31

Handstick mains

0.30

0.34

0.50

0.91

1.25

1.66

1.87

2.38

3.22

Handstick cordless

0.51

0.59

0.87

1.56

4.24

7.39

9.11

13.51

18.10

Robot

0.00

0.00

0.00

0.79

1.45

2.00

2.45

3.58

4.83

Total

20.32

23.22

34.33

35.43

38.28

40.35

41.32

43.00

43.49

The sales and stock numbers for the entire vacuum cleaner market in scope of this study,

is seen in Figure 3 for the years 2005-2030.

18

http://www.iec.ch/dyn/www/f?p=103:30:0::::FSP_ORG_ID,FSP_LANG_ID:1395,34q

19

Preparatory Studies for Eco-Design Requirements of EuPs (II), Lot 17 Vacuum cleaners, TREN/D3/390-2006, Final Report

February 2009, carried out by AEA Energy & Environment, Intertek, and Consumer Research Associates between November

2007 and January 2009. https://www.eceee.org/static/media/uploads/site-2/ecodesign/products/vacuum-cleaners/vacuum-

cleaners-ecodesign-study-final-report-eup-lot-17-final-report.pdf

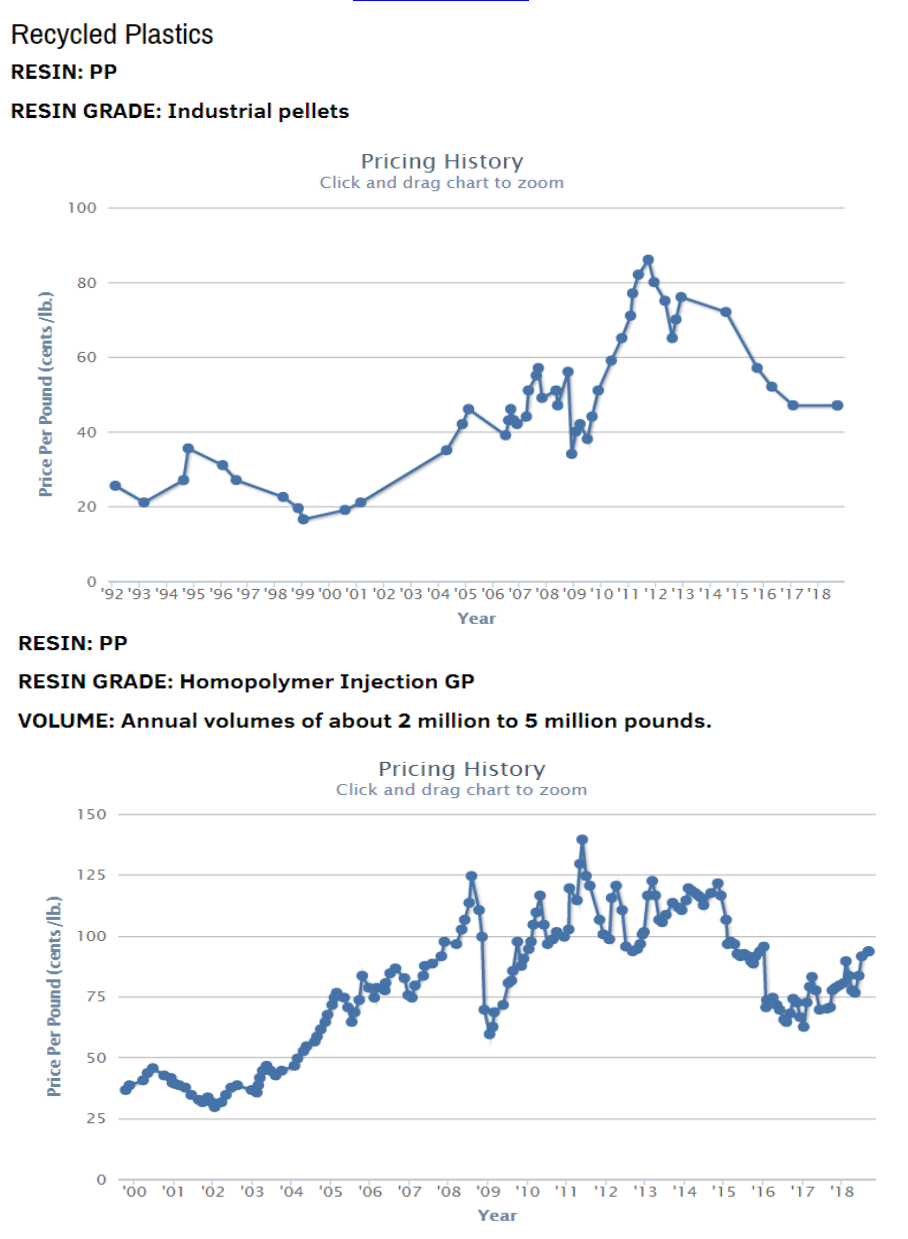

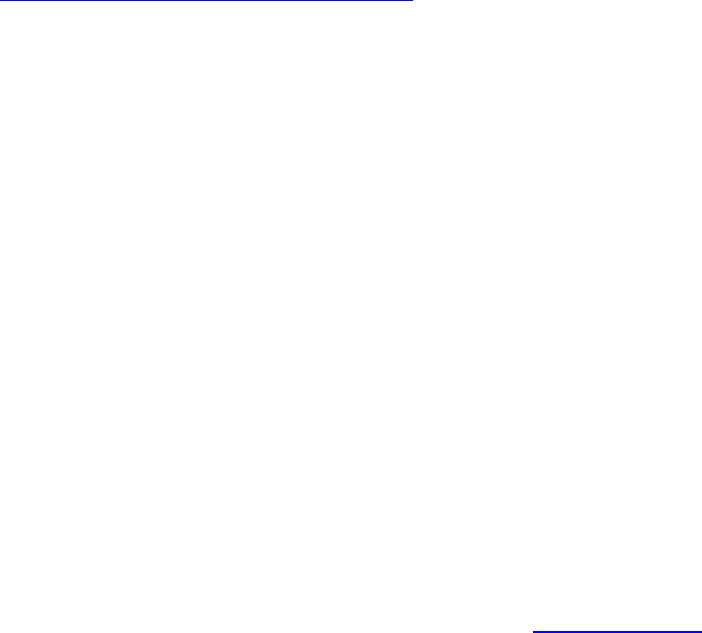

29