Number: UT-PTP7

Revision: 03

TITLE: ISQ-O&G Manual Ultrasonic Thickness &

Corrosion Examination

Date: 07/01/2021

UT-PTP7 Rev. 03 Page 1 of 14 07/01/2021

ISQ-O&G

Manual Ultrasonic

Thickness & Corrosion Examination

ASNT Certification Services, LLC

Document UT-PTP7

Revision 03

The American Society for Nondestructive Testing Certification Services, LLC

All rights reserved

Revision

Date

Summary of Changes

00

05/16/2019

Original Document

01

08/14/2019

Added Appendix A

02

12/19/2019

Additional wording added to Appendix A & Figure 2

03

07/01/2021

Revised thickness range in sections 1.3 & 8.1.2. LLC and Logo changes to the

document.

Number: UT-PTP7

Revision: 03

TITLE: ISQ-O&G Manual Ultrasonic Thickness &

Corrosion Examination

Date: 07/01/2021

UT-PTP7 Rev. 03 Page 2 of 14 07/01/2021

TABLE OF CONTENTS

1. SCOPE

2. REFERENCES

3. ACRONYMS

4. DEFINITIONS

5. QUALIFICATIONS

6. RESPONSIBILITIES

7. EQUIPMENT

8. SPECIMENS

9. STANDARDIZATION

10. EXAMINATION

11. REPORTING

12. APPENDIX A; Signal Evaluation

Number: UT-PTP7

Revision: 03

TITLE: ISQ-O&G Manual Ultrasonic Thickness &

Corrosion Examination

Date: 07/01/2021

UT-PTP7 Rev. 03 Page 3 of 14 07/01/2021

1. SCOPE

1.1. This NDT procedure describes the method for performing manual (non-encoded) pulse-

echo contact straight beam Ultrasonic examinations on carbon steel test specimens

that are utilized in the ASNT Certification Services, LLC ISQ-O&G Ultrasonic

Thickness & Corrosion Scanning exam. This procedure is not applicable for use

outside of the ASNT Certification Services, LLC ISQ-O&G examination.

1.2. The purpose of this procedure is to provide instructions for performing these

examinations to identify the presence of wall loss or mid-wall laminations and to

measure the minimum remaining material wall thickness.

1.3. This procedure is only applicable to carbon steel specimens in the base thickness

range of 0.165” (4.19mm) to 2.500” (63.5mm), for curved specimens of 4” (101.6mm)

diameter or greater up to flat plate, and for bare or coated specimens.

2. REFERENCES

Unless otherwise specified, the latest edition of the below referenced documents are

applicable

2.1. QP-ISQ-2 Industry Sector Qualification Oil & Gas Program

2.2. ASTM E797 Standard Practice for Measuring Thickness by Manual Ultrasonic Pulse-

Echo Contact Method

2.3. SNT-TC-1A Recommend Practice for Personnel Qualification and Certification in

Nondestructive Testing Personnel

2.4. O&G UTT-5 Exam Instructions

2.5. O&G UTT-6 Exam Report Form

3. ACRONYMS

3.1. ANSI American National Standards Institute

3.2. ASNT American Society of Non-destructive Testing

3.3. ASTM American Society for Testing & Materials

3.4. ISQ Industry Sector Qualification

3.5. NDT Nondestructive Testing

3.6. O&G Oil & Gas

Number: UT-PTP7

Revision: 03

TITLE: ISQ-O&G Manual Ultrasonic Thickness &

Corrosion Examination

Date: 07/01/2021

UT-PTP7 Rev. 03 Page 4 of 14 07/01/2021

3.7. UTT Ultrasonic Thickness

4. DEFINITIONS

4.1. Certification Management Committee: The ASNT Certification Services LLC

Committee that has the overall responsibility for developing and maintaining

the technical content of all ASNT Certification Service, LLC certification

programs and shall have the sole responsibility for the determination of

certification outcomes in those programs.

4.2. Industry Sector Qualification (ISQ): A qualification program where practical

demonstration examinations are given to an NDT examiner, for a specific NDT

technique applicable to a given industry sector, to assess competency in performing

examinations. The ISQ shall be awarded upon successful passing of the examination.

4.3. International Services Center (ISC) Certification Group: The ASNT Certification

Services, LLC department responsible for the administration and facilitation of

ASNT Certification Services, LLC certification programs in accordance with

procedures developed by the ASNT Certification Service, LLC Certification

Management Committee (CMC).

4.4. Steering Committee: The group of OG owner/operator subject-matter experts

responsible for the development and maintenance of the ISQ program that fairly and

equitably represents the interests of all parties significantly concerned with the ISQ-

O&G scheme without any particular interest predominating. The parent committee

is the ASNT Certification Services, LLC Certification Management Committee (CMC)

over the Oil & Gas owner/user steering committee for the ISQ-O&G program.

4.5. Test specimen: A sample of a product form containing known discontinuities used

in practical examinations.

5. QUALIFICATIONS

5.1. The ISQ UTT candidates shall understand that the expected prerequisite level of

competency to sit for this exam is at least equal to a Level II ultrasonics limited

certification in A-scan thickness measurement per the guidelines in SNT-TC-1A.

6. RESPONSIBILITIES

6.1. The examination instructions O&G UTT-5 and this examination procedure UT-PTP7,

shall be read and understood by the candidate before applying for the ISQ-O&G UTT

exam. The candidate shall be expected to follow the UTT examination instructions and

the UTT examination procedure during the examination. Failure to do so may cause a

failure on the exam.

6.2. O&G UTT candidates are responsible for bringing and utilizing their own equipment

including: ultrasonic thickness gauge or flaw detector, transducers, cables, reference

standards, couplant, & rags. The candidate is responsible for referring to this

Number: UT-PTP7

Revision: 03

TITLE: ISQ-O&G Manual Ultrasonic Thickness &

Corrosion Examination

Date: 07/01/2021

UT-PTP7 Rev. 03 Page 5 of 14 07/01/2021

procedure and selecting the proper equipment for use during their ISQ UTT exam.

6.3. The candidate shall perform manual (non-encoded) contact straight beam UT

examinations on the ISQ UTT test specimens assigned to them during their exam

which may, or may not, contain service induced or manufactured discontinuities.

6.4. The candidate shall complete their ISQ UTT examination and the associated reporting

in compliance with O&G UTT-5 exam instructions.

6.5. The steering committee and CMC are responsible for this ISQ UTT NDT technique

procedure, and any revisions required for this procedure.

7. EQUIPMENT

7.1. Ultrasonic Instruments

7.1.1. A candidate shall only use an Ultrasonic Thickness Meter with an A-scan

presentation and/or an Ultrasonic Flaw Detector. Digital or Analog

Instruments may be used. A candidate should take the ISQ UTT exam with

the instrument they normally use on a regular basis during their work duties.

Ultrasonic instruments with no A-scan presentation will not be allowed for

use on the ISQ UTT exam, i.e. digital gauges with only a numeric readout.

7.1.1.1. For Instruments with additional B-scan and/or C-scan functions,

the B-scan and/or C-scan functions will have to be switched off

and only the A-scan function shall be utilized during the exam.

7.1.2. Thickness gauging instrumentation should be capable of generating

frequencies within the range of 1 MHz to 10 MHz, with 2.25 MHz to 5 MHz

being the typical range of frequency for use with this procedure.

7.1.3. Ultrasonic instruments used for thickness gauging to this procedure should be

calibrated within the last year.

7.2. Transducers

7.2.1. Straight beam contact or delay line, single and/or dual element, transducers

that are applicable to wall thickness measurements and flaw detection are

acceptable to be used in accordance with this procedure. For Instruments

that have automatic transducer recognition, consult the owner/user manual

for compatibility of the transducer.

7.2.2. Straight beam, pulse echo, single or dual element transducers having element

sizes from 0.125” (3.175mm) to 0.750” (19.05mm), round or square in shape

should be used with this procedure.

7.2.3. The selection of search unit frequency, type, & diameter will depend on the test

specimen thickness and the presence or lack of coating.

Number: UT-PTP7

Revision: 03

TITLE: ISQ-O&G Manual Ultrasonic Thickness &

Corrosion Examination

Date: 07/01/2021

UT-PTP7 Rev. 03 Page 6 of 14 07/01/2021

7.2.3.1. In general, the search unit frequency should be from 2 MHz to 5

MHz. For this exam, thin test specimens or test specimens with

deep corrosion (minimal remaining wall thickness), a higher

frequency is more likely to give more accurate readings. However

very rough corrosion might cause too much scattering of the

Ultrasonic energy at high frequencies, testing at multiple

frequencies may be required. The table below provides frequency

recommendations based on thickness however adequate results

might be achieved outside of these ranges.

Recommended Frequency Ranges

Material Thickness

Frequency (MHz)

< ¼” (6.35mm)

5.0 to 10.0 MHz

¼” (6.35mm) < ¾” (19.05mm)

4.0 to 7.5 MHz

¾” (19.05mm) to < 1 ½” (38.1mm)

2.0 to 5.0 MHz

1 ½” (38.1mm) to < 2 ½” (63.5mm)

2.0 to 5.0 MHz

7.2.3.2. For test specimens under 1” (25.4mm) thickness, a dual element

transducer should be used however consideration should be given

to thin material, under 0.250” (6.35mm) thickness, to ensure no

doubling effect is occurring.

7.2.3.3. For test specimens 1” (25.4) and greater in thickness, a single

element transducer should be used however a dual element

transducer with sufficient focal depth might be adequate to

achieve accurate results.

7.2.3.4. Consideration for test specimen curvature should be given when

selecting transducers for examination. Transducers should be

selected that will sit flat on curved surfaces to minimize errors due

to transducer rocking. Curved exam specimens shall not be less

than ANSI 4” outside diameter pipe sections.

7.3. Couplant

7.3.1. A suitable couplant designed for use in ultrasonic testing should be used for

the exam. The couplant shall be of a type that can be easily cleaned off

specimens with wiping a rag across the surface.

7.3.2. The same couplant that is used for equipment standardization should be used

for examination.

7.3.3. All couplant shall be cleaned off specimens before being returned to the

specimen holding area.

Number: UT-PTP7

Revision: 03

TITLE: ISQ-O&G Manual Ultrasonic Thickness &

Corrosion Examination

Date: 07/01/2021

UT-PTP7 Rev. 03 Page 7 of 14 07/01/2021

7.4. Reference Standards

7.4.1. Reference standards with flat, parallel surfaces, should be used. They should

have thin and thick sections that fully cover the range of specimen thickness

to be inspected. Multiple reference standards might be required to cover the

full range of specimen thickness included in this exam.

7.4.2. Reference standards should be certified with known thickness values.

7.4.3. Reference standards should have similar acoustic properties as the low alloy

carbon steel test specimens.

8. SPECIMENS

8.1. Test Specimens in the ISQ UTT exam shall have the following characteristics:

8.1.1. They shall be low alloy carbon steel.

8.1.2. The thickness range of UTT test specimens shall be from 0.165” (4.19mm) to

2.5” (63.5mm).

8.1.3. Test specimens shall be of either flat plate or curved section product form.

Curved section specimens shall not have a radius smaller than that of an

ANSI 4” outside diameter pipe.

8.1.4. Test specimens may be coated with 10 to 50 mils of coating: fusion bonded

epoxy, two-part polyurethane, or similar.

9. STANDARDIZATION

9.1. The ultrasonic instrument should be standardized (often referred to as calibrated or

technique calibration) for horizontal linearity (thickness) on reference standards

having similar acoustic properties as the low alloy carbon steel test specimens.

9.2. Reference standards should have a minimum of 2 (two) sections of different thickness

which cover the minimum and maximum thickness range expected for the specimen(s)

to be examined. The more steps that are machined into a reference standard and used

for standardization, the better the accuracy of the instrument standardization will be.

9.3. The ultrasonic instrument shall be standardized prior to examination and should be

standardized upon completion.

9.4. The technician should also check their instrument standardization anytime during

their examination when one of the following conditions occur:

9.4.1. Any equipment component is changed: transducer, cable, delay line standoff,

battery, etc.

Number: UT-PTP7

Revision: 03

TITLE: ISQ-O&G Manual Ultrasonic Thickness &

Corrosion Examination

Date: 07/01/2021

UT-PTP7 Rev. 03 Page 8 of 14 07/01/2021

9.4.2. The technician doubts the accuracy of their standardization.

10. EXAMINATION

10.1. Specimen surface condition:

10.1.1. Prior to examination the test specimens should be visually examined, in the

area to be contacted by the transducer, to ensure the scanning surface is free

of couplant residue, loose paint, dirt, mill scale, machining or grinding

particles, or other loose foreign matter that would impair the free movement of

the transducer or affect the accuracy of the thickness measurement results.

10.2. Place transducer on test specimen and move it across the surface to see the average

backwall signal amplitude. Adjust instrument gain to achieve an 80-100% full screen

height signal amplitude of the first back wall reflection for the specific test specimen

under examination. This should be used as the base gain setting for examination of

this test specimen.

10.2.1. Scanning may be performed with an additional +6dB for greater sensitivity to

detect small discontinuities.

10.2.2. Additional gain above base and scanning dB may be needed to evaluate small

indications. Care should be taken in distinguishing between real indications

and background noise in the A-scan when adding gain.

10.3. Each test specimen shall be examined from the scanning surface only to determine the

presence and type of any discontinuities (flaws) in the specimen by scanning the entire

specimen. Possible flaw types are detailed in 11.1.1. No specimens shall include

flaw types from more than one of the three categories detailed in 11.1.1.

10.3.1. Scanning speed should not exceed 6” (152.4mm) per second.

10.3.2. Scanning overlap should be a minimum of 10% of the width or diameter of the

active area of the transducer.

10.4. For test specimens with coating the following methods should be utilized to accurately

measure the minimum and maximum wall thickness.

10.4.1. Measurement calculated by subtracting the first back wall signal from the

second back wall signal. This can be accomplished either by an instrument’s

Echo to Echo function or by manually subtracting the value observed from the

first back wall signal from the value observed from the second back wall

signal.

Note: When using echo to echo, many instrument manufacturers warn users about potential

signal mode conversion that can occur when measuring thicknesses above 0.7". When

Number: UT-PTP7

Revision: 03

TITLE: ISQ-O&G Manual Ultrasonic Thickness &

Corrosion Examination

Date: 07/01/2021

UT-PTP7 Rev. 03 Page 9 of 14 07/01/2021

this occurs, a mode converted shear wave signal can appear before the second backwall

reflection, which can trigger the instrument to focus on it, rather than the true second

backwall reflection, yielding a thinner reading than is actually present.

10.4.2. In some cases, such as on test specimens with rough back wall surfaces, the

echo-to-echo function might not work due to the inability to produce multiple

back wall reflections. As an alternative option for acquiring accurate wall

thickness readings through coating without multiple backwall signals the

following method may be utilized for each individual specimen:

10.4.2.1. Examine the test specimen in the standard first back wall method

to identify areas without wall loss adjacent to the area(s) with wall

loss.

10.4.2.2. Record the measurement of the test specimen with coating in the

standard first back wall technique in an area with no wall loss.

10.4.2.3. Then record a measurement in the same area with no wall loss

utilizing the method in 10.4.1 above to measure the wall thickness

without coating.

10.4.2.4. Subtract the wall thickness reading without coating (echo to echo

method) from the wall thickness measurement with coating

(standard first back wall method) and record the difference. This

recorded value is the equivalent coating thickness as measured by

the UT instrument calibrated for carbon steel.

10.4.2.5. Scan the entire test specimen in the standard first back wall

method to locate the minimum remaining wall thickness.

10.4.2.6. Subtract the previously recorded value for the coating thickness

from the minimum wall thickness observed in the standard first

back wall technique.

10.4.2.7. This method should only be utilized when it is impossible to

acquire a second multiple back wall signal.

10.5. Utilize the examination dry erase specimen sketch note sheet provided by the AEP to

record notations during the exam. Transfer recorded notes / answers from the

specimen sketch note sheet to the dry erase report form O&G UTT-6, also provided by

the AEP, for data recording during the exam.

10.6. Clean off all residual couplant from test specimens before returning them to the

holding area and retrieving any subsequent specimens.

11. REPORTING

11.1. During the exam, the dry erase report form provided by the AEP shall be used for

Number: UT-PTP7

Revision: 03

TITLE: ISQ-O&G Manual Ultrasonic Thickness &

Corrosion Examination

Date: 07/01/2021

UT-PTP7 Rev. 03 Page 10 of 14 07/01/2021

recording examination results. The following details shall be recorded for each test

specimen:

11.1.1. The flaw type determined shall be recorded in the ‘flaw type’ data entry

location for the corresponding specimen by the candidate. The flaw type

options for data entry for each specimen are as follows; ‘N’ for a specimen with

no damage observed, ‘W’ for a specimen observed as containing any form of

wall loss, or ‘M’ for a specimen with one or multiple mid-wall laminations

observed. See Appendix A for more information on signal evaluation.

11.1.2. For test specimens identified as containing wall loss, the minimum remaining

wall thickness for the entire test specimen shall be determined and recorded

in the ‘minimum thickness’ data entry location for the corresponding

specimen by the candidate.

11.1.3. For test specimens identified as containing (a)mid-wall lamination(s), the

minimum remaining full wall thickness for the entire test specimen shall be

determined and recorded in the ‘minimum thickness’ data entry location for

the corresponding specimen by the candidate. The depths or horizontal

dimensions of the mid-wall lamination(s) shall not be recorded.

11.1.4. For test specimens identified as containing no damage, the minimum

remaining wall thickness for the entire test specimen shall be determined and

recorded in the ‘minimum thickness’ data entry location for the corresponding

specimen by the candidate.

11.1.5. The maximum thickness shall be determined for each test specimen, from all

flaw type categories, and recorded in the ‘maximum thickness’ data entry

location for the corresponding specimen by the candidate.

11.2. After examination completion the candidate shall follow the instructions provided in

O&G UTT-5 Exam Instructions to complete their computerized report entry and

submission to the ASNT Certification Services, LLC computerized grading system. Or

in the case of an issue with the computerized report submission system, follow the

AEP’s instructions for hard copy report completion and submission.

11.3. Once report submission is completed the candidate shall clean off the dry erase forms

provided and turn them into the AEP.

Number: UT-PTP7

Revision: 03

TITLE: ISQ-O&G Manual Ultrasonic Thickness &

Corrosion Examination

Date: 07/01/2021

UT-PTP7 Rev. 03 Page 11 of 14 07/01/2021

Appendix A – Signal Evaluation

Careful evaluation of A-scan signals is required to differentiate signal responses generated by wall

loss from signal responses generated by mid-wall laminations or inclusions. Below is some guidance

that can be used to assist with signal evaluation to identify if signal responses are from wall loss or

from mid-wall reflectors. The information provided is guidance only and should not be considered

as absolute for all situations. All items below should be considered when evaluating ultrasonic 0-

degree signal responses from unknown reflectors.

1. Laminations generate signals that are typically higher in amplitude, narrow on the time

base, and have a flat vertical leading edge, similar to a flat back wall response:

a. Sharp, flat leading edge to the signal.

b. Signal has little to no movement horizontally across A-scan display from variation in

sound path. Laminations are at a constant, or near constant, depth and therefore rise

and fall at the same location on the time base.

c. Large laminations close to the surface can have a signal amplitude larger than the

backwall signal from the full material thickness.

d. Laminations almost always create multiple, or repeat, signals in equidistant steps

from the scanning surface. Coated samples are an exception to this guidance as

ultrasonic signals through coating may have considerable ring down, additional cycles

in the sine wave, in the first back wall response that greatly reduce the level of

continued energy required to create multiple back wall signals.

e. Signal responses from laminations are consistent in shape, size, & time base location

regardless of the scanning direction the transducer moves on and off of the lamination

from.

f. Multiple laminations of various sizes and at various depths in one material can be

mistaken as corrosion covering a range of depth. Care must be taken to evaluate these

signals individually to verify they are laminations. These situations are often seen in

older equipment with many small mid-wall laminations.

g. Laminations are most likely contained within the middle half of the material and are

very unlikely to be close to the front or back-wall surface.

2. Areas of wall loss generate signals that are typically lower in amplitude than back-wall

echoes and are broad with multiple peaks:

a. Rough, wide signals, with multiple peaks.

b. Corrosion signals move left of the back-wall signal along the time base.

Number: UT-PTP7

Revision: 03

TITLE: ISQ-O&G Manual Ultrasonic Thickness &

Corrosion Examination

Date: 07/01/2021

UT-PTP7 Rev. 03 Page 12 of 14 07/01/2021

c. Corrosion signals with substantial change in depth likely have responses that move

across a significant amount of the time base.

d. Very unlikely to have amplitude larger than the back-wall. If wall loss is very deep

(close to scanning surface) and has a large plateau (flat area) then it is possible to have

a larger amplitude than a back-wall response, but this is very rare.

e. Corrosion is very unlikely to create multiple, or repeat, signals. If wall loss is very deep

(close to scanning surface) and has a large plateau (flat area) then it is possible, but

this is also very rare. Samples with erosion that have a smooth area that is parallel to

the scanning surface are an exception to this guidance. These types of areas can

generate multiple reflection signals like a lamination. However, areas of erosion will

generate changes in signal behavior when moving the transducer on and off of the

eroded area in various scanning directions unlike laminations which will generate the

same signal behavior in every direction as the transducer is moved on and off of the

area containing the lamination.

f. Shallow internal pitting can be seen in small changes to the back-wall signal. Monitor

drops in signal amplitude in conjunction with slight movement to the left on the time

base line.

g. Shallow pitting and corrosion will generate signals close to the full sample back-wall

thickness at undamaged areas.

h. Isolated areas of corrosion with steep sides to the wall loss (i.e. large single pits) can

generate A-scan signals similar to large laminations where the back-wall signal

disappears completely, and a signal appears with shorter sound path. In a situation

where this occurs, care must be taken to verify if there is any movement on the time

base to the left (shorter sound path) along with reduced amplitude of the back-wall

signal and/or a slight movement to the left (shorter sound path) along with increasing

amplitude of the mid-wall signal. If either of these conditions occur the reflector is

likely an isolated pit with significant wall loss rather than a mid-wall lamination.

3. Coated parts can cause additional difficulties in signal evaluation:

a. Coating can cause an increase in signal ring-down, additional cycles in the sine wave,

which makes all signals seem broader with an increased number of signal cycles seen

on the A-scan. This makes all signals, including clean back-wall signals and

laminations, to appear broader. Coating on samples that creates additional signal

ring-down can also cause laminations to not generate multiple signals.

b. Extra care must be taken on coating parts when evaluating signals from laminations

to verify they do not move back and forth on the time base.

Number: UT-PTP7

Revision: 03

TITLE: ISQ-O&G Manual Ultrasonic Thickness &

Corrosion Examination

Date: 07/01/2021

UT-PTP7 Rev. 03 Page 13 of 14 07/01/2021

Figure 1 – Signal Patterns (© ASNT 2019)

The following figure provides some examples of signal patterns indicative of the various scenarios

detailed. The figure assumes a back-wall signal from an undamaged area on a part was set to 80%

full screen height at a position on the time base 40% across the screen from the left side (0

distance).

Number: UT-PTP7

Revision: 03

TITLE: ISQ-O&G Manual Ultrasonic Thickness &

Corrosion Examination

Date: 07/01/2021

UT-PTP7 Rev. 03 Page 14 of 14 07/01/2021

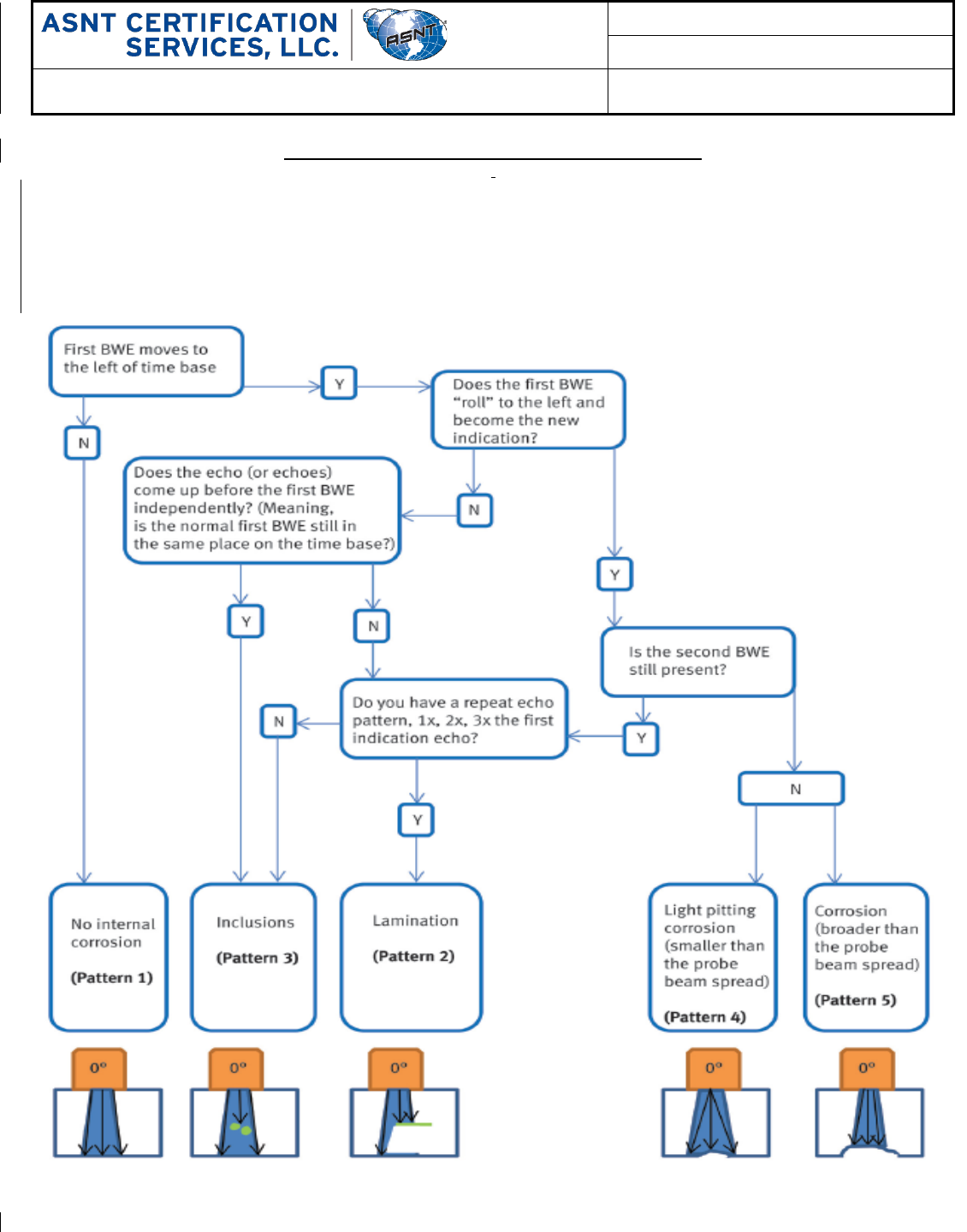

Figure 2 – Evaluation Flowchart (© ASNT 2019)

)

The following figure provides some guidance on signal evaluation in the form of a flowchart that can

be followed for differentiating corrosion from mid-wall laminations or inclusions. This flowchart is

not absolute as every flaw in a material can exhibit different ultrasonic signal behaviors.

Information provided above in sections 1. Laminations and 2. Wall loss should be considered when

determining the nature of ultrasonic signals.