OPERATING MANUAL

HANDHELD AUDIO AND

ACOUSTIC ANALYZER

XL2

Made in

Switzerland

Contact NTi Audio at

Headquarter

France +33 4 78 64 15 68 [email protected]

Germany +49 201 6470 1900 [email protected]

www.nti-audio.com

Firmware V4.84

Version 4.84.00 / Aug 23

All information subject to change without notice.

© All rights reserved.

® XL2, XL2-TA, EXEL, M2230, M2340, M2211, M2215, M4261, MA220, MA230,

™ M2230-WP, M2340-WP, M4261-WP, WP30-90, WP30-150, WP61 and Minirator are trademarks

of NTi Audio.

NTi Audio AG

Im alten Riet 102, 9494 Schaan

Liechtenstein, Europa

is an ISO 9001:2015 and ISO 14001:2015 certified company.

3

Table of Contents

Table of Contents

5. Acoustic Analyzer .......................................................... 64

FFT Analysis + Tolerance ..............................................64

Reverberation Time ...................................................... 74

Polarity .........................................................................86

Delay Time ...................................................................90

1/12 Octave + Tolerance (optional) ............................... 96

Noise Curves (optional) ..............................................108

Speech Intelligibility STIPA (optional) ......................... 118

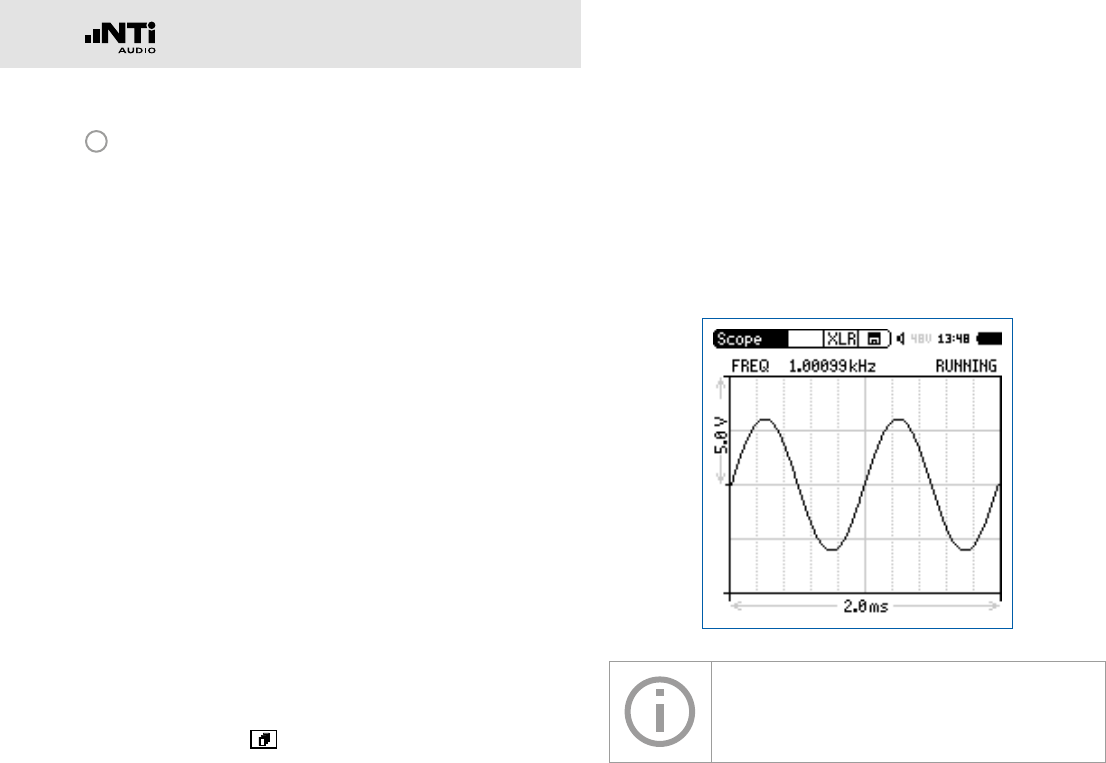

6. Audio Analyzer ............................................................135

RMS / THD+N ............................................................ 135

Oscilloscope ..............................................................138

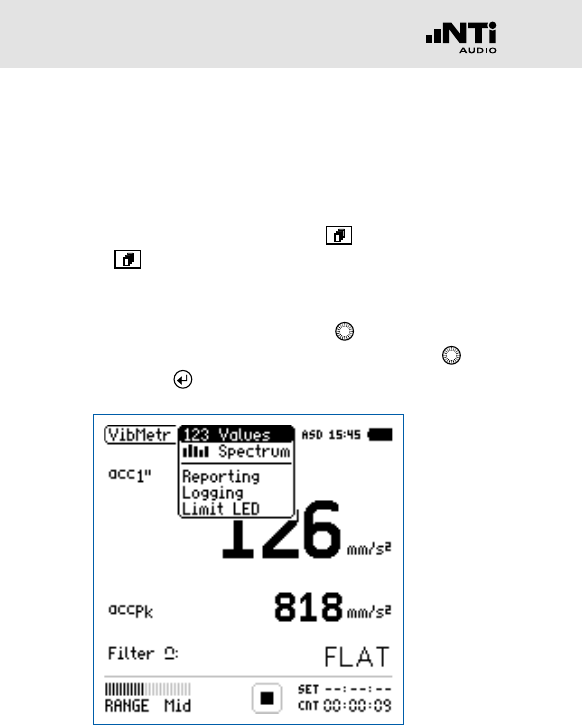

7. Vibration Meter ............................................................139

VibMeter / Spectrum .................................................139

FFT Analysis + Tolerance ............................................ 146

Oscilloscope ..............................................................150

1/12 Octave + Tolerance (optional) .............................151

8. Calibration ...................................................................156

9. Profiles .........................................................................163

10. Spectral Limits Option (Capture + Tolerances) .......170

11. System Settings ........................................................183

Settings ......................................................................183

1. Introduction .....................................................................5

2. Overview .......................................................................... 7

Operation .......................................................................9

The Screen Display ...................................................... 11

3. Getting Started .............................................................14

Power Supply .............................................................. 14

Attaching the Hand Strap .............................................17

Unfolding the Stand ..................................................... 18

Connecting the XL2 ....................................................18

Switching the XL2 On and Off .....................................20

Select Measurement Function .....................................20

Calibration prior Measurement ....................................21

4. Sound Level Meter ........................................................ 22

Overview .....................................................................26

Sound Level Meter - Getting Started ...........................34

RTA Measurement - Getting Started ...........................39

Reporting .....................................................................43

Wav-File Recording ......................................................46

Events (optional) ..........................................................49

Limits ...........................................................................56

Correction Value KSET .................................................58

Locked Run Mode ........................................................62

4

Table of Contents

Vibration .....................................................................186

Scheduler ................................................................... 187

Options ......................................................................189

Information ................................................................190

12. Data Management ....................................................191

Record Voice Notes .................................................... 197

Recall Measurements ................................................ 203

Append Measurements ............................................205

13. XL2 Projector PRO Software .................................... 210

14. Data Explorer (optional) ........................................... 212

15. Building Acoustics (optional) ...................................214

16. Room Acoustics (optional) .......................................216

17. Sound Power (optional) ............................................ 218

18. Unattended Noise Monitoring .....................................220

19. Time Synchronization...............................................226

20. Remote Measurement ..............................................230

21. Microphones .............................................................232

22. Further Information ..................................................246

My NTi Audio .............................................................246

Firmware Update .......................................................249

Options ......................................................................250

Warranty Conditions ..................................................271

Service and Repairs ...................................................272

Calibration Certificate .................................................272

Declaration of Conformity .......................................... 274

23. Technical Data XL2 .................................................... 276

24. Technical Data Microphones ....................................288

25. Technical Data PreAmplifier ......................................298

Appendix .........................................................................299

Appendix 1: Standard - Optional Features .................299

Appendix 2: Factory Default Profiles .........................303

Appendix 3: Description Sound Levels ......................308

Appendix 4: Common Sound Levels ..........................313

Appendix 5: Vibration Meter Functions ......................319

Details IEC 61672 & IEC 61260 ....................................... 320

General Information ...................................................322

Class 1 Sound Calibrator ............................................ 325

Accessory ..................................................................325

Level Linearity ............................................................326

Level Linearity of Octaveband-Spectrum ................... 328

Level Linearity of Third-Octaveband-Spectrum ..........329

Self-generated Noise with Microphone .....................330

Frequency Response Corrections .............................. 332

Frequency Weighting .................................................336

Directional Response (dB) .........................................337

Information for Calibration ............................................342

5

Introduction

- Room Acoustics

- Building Acoustics

- Reverberation Time

- Noise Curves

• Industrial Quality Control

• Condition Monitoring

How to Read this Manual

The XL2 push buttons are displayed as icons

, , , ,

, , , , . A detailed description of the push buttons is

listed in the chapter Overview - Operation.

Menu items displayed on the XL2 page screens are shown in

this user manual by a bold font, e.g., SLMeter, Parameter, ...

1. Introduction

Thank you for purchasing the XL2 Audio and Acoustic Analyzer.

The XL2 Analyzer forms the unique combination of a state-of-

the-art Sound Level Meter, a comprehensive Acoustic Analyzer

as well as a powerful Audio Analyzer. The wide range of func-

tionalities is tailored for:

• Evacuation Systems

- Speech Intelligibility

• Electroacoustic Installations

- Installed Sound

- AV Installations

- Cinemas

• Noise Measurement

- Unattended Noise Monitoring

- Environmental Noise

- Occupational Health

- Vehicle Noise

- Sound Power

• Live Sound

- Sound Level Monitoring

- Front of House

- PA Rental

• Broadcast

• Room & Building Acoustics

6

Introduction

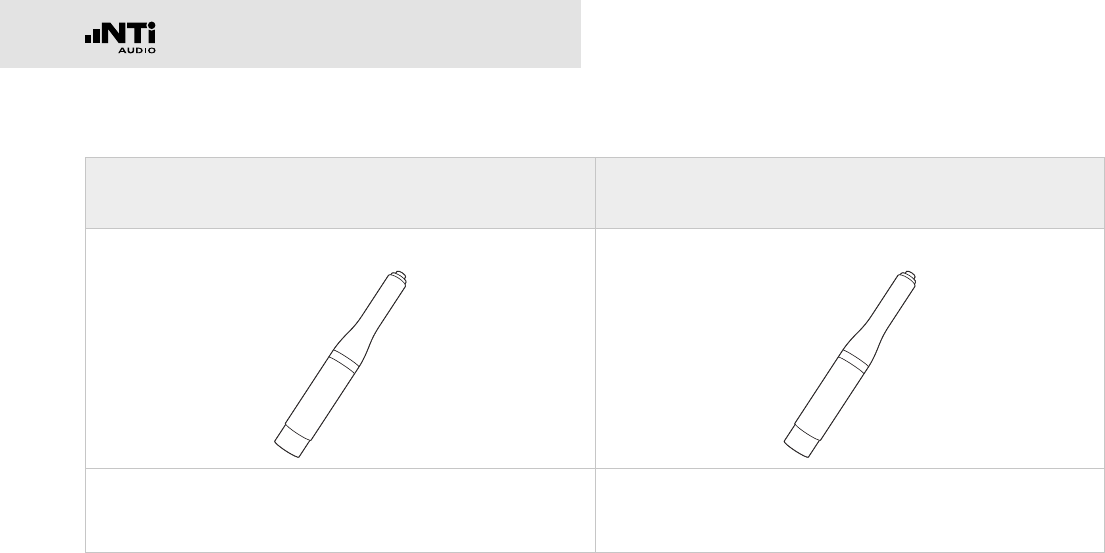

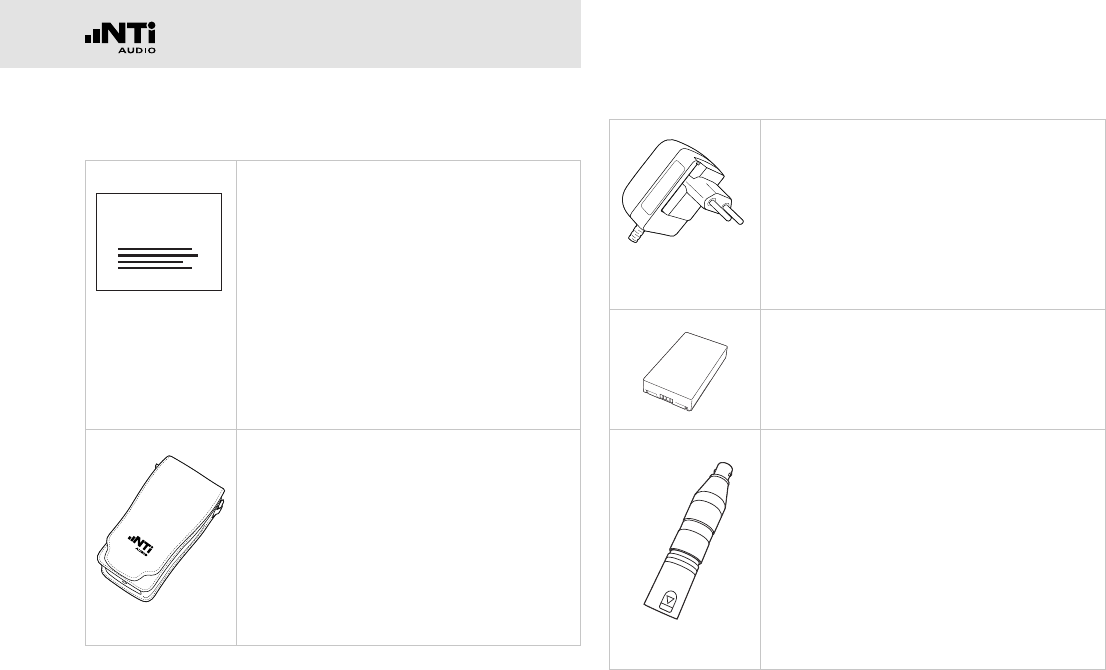

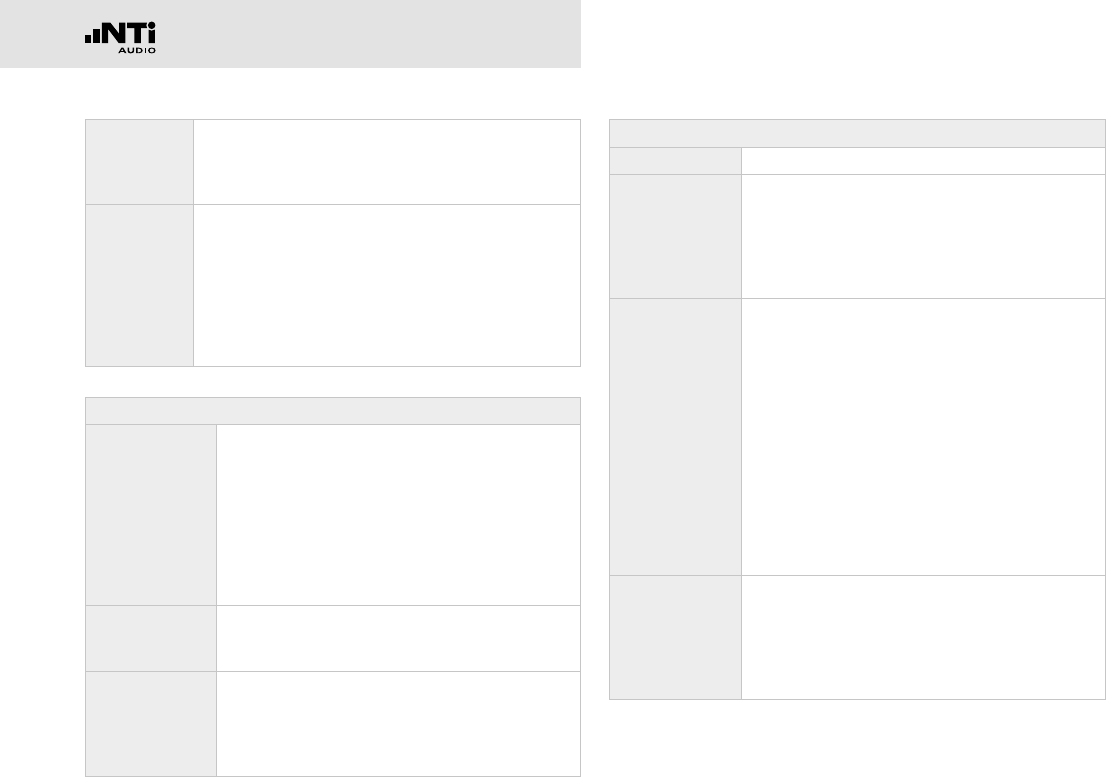

Product Configurations

The following items are included with the respective model:

XL2

without

Micro-

phone

• XL2 Analyzer

• USB Flash Drive with test signals

• USB cable

• Li-Po battery

• Hand strap

• Operating manual

XL2 +

M2230

• XL2 Analyzer

• M2230 Measurement Microphone

consisting of

- Microphone PreAmplifier MA220

- Microphone Capsule MC230 or MC230A

• 50 mm Windscreen

• Microphone-holder MH01

with Adapter 5/8“ - 3/8“

• Individual Frequency Response Chart

• USB Flash Drive with test signals

• Li-Po battery

• USB cable

• Hand strap

• Operating manual

XL2 +

M2211

• XL2 Analyzer

• M2211 Measurement Microphone

consisting of

- Microphone PreAmplifier MA220

- Microphone Capsule 7052

• 33 mm Windscreen

• Microphone-holder

with Adapter 5/8“ - 3/8“

• USB Flash Drive with test signals

• Li-Po battery

• USB cable

• Hand strap

• Operating manual

XL2 +

M4261

• XL2 Analyzer

• M4261 Measurement Microphone

• 33 mm Windscreen

• Microphone-holder

with Adapter 5/8“ - 3/8“

• USB Flash Drive with test signals

• Li-Po battery

• USB cable

• Hand strap

• Operating manual

7

Overview

8

9

7

Headphone

Output

SD Card

TOSLink Output

1

2

3

4

5

6

Voice Note Input

RCA Input

XLR Input

Digital I/O

USB Connector

DC Power Socket

10

Speaker

11

Tripod Mount

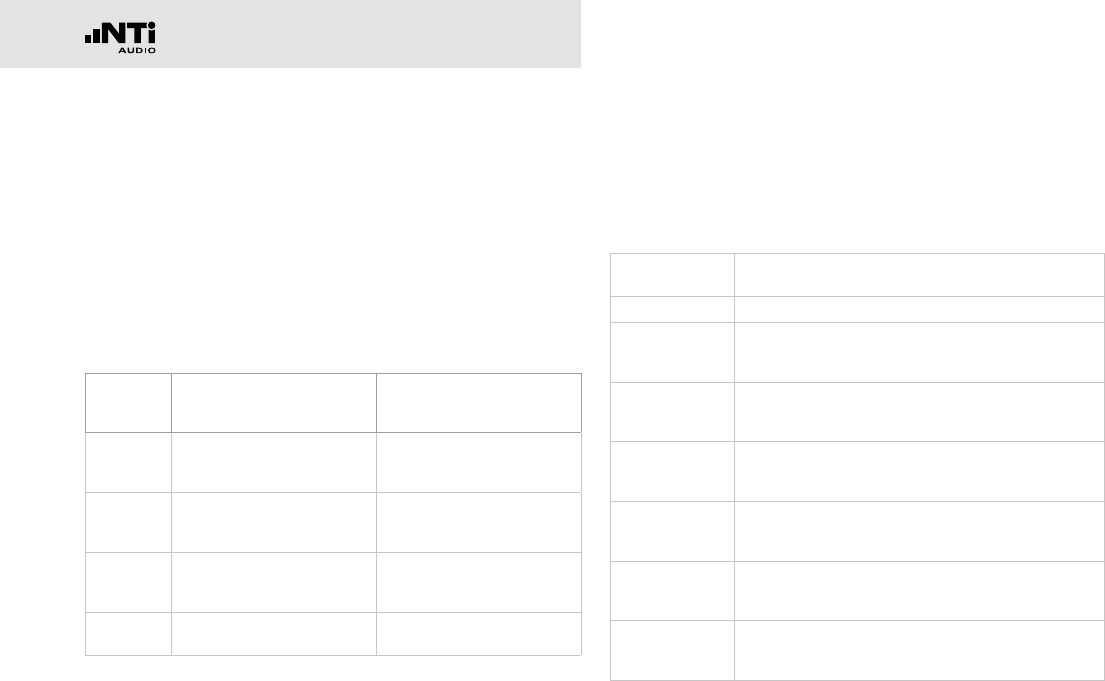

2. Overview

XL2 interfaces:

8

Overview

1

XLR Signal Input

Either a balanced audio signal, an NTi Audio measure-

ment microphone or the microphone pre-amplifier MA220

plug directly into the XLR input. The Automated Sen-

sor Detection (ASD) technology reads the electronic

data sheet of any connected NTi Audio device after the

48 V microphone phantom power is activated.

2

RCA Input

Unbalanced audio signal input.

3

Voice Note Input

Internal microphone for recording voice notes and measur-

ing polarity and delay time. For polarity measurements, an

external microphone may also be used.

4

DC Power Socket

Socket for mains power adapter. Further details in the chap-

ter Power Supply in this manual.

5

USB Connector

Mini-B USB connection, for accessing the SD Card.

6

Digital I/O

Programmable digital inputs/outputs.

7

SD Card

For storing data, screenshots, voice notes, wav-files -

required to power on and run the instrument.

8

TOSLink Output

24 bit linear PCM audio signal output. For future use; not

active at this time.

9

Headphone Output

The XLR/RCA input signals are routed to the headphone

connector (3.5 mm Minijack; mono monitor wired to both

channels of stereo jack). Connecting headphones mutes the

internal speaker. To connect the headphone output direct-

ly to a line input, a load impedance < 8 kOhm is required

for proper operation. This can be achieved by inserting a

1 kOhm resistance between tip and ground of the output

jack.

10

Speaker

The XLR/RCA input signals are routed to the speaker. Press

the speaker button

to toggle the speaker on/off. Press

and hold the speaker button to access the volume control.

Set the speaker level with the rotary wheel

.

11

Tripod Mount

Mechanical mount for attaching the XL2 to a tripod or mi-

crophone stand.

9

Overview

Operation

9 8 7

6

5

4

3

2

1

1

Page Control

Switches among various screens depending on the menu

function selected.

2

Volume of Speaker and Headphone Output

• Press the button

briefly to enable or disable the

speaker.

The speaker is activated and the speaker or headphone

icon appears in the upper menu bar.

• Press and hold the speaker button .

A pop-up window for volume is displayed.

10

Overview

• FFT + Tol: The limit button lights up green for results

within tolerance and red for out-of-tolerance results.

• Polarity: The limit button lights up green at positive polar-

ity and red at negative polarity.

• 1/12 Oct + Tol: The limit button lights up green for results

within tolerance and red for out of tolerance results.

5

Pause

Pauses the current measurement. Press the pause button

or the start/stop button to continue the measure-

ment. The data logging is continued in the function SLMe-

ter/RTA during the pause period and listed in the log file.

6

Start/Stop

Starts and stops a measurement.

7

Enter

Confirms a selection.

8

Rotary Wheel

Selects the required measurement function or the individu-

al measurement parameter.

9

ESC

Terminates an entry, returns to the top menu level or closes

an open window.

• Hold the speaker button

down and adjust the level

of the speaker and headphone outputs with the rotary

wheel

. Digital gain control prevents gain increases be-

yond a level that will cause signal clipping. The maximum

gain setting depends on the connected input signal.

• The headphone output provides a linear output signal us-

ing the SLMeter function over a measurement range of

57 dB. The minimum Z-weighted sound pressure level at

reference sensitivity is:

- M2230, M2340: 58 dB

- M2211: 64 dB

- M4261: 66 dB

3

Power & Backlight

The power button switches the instrument on. The XL2 is

immediately ready for operation. Holding down the power

button

for one second switches the XL2 off. Additionally,

a brief press of the power button

toggles the backlight

during operation.

4

Limit

• SLMeter: The limit button lights up green, yellow or red

according to the settings in the Limit page. Press the

limit button

to access the Limit page. For more details

visit the chapter Sound Level Meter: Limits.

11

Overview

The Screen Display

The XL2 displays the actual sound levels also in case of no

measurement has been started. Any displayed averaged level

refers to the previous measurement period. The XL2 shows

four lines in case of no previous measurement period is ap-

plicable.

Display Contrast Setting

• Hold down escape

and turn the rotary wheel until the

desired contrast is reached.

Updating of display

• Numeric values

Updated every 500ms independent of the measurement

function. The maximum time span between the end of

the measurement period and the first test result display is

500ms.

• Graphs and spectra

Updated every 50ms

1

2 3 4 75 986

The display is updated continuously during measurement.

12

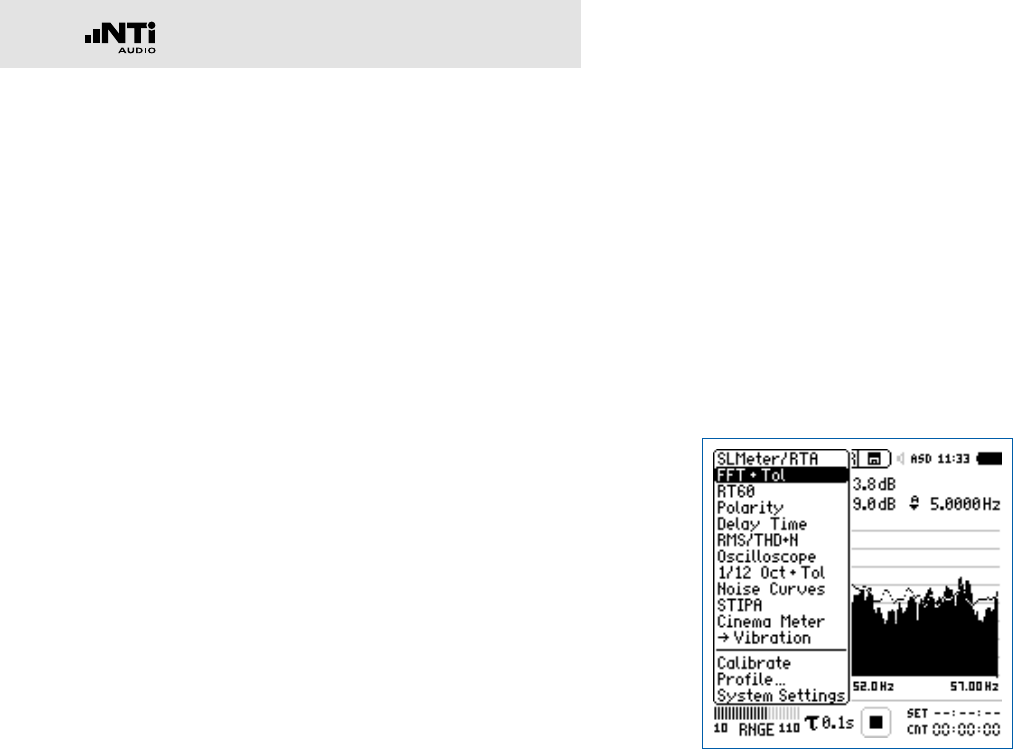

Overview

1

Measurement Results

Individual level measurement results.

2

Main Menu

SLMeter/RTA SPL & RTA Measurement

FFT + Tol FFT Analysis with optional Tolerance

Management

RT60 Reverberation Time

Polarity Polarity

Delay Time Delay Time

RMS/THD+N RMS Level and Distortion

Oscilloscope Scope

1/12 Oct + Tol Spectral Analysis with Tolerance Man-

agement (optional)

Noise Curves Noise Curves

STIPA Speech Intelligibility (optional)

Cinema Meter Calibration and verification of cinema

loudspeaker systems (optional)

Calibrate Calibration Menu for microphone

Profile ... Store and load measurement profiles

System System Settings

3

Page Selector

Toggles between available measurement and result pages

within the same function menu. Alternatively use the page

button

.

4

Input Selector

Select XLR or RCA input connectors as the source.

5

Memory Menu

The memory menu is used for data storage management.

One of the following symbols flashes before or after start-

ing the measurement:

9-8-7 Time in seconds until instrument is settled and

measurement will start.

RUN Indicates the ongoing measurement.

LOG Indicates the ongoing measurement with data

logging.

AUD Indicates the ongoing measurement with data

logging and audio recording.

Evt Indicates an ongoing triggered-event recording.

13

Overview

After a completed measurement, the memory symbol

indicates a non-saved measurement report. Your measure-

ment needs to be stored manually. For more details visit

the chapter Data Management.

6

Speaker/Headphone

Indication of enabled rear speaker or headphone output.

7

Phantom Power Supply

48V The XL2 provides 48 V Phantom power supply

to the connection microphone or sensor.

ASD An NTi Audio measurement microphone with

automated sensor detection ASD is connect-

ed. The XL2 reads the electronic data sheet of

the microphone and switches the 48 V Phan-

tom power automatically on

48V Phantom power is switched off.

8

Real-Time Clock

The real-time clock is set in the System menu.

9

Battery Symbol

The battery symbol indicates the battery status as follows:

Using rechargeable Li-Po battery:

Level indication 100% (U > 4.0 Volt).

(Battery charges when mains adaptor connected)

Level indication:

75%: U = 3.9 - 4.0 Volt

50%: U = 3.8 - 3.9 Volt

25%: U = 3.7 - 3.8 Volt

Level indication 0% (U < 3.7 Volt). The battery is

almost empty and must be recharged.

The battery is being recharged by the mains

power adapter.

The XL2 is connected via USB to a computer.

The battery charge level decreases slowly dur-

ing XL2 usage.

Using standard AA batteries:

No level indication as long as U > 4.5 Volt.

Level indication 0% (U < 4.5 Volt). The batteries

are almost empty and should be replaced.

Using mains or supply:

No indication of battery status.

14

Getting Started

3. Getting Started

Power Supply

The XL2 offers flexible power management options and can be

operated either by

• Replaceable, rechargeable lithium-polymer (Li-Po) battery

(included with the XL2 Analyzer)

• 4x AA-batteries

• Mains Power Adapter

The new battery is charged to approximately 50% and should

be fully charged before use with:

Battery Charger

(optional)

Charging Time: approx. 3 hours

NTi Audio #: 600 000 332

Mains Power

Adapter

(optional)

Charging Time: approx. 6 hours

Leave the battery inside and switch off

the XL2

. Running the XL2 during

charging prolongs the charging time.

NTi Audio #: 600 000 333

USB Power

from PC

Charging Time: approx. 6 hours

Switch off the XL2

for charging. The

charging power is equal or less than the

power consumption.

Operation using Mains Power Supply

You can also operate the XL2 with the optional NTi Audio Mains

Power Adapter. During such operation it is recommended to

leave the batteries inside the instrument.

Mains Power Adapter

• Electrically-isolated, linear DC power supply

• A decreased THD+N performance will oc-

cur with unbalanced input signals when us-

ing switching-type power supplies (approx.

3 dB).

• Non-NTi Audio power supplies may have fur-

ther negative effects on measurements.

• Damage caused by using an inappropriate ex-

ternal DC supply is not covered by warranty.

DC Power supply specifications

• Voltage: 7.5 - 20.0 Volt

• Power: minimum 6 Watt

• Connector type: 2.1 x 5.5 x 9.5 mm

• Polarity:

.

15

Getting Started

Rechargeable Li-Po Battery

• Open the battery cover at the rear of the instrument.

• Insert the rechargeable battery with the contacts edge first.

• Close the battery cover.

Switch off the XL2 for faster recharging by

mains power adapter or USB connection.

Caution

• Switch the XL2 off prior opening the battery

cover in order to prevent any electronic dis-

charges.

• Avoid short-circuits.

• Operate and charge the battery between 0°C

and 45°C (32°F - 113°F).

• Do not heat the battery above 60°C.

• Do not place the battery in or near fire.

• Do not solder directly on to the battery.

• Do not disassemble the battery.

• Do not insert the battery in reverse polarity.

• Remove the battery for applications with a

connected mains power adapter over mul-

tiple weeks.

1.

3.

2.

16

Getting Started

AA-Batteries

Alternatively, the XL2 can be powered by AA type batteries

• Open the battery cover.

• Insert 4 fully-charged AA batteries, observing correct polarity

of the +/- indications in the battery compartment.

The polarity alternates with successive batteries.

• Close the battery cover.

• Switch the XL2 off prior opening the battery

cover in order to prevent any electronic dis-

charges.

• Use only similar batteries from the same

manufacturer.

• Replace discharged batteries with new ones.

• Do not mix used and new batteries.

• During operation, the battery temperature

may increase noticeably. This is not a defect.

• Remove all batteries if the XL2 is not to be

used over a long period of time.

1.

2.

17

Getting Started

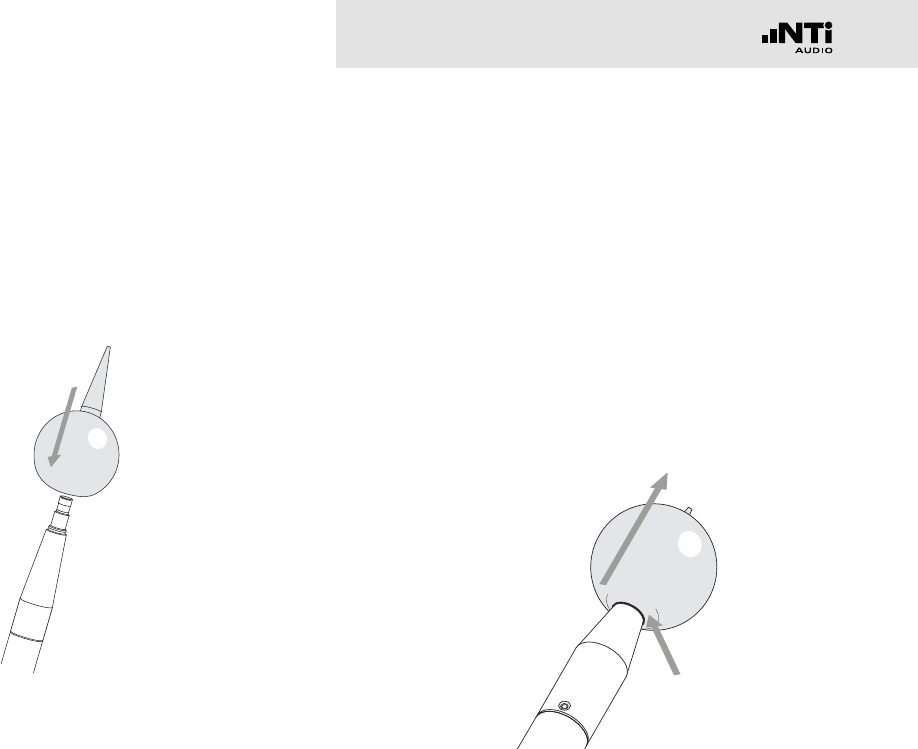

Attaching the Hand Strap

To avoid accidentally dropping the XL2, a hand strap is supplied

with the instrument.

• Pull the loop of the hand strap through the opening.

• Pull the other end of the hand strap through the loop.

• Pull the hand strap tight.

2.1. 3.

18

Getting Started

Unfolding the Stand

A convenient table stand is attached to the rear of the instru-

ment.

• Unfold the stand and rest the XL2 on a flat surface.

Connecting the XL2

Acoustic Measurements

Connect an NTi Audio measurement microphone to the XLR

input connector of the XL2.

19

Getting Started

Audio Measurements: XLR Connection

• Connect the source to the XL2 with an XLR cable.

• Select the XLR input in the menu.

Audio Measurements: RCA Connection

• Connect the source to the XL2 with an RCA (cinch) cable.

• Select the RCA input in the menu.

20

Getting Started

Switching the XL2 On and Off

Switching On the XL2

Press power

to switch on the XL2.

There is a brief sound of relays and the display illuminates.

Switching Off the XL2

Press power

and hold it down for one second to switch off

the XL2.

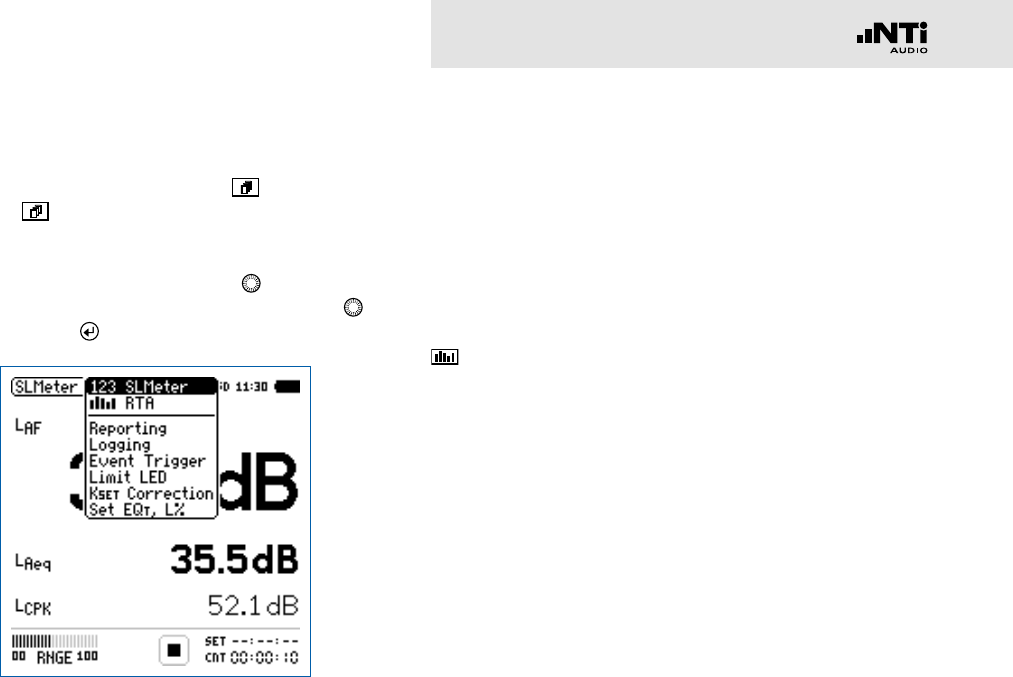

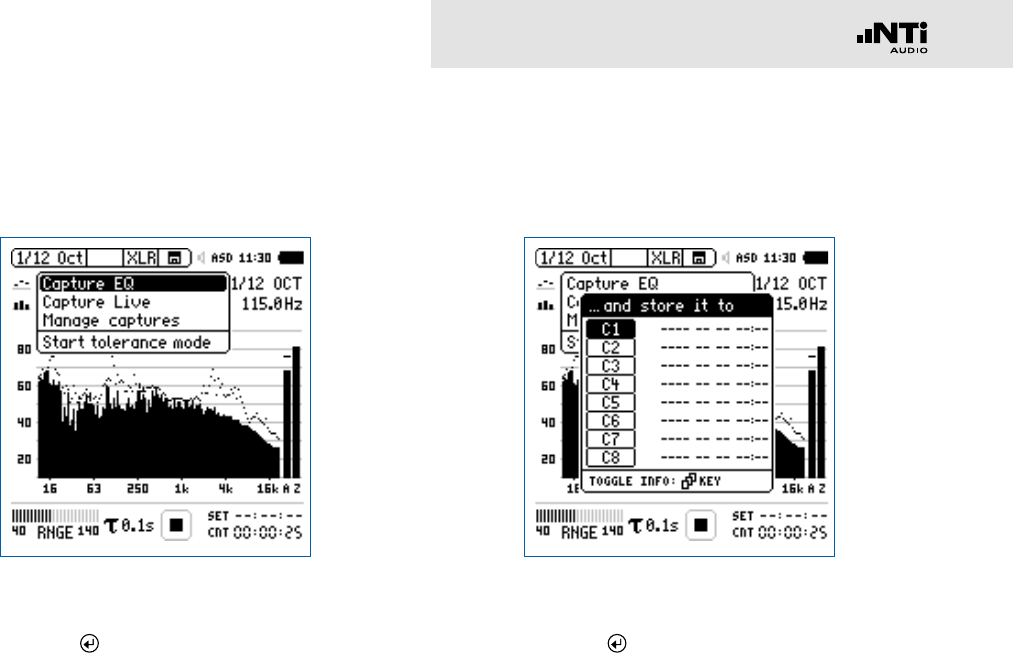

Select Measurement Function

• Navigate with the rotary wheel to the main menu bar.

• Confirm with enter

to select the measurement function.

The main menu window opens

Main menu with enabled options

• Scroll up/down with the rotary wheel to select the re-

quired function and confirm with enter

.

The measurement function is selected.

21

Getting Started

Setting the Parameters with the Rotary Wheel

• Turn the rotary wheel

to navigate within the display

screen.

The selected parameter is highlighted with a black back-

ground.

• Confirm with enter .

The parameter display flashes and/or available parameters

or settings are shown.

• Turn the rotary wheel to set the parameter or toggle with

enter

through the settings.

• Confirm with enter

.

Now the parameter is set.

Calibration prior Measurement

We recommend the daily calibration of the XL2 Analyzer with

the Sound Calibrator. This ensures accurate measurement re-

sults.

For more details see chapter Calibration.

22

Sound Level Meter

4. Sound Level Meter

The XL2 provides, together with the measurement micro-

phone, a precise sound level meter for monitoring live sound

events and/or environmental noise.

The Type Approval Option upgrades the instrument to the

XL2-TA, the sound level meter dedicated to certified measure-

ments. The XL2 with the M2230 microphone forms a type ap-

proved sound level meter offering class 1 performance accord-

ing IEC61672 (see chapter Options and Accessories)

For example, Actual, Lmin, Lmax, Leq with frequency weight-

ing A, C and Z and time weighting F and S can be measured

at the same time. All measurement results are simultaneously

available. You may log all acquired level information, including

real-time information, onto the removable SD Card. To com-

plete the documentation of the measured sound pressure lev-

els, the XL2 offers wav-file recording, as well as the facility

to add voice notes for each measurement. The XL2 measures

correction values between the loudest point of the live event

and the actual measurement positions in accordance with DIN

15905-5 and V-NISSG. In parallel with the wide band param-

eters, the XL2 measures the real-time spectrum either in 1/1 or

1/3 octave-band resolution. The RTA perfectly suits tasks such

as optimization of sound systems

Extended Acoustic Pack (optional)

The Extended Acoustic Pack offers the following additional fea-

tures for sound-level and acoustic measurements:

• SLMeter/RTA function

- Recording of linear wav-files (24 bit, 48 kHz)

- Percentiles for wide band and spectrum with flexible set-

ting from 0.1% to 99.9%

- Sound Exposure Level L

AE

- 100 ms logging

- RTA logging of Lmin and Lmax

- Event-triggered audio and data recording

- Time weighting: Impulse (LxI, LxIeq with x= A, C, Z)

- True peak level in 1/1 and 1/3 octave resolution

- Clock-impulse maximum level (TaktMax) in accordance

with DIN 45645-1 and DIN 45657

- Impulsiveness detection in accordance with BS4142:2014

and NordTest ACOU 112

• FFT function

- High-resolution Zoom-FFT with selectable frequency

ranges and resolution up to 0.4 Hz in the range of 5 Hz to

20 kHz

• RT60 function

- Reverberation time in 1/3 octave resolution

• 1/12 octave Spectral Analyzer

(requires Spectral Limits Option)

- Recording of linear wav-files (24 bit, 48 kHz)

23

Sound Level Meter

The sound level meter offers different pages:

Page Selection using the Page Button

• Press page to toggle between the 123 SLMeter page

and the RTA page.

Page Selection using the Rotary Wheel

• Select the page 123 SLMeter with the rotary wheel .

• Confirm with enter

.

Menu with enabled options

You have selected the individual sound level meter page.

123 SLMeter: Sound Level Meter

Displays the selected broadband sound level results. You can

change the font size of the result. Depending on the font size

chosen, the XL2 shows 3 or 5 results simultaneously. Individual

frequency weighting, time weighting, actual, minimum, maxi-

mum and correction values can be chosen for each displayed

result.

RTA: Real-Time Spectrum

Displays the 1/3 or 1/1 octave spectrum of the selected sound

level within the audio band. Additionally the wide band result is

shown graphically by a bar.

Reporting: Report Setting

Here you set which sound pressure levels shall be stored in a

.txt file after the completed measurement. Choose between:

ALL Stores all sound pressure levels.

Selected Stores up to 10 different individually-defined

sound pressure levels.

For details refer to the chapter Reporting.

24

Sound Level Meter

Logging: Setup of Data Logging

The XL2 features a powerful sound level meter data logger,

which allows you to record all required sound level values dur-

ing the measurement. In the logging page you set which sound

pressure levels shall be logged over time. For details refer to

the chapter Logging. Choose between:

ALL Logs all sound pressure levels.

Selected Logs up to 10 different individually-defined sound

pressure levels.

Event Trigger: Event Setting (optional)

The event function is available with the optional Extended

Acoustic Pack. The XL2 event feature offers the following func-

tionalities:

• Automated event triggered at noise levels above/below a

preset value including setting markers for specific noise cat-

egories. Application example: Recording the noise level for

L

AF

> 80 dB.

• Event triggered by external key press of the XL2 Input Key-

pad. You can utilize four keys (1-4) to categorize any noise of

interest or noise to be later excluded in the post-processing.

A typical application is categorizing any annoying industrial

noise by persons living in the neighborhood.

Limit LED: Limit Setting

H

ere you set the function

of the limit LED , thereby highlight-

ing any sound level that exceeds the pre-set limits in orange

or red color. Further, external peripherals are controlled by the

optional Serial I/O Interface based on the sound level, such as

displaying sound levels on a large external red-orange-green

lamp. For details refer to the chapter Limits.

K

SET Correction: Setup of Correction Values

This page provides a wizard to measure correction values,

which could be helpful for compliant sound level monitoring

of live events. It measures the correction values between

the actual measurement position and the loudest posi-

tion accessible by the audience. The XL2 displays and logs

the selected sound pressure levels including the correction

values, allowing the sound engineer to monitor the sound

level at the loudest position in the audience. The measure-

ment meets the requirements of the standards DIN15905-5

and V-NISSG. For details refer to chapter Correction Value

K

SET.

25

Sound Level Meter

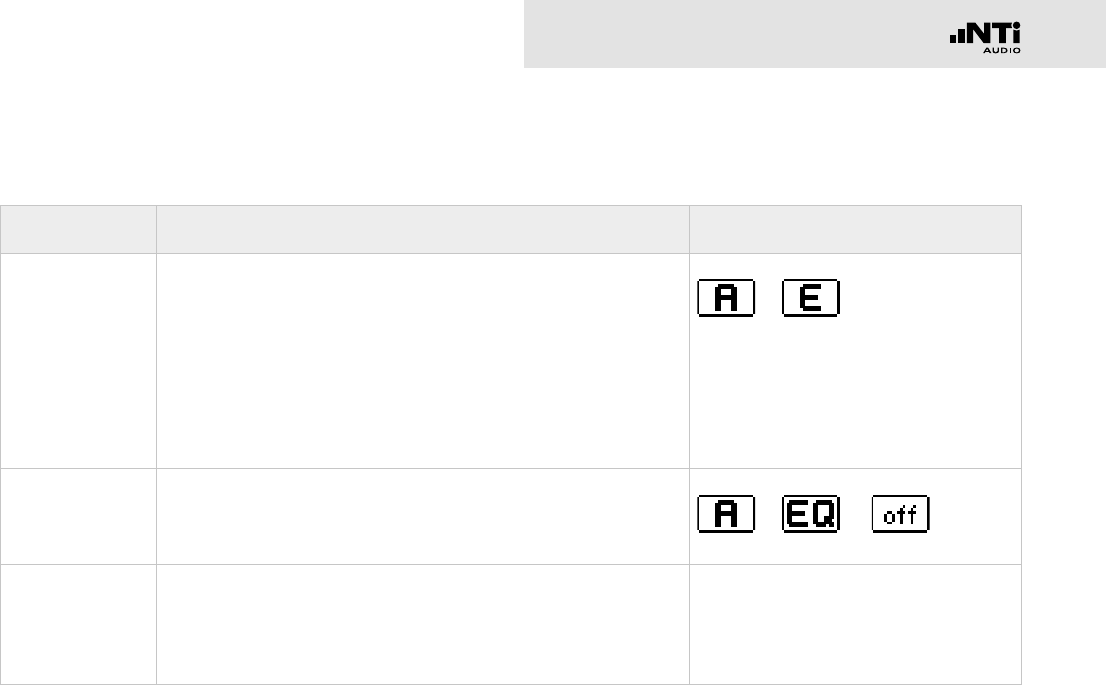

Set EQt, L%: Selection of measured levels

This page allows setting the following levels:

• Moving Time-average Sound Level

Gliding Leq with selectable time window from one second to

one hour. Four individual levels can be configured. This level

is also called “running Leq,T” or “sliding Leq,T”.

• Percentile Sound Level

- Allows the individual configuration of seven statistic lev-

els from 0.1% to 99.9% (optional with Extended Acoustic

Pack).

- The Broadband Source for the calculation of the level sta-

tistics can be chosen from a set of different levels with

either a frequency weighting A, C or Z. The time weight-

ings F, S and the moving time-averaged sound level for one

second are supported.

26

Sound Level Meter

Overview

Numeric Result Page

The numeric result page 123 SLMeter displays the selected

broadband sound level results. You can change the font size of

the result. Depending on the font size chosen, the XL2 shows

three or five results simultaneously. Individual frequency

weighting, time weighting, actual, minimum, maximum and

correction values can be chosen for each displayed result.

8

4 5

6

7

1

2

3

Real-Time Analyzer Page

The real-time analyzer page

RTA measures and displays

the 1/3 or 1/1 octave spectrum from 6.3 Hz to 20 kHz including

wideband results. The real-time spectrum RTA is measured in

parallel with the A and Z-weighted wideband levels.

14

13

11

12

16

9

10

15

17

27

Sound Level Meter

1

Sound Level Result 1

All sound levels are measured and logged simultaneously.

You select which sound levels should be displayed.

Change Parameter

• Turn the rotary wheel

to select the parameter Lxx.

• Press enter

to open the selection menu and choose

the wideband sound pressure level to be displayed.

• Turn the rotary wheel

to select the required test result

parameters and confirm with enter

.

Change Font Size

• Turn the rotary wheel to select the actual test result.

• Press enter

1x, 2x or 3x to set the font size to small,

medium or large.

The XL2 shows 3 sound levels on the display if a large font

is chosen, otherwise it shows 5 sound levels.

2

Sound Level Result 2 & 3

Follow the setting instructions for sound level result 1.

3

Sound Level Result 4 & 5

To display sound level results 4 & 5, choose a smaller font

for all results. Follow the setting instructions for sound level

result 1.

4

Input Range

The XL2 Analyzer provides three input ranges to accom-

modate the wide range of input signals. The individual rang-

es are based on the microphone sensitivity setting in the

calibration menu of the XL2. For example, at a sensitivity

S=20mV/Pa the input ranges are

• Low: 10 - 110 dBSPL

• Mid: 30 - 130 dBSPL

• High: 50 - 150 dBSPL

Select the lowest possible input range according to the

maximum level expected during the measurement; e.g., if

the sound pressure will always be below 110 dBSPL, then

select the lowest input range 10 - 110 dBSPL.

5

Run Indication

The run indication shows the measurement status running,

paused or stopped. Various measurement settings are

locked during ongoing measurements, such as changing

the input ranging or the preset measurement time.

28

Sound Level Meter

6

Actual Measurement Time

Counts actual measurement time in hrs:min:sec. Supports

time modes: continuous, single and (synchronized) repeat.

Timer Mode Continuous

(applicable for standard measurements)

All values are recorded and monitored continu-

ously after starting a measurement with start

.

The actual measurement time is shown.

Timer Mode Single

Automatically stops the measurement after the

pre-set measurement time.

• Set the required measurement time.

• Start the measurement

.

The actual measurement time counts back to zero and

the measurement ends.

• All measurement results may be recalled.

Timer Mode Repeat

Provides automated repeated measurements with

user-defined, preset measurement time cycles.

• Set the required measurement time.

• Press start

.

The actual measurement time counts back to

zero. When the preset measurement time has

elapsed, the measurement time and the mea-

surement results are reset and a new mea-

surement is started. All measurement results

of the previous cycle are reset.

• Press stop

to complete the measurement.

29

Sound Level Meter

8

Phantom Power Supply

48V The XL2 provides 48 V Phantom power supply

to the connection microphone or sensor.

ASD An NTi Audio measurement microphone with

automated sensor detection ASD is connect-

ed. The XL2 reads the electronic data sheet of

the microphone and switches the 48 V Phan-

tom power automatically on

48V Phantom power is switched off.

9

Result Symbols / Capture

This field offers two functions:

• Symbols for measurement results

15

Upper RTA parameter displayed as line.

Lower RTA parameter displayed as bargraph.

Timer Mode Repeat Synchronized

Provides automated repeated measure-

ments synchronized to the XL2 real-time clock.

Press start

to begin the measurement.

In order to align the selected preset measurement

time with the real-time clock, the XL2 shortens

the first cycle to match the real-time clock syn-

chronization. All following measurement cycles

are synchronized to the real-time clock.

For example, the cycle time setting is 30 minutes

and the measurement starts at 7.50 a.m. -> the

first test cycle measures from 7.50 - 8.00 a.m.

Thereafter a new test cycle starts automatically

for 30 minutes. The 30-minute cycles repeat until

the measurement is stopped.

The measurements in the synchronized repeat

timer mode start exactly on the half or full hour in

accordance with DIN 15905.

7

Preset Measurement Time

Adjustment of preset measurement time for single and re-

peat timer setting.

30

Sound Level Meter

11

Y-Scale setting

• Select the Y-Axis with the rotary wheel

and confirm

with enter

.

• Select the zoom factor between 20, 10, 5, 2.5 dB/div

and confirm with enter

.

• Scroll up and down with the rotary wheel

to select the

Y-axis range.

• Confirm with enter

.

12

RTA Measurement Result

Real-time analyzer results in 1/1 octave or 1/3 octave band

resolution. Adjust the resolution at

17

.

13

X-Scale setting

Toggles X-scale range between

20 Hz - 20 kHz RTA levels including wide band results

6.3 Hz - 8 kHz RTA levels including wide band results

6.3 Hz - 20 kHz RTA levels

• Select the X-Axis with the rotary wheel

and confirm

with enter

.

• Toggle with the rotary wheel

between the ranges.

• Confirm with enter

.

• Capture

One of the displayed RTA readings may be captured. Any

measurement data can then be compared with this cap-

tured reference live on the XL2 Analyzer. For example,

compare the RTA spectrum of the left and right speakers.

• Select the parameter to be captured.

• Confirm with enter

, to capture the reading.

• Select the upper RTA parameter

15

and choose

Capt.

• Confirm with enter

.

The lower RTA reading can be compared with the previ-

ously-captured reference data.

10

Measurement Result

Actual level result of the indicated frequency band. The cur-

sor readout displays the center frequency and the level of

the band pointed to by the arrow.

Upper parameter displayed as line.

Lower parameter displayed as bargraph.

31

Sound Level Meter

The cursor readout may be set manually to any

frequency band or wide band level. The readout re-

mains at the selected frequency.

• Select the frequency with the rotary wheel

.

• Press enter

.

• Select the frequency of interest.

• Confirm with enter

.

The cursor readout

11

displays the measure-

ment results of the selected frequency band.

16

Setting of Test Result Resolution

Set the RTA result display to 1/1 octave or 1/3 octave band

resolution as follows:

• Turn the rotary wheel

to select the parameter

17

.

• Press enter

to toggle between 1/1 OCT and 1/3 OCT

and set this parameter.

14

Broadband Results

Actual sound level.

The broadband sound pressure level Leq, Lmin, Lmax and

Live are displayed here. The Live level is displayed with

time weighting Fast.

A A-weighted broadband sound pressure level

Z Broadband sound pressure level without any fre-

quency weighting

15

Readout Frequency

You may select any frequency to read out individual levels.

The selected frequency is indicated by the cursor arrow.

Choose between the following settings:

The cursor follows automatically the highest level,

e.g. tracing feedback frequencies at live sound.

• Select the frequency with the rotary wheel

.

• Press enter

.

• You may readout any individual frequency.

• Return to auto frequency with enter

.

The cursor returns to the frequency with high-

est level bar.

32

Sound Level Meter

17

Measurement Unit

Select the measurement unit as follows:

dB Sound level in dBSPL

This measurement unit is permanently selected

when an NTi Audio measurement microphone

with electronic data sheet is connected.

dBu Input level in dBu

dBV Input level in dBV

V Input level in Volt

LOW - Indication

The low indicator for an individual level “<” is displayed when:

• The measured sound pressure level is below the selected

linear measurement range. In this case the results shown

are most likely higher than the actual sound pressure level ->

choose the next lower measurement range.

• The measured sound pressure level is just above the residual

noise of the connected NTi Audio measurement microphone.

This reduces the measurement accuracy -> choose another

microphone designed for low level measurements.

The low condition is registered in the log and report files in the

column “Low(eq/peak)“ individually for all frequency weight-

ings, the RMS and the peak levels.

33

Sound Level Meter

Overload Indication

In case the measurement result exceeds the preset measure-

ment range, then limit arrows indicate this overload condi-

tion. The arrows

are displayed for as long as the overload

exists, and at least for a minimum of 1 second. Furthermore,

such an overload condition triggers the OVR indication in the

bottom line, which remains displayed for the complete mea-

surement period. These overload indications are reset at the

start of a new measurement. All overload conditions are regis-

tered in the log and report files.

Possible causes for exceeding measurement ranges are

• The measured sound pressure level exceeds the pre-set

measurement range during the measurement period. Once

this happens, the OVR indication remains displayed for the

complete measurement period -> select the next higher

measurement range or reduce the input signal level as ap-

plicable.

• The input level is near the maximum level of the connected

NTi Audio measurement microphone.

34

Sound Level Meter

Sound Level Meter - Getting Started

Test Preparations

• Connect the measurement microphone to the XL2.

• Switch on the XL2

.

The XL2 reads the electronic data sheet of any connected NTi

Audio ASD microphone and switches the 48 V phantom power

automatically.

The 48 V phantom power indication in the upper menu bar

changes to ASD. The XL2 is ready for acoustic measure-

ments.

• Position the XL2 at the measurement location using a micro-

phone stand or a tripod.

• Select the SLMeter function in the measurement menu and

toggle with page

to the numeric result page .

All wideband and RTA levels are measured and

logged simultaneously. You select which sound

levels should be displayed.

Select Displayed Test Result

This example describes the setting of the commonly-used ac-

tual sound pressure level L

AF

(level L, frequency weighting A,

time weighting F).

• Select the first parameter setting with the rotary wheel

.

• Confirm with enter

.

Press start to measure and display the

sound levels results indicated with ----.

35

Sound Level Meter

Select Frequency Weighting

The pop-up window FREQ WEIGHTING appears.

• Select the frequency weighting A.

Installation of the Extended Acoustic Option

adds more items to the pop-up window

• Confirm with enter .

Select Time Weighting

The pop-up window extends with TIME WEIGHTING.

• Select the required time weighting; e.g.

(=Fast).

• Confirm with enter .

36

Sound Level Meter

Select Parameter

The pop-up window extends with PARAMETER settings.

• Select the parameter live.

• Confirm with enter .

Select Correction Value

The pop-up window extends with CORRECTION settings.

• Select the parameter off.

• Confirm with enter .

The pop-up window closes and the measured sound pres-

sure level L

AF

is displayed.

37

Sound Level Meter

Select further Sound Levels

• Select further sound pressure levels as described above;

e.g., L

Aeq

and L

AFmax

Select Input Range

• Select the lowest possible input range based on the maxi-

mum level expected during the measurement. Wrong input

ranges are indicated by a “<” in front of the measurement

value or a flashing OVR message in the lower menu bar.

• Select the input range RNGE and press enter

.

• Turn the rotary wheel

to set the applicable input range and

confirm with enter

.

The numeric result page and the real-time ana-

lyzer page use the same input range.

38

Sound Level Meter

Start Measurement

• The XL2 is ready to measure the sound levels L

AF

, L

Aeq

and

L

AFmax

.

• Press start

.

The run indication switches to running . The integrated

sound pressure level over time L

Aeq

and the maximum lev-

el in the measurement period L

AFmax

are displayed. The

parameter RUN, LOG (logging is enabled) or AUD (audio

recording is configured) flashes in the memory menu.

Stop Measurement and Data Saving

• Press stop

.

The XL2 stores the broadband sound pressure levels and

the real-time analyzer results simultaneously.

• Press enter to confirm. The measurement data is stored

on the SD Card in ASCII format.

The sound pressure level measurement is completed.

39

Sound Level Meter

Data Post-Processing

The XL2 stores all data and audio onto the SD card for direct

transfer to a computer. Audio data is stored as .wav files. Data

reports and log files are stored in plain text format, which can

be opened with any text editor (Notepad, Wordpad, etc.). The

data is tab-delimited, so dropping the .txt file into a spreadsheet

application will conveniently show the results in columns.

Furthermore, a series of free MS Excel application templates pro-

vide a convenient way to view the measurement results of specific

tasks and create simple reports. They are available as free down-

load for all registered XL2 customers on the support website at

https://my.nti-audio.com. (Enable all macros when opening the

document.)

For the most comprehensive analysis of logged noise monitor-

ing data, use the XL2 Data Explorer software. The data import

into the software is enabled by the Data Explorer Option, which

needs to be installed in the XL2 Sound Level Meter. More de-

tails in chapter XL2 Data Explorer.

RTA Measurement - Getting Started

Test Preparations

The XL2 reads the electronic data sheet of any connected ASD

microphones provided by NTi Audio and switches the 48 V

phantom power automatically on as follows:

• Connect the measurement microphone to the XL2.

• Switch on the XL2

.

The 48 V phantom power indication in the upper menu bar

changes to ASD. The XL2 is ready for acoustic measure-

ments.

• Position the XL2 at the measurement location using a micro-

phone stand or tripod.

• Select the SLMeter function in the measurement menu and

toggle with page

to the real-time analyzer (RTA) page

.

All wideband and RTA levels are measured and

logged simultaneously. You select the sound

levels to be displayed.

40

Sound Level Meter

RTA Configuration

The XL2 displays two different sound pressure levels at the

same time. You configure which test results to display; e.g.,

L

ZFmax

and L

ZF

live

.

• Ensure no other measurement is going on. The run indication

should display the stop symbol

.

• Select the LZF value with the rotary wheel

.

• Confirm with enter .

Select RTA Frequency Weighting

The pop-up window FREQ WEIGHTING appears.

• Select the frequency weighting Z.

• Confirm with enter .

Press start to measure and display the

sound levels results indicated with ----.

41

Sound Level Meter

Select Upper/Lower RTA Parameter

• Select the parameter shown to the right of the upper LZF

value with the rotary wheel

; e.g. max.

• Press enter

.

The pop-up window PARAMETER appears.

• Select the parameter max.

• Confirm with enter .

• Follow the same instruction and select the lower RTA pa-

rameter live.

Select RTA Time Weighting

The pop-up window extends with TIME WEIGHTING.

• Select the required time weighting; e.g.,

(=Fast).

• Confirm with enter .

42

Sound Level Meter

Select Input Range

• Select the lowest possible input range according to the maxi-

mum level expected during the measurement. Wrong input

ranges are indicated by a < in front of the measurement val-

ue or a flashing OVR message in the lower menu bar.

• Select the input range RNGE and press enter

.

• Turn the rotary wheel

to set the applicable input range and

confirm with enter

.

The numeric result page and the real-time ana-

lyzer page use the same input range.

Start RTA Measurement

• The XL2 is ready to display the measured sound pressure

levels L

ZFmax

and L

ZF

live

.

• Press start

.

The run indication switches to running . The actual sound

level L

ZFlive

and the maximum level L

AFmax

are displayed.

The parameter RUN , LOG (logging is enabled) or AUD (au-

dio recording is configured) flashes in the memory menu.

43

Sound Level Meter

Stop the Measurement and Data Saving

• Press stop

.

The XL2 stores the broadband sound pressure levels and

the real-time analyzer results simultaneously.

• Press enter to confirm. The measurement data is stored

on the SD Card in ASCII format.

The RTA measurement is completed.

Reporting

A report saves the conducted measurements onto the installed

SD Card. The XL2 Supports setting the individual levels to be

stored in the report after the measurement is completed.

1

2

3

1

Add Spectra

No No RTA measurement reporting.

Leq The RTA Leq level is stored in the report.

44

Sound Level Meter

Leq, Lmax,

Lmin

The RTA Leq, Lmin, Lmax levels are stored

in the report.

All All RTA levels are stored in the report.

2

Report Values

Choose between the following result reporting:

ALL Records all available sound pressure levels

without correction values.

Selected Records a subset of up to 10 different levels,

including correction values if you require.

• Select Report Values with the rotary wheel

.

• Press enter

to toggle between All or Selected.

3

Selected Report Values

• By setting Selected at

2

up to 10 individual report val-

ues can be chosen. Select the first value Lxx with the

rotary wheel

and press enter .

The pop-up window for level selection appears.

• Select the reporting level with the rotary wheel

and

confirm with enter

.

Logging

The XL2 features a powerful sound level meter data logger,

which allows you to record all required sound level values dur-

ing the selected period of time. All results are logged onto the

SD Card. The measurement results can be loaded to a PC for

documentation and visualization. The LOG menu offers the de-

tailed setup of the log report.

1

2

3

4

5

6

7

45

Sound Level Meter

1

Logging

Select Logging with the rotary wheel

and press enter

to enable the automated logging of test results.

On The XL2 logs measurement data every interval

dt

2

.

Off No Logging

2

Interval Dt

Adjust the logging interval. The optional Extended Acoustic

Pack offers the additional 100 ms logging.

3

Add Spectra

Set the RTA logging for each logging interval here.

No No RTA spectrum is logged.

Leq The Leq spectrum is logged.

Leq, Lmax,

Lmin

The Leq, Lmax and Lmin spectrum is

logged simulatenuously (requires optional

Extended Acoustic Pack).

4

Log Audio

The XL2 logs audio data as a wav-file. Choose among the

following settings:

Off Audio logging is off

On Audio logging is activate from mea-

surement start to stop.

Events Only Audio logging of triggered events

only.

For more details read the chapters Wav-File Recording and

Events.

5

Format

Choose among the following audio recording settings:

Compressed Compressed audio logging

Compressed+AGC Compressed audio logging with

automated gain control

24Bit_48kHz Linear audio logging in 24 bit,

48 kHz resolution (optional with

Extended Acoustic Pack)

46

Sound Level Meter

6

Log Value Setting

Choose between the following settings:

ALL Logs all available sound pressure levels with-

out correction values.

Selected Logs a subset of up to 10 different sound

pressure levels, including correction values if

you require.

• Select Log Values with the rotary wheel

.

• Press enter

to toggle between All and Selected.

7

Selected Log Values

By setting Selected at

5

up to 10 individual log values can

be chosen.

• Select the first value Lxx with the rotary wheel

and

press enter

.

The pop-up window for level selection appears.

• Select the logging level with the rotary wheel

and con-

firm with enter

.

At 100ms Logging is the log value selection limited to five

different parameters.

Wav-File Recording

The XL2 records a wav-file of the measured input signal and

stores it on the SD Card. The available formats are:

• Compressed (default, using ADPCM compression). A new

wav-file is started automatically after 12 hours of recording

(typical maximum wav-file size = 512 MByte)

• Compressed+AGC, compressed with automated gain con-

trol. The gain control increases the level of low-level signals,

so that the wav-file is well-leveled during playback on the

PC.

• 24Bit_48kHz, linear wav-file logging in 24 bit, 48kHz resolu-

tion with the optional Extended Acoustic Pack. A new wav-

file is started automatically after 1 hour of recording (typical

maximum wav-file size = 512 MByte)

Broadcast Wave Format BWF

The XL2 stores scaling factor, serial number,

date, time and time zone within the wav-file (ac-

cording to EBU TECH 3285). This information is

available through professional audio/video tools

typically used in broadcast.

47

Sound Level Meter

Sample name of wav-file:

1

MyTest_SLM_000_Audio_FS133.0dB(PK)_00.wav

2 3 4

5

1

MyTest

File name defined by user.

2

SLM

Measurement function.

3

000

Automatically incrementing file number.

4

Audio_FS133.0dB(PK)

Audio file with full scale peak level. In case of a Com-

pressed + AGC recording, the file name reads “AGC”; this

file contains corrected level information only.

5

00

For wav-file recording over longer periods, the XL2 splits

the audio data into individual wav-files with about 500 MB

(compressed audio: 12 hours; linear: 1 hour), keeping the

file size small for easier handling on the PC. The number

5

increments for each successive wav-file.

The advantage of wav-file recordings is to identify and docu-

ment sound sources after the measurement. For example, at

a live event an excessive peak level may have been measured

and logged. Actually, this peak level was caused by people

shouting nearby the measurement microphone, and not by the

audio system being monitored. The recorded wav-file assists in

verifying this and the test results can then be post-processed.

Pausing Measurement

If any ongoing measurement is paused

, the

XL2 continues the recording of wav-files during

the paused period. The logged data and audio

data can be synchronized using the stored real-

time information.

Events

The wav-files are stored in a folder, named, for

example,

2011-11-30_SLM_000_AudioEvent_0001-0200.

The actual wav-files are named for example, as

xxxx_FS133.0dB(PK).wav (xxxx = incrementing

number)

48

Sound Level Meter

Another example is environmental noise monitoring: Listening

to the recorded wav-file after the measurement may help to

determine the predominant sound source. The XL2 Analyzer

preserves the original absolute test signal level in the recorded

wav-file.

The XL2 Analyzer provides three input ranges to accom-

modate the wide range of input signals. The dynamic range

of the recorded wav-file is set according to the selected in-

put range. For example, at a microphone sensitivity of

S= 20 mV/Pa, the full-scale peak level is:

Range Name Range Level Full-scale peak level

Low 10 - 110 dBSPL 117.8 dBSPL

Mid 30 - 130 dBSPL 135.9 dBSPL

High 50 - 150 dBSPL 159.9 dBSPL

Select the lowest possible input range accord-

ing to the maximum level expected during the

measurement; e.g., If the sound pressure will

always be below 110 dBSPL, select the lowest

input range 10 - 110 dBSPL.

49

Sound Level Meter

Events (optional)

The event function is available with the XL2 Extended Acoustic

Pack Option. The XL2 Analyzer may be configured to record

wav-files and additional noise levels only when triggered, in-

stead of the complete measurement duration.

Advantages

Reduces the data volume acquired, thereby

• Simplifying data post-processing

• Saving memory for long-term measurement applications.

Events

Events are triggered either automatically by sound levels above/

below a preset value or manually by external key press using

the XL2 Input Keypad.

Data Logging

The XL2 Analyzer logs the data specified in the

LOG setting for the complete measurement du-

ration into a log file. The markers and triggered

events results are added to the same log file.

The XL2 Input Keypad is available as an acces-

sory. Please see chapter Options and Accesso-

ries for details.

Recommendation

With the large storage capacity of the XL2, NTi Audio recom-

mends logging at a 1 second or faster interval. This allows the

accurate collection of event data; one event will be stored with-

in a logged interval. If results for reporting are required at lon-

ger intervals, e.g. one hour, the XL2 Data Explorer software is

recommended. It easily combines logged data into longer audit

intervals. An additional advantage of a faster logging interval is

that only an entire logged interval can be excluded from the

average. This is useful when a qualified noise consultant judges

that a sound is not caused by the object under test or is not a

normal sound for a measurement location.

Functions

The XL2 event feature offers the following functionalities:

• Automated event triggered at noise levels above/below a

preset value including setting markers for specific noise cat-

egories. Application example: Recording the noise level for

L

AF

> 80 dB.

• Event triggered by external key press of the XL2 Input Key-

pad. You can utilize four keys (1-4) to categorize any noise of

interest or noise to be later excluded in the post-processing.

A typical application is categorizing any annoying industrial

noise by persons living in the neighborhood.

50

Sound Level Meter

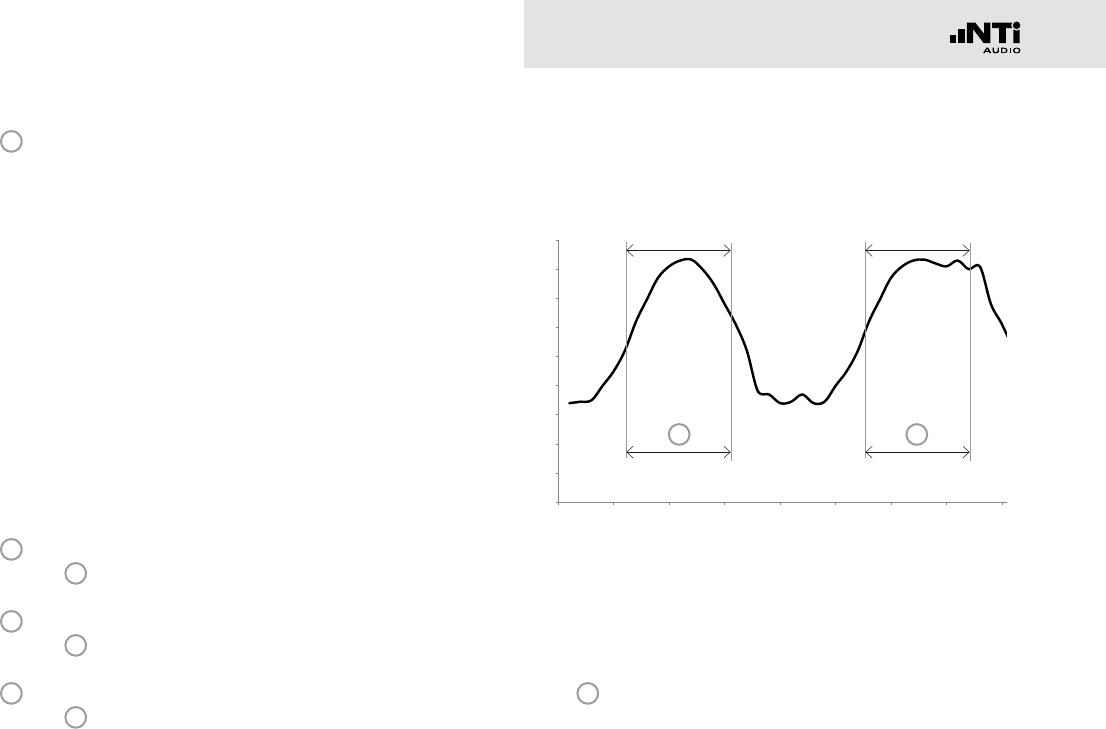

Trigger Events: on level above/below

100

90

80

70

60

Time [seconds]

3

Event Duration

2

14

13 12

Level [dB]

Features:

• The levels L

Aeq

, L

Zeq

and L

CPeak

are recorded for the event

duration.

• Audio data is recorded for the triggered event duration only,

thus simplifying data post-processing and saving memory

space for long-term measurements.

• Setting markers by external key press of the XL2 Input Key-

pad.

14

1

2

3

5

6

7

11

4

8

9

10

13

12

51

Sound Level Meter

1

Trigger Events

Choose from the following settings:

Off No event triggering

on level

above

Events are triggered at noise levels above the

preset value

2

for the start duration

13

.

on level

below

Events are triggered at noise levels below the

preset value

2

for the start duration

13

.

on ext.

key

press

Events are triggered by external key press.

2

Start [dB]

Set the level at which the triggered event is started.

Start Duration

13

The event start is triggered when the noise level is higher

(or lower) than the preset value and continues for the pre-

set duration.

3

Stop [dB]

Set the level at which the triggered event is stopped.

on level

above

Stop level = Start level

2

- Hysteresis

14

on level

below

Stop level = Start level

2

+ Hysteresis

14

Stop Duration

12

The event stop is triggered when the noise level is lower (or

higher) than the preset value and continues for the preset

duration.

Hysteresis

14

Set the hysteresis to an appropriate value to prevent rapid

switching on and off as the level drifts around the Start

level.

4

Level Selection

Define the level type to be monitored.

52

Sound Level Meter

5

Log Audio

The XL2 logs audio data as a wav-file. Choose from the fol-

lowing settings:

Off Audio logging is off

On Audio logging is activated from

measurement start to stop.

Events Only Audio logging of triggered events

only.

For more details read the chapter Wav-File Recording.

6

Format

Choose from the following audio recording formats:

Compressed Compressed audio logging

Compressed+AGC Compressed audio logging with

Automated Gain Control (AGC)

24Bit_48kHz Linear audio logging in 24 bit,

48 kHz resolution. (Required for

post-processing on the PC with

Extended Acoustic Pack)

7

Audio Logging Period

If Log Audio

5

is set to Events Only, then the duration

for the audio recording may be further specified:

Recording

whole event

Records a wav-file for the whole trig-

gered event duration.

Stop recording

after

Records a wav-file for the specified

period after the event start is trig-

gered.

8

Status Information

Displays current trigger status:

• Waiting for trigger

• Armed (during start duration

13

)

• Audio + data recording

• Completing log cycle

9

Actual Level

Measurement result of the defined level

4

.

10

Event Counter

Counts the number of triggered events that have occurred

during the ongoing measurement.

53

Sound Level Meter

11

Trigger and Marker Monitor

Answers the question: What caused the triggered event?

Lvl Event automatically triggered by level.

1 Event triggered or marker added by pressing key 1

of the XL2 Input Keypad.

2 Event triggered or marker added by pressing key 2

of the XL2 Input Keypad.

3 Event triggered or marker added by pressing key 3

of the XL2 Input Keypad.

4 Event triggered or marker added by pressing key 4

of the XL2 Input Keypad.

12

Stop Duration

See

3

.

13

Start Duration

See

2

.

14

Hysteresis

See

3

.

Trigger Events: on external key press

Trigger Events by pressing a button on the external input key-

pad with automated or manual stop of the event.

100

90

80

70

60

Time [seconds]

Event Duration

15

Event Duration

15

key press

Level [dB]

key press

Features:

• The levels L

Aeq

, L

Zeq

and L

CPeak

are recorded for the event

duration.

• Audio data may be recorded for the user-defined event dura-

tion

15

after the key press.

• Retrigger with every repeated key press within the event

duration.

54

Sound Level Meter

15

16

15

Event Stop Mode and Event Duration

on key release The event is recorded as long as the

button of the input keypad is kept

pressed; the Event period is at least

Min. Event Duration long.

on ext. key-

press

The event is stopped by pressing a but-

ton on the external input keypad; the

Event period is at most Max. Event

Duration long.

16

Button Functionality of Input Keypad

treat each key

separately

All four buttons operate individually.

For example pressing the button 2

will be recorded as button 2 in the

measurement report. This allows you

to distinguish different acoustic noise

sources.

treat all keys as

Key 1

All four buttons operate in parallel and

any button press will be recorded as

button 1 in the measurement report.

55

Sound Level Meter

How to Setup the XL2 for Triggered Event Measurements

• Select the logging page, set Logging On, Interval dt:

00:00:01 and choose the required log values.

• Setup the event page. For example, the screenshot below

starts the event recording after L

AF

exceeds 80 dB for 2 sec-

onds and stops after L

AF

is lower than 70 dB for 3 seconds.

• Select the memory menu and create a new folder. This folder

will then be displayed in the memory menu. All log data and

event wav-files are stored in this folder.

The XL2 is ready for the triggered event measurement.

Logging Enabled

Triggered-event recording requires the activa-

tion of sound level logging. Using the default

Interval dt: 1 second is recommended.

Auto Save

If Log Audio

5

is set to Events Only, then

the XL2 sets per default Naming+Saving: auto

in the memory menu. This ensures that the re-

corded triggered event data is stored on the SD

Card.

For convenience, in case more than 20 triggered

events have been recorded, the Autosave ->

Delete function is disabled, as deleting such

multiple wav-files on the XL2 is time-consum-

ing.

Wav-files

All triggered-event wav-files are stored in an in-

dividual folder. For details see chapter Logging.

56

Sound Level Meter

Limits

The limit page offers two functions:

• Setup of limit LED

function; enabling the XL2 to highlight

any sound levels that exceed the pre-set limit in orange or

red color. The default color is green.

• Limit parameter setup for external connected accessories,

such as the Digital I/O Adapter PCB, the Limit Light or the

Stack Light. These accessories connect to the digital I/O in-

terface of the XL2.

1

2

3

8

4

5

6

7

1

Limit LED On/Off

Select Limit LED with the rotary wheel

and press enter

to enable/disable the limit function.

2

LED - Level 1

Select one sound level for the limit LED indication

.

• Select the soun

d level field with the rotary wheel .

• Press enter

and select the sound level for the limit

LED indication.

3

Selected Level Values

To set the level values for the limit LED

,

• Select the Red or Orange soun

d level with the rotary

wheel

and press enter .

• Set the level value with the rotary wheel

and confirm

with enter

.

4

Digital I/O On/Off

Select Digital I/O with the rotary wheel

and press enter

to enable/disable the operation of externally connected

accessories.

57

Sound Level Meter

5

I/O - Level 1

Setup of the level type 1, which is used to trigger externally

connected accessories.

• Select the

level field with the rotary wheel .

• Press enter

and select the level for the control of the

external accessory.

6

Selected Sound Level Values

To set the level values for the control of the externally con-

nected accessory.

• Select the Out 1, Out 2, Out 3 or Out 4

level with the ro-

tary wheel

and press enter . The Limit Light and the

Stack Light use Out 1 for red, Out 2 for yellow and Out

3 for green light.

• Set the level value with the rotary wheel

and confirm

with enter

.

7

I/O - Level 2

Follow the setting for I/O - Level 1. The I/O level 1 may be

combined with I/O level 2 using and/or combinations, pro-

viding indications in level ranges. Alternatively, other levels

can be selected for the control of the externally connected

accessories.

8

LED - Level 2

Follow the setting for LED - Level 1.

I/O Limits with Triggered Events

If event recording is enabled, the digital output

4 (Out 4) is utilized, e.g. as confirmation feed-

back to the XL2 Input Keypad. Therefore the

limit setting of Out 4 is disabled.

58

Sound Level Meter

Correction Value KSET

The correction value page offers a measurement wizard for live

event monitoring, applicable in case the measurement location

differs from the loudest position in the live event area.

Measurement Position

The goal at live event monitoring is to measure the sound level

at the loudest position accessible by the audience. Setting up

any sound level measurement at this loudest location is typi-

cally not practical, thus an alternative measurement position is

chosen. The recommended measurement position in order to

minimize the influence that audience noise has on the mea-

surement:

• Mount the measurement microphone in front of the main

speakers

• Position the XL2 Analyzer at front of house (FOH)

• Connect the XL2 Analyzer and measurement microphone

using a professional audio cable

Positioning the measurement microphone at

front of house (FOH) may result in audience

noise interfering with the measurement results.

The audience noise will be further amplified by

the measured k-values.

2

1

1

Correction k1

The correction k1 is based on the LAeq.

2

Correction k2

Select the level type for correction k2.

LCpeak

for Germany DIN15905-5;

correction is based on LCpeak measurement

LCeq correction is based on LCeq measurement

59

Sound Level Meter

Level Difference

Prior to the start of the live event, the level difference between

the loudest and the measurement position is measured. The

XL2 Analyzer calculates the level difference automatically based

on the individual sound level measurements at both locations.

This level difference is included in the sound level reading dur-

ing the live event, and the XL2 thereby displays and records the

sound pressure level of the loudest point.

XL2 positioned at FOH

Loudest

Audience

Position

Level difference

Measurement

Position

(Microphone)

audience area

How to Measure the Correction Value

• Play a Pink noise signal at the typical sound level of the live

event (signal source: Minirator or NTi Audio Test CD or or

USB Flash Drive)

• Select the correction page

.

• Search the audience area for the location with the highest

sound pressure level and position the XL2 Analyzer.

• Turn the rotary wheel

to select the parameter RUN next

to Audience, select LA, LC or LA&LC and press enter

.

The XL2 measures the sound level at the loudest position

for 15 seconds. The timer counts down to zero.

60

Sound Level Meter

• Wait until the measurement is completed.

• Position the XL2 at the measurement position.

• Turn the rotary wheel

to select the parameter RUN next

to Measure, select LA, LC or LA&LC and press enter

.

The XL2 measures the sound level at the measurement

position for 15 seconds. The timer counts down to zero.

• Wait until the measurement is completed.

• The correction values k1 and k2 are calculated and displayed

including date and time.

61

Sound Level Meter

Manual Setting of Correction Values

You may fine-tune the correction values k1 and k2 manually.

Such fine-tuning adds the remark “Manually Adjusted” in the

log file.

2

3

1

• Turn the rotary wheel to select the correction value

3

and press enter

.

The selected correction value starts flashing.

• Set the correction value with the rotary wheel .

The note “Manually Adjusted” is displayed at

2

.

• To undo the manual setting turn the rotary wheel

to select

the parameter UNDO at

2

.

• Confirm with enter

.

Reset Correction Values

You may clear all correction values back to zero

by pressing the Clear All

1

and confirm with

enter

.

Display k1 and k2 during Measurement

The correction values k1 and k2 can be dis-

played in the numeric result page during the on-

going sound level measurement instead of any

other sound levels.

Correction Values in Profiles

The correction values k1 and k2 can optionally

be stored within profiles. Loading the profile,

sets the stored correction values.

62