Chemistry of Polymers

A

uthor: Judith Exler (Kollman, Christopher S., Chem 13 News, January 1994)

Date Created: 2008

Subject: Chemistry

Level: High school

Standards: New York State – www.emsc.nysed.gov/ciai/

Standard 1 – Analysis = inquiry and design

Standard 4 – The physical setting

Standard 6 – Interconnectedness; common themes

Standard 7 – Interdisciplinary Problem solving

New York State – Chemistry core curriculum

VII.6 – Types of organic reactions include addition, substitution,

polymerization, esterification, fermentation, saponification and

combustion.

Schedule: Three 45 minute classes

Objectives:

Students will review solubility/polarity and

intermolecular forces while being introduced

to physical properties of polymers.

Students will:

• Test a variety of plastics for solubility,

density, and melting point.

• Students will use the results of their tests

to build a concept map for determining the

identity of an unknown plastic.

• Students will attempt to determine the

identity of an unknown plastic.

• Students will analyze their concept maps

and suggest improvements.

• Students will be able to explain how

polarity affects solubility.

• Students will be able to explain the

relationship between intermolecular

forces, boiling point, and bonding.

• Students will be able to compare the mass

of two different polymers when given the

volume and the density.

Vocabulary:

Solubility

Intermolecular forces

Polymer

Mass

Bonding

Polarity

Boiling point

Density

Volume

Polymerization

Materials:

For Each Pair:

Safety Goggles

One sheet #6 plastic

(day 3)

Activity Sheets

Set of plastic pieces

4 Beakers

70-90% isopropyl

alcohol

Mazola corn oil

Water

Stirring rod

Beaker tongs

Small tongs (to pick

up plastic pieces)

or forceps

Hot plate

For teacher:

Copper wire

Alcohol or Bunsen

burner

Matches

Toaster oven,

aluminum foil,

safety mitts

(day3)

Safety:

Students should wear safety goggles during

Explore activities on the first two days.

Chemistry of Polymers

- 2 –

Science Content for the Teacher:

Student pre-knowledge

During the fall semester, students were introduced to the concepts of density, solubility

(types of bonding), and intermolecular forces (melting/boiling points). In order to access

previous knowledge and put it into long-term memory, repetition is required.

Polymer Basics

Polymers are made up of chains of smaller molecules called monomers. A biological

example is protein which is made up of amino acids. Most plastics are derived from

petroleum products. The physical and chemical properties of a polymer depend on the

monomer that it is made of. Some differences between plastics can be seen, felt or

smelled. (For example, one can burn a plastic and observe its odor, texture, and color of

the flame.) Other differences that can be tested include: melting point, solubility, density,

bounciness, transmission of polarized light, and glass transmission temperature*. These

properties can be modified by techniques such as adding fillers, plasticizers, and pre-

heating. New plastics are made by combining different monomers in order to obtain

desired properties.

Intermolecular forces

The greater the intermolecular forces between molecules, the higher the melting and

boiling temperatures. Polar molecules have greater intermolecular forces than nonpolar

molecules because the slightly negative end of one molecule is attracted to the slightly

positive end of another molecule (dipole-dipole attraction). Hydrogen bonding between

molecules is a very strong intermolecular force. The bigger the molecule, the more of it

there is to exert an intermolecular force so polymers generally have stronger

intermolecular forces than the monomers that they are composed of.

Polyethylene is very nonpolar so it melts at low temperatures compared to many other

plastics.

Kevlar is a polyamide. Amide groups can form hydrogen bonds between adjacent chains:

the positive hydrogen atoms in N-H groups of one chain are strongly attracted to the

oxygen atoms in C=O chains. Kevlar can withstand temperatures up to 400° C (and as

low as -198° C).

*Glass transition temperature- below this temperature, plastics become brittle.

Chemistry of Polymers

- 3 –

Preparation:

Teacher set-up

1. When you are setting up for this lab remember to keep flammables liquids away from

hot plates and flames. Also make sure that students are wearing safety glasses and not

breathing in fumes during this experiment.

2. If you do not want your students to do the copper wire test on their own, have them

bring their plastics up to you for testing. (You can ask individual groups to come up

every 3 to 4 minutes.)

3. Each group needs to have samples of the plastics being tested. Ten pellets of each

plastic are recommended.

4. If your school doesn’t allow the use of acetone, you can find it in some nail polish

removers. Check the bottle to make sure that it is the active ingredient in the nail

polish that you are buying. Using fingernail polish instead of acetone takes more time

so check how long it takes the plastic to soften before doing this lab. Also, throw the

acetone-covered pellets away in a hazardous waste container.(You need to use a fume

hood with acetone).

5. Use 70 to 90 % isopropyl alcohol for the alcohol float/sink test. To prepare 100 mL of

alcohol solution 65 mL of 70 % isopropyl alcohol in a 250 mL beaker with 35 mL of

water.

Mazola corn oil has the correct density for separating plastic #4 and 5.

Classroom Procedure: Day 1

Engage (Time: 5-10 minutes)

Teacher asks the students what are some organic molecules in the body. (Hint: They

contain carbon and hydrogen.) Teacher explains that “poly- means “many” and – “mer”

means “part.” (Teacher may elicit meaning of polymer.) She draws a picture of two

monomers on the board and then shows how they the bonds open up when they join

together during polymerization.

Explore (Time: 25 minutes)

Students collect data on how their polymers react to different tests.

Explain (Time: 10 minutes)

Students review their results and hypothesize some reasons for the differences between

the plastics. The teacher leads them into a discussion of solubility and polarity.

Expand –Homework

Students look at different containers that they use at home. They should list 5 examples

of containers (for example: Beautiful Hair shampoo) and their recycle number.

Classroom Procedure: Day 2

Engage (Time: 5-10 minutes)

Chemistry of Polymers

- 4 –

Teacher asks a question about the properties of Kevlar (for bullet proof vests) versus

polypropylene. Kevlar has a melting point of 400°C and polypropylene has a melting

point of 160 to 170° C. Obviously, Kevlar must have stronger intermolecular forces.

What are some examples of strong intermolecular forces? Teacher tries to elicit hydrogen

bonding, polarity, structure which might cause intertwining of polymer strands (like

spaghetti).

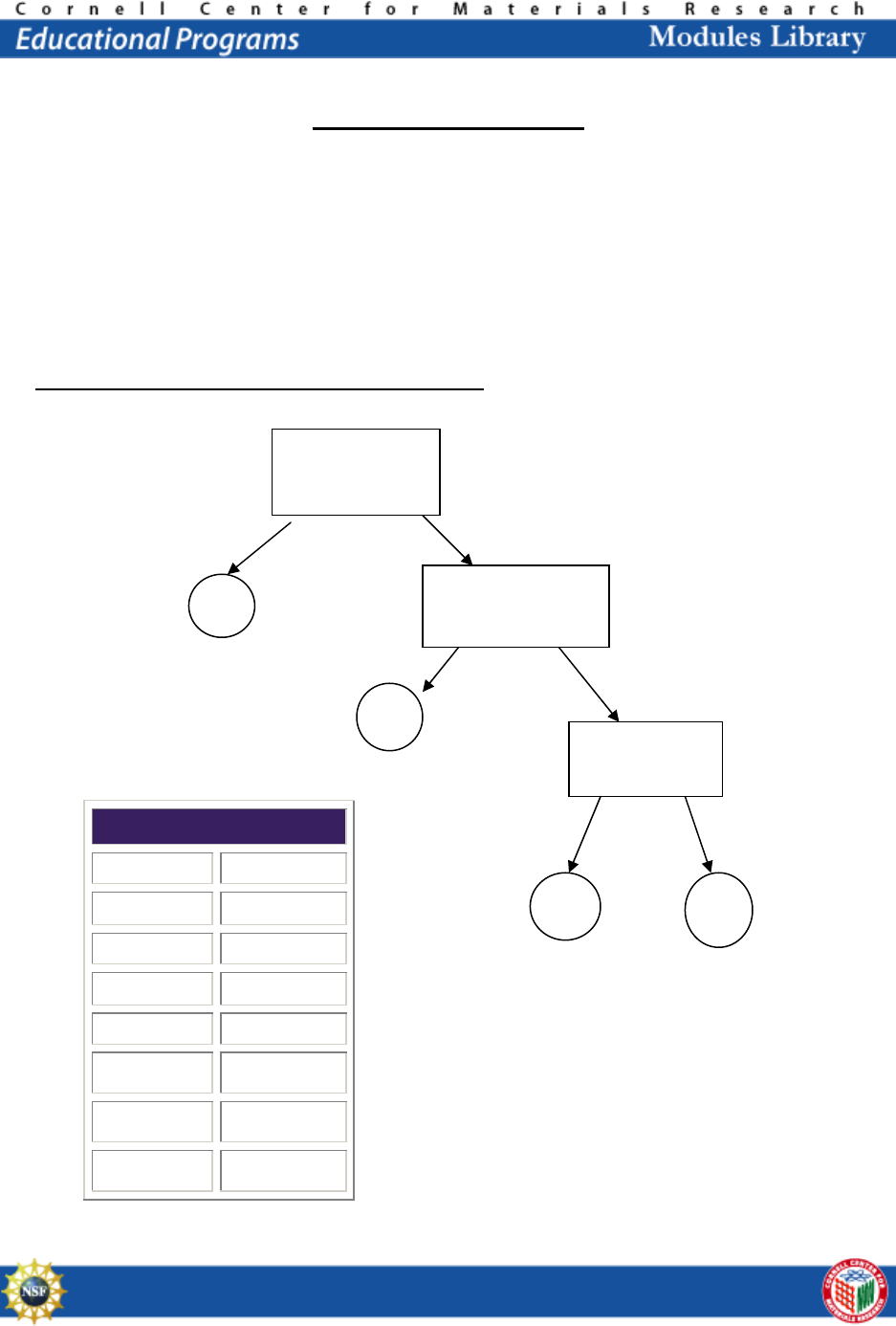

Explore (Time: 10 minutes concept map; 15 minutes testing)

Students use a template (as a scaffold) to create a concept map using density in order to

determine the identity of four different plastics. Then they test the plastics and

hypothesize what the four plastics were.

Explain (Time: 10 minutes)

Groups report on their results and what they could change their testing procedure to

improve it. Teacher elicits how students used (or didn’t use) the density data provided in

order to set up their concept map. Teacher clears up misconceptions about density.

Classroom Procedure:Day 3

Engage (Time: 10 minutes )

Do now: What do you know about polymers and polymerization?

Teacher makes a KWL chart using the answers from the do-now. The teacher then asks

the students if they have any questions about polymers. If the students failed to provide

important concepts (or questions) about polymers, she then asks the students some

questions and, either puts their answers under K or puts the question under W.

Explain (Time: 10 minutes)

a. Teacher goes over the answers to W.

b. Teacher explains the day’s activity. Today we are going to use a piece of polystyrene

container to show the property of memory that some plastics have. Many plastics are

heated and then stretched into a particular shape. Some of these plastics will return t to

their original shape when they are reheated. We are going to use this property to make

necklaces. You will be assigned a monomer. Write the name of the polymer, and draw a

picture of the corresponding monomer on the plastic with a permanent magic marker.

You can add other designs to it. Make a hole in it where you would like to put string.

Explore (Time: 10 minutes)

Students make “shrink dinks.”

Synthesis (Time: 15 minutes)

The teacher throws a potato (or other object) to one student who has to tell the class

something that he knows about polymers. He then throws the potato to another student

who adds another fact. As soon as the student has contributed to the class, the teacher will

take the plastic artwork and put it in a 163° C (325° F) toaster oven for 4 minutes. If there

Chemistry of Polymers

- 5 –

isn’t time for some students’ work to go in the oven during class, the teacher will put it in

after class and return it the next day.

Assessment:

The following rubric can be used to assess students during each part of the activity. The

term “expectations” here refers to the content, process and attitudinal goals for this

activity. Evidence for understanding may be in the form of oral as well as written

communication, both with the teacher as well as observed communication with other

students. Specifics are listed in the table below.

1= exceeds expectations

2= meets expectations consistently

3= meets expectations occasionally

4= not meeting expectations

Engage Explore Explain Expand/Synthesis

1

Shows leadership in

the discussion and

offers creative ideas

reflecting a good

understanding of

chemistry,

All investigations are

completed in a timely

manner. Data and

question sheet are

completely filled out.

Seen to be actively

participating when

teacher walks around

the room.

Group is able to

present correct results

in a clear manner.

Group is able to

answer questions.

Group listens actively

during other group

presentations and asks

questions.

2

Answers do-now

questions correctly in

notebook in a timely

manner. Listens

politely to other

students.

All investigations are

completed in a timely

manner. Seen to be

actively participating

when the teacher

walks around the

room. Data table is

filled out but some

discussion questions

are unanswered.

Group is able to

present correct

answers in a clear

manner. Group is able

to answer questions.

Group needs one or

two reminders to

listen quietly to other

groups. No questions

asked of other groups.

3

Copies answers from

board within 5

minutes after they are

written down. May

need to be asked to

quiet down once or

twice.

Data table and

discussion questions

are completely

answered. No active

participation noted.

Group is able to

present some correct

answers. Group needs

to occasionally be

asked for clarification

or to speak up. Group

needs two or three

reminders to listen

quietly to other

groups.

4

Talks to friends

during brainstorm

about non-chemistry

topics. Doesn’t take

any notes.

Student is not noted

by the teacher to be an

active participant.

Data table and

discussion questions

are incomplete.

Group uses some

evidence that is

flawed or just doesn’t

present answers.

Several reminders are

needed for the group

to be quiet during

other presentations.

Chemistry of Polymers

- 6 –

Extension Activities:

1- Students can do a lab investigating the density of all 6 recyclable plastics (HOP

on plastics activities)

2- Students can see what happens if you burn different plastics. (Brian Niece’s

website)

3- Students can make polymers such as slime, glueup, nylon 66.

Supplemental Information:

The following books and websites are recommended:

Polymer Chemistry: Introduction to an Indispensable Science

By: David Teegarden, NSTA Press, 2004

www.polymerambassadors.org/index.html

www.pslc.ws/macrog.htm

www.americanchemistry.com-

click on “learning center” and then “hands on plastic”

www.assumption.edu/users/bniece/Olympiad/Olympiad.html

www.matse1.mse.uiuc.edu/~tw/home.html

www.polymers.eezway.com-they sell samples of polymers

Safety:

Safety goggles should be worn at all times during the “explore” portion of the activity on

the first two days.

Acknowledgments:

I wish to thank:

Principal Steve Satin and Assistant Principal Amal Abadi, Norman Thomas High School,

NYC.

CCMR Staff: John Sinnott, Kit Umbach, Ron Kemp, Anthony Condo, Maura Weathers,

Yuanming Zhang, Mick Thomas, John Grazul, Nev Singhota, Kevin Dilley, Jane Earle

Wilson Laboratory: Lora K. Hine, Ken Finkelstein

Cornell Nanoscale Science: Melanie-Claire Mallison

Jay Dubner: Summer Research Program for Teachers

Cornell University

National Science Foundation

Chemistry of Polymers

- 7 –

Activity Sheet One

Student Name_____________ Period_________

Procedure:

1. Notice the test areas in the room. Some tests are to be done only at those locations,

while others will be performed at your lab desk.

2. Acetone Test- Put the pellets in the fingernail polish container. Wait at least 5

minutes before removing them and testing for solubility. If one of the plastics has

softened slightly, then it is plastic #5 (polystyrene). (Acetone is a nonpolar solvent.)

(Note: KEEP THIS TEST AREA AWAY FROM FLAMES. Acetone is highly

flammable and must be kept away from flames and covered when not in use. Have

tongs or forceps available.

3. Water test

a. Solubility-Put plastic pellets in water and stir. Since water is a polar

molecule, any plastic that dissolves in water is also a polar molecule (plastic

#7-other-biodegradable packing peanuts).

b. Density- Does the plastic sink or float in water? (Density of water = 1 gm/mL)

4. Alcohol test- Does the plastic sink or float in alcohol? Use tongs or forceps to remove

plastic pellets. Discard plastics in beaker or other container which has been provided

for each group. (Density of alcohol solution is 0.93 g/mL).

5. Oil test-Put the plastics in the oil. Do they sink or float? Use tongs or forceps to

remove and discard plastics. (Density of corn oil is 0.917 g/mL)

6. Heat test-Heat pellets in boiling water for 30 seconds. Remove with tongs and test for

softening. (Note: although PET has a melting point of between 250 to 260°C, it will

start to soften at 100° C). The greater the intermolecular forces holding the molecules

together, the higher the melting/boiling point will be.

7. Copper wire test-Using forceps, the teacher will hold the 5 cm length of copper wire

in the hot part of the flame of a Bunsen burner or alcohol burner until it is red hot.

She will remove from the flame and carefully touch a plastic pellet with the hot wire.

It may stick to the wire at this point so she will need to take another pair of forceps to

pull the pellet off the wire. Place the wire with some plastic glob on it (not the pellet)

back in the flame, observing the color of the flame that comes from the glob. You will

notice a green or orange flame color. Quench the sample in a beaker of water to stop

the burning and cool the wire. If there is more time, students may do this test at their

lab desks.

Chemistry of Polymers

- 8 –

Data table

Test 1-PETE 2-HDPE 3-PVC 4-LDPE 5-PP 6-PS 7-other

Water

solubility

Acetone

solubility

Sink/float

water

Sink/float

alcohol

Sink/float

oil

Copper

wire test

Heat test

Questions:

1. Which three plastics had the highest density?

2. Which plastic exhibited the lowest density?

3. The density of LDPE (low density polyethylene) was between what two numbers?

4. Explain in terms of intermolecular forces, why PVC (polyvinyl chloride) has a lower

melting point than PP (polypropylene)?

5. Explain in terms of molecular polarity, why the biodegradable peanuts are more

soluble in water than the polystyrene peanuts.

The following are the codes and abbreviations for recyclable plastics:

1. PET - polyethylene terephthalate 5. PP - polypropylene

2. HDPE - high density polyethylene 6. PS - polystyrene

3. PVC - polyvinyl chloride 7. other

4. LDPE - low density polyethylene

Chemistry of Polymers

- 9 –

Activity Sheet Two

Today you will design and test a flow chart to distinguish between four different plastics,

you will perform the experiment, and then we will discuss it as a class.

The density of water is 1.00 g/mL, the density of corn oil is 0.93 g/mL, and the density of

the alcohol solution is 0.917 g/mL. The four plastics that you will be testing are PET,

HDPE, LDPE, and PP. (Note: PS or PVC may be used instead of PET according to

availability. (10 minutes to design concept map)

Concept Map for Determining Type of Plastic

Density Table

Substance Density

Water 1.00

(1) PET 1.38-1.39

(2) HDPE 0.95-0.97

(3) PVC 1.16-1.35

(4) LDPE 0.92-0.94

(5) PP 0.90-0.91

(6) PS 1.05-1.07

Chemistry of Polymers

- 10 –

You have 10 minutes to test the plastics and determine which was which.

Questions (Each group is required to orally answer at least one question depending on

time constraints)

1. Which plastic was A, B, C, and D?

2. Why would a 150 pound fat person float more easily on water than a 150 pound

muscular person? Explain your answer.

3. How easy was it for you to identify the plastics using your concept map?

4. What changes would you suggest in order to improve your concept map?

5. Could you improve your concept map by adding any other tests or observations?

Explain.

Chemistry of Polymers

- 11 –

Common Plastic Resins Used in Packaging

Polyethylene Terephthalate (PET or PETE):

High Density Polyethylene (HDPE):

Vinyl (Polyvinyl Chloride or PVC):

Low density polyethylene (LDPE):

Polypropylene (PP):

Polystyrene (PS):

Resin Identification Code

The Society of the Plastics Industry, Inc. (SPI) introduced its resin identification coding

system in 1988 at the urging of recyclers around the country.