SHALE OIL:

Exploration and

Development

Presented By: Justin Brady, Laura Kerr,

Mike Potts

Senior Capstone Project

Spring 2006

Current Energy Crisis

• World’s main source of energy: Petroleum

• Demand exceeding supply

– April 17, 2006: Oil reaches

$70/barrel

• Opportunity to develop alternate energy sources

– Large economic incentive

Why Shale Oil?

• Currently, United Arab Emirates hold

50% of world’s known oil reserves

How much does the

US hold?

2%

How many reserves would

be added from developing

oil shale?

2 TRILLION BARRELS

•Result: US takes over as leader in the world

in oil reserves.

Outline

• Introduction to Shale Oil

• Project Statement

• Subsurface Operations

– Reservoir Temperature Profiles

– Heating

– Freeze Walls

– Reservoir Composition Analysis

• Surface Facilities

– Oil/Gas Processing

– Power Plant

• Pipelines to Market

• Production Schedule

• Economics and Risk

Shale Oil: Definition

• Sedimentary rock

with a high organic

content

– Organic matter is

known as kerogen

• Kerogen:

– MW

avg.

=3000

– Approximate formula

C

200

H

300

SN

5

O

11

1

1. Feng H.Y. Rates Of Pyrolysis Of Colorado shale oil. p. 732. American Institute Of Chemical Engineers Journal . Vol. 31 No. 5. 1985.

Shale Oil: History in the US

• Office of Naval

Petroleum and Shale

Oil Reserves formed

in 1912

• First Demonstration

mine opened outside

of Rifle, Colorado

just after World War

II

Shale Oil: History in the US

• TOSCO opened an experimental mine and

production plant near Parachute, Colorado in

1960’s

• Exxon opens Colony II project outside of

Parachute, Colorado in 1980

– Colony Project is closed in May of 1982

– Nearly 2,200 people unemployed

– Loss of more than $900 million.

Project Statement

• Determine which method of production of

shale oil is the most feasible.

• Analyze production process to determine

– Subsurface designs

– Reservoir characteristics

– Surface processing facilities

– Scheduling of project

– Pipelines

• Perform an economic analysis on project.

Shale Oil Production Methods

Above Ground

Retorting

• Mining of ore

• Well known technology

• Large environmental

impact

– Popcorn effect

– Large open mines

– Emissions

In-Situ

Conversion

• Underground

conversion

• Research in progress

• Lower environmental

impact

• Not commercially proven

In-Situ Conversion

• Currently being explored by Shell Oil

with the Mahogany Project.

• Entails the heating of kerogen in the

ground and extracting the produced

hydrocarbons for further processing.

In-Situ Process Overview

• Step 1: Heating

– Conversion of kerogen

to oil and gas

• Step 2: Freeze Wall

Construction and Water

Removal

– Impermeable wall

around production site

– Prevents large

environmental impact

1. Mut, Stephen. The Potential of Oil Shale. 8/20/05

In-Situ Process Overview

• Step 3: Production

– Products from kerogen

conversion

• Step 4: Processing and

Transportation

– Oil and gas separation

– Pipelines to market

Schedule Table

site preparation: drilling wells, freeze wall formation, water removal

heating only

Production: refrigeration and heating continues

water injection

site reclamation

Reservoir Temperature Profile

• Unsteady state 1D

temperature profile

• Profile created for

– Heater to heater 60

feet apart (25

heaters/acre)

1

– Heat given off by

reaction accounted

for

– Initial Reservoir

temperature 150

o

F

1. Bartis et. al. Oil Shale Development in the United States. Rand Santa Monica, California: 2005 p. 50

.

Reservoir Temperature Profile

• Heat balance on reservoir

q

z

T

k

t

T

C

p

−

∂

∂

=

∂

∂

2

2

ρ

1. Guerin, Gilles 2000. Acoustic and Thermal Characterization of Oil Migration, Gas Hydrates Formation and Silica Diagenesis, PhD. Thesis,

Columbia University

• Concentration due to cracking

k

RT

E

k

CAe

dt

dC

a

)(

−

−=

Accumulation Conduction Generation

Reservoir Temperature Profile

• Approximation Equation

p

rxk

RT

E

tititititti

C

HCAte

T

x

t

TT

x

t

TT

a

ρ

αα

)(

|

2

)||(||

)(

2

11

2

∆−

−

∆

∆

−+

∆

∆

=−

−

−+∆+

Accounts for heat of

reaction due to

cracking of kerogen

Accounts for heat spreading

linearly away from each

heater into the reservoir

rock

Temperature at

certain time and

distance between

heaters

t

T

∂

∂

=

2

2

z

T

∂

∂

α

p

C

q

ρ

−

Reservoir Temperature Profile

Assumptions

• Thermal diffusivity assumed constant

• Models only include periods of time when no fluid

flow is occurring in reservoir

• Heaters assumed to be in a hexagonal pattern in the

earth

• Heat generation from reaction is calculated from

average kinetic values of kerogen cracking

• Heat lost to overburden by heaters not considered

Temperature vs. Reservoir Distance:

Heat of Reaction Included

0.0

200.0

400.0

600.0

800.0

1000.0

1200.0

1400.0

1600.0

0.0 10.0 20.0 30.0 40.0 50.0 60.0

Distance (ft)

Temperature (F)

3.5yr 21 months 3 year Beginning of heating 10.5 months

Reservoir Temperature Profile

Takes 3.1 years to start production of the well in

the center of the heaters.

Temperature vs. Reservoir Distance

0.0

200.0

400.0

600.0

800.0

1000.0

1200.0

1400.0

1600.0

0.0 10.0 20.0 30.0 40.0 50.0 60.0

Distance (ft)

Temperature (F)

3.5yr 21 months 3 year Beginning of heating 10.5 months

Reservoir Temperature Profile:

No Heat from Reaction

Takes 3.3 years to start production of the well in

the center of the heaters.

Reservoir Temperature Profile:

Heater to Freeze Wall

Temperature vs. Reservoir Distance:

Heater to Freeze Wall

0

200

400

600

800

1000

1200

1400

1600

0 10 20 30 40 50 60

Distance (ft)

Temperature (F)

0 hrs 10 months 24 months

48 months 72 Months 130 months

2D Reservoir Temperature

Profile

• Developed using

ANSYS

• Initial reservoir

temperature 150

o

F

• Freeze walls

included as

boundary condition.

30 ft 30 ft30 ft 30 ft

Production wellHeater

Shale Oil:

Subsurface Operations

• Drilling costs

• Refrigeration costs

• Pumping costs

• Heating costs

Drilling Costs

• Consists of wells for heaters and

producers

– 250 wells for heaters per 10 acre plot

– 80 producer wells

• Total well costs of $26.4 million.

– $80,000

2

per well.

2. Brown, Randy. Field Engineer XAE inc.

Freeze Wall Construction

• Constructed of

double wall pipes

placed 8 ft. apart

• Calcium chloride

brine at -10 degrees

F is circulated.

• Water in the soil

freezes creating an

impermeable

barrier.

*Soil freeze technologies

Freeze Wall: Duty & Costs

WQ K 10*0.5

6

=

waterfreezing

M*)(**

∆Η

+

−

=

initialfinalp

TTCMQ

z

T

kQ

∂

∂

−

=

Purchase cost for 5.0*10

6

KW of refrigeration

1

: $12.5 million

Operating Cost

2

: $3.2 million per day

1. Peters et al p.894 fig. B-7

2. Peters et al p.898 table B-1

During freezing:

During production:

KWQ 7.8

=

Pumping

• Ground water

trapped within

freeze wall

• Must be

removed to

prevent

contamination

Heaters

500 ft, Shale

2000 ft,

Overburden

Producing well

Ground water

Pumping Costs

• A pump is needed to remove water

from within the freeze wall.

– 2 barrels of water for every barrel of oil

6

– Pumps must handle 1.6 million gallons per

hour to remove the water in 2 weeks.

• Centrifugal pumps

• 80 pumps, $23,000 per pump

7

• $120,000 electricity needed per day

6. Bartis et. al. Oil Shale Development in the United States. p. 50. Rand Santa Monica, California: 2005

7. Peters et. al. Plant Design And Economics For Chemical Engineers. P. 516, Mcgraw-Hill: New York 2003.

Heating: Challenges

• Challenges

– Regulated at a constant temperature

– Must operate at high temperatures

– Must have a large power output.

Heating: Solution

Overburden

Shale

Heaters

Supporting

casing

•Electric heaters

lowered to the bottom

of well hole

•Extends the entire

length of the shale

layer

2000 ft

500 ft

Heating Element

•Chromel AA* heating

element

•68% nickel

•20% chromium

•8% iron

•Self regulating:

1500

o

F

*Trademark of Hoskins Manufacturing

2 Handbook of chemical engineers, p. 4-201 8th ed.

2

Heater Design

Heating

Element

Electrical

Insulator

Steel

Casing

6”

.5”

6”

10’

•Cylindrical design

•Electric heating

element suspended

in the center.

•Spaced from the

casing by electrical

insulators

Heater Design

Heating

Element

Ceramic

Insulator

Steel

Casing

.5”

6.625”

Heating Costs

Electrical

• 165 KW per heater

• Operating at 480 V AC

and 350 amps

• Electrical costs heating:

– $.08 per KW-hr

4

$80,000

per day total

Materials

• Steel Casing

– $10 per foot

• Heater element

– $20 per foot

• Porcelain insulator

– $14 each, 250 per

heater

• Total material cost:

$80,000 per heater

Reservoir Composition Study

• Heating process causes

cracking of kerogen.

• Estimation of composition

of products in reservoir

needed.

• A temperature profile is

necessary for composition

computation

• Ultimately, reservoir

characteristics will allow

design of processing

facilities.

Reservoir Composition Model

• Cracking process under

the earth

– Kerogen:

• MW

avg.

=3000

• Approximate formula

C

200

H

300

SN

5

O

11

• Modeled using

visbreaking model

• Using temperature

profile, predicts

concentrations of

hydrocarbons in

reservoir

Reaction depiction for thermal cracking

1

1. Castellanos, Julian. Visbreaking Yields. Encyclopedia of Chemical Processing and Design vol. 62. Marcel Dekker: New York. P411,

Composition Model

∑∑

−

=+=

∗−=

2

1

,

2

,

i

j

ji

n

ik

ikik

Si

KCsCsK

dt

dC

Example of hydrocarbon cracking

Reservoir Composition

Weight Fractions of Hydrocarbons During Heating

In Reservoir

0

0.2

0.4

0.6

0.8

1

C1-C5 C6-C10 C11-C15 C16-C20 C30-C40 C50-C60 C70-C280

Carbon amount in Hydrocarbons

Weight Fraction

700 F 800 F 900 F 1000 F 1100

Problems With Composition

Model

• Averaged K-Values must be used due to the

large amounts of data

• Parameters are fit to laboratory data that may

not be similar to reservoir

• Does not account for coking in reservoir

• Results are not close to reported results from

experimental site

Suggested Solution for

Composition Model

• Use a tool with a larger capacity than

excel

• Use a model specifically developed to

calculate products from kerogen

– Example: Braun and Burnham’s model of

decomposition of kerogen

Oil Processing Design

Specifications

Oil composition

1. No significant sulfur content

2. Carbon solid from cracking is

not produced

3. Heavy hydrocarbons are not

produced

4. TBP curve of a sample light

sweet crude oil is being used

currently.

• Update with compositional

model results

Production

1. 20 acres produced from one

facility

2. Water treatment will function ¼

of the time of the oil treatment

1. Bartis et. al. Oil Shale Development in the United

States. p. 50. Rand Santa Monica,

California: 2005

Oil Surface Facilities

Considerations

• Elevation changes

• High temperature fluid

• Piping will be above

ground

• Two different

transportation routes for

oil and gas

• Some gas will be used

for running electricity

plant

Experimental project site

Oil Processing Skeleton Model

Oil Processing

Water processing

Oil Processing Facilities

•Inlet temperature= 680

o

F

•Inlet pressure= 1000psia

Separates C

1

- C

5

and

from heavier products

Sent to Denver

refinery for sale

Water Processing Facilities

Pumps water back

Into well

•Inlet temperature = 680

o

F

•Inlet Pressure= 1000psia

To oil

processing

Processing Facilities

• Future options for gas treatment

– Create a gas plant on site

– Use ethane to make ethylene on site

– LPG to market with oil

– Burn gas production for power generation

Power Plant Options

Nuclear Power Plant

• Bad public opinion

• Low emissions

Gas Powered Plant

• Methane is priced high

• Producing methane on sight

Coal Powered Plant

• High emissions

• Coal supply needed

Power Plant

• Combined Cycle

– Capital Cost,

$500M

– Operating Cost,

$60,000/day

– Natural Gas

Required, 110M ft

3

– Electricity

Generated, 800

MW

– Efficiency, 57%

R.H. Kehlhofer, et al., Combined-Cycle Gas & Steam Turbine Power Plants

Gathering Pipelines

• Well to Header

– 4” Schedule 80,

Carbon Steel

– Oil & Gas

• Header to Main

Gathering Pipe

– 8” Schedule 80,

Carbon Steel

– Oil & Gas

• Main Gathering Pipe

to Processing Facility

– 20” Schedule 80,

Carbon Steel

– Oil & Gas

To further

collection

and

processing

Producing wells

surrounded by heaters

Header

Sell Pipelines

• Gas to/from Market

– 8” Schedule 80, Carbon

Steel

• Oil to Market

– 12” Schedule 80, Carbon

Steel

• Gas to Power Plant

– 16” Schedule 80, Carbon

Steel

Pipeline Costs

Pipe Description Contents D (in) Schedule Length (ft) $/foot Total Cost

1. From Well Oil & Gas 4 80 400000 10$ 4,000,000$

2. From 1 Acre Oil & Gas 8 80 100000 30$ 3,000,000$

3. From 10 Acres Oil & Gas 20 80 1000 100$ 100,000$

4. Crude Oil to Sell Oil 24 80 1188000 110$ 130,680,000$

5. Gas to sell Gas 8 80 1188000 30$ 35,640,000$

6. Gas to Power Plant Gas 10 80 10500 40$ 420,000$

1

1

2

3

5

6

4

Total Piping Cost= $173,840,000

Production Schedule

• Ten acre tracts

• 40,000 BPD per tract

• A new tract every year

Schedule Table

site preparation: drilling wells, freeze wall formation, water removal

heating only

Production: refrigeration and heating continues

water injection

site reclamation

Environmental Effects

• Location

– Colorado Rocky Mountains

– Lack of infrastructure

– Low population

– Natural habitats affected largely

• Ground Coverage

– Drilling cannot occur on slope

– Wells spaced 30-60 ft apart

– Large land clearings necessary

• Emissions

– Choice of power plant

– Processing on site

Crude Oil Price Forecast

Crude Oil Forecasted Prices

(Price per Barrel, $US 2004)

$0.00

$10.00

$20.00

$30.00

$40.00

$50.00

$60.00

$70.00

$80.00

$90.00

2000 2005 2010 2015 2020 2025 2030 2035

Year

Dollars

Most Likely

High

Low

Natural Gas Price Forecast

Natural Gas Forecasted Prices

(Price per Thousand Cubic Feet, $US 2004)

$0.00

$1.00

$2.00

$3.00

$4.00

$5.00

$6.00

$7.00

$8.00

$9.00

2000 2005 2010 2015 2020 2025 2030 2035

Year

Dollars

Most Likely

High

Low

Pricing Estimations

• Includes

• Equipment costs

• Heating

• Cooling

• Power Plant

• Drilling

• Production taxes

• Operating costs

• Excludes

• Logistical costs

• Extensive Road

building

• Transporting materials

• Relocating employees

• Research costs

• Reclamation costs

Processing Equipment Costs

Component Basis of Estimation Cost

a. Heat Exchangers 5 @ $15,867 $80,000

b. Distillation D=3m, H=6m, 10 trays $87,000

c. Mixer #2 D=.508 $16,000

d. Mixer #1 D=.4572m $14,000

e. Flash #1 D=1m, H=10m $15,000

f. Pump .0544 m3/s, 6800 kPa $40,000

g. Pumps (piping) 2 w/ .151 m3/s, 1035 kPa $32,000

h. Heat Exchangers 3 w/ SA= 100 ft2 $3,600

i. Expander P=1932 kW $235,000

j. Expander #2

P=552 kW

$105,000

k. Compressor 5800 kW, centrifugal-rotary $1,100,000

$1,727,600Processing Equipment Costs

Extraction Equipment Costs

$541,067,000 Extraction Equipment Costs

$500,000,000.00

Combined Cycle,

$400/kWhd. Power Plant

$1,840,000.00

80, 1.6M gal/hr

water, 2 weeksc. Pump

$12,500,000.00800 KW capacityb. Refrigeration plant

$25,000,000.00

25/acre @

$100,000a. Heaters

Cost

Basis of

EstimationComponent

Total Capital Investment = $867 million

Component

Basis for Estimate

Cost Per Year

I. Manufacturing Cost

A. Direct Production Costs

1. Raw Materials

a. Cooling Water 178M lb/hr $0.08/1000kg $1,650,000

2. Operating Costs

a. Drilling Costs (contract) $22,400,000

b. Operating Labor $2,000,000

c. Refrigeration $0.68 per KW $196,000,000

$220,400,000

3. Direct Supervision and Clerical 15% of Operating Labor $300,000

3. Utilities (Power Plant)

a. Variable Operating Costs $86,500/day $31,572,500

b. Fixed Operating Costs $3.6M/year $3,600,000

4. Maintenance and Repair 7% of FCI $57,798,000

5. Operating Supplies 15% of Maintenance and Repair $8,670,000

6. Laboratory Charges 5% of Operating Labor $100,000

7. Patents not applicable $0

B. Fixed Charges

1. Capital Costs Straight Line Depreciation, 25 years $33,027,000

a. BLM Production Tax 12.5% of Gross $228,617,750

b. Insurance .7% of FCI $5,780,000

c. State Production Tax 1% of Gross $18,289,420

C. Overhead Costs 10% of the Total Product Cost $56,000,000

II. General Expenses

A. Administration Costs 20% of Operating labor and maintenance $11,960,000

Total Annual Cost

$677,800,000

Total

Annual Costs

Cost per barrel: $23.21

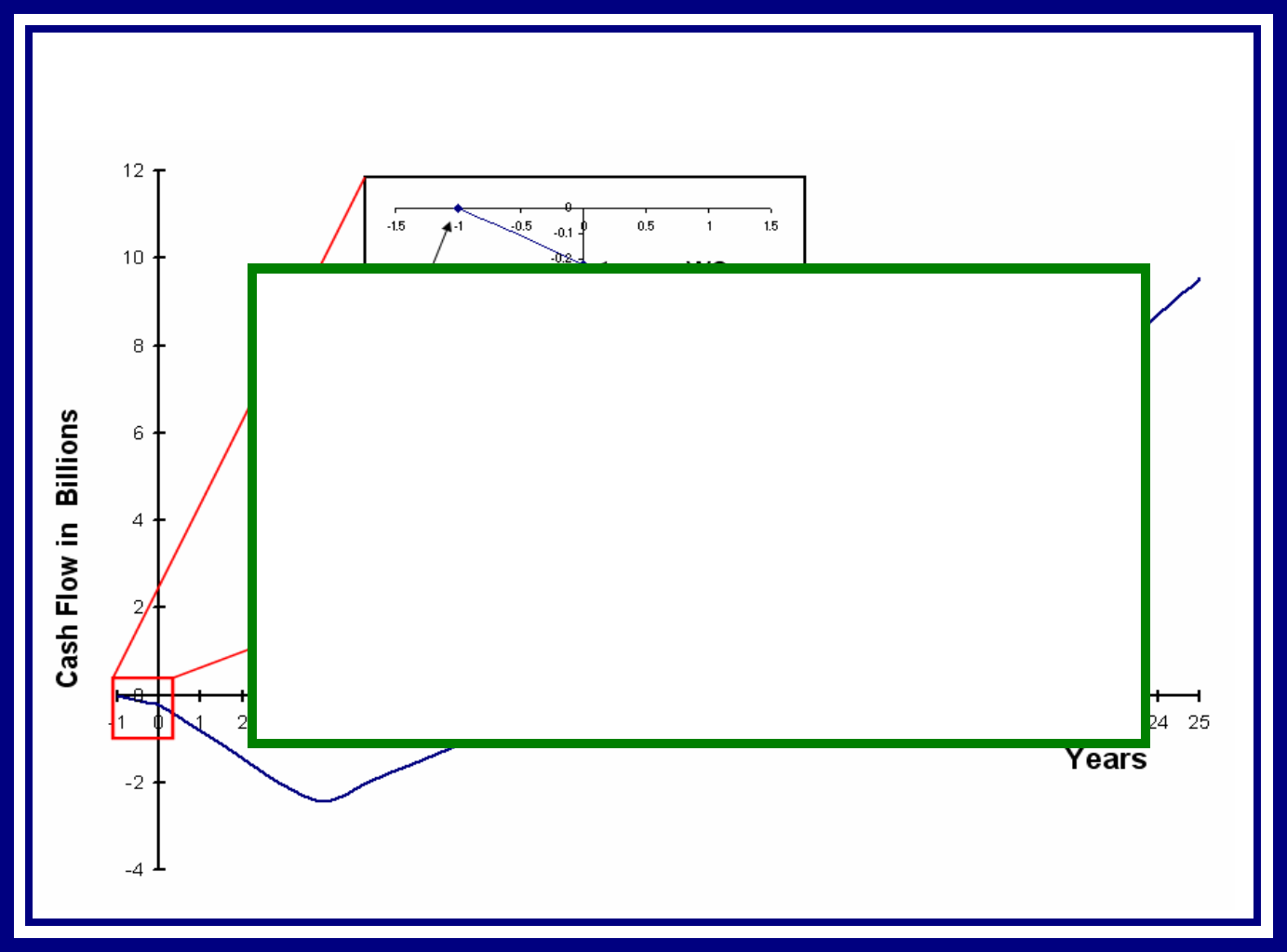

Profit Estimates

Input picture of cash flow position thing!!!!!

Payback period:

9.7 years

Cash Flow at 25 years:

$9.7 billion

NPV at 8%:

$1.5 billion

Return on Investment:

162%

Risk Assessment

Distribution for NPV / Net Income/G30

Values in 10^ -10

Values in Billions

0.000

0.500

1.000

1.500

2.000

2.500

Mean=1.485529E+09

-6 -4 -2 0 2 4 6 8 10-6 -4 -2 0 2 4 6 8 10

5% 90% 5%

-1.4391 4.3723

Mean=1.485529E+09

Distribution for Total / ROI/F29

0.000

0.200

0.400

0.600

0.800

1.000

Mean=0.9269187

-2 -1 0 1 2 3 4-2 -1 0 1 2 3 4

5% 90% 5%

-.1468 1.9868

Mean=0.9269187

Risk Assessment

Future Work

• Logistics

– Transportation of materials

– Drilling complications

– Reclamation Process

– Work Force

• Optimizations

– Heater to heater distances

– Heater temperature

– Heater material

– Composition of reservoir

• 3D temperature profile

• Detailed project risk assessment

Questions?

Net Present Values:

Varied Rates

Rate NPV (25 years)

0.08 $1.5 billion

0.10 $0.8 billion

0.12 $0.4 billion

0.15 $-0.1 billion

Risk Assessment:

NPV with Rate=10%

Distribution for NPV / Net Income/G30

Values in Billions

0.000

0.200

0.400

0.600

0.800

1.000

Mean=8.349873E+08

-6 -4 -2 0 2 4 6 8

-1.4-1.4-1.4-1.4

-6 -4 -2 0 2 4 6 8

4.99% 90.01% 5%

-1.4 3.0769

Mean=8.349873E+08 Mean=8.349873E+08

Risk Assessment:

NPV with Rate=12%

Distribution for NPV / Net Income/G30

Values in Billions

0.000

0.200

0.400

0.600

0.800

1.000

Mean=3.687469E+08

-4 -3 -2 -1 0 1 2 3 4 5-4 -3 -2 -1 0 1 2 3 4 5

5% 90% 5%

-1.3767 2.1075

Mean=3.687469E+08

Risk Assessment:

NPV with Rate=15%

Distribution for NPV / Net Income/G30

Values in Billions

0.000

0.200

0.400

0.600

0.800

1.000

Mean=-1.012595E+08

-4 -3 -2 -1 0 1 2 3 4-4 -3 -2 -1 0 1 2 3 4

5% 90% 5%

-1.3296 1.1296

Mean=-1.012595E+08

Temperature Profile:

Affect of Thermal Diffusivity

Thermal Diffusivity vs. Time

0

20000

40000

60000

80000

100000

0.003 0.008 0.013

Thermal Diffusivity (ft^2/hr)

Time

(hrs)

40 ft 50 ft 60 ft 30 ft 70 ft

Temperature Profile:

Affect of Heater Distance

Heater Distance vs. Time

0

20000

40000

60000

80000

100000

25 35 45 55 65 75

Heater Distance (ft)

Time (hrs)

.004 ft^2/hr .008 ft^2/hr .016 ft^2/hr

Reservoir Production:

Fracturing

Reservoir

Heater

Water and

Sand

Heater