9/24/2018

1

Time Overcurrent Relays

U

I

ECE525

Lecture 11

Time Overcurrent Relays

More or less

approximates

thermal fuse

» Allow

coordination

with fuses

Reset

Position

Time Dial

Setting

Direction

of

Current

Induced

Torque

Restraining

Spring

Disk

Time Overcurrent Relays

U

I

ECE525

Lecture 11

Basic equation

s

= restraining spring

torque

I = applied current

I

p

= pick up current

K

d

= disk damping

factor

= angle of disk

rotation (proportional

to Time Dial Setting

(TDS)

t

K

I

I

T

d

p

s

1

2

Operating torque Restraining Torque

9/24/2018

2

Time Overcurrent Relays

U

I

ECE525

Lecture 11

Relay Response

12

2

12

1 tt

I

I

K

pd

s

t

K

I

I

d

p

s

1

2

1. Operating torque = Restraining Torque

2. Integrate w.r.t. Time

timetrip

I

I

K

TDS

pd

s

1

2

3. TDS (setting angle),

where triptime = t

2

-t

1

Time Overcurrent Relays

U

I

ECE525

Lecture 11

Relay Response

4. Finding trip time

1

1

2

2

M

A

TDS

I

I

K

TDStimetrip

p

s

d

Where: M = I/I

p

A = K

d

/t

s

9/24/2018

3

Time Overcurrent Relays

U

I

ECE525

Lecture 11

Standard Curves --

standard formats

2

1 M

C

TDStr

B

M

A

TDStt

p

1

Reset Time (M < 1)

Trip time (M

1)

Some manufacturers include disk inertia in B

Time Overcurrent Relays

U

I

ECE525

Lecture 11

US and IEC curve

parameters

Curve A B C P

U.S. Moderately inverse (U1) 0.0104 0.2256 1.08 0.02

U.S. Inverse (U2) 5.95 0.180 5.95 2.00

U.S. Very inverse (U3) 3.88 0.0963 3.88 2.00

U.S. Extremely inverse (U4) 5.67 0352 5.67 2.00

U.S. Short-time inverse (U5) 0.00342 0.00262 0.323 0.02

I.E.C. Class A - Standard inverse (C1) 0.14 0.0 13.5 0.02

I.E.C. Class B – Very inverse (C2) 13.5 0.0 47.3 2.00

I.E.C. Class C – Extremely inverse (C3) 80.0 0.0 80.0 2.00

I.E.C Long-time inverse (C4) 120.0 0.0 120.0 2.00

I.E.C Short-time inverse (C5) 0.05 0.0 4.85 0.04

9/24/2018

4

Time Overcurrent Relays

U

I

ECE525

Lecture 11

US Inverse (U2)

Characteristic

Time Overcurrent Relays

U

I

ECE525

Lecture 11

Comparison of curves

9/24/2018

5

Time Overcurrent Relays

U

I

ECE525

Lecture 11

Extremely Inverse Curve

and 50E fuse

Time Overcurrent Relays

U

I

ECE525

Lecture 11

Example

Vs

Z1

Local

Load

Local

Load

Local

Load

Faulted

Line

Bus

#1

Bus

#2

Bus

#3

Z3

Z4

Z2

Source

R3R2

R4

• Want the relay on the faulted line, R4, to be the only relay to trip

• Max and min fault current (based on ends of faulted line)

1 2 3

1 2 3 4

9/24/2018

6

Time Overcurrent Relays

U

I

ECE525

Lecture 11

Example continued

The desired coordination can be accomplished by:

increasing the time dial settings as one proceeds toward

the source.

» If relay R2 is expected to provide backup protection for

relay R4,

» Then R4, the relay with the greatest source impedance, would

be set with the lowest time dial setting

Time Overcurrent Relays

U

I

ECE525

Lecture 11

Example continued

» If I

MIN

is defined as the minimum fault current,

» Then the pickup current must be set at or below this current but

above maximum load current.

» Usually with a margin around both

» For relays R2 and R3, the TDS must be set to trip no

faster then the next downstream device when the fault

current is maximum for an out of zone fault

9/24/2018

7

Time Overcurrent Relays

U

I

ECE525

Lecture 11

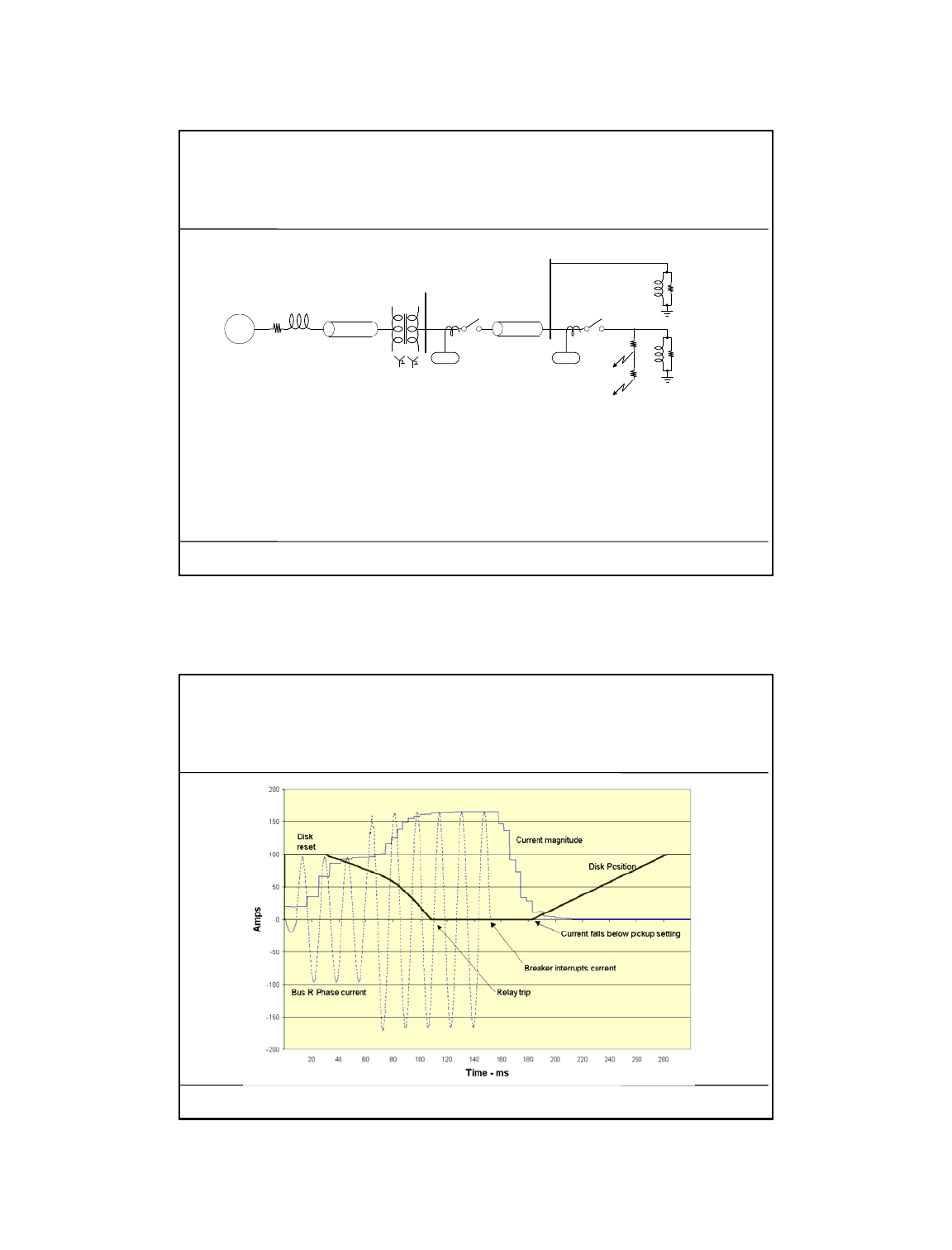

EMTP relay simulation

Gen

Xfmr

Breaker

Breaker

Source

Impedance

230KV

Fault #2

C-G

Fault #1

C-G

69KV

52 52

S Bus

R Bus

Load

Load

225

25

250 resistive fault is initiated at 8.3 ms and progresses to a 25 fault at 62 ms

as can occur by a tree branch coming in contact with the wire.

Time Overcurrent Relays

U

I

ECE525

Lecture 11

Example with a trip

9/24/2018

8

Time Overcurrent Relays

U

I

ECE525

Lecture 11

Comparing relay

coordination (light load)

Time Overcurrent Relays

U

I

ECE525

Lecture 11

Comparing relay

coordination (heavy load)

9/24/2018

9

Time Overcurrent Relays

U

I

ECE525

Lecture 11

Directional Control vs

Direction Supervision

32

Directional

Element

(32)

Reference

Signal

Phase

Current

50/

51

Overcurrent

Element

(50 or 51)

Phase

Current

50/51

52

DC Bus -

AC Circuit

Breaker

b. Directional Control

32

DC Bus +

32

Directional

Element

(32)

Reference

Signal

Phase

Current

50/

51

Overcurrent

Element

(50 or 51)

Phase

Current

32

50/51

52

DC Bus +

DC Bus -

AC Circuit

Breaker

a. Directional Supervision

Time Overcurrent Relays

U

I

ECE525

Lecture 11

Directional Step-Time

Overcurrent (ANSI 67)

The directional overcurrent relay can be perceived as a

type 50 instantaneous element controlled by a type 32

directional element

If the type 67 relay element is to provide backup protection,

they use definite time delay for downstream coordination

The 67 element requires more attention to detail for

coordination than do type 51 relays

» The advantage that the stepped time has over the 51 is that

the time steps are independently set

.

» The disadvantage is that overreach errors have a more

pronounced affect that often proves difficult to

coordinate

9/24/2018

10

Time Overcurrent Relays

U

I

ECE525

Lecture 11

Directional Step-Time

Overcurrent (ANSI 67)

Bus S

2

G 1

Load

1

Load

2

Load

3

Load

4

F1 F2 F3 F4

Load 5

Increasing

time

51

67

Time Overcurrent Relays

U

I

ECE525

Lecture 11

Overcurrent Elements in

Microprocessor Relays

Expect the relay to be able to coordinate with

fuses and electromechanical relays

Implement relay function using the standard

curve equations

Use digital filters to compute RMS magnitude

from measured currents

Add directional supervision

Take advantage of some calculations difficult

to do without microprocessor