COMPRESSOR MODELS

Doosan Infracore Portable Power

1293 Glenway Drive

Statesville, N.C. 28625

DoosanPortablePower.com

Book: 22893804 (12-2012) Rev C

T

D

T

ELECTRONIC SERVICE

MANUAL

HP675EWCU

XP750EWCU

HP750EWCU

XP825EWCU

1()

TABLE OF CONTENTS

SECTION1.......ManualDescription

SECTION2.......GeneralInformationAndOperationalTheory

SECTION3.......ServiceTools

SECTION4.......ElectronicSystemsTroubleshooting

Procedures And Techniques

SECTION5.......SystemSchematicDiagrams

SECTION6.......ElectronicComponent Location Drawings

SECTION7.......IndividualCircuitDiagrams

SECTION8.......ElectricalConnector Information

SECTION9.......ElectricalPartsList

SECTION10......AlertsandShutdownsList

SECTION11......RecommendedSpareParts

SECTION 12 Software Information....

2()

SECTION 1

MANUAL DESCRIPTION

This manual contains all of the information concerning the electrical and electronic systems for

the HP750EWCU Family of compressors. It provides all information necessary to service, trou-

bleshoot and order parts for this machine.

It is organized into 12 sections.

Sections 2 -- 4 cover systems operation and troubleshooting procedures.

Sections 5 -- 7 have location diagrams, drawings of specific circuits and systems schematics.

Section 8 has information concerning the electrical connectors used, including removal and re-

placement.

Section 9 contains the parts list with ordering information.

Section 10 contains the list of Alerts and Shutdowns.

Section 11 contains a list of recommended spare parts for servicing.

Section 12 contains software information.

3()

SECTION 2

GENERAL INFORMATION

and

OPERATIONAL THEORY

4()

GENERAL INFORMATION AND OPERATIONAL

THEORY

General

The mid--range machine has an electronic monitor

and control system to provide discharge air pressure

control and engine and package monitor functions.

The system uses the WEDGE controller to perform

these functions. The electrical system connects all the

necessary switches, sensors and transducers to the

WEDGE controller in order for it to perform the monitor

and control functions.

WEDGE Controller

The WEDGE controller is the heart of the machine

monitor and control system. It provides data

collection, alarming and control functions for

compressor operations. It is a microcontroller based

unit with analog and digital inputs and outputs.

The W EDGE controller is attached to the back of the

control panel. The LED annunciators are part of the

front panel of the WEDGE. They can be seen through

the laminate on the front of the control panel.

The WEDGE is attached to the control panel with four

#10 size nuts.

The first function of the WEDGE controller is to scan all

analog and digital inputs at a fixed interval. These

inputs are scanned every 50 milliseconds. The analog

values are then compared against minimum and

maximum v alues and an ALERT or SHUTDOWN is

issued, if a value is out of range. The various ALERTS

and SHUTDOWNS are listed in Section 10 of this

manual.

The second function of the WEDGE controller is

machine discharge pressure control. The WEDGE

monitors the regulation system air pressure and varies

the engine throttle to maintain the setpoint discharge

air pressure. The setpoint pressure is set using the

regulator on the separator tank.

The third function of the WEDGE controller is to

communicate with the diesel engine via the J1939

CAN network. It retrieves diagnostic information over

J1939.

5()

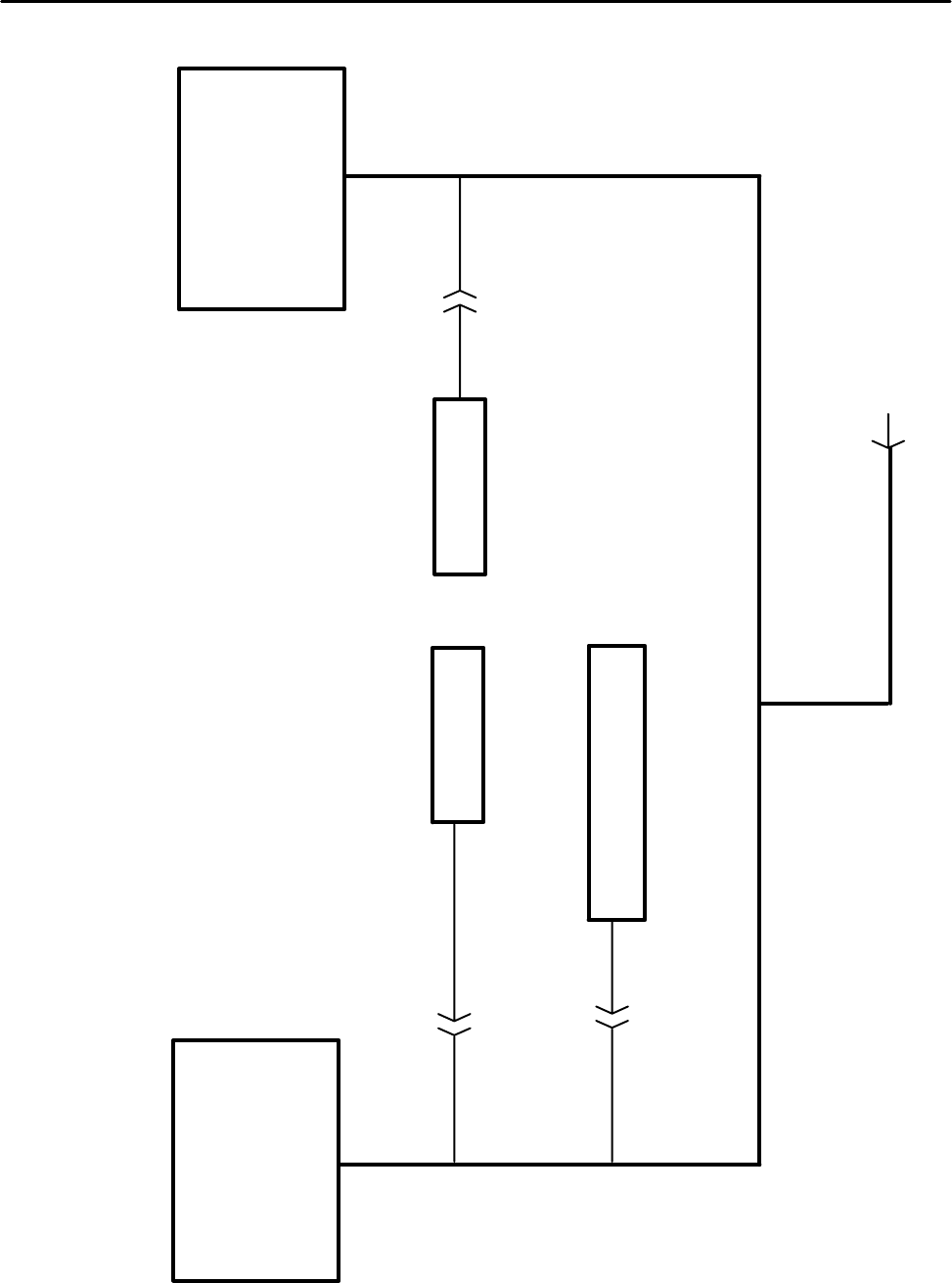

FIGURE 2--1

MID RANGE MACHINE

WEDGE

Controller

CONTROL PANEL SWITCHES

GAUGES

24VDC HEATERS

ENGINE ECM DIAGNOSTIC

INTERFACE

ESTOP SWITCHES

SOLENOID VALVES

SPEED SENSOR

FUEL LEVEL SWITCH

PRESSURE TRANSDUCERS

TEMPERATURE SENSORS

BATTERY STARTING AND

CHARGING SYSTEM

W1

P2,P3

W1

P1

HOURMETER

CONTROL PANEL HARNESS

W1W1

6()

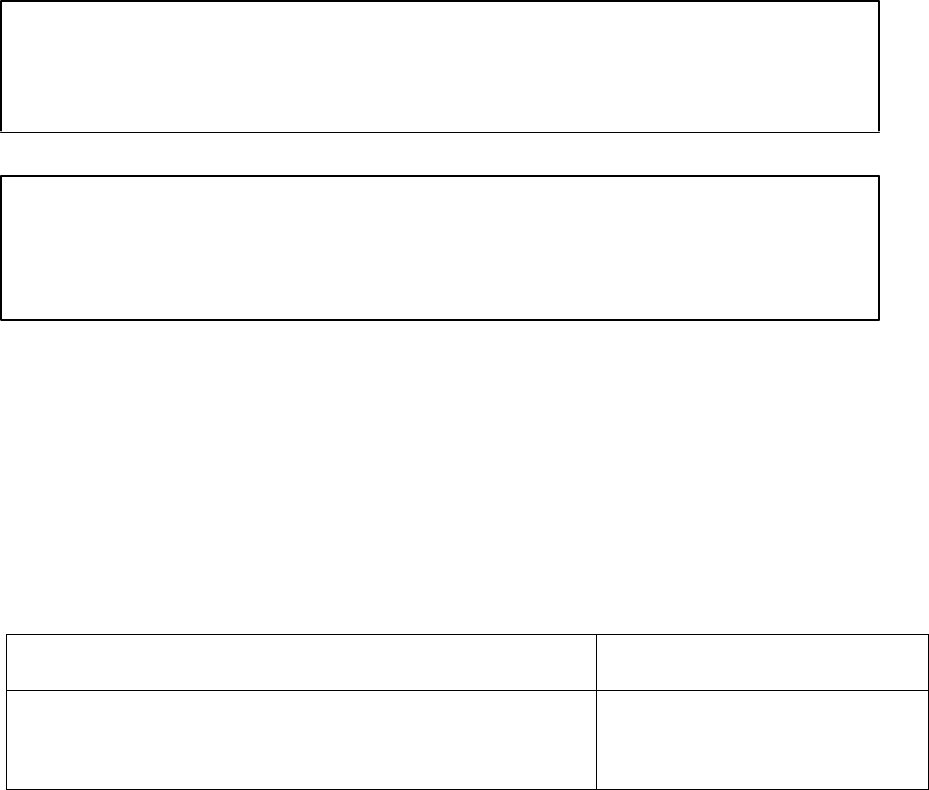

FIGURE 2--2

WEDGE

CONTROLLER

WEDGE TO ENGINE INTERFACE

CUMMINS ENGINE

J1--35

J1--34

J1--1

J1--37

J1--24

CUMMINS

ENGINE

CONTROLLER

J4--46

J4--47

J4--37

J4--39

J4--30

CAN HI

CAN LO

CANSHLD

J1--38

FREQ -- THT +

RANGE = 150 Hz (IDLE) to 375 Hz (Full Speed) AT 24VDC

KEY SWITCH

7()

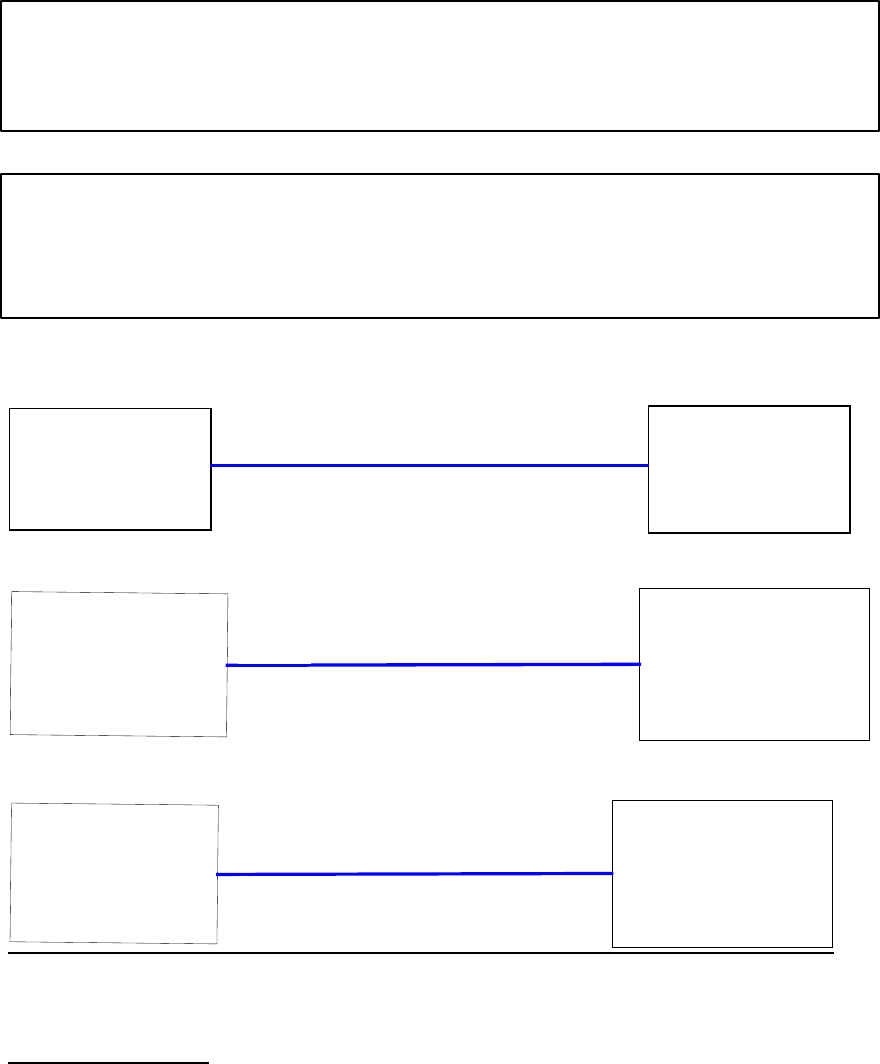

J1939 CAN COMMUNICATIONS SCHEMATIC

ENGINE

CONTROLLER

WEDGE

CONTROLLER

P14

TERMINATOR

TERMINATOR

ENGINE DIAGNOSTICS JACK

J11

TR1

TR2

CAN NODE WITH POWER

P15

P13

FIGURE 2--3

8()

The wedge uses the frequency throttle to communi-

cate with the engine. A s quare wave frequency signal

from 150 Hz to 375 Hz is sent from the WEDGE con-

troller to the engine controller.

The signal is a linear signal from 150 Hz at engine idle

to 375 Hz at maximum run speed.

Figure 2--2 shows the signals between the engine

controller and the WEDGE controller.

Sensors and Transducers

The electronics system contains sensors and trans-

ducers that are used to collect data from the compres-

sor. The temperature is measured by a thermistor.

This device exhibits a change in resistance as the tem-

perature changes. The resistance causes an input

voltage change to the WEDGE controller input and is

interpreted as a temperature change.

The electronics system also uses pressure transduc-

ers to measure compressor pressure changes. These

devices have an output signal of .45 VDC to 4.5 VDC,

corresponding to 0 psi and the maximum measured

psi for a particular device. The maximum pressure

transducer ranges are 100, 225 and 500 psi. The 100,

225 and 500 psi devices are gauge pressure devices.

These transducers are provided with 5 VDC excitation

to power the device. These are three wire devices: ex-

citation, signal and ground.

Digital Inputs and Outputs

The W EDGE controller scans digital inputs such as

switch contacts. These are either “ON” (24VDC) or

“OFF” (0 VDC). These digital inputs are connected to

switches within the package such as the key start

switch, air filter switches and IQ filter switches.

The WEDGE controller provides 24 VDC digital

outputs to control solenoids, start compressor and DC

heaters. These are 24 VDC “ON” and 0 VDC “OFF”.

They are current limited and short circuit protected.

Controller Outputs

The WEDGE controller has three types of outputs: fre-

quency, pulse width modulated (PWM) and 24 VDC

digital (ON /OFF). The frequency output is used as a

throttle signal for the engine.

The WEDGE controller varies the frequency from 150

Hz to 375 Hz, corresponding to idle to maximum

speed. The frequency signal is a 50% duty cycle, 24

VDC, square wave. This throttle signal is used with the

Cummins engine.

The PWM signal is used as a throttle signal for the Cat-

erpillar engine. It has a base frequency of 500 Hz and

the duty cycle varies from 10% to 90%.

Pressure Control

The discharge pressure is controlled by manipulating

the engine speed and compressor inlet valve position.

The inlet valve position is controlled pneumatically and

the engine speed is determined by the WEDGE con-

troller. The WEDGE measures the pneumatic system

regulation pressure and computes an engine throttle

setting. This throttle setting is sent to the engine via the

frequency throttle, PWM or J1939 throttle, depending

on which technique is used. The engine controller will

control engine speed to this throttle setting.

Electronic Engine

The mid--range machine contains an emissions

certified diesel engine. In order to meet the emissions

requirements, the engine has an electronic control

system.

The control system handles all monitor, alarm and

control functions for the engine. The WEDGE control-

ler communicates with the engine controller over the

J1939 CAN network.

The WEDGE controller sends throttle settings to the

engine and receives diagnostic and run time data from

the engine over the J1939 CAN network. A frequency

throttle interface is currently used with the engine.

Figure 2--2 shows the connections between the

WEDGE controller and the engine controller.

9()

J1939 Data Link

The CAN network is a single pair shielded cable

located with the W1 main harness. Figure 2--3 shows

a layout of the CAN harness or “backbone” as it is

referred to. The termination resistors (Terminator) are

important to prevent reflections on the transmission

line and must be in place for the network to function

properly. The shield from the cable is connected to the

machine metal at the WEDGE controller end.

This connection must be properly made with good

metal--to--metal contact between the wire terminal and

the machine metal.

The engine diagnostics connector is located on the left

side of the engine. This is used to connect the engine

manufacturer’s service tools to the CAN network. This

connector also provides 24 VDC to power these

service tools.

Electrical System

The electrical system consists of the wiring harnesses

and associated electrical devices such as relays,

switches, lights, solenoids and alarm horn. There are

two wiring harnesses on the machine. They are as fol-

lows:

22770879 W1 Chassis Main Harness

22784698 Control Panel Wiring Harness

The schematic diagrams show the connections for

these harnesses. Figure 2--1 is a system schematic

showing harness connection with devices and

controllers. Section 8 includes information on

connectors used in the harnesses.

The electrical circuits are protected using ATC style

fuses. A fuse should only be replaced with one of the

same rating. Replacing a fuse with one of a large

rating could lead to harness damage. If a fault occurs

and the circuit does not have the appropriate size fuse,

wires could be burned in the harness and damage

other circuits.

10()

KEY ELECTRICAL COMPONENTS FUNCTION

PT1:

PT1 is a 0--225 (or 0--500 depending upon machine model), psi gauge pressure transducer that measures

discharge air pressure.

PT2:

PT2 is a 0--100 psi gauge pressure transducer that measures regulation system pressure.

U1:

U1 is resistive level detector that measures the fuel level in the fuel tank.

It provides a continuous reading of fuel level. It also has a switch for low fuel level and low fuel shutdown.

These switches connect to WEDGE.

RT1:

RT1 is a 10K ohm Thermistor temperature sensor that measures separator tank temperature.

Its range is --30 to 255_ F.

RT2:

RT2 is a 10K ohm Thermistor temperature sensor that measures airend discharge temperature.

Its range is --30 to 255_F.

K1:

K1 is SPST, 24VDC relay used to activate the engine starter.

K2:

K2 is a SPDT, 24VDC relay used to s witch power.

K3:

K3 is a SPST, 24VDC relay used to power the engine air intake heater.

K4: K4 is a SPDT, 24VDC Relay used to power the IQ system option.

11()

OPERATING INSTRUCTIONS

OPERATING CONTROLS AND INSTRUMENTS

The operating controls and instruments are arranged on the control panel as shown above. A description of each

panel device is as follows:

1. Hourmeter: Records running time for

maintenance.

2. Compressor Discharge Pressure Gauge:

Indicates pressure in receiver tank.

3. Fuel Level Gauge: Indicates amount of fuel

in tank.

4. Power Switch: Activates systems for

STARTING and STOPPING.

5. Service Air Switch: After warm--up, PUSH.

Provides full air pressure at the service outlet.

Allows unit to warm--up at reduced pressure.

6. Engine Speed Gauge: Indicates engine

speed (RPM)

7. Discharge Air Temp. Gauge: Indicates

airend discharge temperature.

8. Engine Oil Pressure Gauge: Indicates

engine oil pressure.

9. Engine Water Temp Gauge: Indicates

coolant temperature.

10. Voltmeter: Indicates charging system

voltage.

11. Spare: Used for optional accessories.

12. Inlet Heater/Wait to Start Lamp: Indicates

engine manifold pre--heater is energized.

Wait until lamp extinguishes before engaging

starter.

12()

WEDGE DIAGNOSTIC DISPLAY

1 High Compressor Temp: Fault indicator lamp. Indicates shutdown due to high compressor temperature.

2. Low Engine Oil Pressure : Fault indicator lamp. Indicates shutdown due to low engine oil pressure.

3 . High Engine Coolant Temp: Fault indicator lamp. Indicates shutdown due to high engine water temperature.

4 . Low Fuel Level: Fault indicator lamp. Indicates shutdown due to low fuel level. Lamp blinkl warning.

5 . Low Battery Voltage:Alarm indicator lamp. Indicates battery or charging system requirer s ervice.

6 . Low Radiator Coolant Level: Alarm indicator lamp. Indicates engine coolant needs service.

13()

OPERATIONAL INFORMATION FOR LOW PRESSURE MACHINE

Power “ ON” at Control Panel:

1. Key switch signal (24VDC) supplied to engine controller by WEDGE controller

2. Frequency throttle signal OFF

3. Unloader solenoid valve (L2) is closed (de--energized)

Engine Start--up:

When the key is switched to the engine crank position:

1. Unloader solenoid valve (L2) is closed (de--energized).

2. Key switch signal (24VDC) is supplied to engine controller.

3. K1 auxiliary start relay is energized.

4. Run/Start solenoid valve (L1) is opened (energized).

Run/start solenoid stays open and unloader solenoid valve stays closed for 10 seconds after the key is

released if the engine does not start.

When the engine speed reaches 600 RPM (engine start declared):

1. Engine speed is set to 1500 RPM.

When the engine speed reaches 1450 RPM:

1. Unloader solenoid valve is opened (energized).(L2)

2. Run/Start solenoid valve is closed (de--energized). (L1)

When the separator tank pressure reaches 50 psi:

1. Run/Start solenoid valve is opened (energized). ( L1)

After 5 seconds:

1. Engine speed is set to idle (1200 RPM if air end discharge temperature is approximately 150 degrees

F or (if J1939 CAN is functioning) if the engine coolant is 100 degrees F. Otherwise, the engine idle

stays at 1500 RPM.

Loading:

When the “Service Air” switch is pushed:

1. Engine speed is set to 2000 RPM

When engine speed reaches 1900 RPM:

1. Run/Start solenoid valve is closed (de--energized).

After 2 seconds and if the regulation system pressure is 4 psi or greater:

1. Compressor pressure control is engaged.

14()

READING AND SETTING THE DISPLAY

UNITS

The WEDGE has four choices for display units:

_F, PSI

_C, Bars

_C, kPa

_C, Kg/cm2

To determine which units the WEDGE has been configured for:

1. With the machine power off (Key turned OFF)

2. Press and hold the “Service Air” Switch

3. Turn the key switch directly to the crank position.

4. Hold these switch positions until the 4 digit LED display on the WEDGE goes blank.

5. Release “Service Air” switch, release key switch to “ON”.

Units will be displayed for 2 seconds after which the current selection will be displayed as:

_F, PSI will be displayed as “PSI”

_C, Bars will be displayed as “bAr”

_C, kPa will be displayed as “HPA”

_C, Kg/cm2 will be displayed as “H9C”

To change the units setting:

1. With the WEDGE showing the current setting, press and release the “Service Air” switch until the desired setting

appears on the display.

2. Once it appears, do not release the “Service Air” switch. Hold it in the ON position until the WEDGE restarts.

This will select units selection that was displayed.

3. Release the “Service Air” switch. The compressor is ready to start.

15()

WEDGE SERVICE DIAGNOSTICS

The WEDGE controller provides a diagnostic capability that allows various internal parameters to be viewed on

the 4--digit LED display. These can be accessed with the machine stopped or while it is operating. If the machine

is stopped, the “Service Air” switch on the control panel is used to toggle through the list of parameters. If the ma-

chine is operating, the “ Start” position of the key switch is used. To view the parameters, toggle the switch or key

and a number (2--15) will appear on the LED display. After 3 seconds, it will extinguish and the parameter will be

displayed. The toggle only works in the ascending order direction, but it will wrap around and start over.

Display Parameter Remarks

2 RPM From Engine Flywheel Sensor

3 Engine RPM Filtered RPM Value

4 Reg. Sys. Pressure PSI

5 Sep. Tank Pressure PSI

6 Discharge Temperature Deg F

7 Sep. Tank Temperature Deg F

8 Engine Target RPM Wedge Signal to Engine

9 Machine Type *

10 Engine Coolant Temp. From CAN, Deg F

11 Engine Oil Temp. From CAN, Deg F

12 Engine Oil Pressure From CAN, PSI

13 Intake Manifold Temp. From CAN, Deg F

14 RPM From CAN

15 Fault Code List Cummins/CAT codes

16 Throttle Position

17 Boost Pressure

18 Engine Hours

19 Load at Speed Percent

20 Set Machine ID

16()

ENTERING MACHINE ID FOR WEDGE CONTROL SYSTEMS with V1.60 or Greater Software

For machines with the WEDGE controller mounted inside the control panel/instrument panel box, the “Service

Air” switch is used to enter the machine ID. Disconnect the fuel level gauge (located in the fuel tank) before

starting the process and reconnect once the process is completed.

For machines with the WEDGE controller mounted in the engine compartment, the rocker s witch beside the

WEDGE is used to enter the machine ID.

For the instructions below, the “Service Air” or rocker s witch will be referred to as the “data input switch”.

1. Examine the machine data plate to confirm the machine model.

Using the machine model and the machine models list on page 2 of this document, locate the proper

machine ID.

2. Turn power to the ”ON” position. Machine must not be operating.

3. Toggle the data input switch twice and the number “2” will appear on the WEDGE 4--digit LED display.

Continue to toggle the switch until the number “9” is reached. Read the machine ID on the

display, if it matches the proper machine ID in Step 1, stop. If not, proceed to step 4.

4. Continue to toggle the switch until number “19” is reached. Push and hold the data input switch and the

number “20” will appear. Continue to hold the switch. After 1 second, the current machine ID will appear in

the display. Continue to hold for 9 more seconds and a blinking “--” will appear. Release the switch.

5. Toggle the data input switch, the display will show “0”. Toggle the data input switch until the proper machine

ID appears on the display, then stop the toggle sequence.

6. Wait until the controller performs a reset function (or power up) (approximately 10 s econds). At reset, the

controller display first goes blank, then all annunciator LED’s light, the 4--digit LED display shows all 8’s,

the display then shows the installed software version and finally the display goes blank and the engine oil

pressure and alternator LED begin flashing. At this point the controller has stored the machine ID selected

in step 5.

7. Using the data input switch, toggle to service diagnostic number “9”.

The number “9” will appear for 1 second and then the machine ID will appear. The ID should be the same

as the one entered in steps 4--6. If not, go back to step 4 and enter the ID again.

17()

ESA Models/Wedge Machine

ID

Models

Machine ID

7/120,9/110. 10/105, 14/85 7

7/170. 10/125.14/115 8

9/230,9/270,9/300. 12/235 5

17/235,21/215 6

MSA Models/Wedge Machine

ID

Model Machine

ID

P425WJD, XP375 WJD, HP375WJD 7

VHP300WJD

P600WJD, HP450WJD, VHP400WJD 8

XP1060WCU, HP935WCU, MHP825WCU 5

VHP750WCU

XHP750WCU 6

MHP825WCAT, VHP750WCAT 2

XP1060HACAT,XP950HACAT

SHP825WCAT, XHP750WCAT. XHP650WCAT 3

HP1300CWCU,HP1600CWCU 0

XHP1170WCU 1

XHP1070AWCAT, XHP1170WCAT. XHP1170SCAT 4

HP1600WCAT 9

HP675EWCU, XP750EWCU, HP750EWCU, 10

XP825EWCU

SIRC Models/Wedge Machine

ID

Models

Machine ID

P1060WCAT, XP950WCAT, HP935WCAT 2

MHP825WCAT .VHP750WCAT

XHP750WCAT 3

18()

SECTION 3

SERVICE TOOLS

19()

SERVICE TOOLS

Service Tools

The following special tools are recommended to perform service procedures in this manual. The tools can

be purchased from Doosan Portable Power or other sources listed.

Tool Tool Description

22216691 Digital Multimeter (Fluke 87)

Used to measure electrical circuits; Volts, amps, ohms

54729660 Packard Weather--Pack Terminal Removal Tool

Used to repair Packard Electric Weather--Pack Connectors

54699632 Deutsch Terminal Removal Tool (Blue)

Used to repair Deutsch connectors

54699640 Deutsch Terminal Removal Tool (Red)

Used to repair Deutsch connectors

54699624 Deutsch Terminal Removal Tool (Yellow)\

Used to repair Deutsch connectors

22216667 Deutsch Terminal Crimp Tool (HDT--48--00)

Used to crimp Deutsch connector terminals

54729710 Electrical Contact Cleaner

Used to clean electrical contacts and connectors

54729728 PDA Service Tool

Used to load software & extract service and fault logs

54699616 Deutsch Terminal Removal Tool

Used to repair Deutsch connectors

54749544 RTD Simulator Plug

Used to test RTD circuits

54749551 Thermistor Simulator Plug

Used to test thermistor circuits for Intellisys controller systems

22073878 Thermistor Simulator Plug

Used to test thermistor circuits for WEDGE controller systems

54749635 Connector R epair Kit

Used to make connector repairs for Deutsch and Packard Electric Connectors

54699657 Deutsch Terminal removal Tool

Used to repair Deutsch connectors

54749643 Packard Metri--Pack Terminal Removal Tool

Used to repair Packard Electric onnectors

20()

22168868 Pressure Transducer Simulator

Used to test pressure transducer circuits

22147540 Test Adapter Kit Test adapters for various connectors to be

Used when making electrical measurements

22146393 Removal Tool Kit Assortment of most used Deutsch removal tools

22216675 Deutsch Crimp Tool (DTT --20--00)

Used to crimp Deutsch connector terminals

22216683 Packard Electric Crimp Tool (12155975)

Crimps 150 and 280 series pins

22255947 Packard Electric Crimp Tool (12039500)

Crimps 150 series pull to seat pins

22216709 Fluke Test Lead Set (TL20)

Contains needle probes, alligator clips, test leads

heat shrink tubing that are used on harnesses

22216725 Fluke Insulation Piercing Probe (AC--89)

Used to connect to a wire for measurements

22216733 Fluke Meter Case (C25)

Case for Fluke 87 meter including storage for test leads and probes

54740675 RS232 Heavy Duty Serial Cable

Connects lap top computer or PDA Service Tool

to WEDGE or Intellisys controller

22252969 Wire Terminal Kit

Contains a selection of terminals with

corresponding heat shrink tubing that are used on harnesses

22281588 Connector Wrench

22282107 5/32 “T” hex screwdriver wrench

22282172 1/4” Flex Shaft Nutdriver

Used to remove ECM connector on John Deere engines

22252993 WEDGE Connector Kit

Includes the 40--pin connector housing and pins for the harness connector

22253009 CAN Communications Adapter

Converts RS232 to J1939 CAN, used with lap top computer

or PDA Service Tool.

22253017 Adhesive Heat Shrink Assortment

Selection of most used heat shrink sizes

21()

22221303 Service Tool Kit

Kit consists of the following P/N’s: 22216691 22216667

22216675 22216683 54729660 54749643 54699657

22146393 22147540 22073878 54749635 22168868

22216709 22216725 22216733 54740675

22254775 ATC Fuse Assorlment Kit

Kit contains 5, 7--1/2, 10, 15,20,25, and 30 Amp fuses

22254734 Packard Crimp Tool (12014254) Crimps Sealed

Weather Pack Connector pins

22()

Tool No. Tool Description Tool Illustration

22216691

Digital Multimeter

54729660 Weather--Pack Terminal Removal Tool

54699632 Deutsch Terminal Removal Tool (Blue)

54699640 Deutsch Terminal Removal Tool (Red)

54699624 Deutsch Terminal Removal Tool (Yellow)

22216667 Deutsch Crimp Tool

23()

54729710

Electrical Contact Cleaner

54729728 Virtual Technician Service Tool Kit

54699616 Deutsch Terminal Removal Tool

54749544 RTD Simulator Plug

22073878 Thermistor Plug

54749635 Connector Repair kit

54699657 Deutsch Terminal Removal Tool

24()

54749643

Packard Metri--Pack Removal Tool

22168868 Pressure Transducer Simulator

22147540 Test Adapter Kit

22146393 Removal Tool Kit

22216675 Deutsch Crimp Tool

22216683 Packard Electric Crimp Tool

25()

22216709

Fluke Test Lead Set

22216725 Fluke Insulation Piercing Probe

(single probe)

22216733 Fluke Meter Case

54740675 RS232 Serial Cable

22252969 Wire Terminal Kit

26()

22281588

22282107

Connector Wrenches

22282172 1/4’’ Flex Shaft Nutdriver

22252993 WEDGE Connector Kit

22253009 CAN Communications Adapter

22253017 Adhesive Heat Shrink Assortment

27()

22255947

Packard Electric Crimp Tool

22254734 Packard Electric Crimp Tool

28()

SECTION 4

ELECTRONIC SYSTEMS TROUBLESHOOTING

PROCEDURES AND TECHNIQUES

29()

General

A thorough analysis of the problem is the key to successful troubleshooting. The more information known

about a problem, the faster and easier the problem can be solved.

Troubleshooting charts are included to act as a guide to the troubleshooting process. They are organized so

the easiest and most logical things are performed first. It is not possible to include all the solutions to problems

that can occur or list all possible problems. The charts are designed to stimulate a thinking process that will

lead to solution of the problem.

Basic Troubleshooting Steps

• Collect all facts concerning the problem

• Analyze the problem thoroughly

• Relate the symptoms to the basic electrical / electronic systems and components

• Consider any recent repairs that could relate to the problem

• Double c heck before replacing components

• Review the controller fault log for clues as to the problem

• Determine the cause of the problem and make a thorough repair

30()

MEASURING VOLTAGE, RESISTANCE,

FREQUENCY AND DUTY CYCLE

General Measuring Guidlines:

Since the electrical system uses sealed connectors and splices, access of test points can be difficult. It is rec-

ommended that a test probe kit be used to access the signals to prevent damage to wires and connectors.

Back probing connectors and insulation piercing test probes can cause damage that can cause future failures.

Measuring Voltage:

A digital voltmeter is recommended to make measurements. Voltage measurements are made by connecting

the R ED + lead to the desired signal and the BLACK lead to the common. The test lead connections must be

secure or incorrect readings will result. Use circuit common for the Black lead, not chassis ground or other

metal connection. Circuit common will be any of the BROWN wires or battery negative can be used.

IMPORTANT INFORMATION

DO NOT USE MACHINE FRAME, SHEET METAL, PIPING OR OTHER METAL COM-

PONENTS AS COMMON OR GROUND WHEN MAKING VOLTAGE OR FREQUENCY

MEASUREMENTS.

Measuring Resistance:

Extra care must be taken when making resistance measurements. Test probe connections are crucial to cor-

rect readings. Ensure the test probe makes a solid connection with the wire(s) or connector pin(s) under test.

the test probe kit may help with these types of measurements. Make sure system power is turned OFF while

making resistance measurements.

Measuring Frequency:

Frequency is measured in the same manner as voltage, but the meter is set for “HZ” or frequency. Good con-

nections are important or false readings will occur.

Measuring Duty Cycle:

To measure duty cycle, setup the meter as if measuring frequency or voltage. Select the “%” or duty cycle

function and take the measurements. As of the date of this writing, Fluke is the only known digital voltmeter

that has the duty cycle feature. The Fluke Model 87 Digital Meter has the duty cycle function.

31()

TROUBLE SHOOTING FLOW CHART

B

B

Control panel key is turned to “ON” position,

WEDGE controller annunciator lamps and 4

digit LED display do not come on

Check F1 fuse

Check operation of switch S1

Check wiring from S1 to WEDGE controller

Check battery voltage, ensure battery dis-

connect switch is turned ON

WEDGE controller annunciator lamps & 4

digit LED display initialize OK but alternator

lamp and engine oil pressure lamps do not

blink.

J1939 CAN communications not working –

Check for 24VDC key switch at engine, CAN

network wiring problem

Ensure 24VDC power to engine ECM

Check connector pins

Engine cranks but will not start

Ensure key switch (24VDC) at engine

Frozen fuel cooler or associated piping

Estop button pressed (ESA units) or

Estop jumpers not making connection

Clear active engine fault code

Engine does not crank when key turned to

crank position

Check switch S1

Check relay K1

Check starter solenoid

Check starter motor

Check WEDGE output to K1 relay

Check battery voltage

B

B

Compressor f ails to load

when “Service Air” switch pressed

Check Run/Start valve operation

Verify frequency throttle signal at engine

Check “Service Air” switch operation

32

COMPRESSOR FAULT CODES

DESCRIPTION AND TROUBLESHOOTING

Following, are the descriptions of the COMPRESSOR fault codes. These are indicated when the

“COMPRESSOR MALFUNCTION” lamp is illuminated. The compressor malfunction lamp is

shown on the control panel picture in Section 2 of this manual. It is indicated by Item number 9.

The engine fault codes are indicated by the “ENGINE MALFUNCTION” lamp that is located under

the “COMPRESSOR MALFUNCTION” lamp.

The engine fault codes are listed in Section 10 of this manual.

Be sure to determine which malfunction lamp is illuminated before beginning the troubleshooting

process.

33

COMPRESSOR CODE 1

Engine Speed Less Than 800 RPM

Explanation:

The WEDGE has received an engine speed less than 800 RPM for 30 seconds.

Effect:

Code 1 is a shutdown condition and will shutdown the machine.

TROUBLESHOOTING STEPS

Code 1

Action Result

Check engine fault codes for an engine

shutdown. Check for engine fuel system

restriction (filter).

34

COMPRESSOR CODE 2

Engine Speed Greater Than the RPM limit.

Explanation:

The WEDGE has received an engine speed greater than 2100 RPM for 30

seconds.

Effect:

Code 2 is a shutdown condition and will shutdown the machine.

TROUBLESHOOTING STEPS

Code 2

Action Result

Check engine fault codes for an engine

shutdown.

35

COMPRESSOR CODE 3

Engine Crank Time Exceeded

Explanation:

The engine crank time has exceeded 15 seconds.

Effect:

Code 3 is a shutdown condition and will shutdown the machine.

TROUBLESHOOTING STEPS

Code 3

Action Result

Crank engine for less than 15 seconds.

Book 22893804 (8-31-06) Rev. A

36

COMPRESSOR CODE 5

Engine Oil Temperature

Explanation:

The WEDGE has received an engine oil temperature greater than 252° F.

Effect:

Code 5 is an ALERT condition and will not halt machine operation.

TROUBLESHOOTING STEPS

Code 5

Action

Result

Step1:

Refer to the engine manufacturer’s service manual for

instructions.

Book 22893804 (8-31-06) Rev. A

37

COMPRESSOR CODE 6

Engine Intake Manifold Temperature

Explanation:

The WEDGE has received an engine intake manifold temperature greater than

180° F.

Effect:

Code 6 is an ALERT condition and will not halt machine operation.

TROUBLESHOOTING STEPS

Code 6

Action

Result

Step1:

Refer to the engine manufacturer’s service manual for

instructions.

Book 22893804 (8-31-06) Rev. A

38

COMPRESSOR CODE 8

Water in Fuel

Explanation:

The WEDGE has received a water in fuel indication from the engine.

Effect:

Code 8 is an ALERT condition and will not halt machine operation.

TROUBLESHOOTING STEPS

Code 8

Action

Result

Step1:

Check the machine fuel system and engine fuel filters.

Step 2:

Refer to the engine manufacturer’s service manual for

instructions.

Book 22893804 (8-31-06) Rev. A

39

COMPRESSOR CODE 10

Engine Not Responding To Throttle Command

Explanation:

The engine has not responded to a request from the WEDGE for engine speed

change during engine start. This ALERT will only occur during the idle speed

time, right after engine start.

Effect:

Code 10 is an ALERT condition and will not shutdown the machine. The

machine will not perform properly due to the low speed condition.

Throttle Circuits:

C

A

T

E

N

G

I

N

E

C

O

N

T

R

O

L

L

E

R

WEDGE

CONTROLLER

PWM

Throttle

J2-10 J1-38

Blu

W131

E

N

G

I

N

E

C

O

N

T

R

O

L

L

E

R

WEDGE

CONTROLLER

Analog

Throttle

J50-F2 J1-13

Blu

W054

Circuit Description:

J2-66

CUMMINS ENGINE

CONTROLLER

WEDGE

CONTROLLER

J40-30 W073 Freq Throttle Blue J1-38

Book 22893804 (8-31-06) Rev. A

40

As shown in the circuits above, the WEDGE provides three types of throttle

outputs: frequency, PWM and analog.

TROUBLESHOOTING STEPS

Code 10

Action

Result

Step1:

Measure the throttle signal at the engine connector.

If signal not present, check wiring

and verify throttle output at

WEDGE.

Step 2:

Engine may not be able to fuel properly due to restricted fuel

filters

Replace fuel filter (s)

Step 3:

Verify correct machine ID is installed.

Step 4:

Check connector pins at WEDGE controller and connector at

engine controller for corrosion.

Book 22893804 (8-31-06) Rev. A

41

COMPRESSOR CODE 11

Too Many Start Attempts During Auto Start

Explanation:

The WEDGE has made three attempts to start the machine as commanded by

the Auto Start Stop controller. The machine failed to start.

Effect:

Code 11 is a SHUTDOWN condition and will shutdown the machine.

TROUBLESHOOTING STEPS

Code 11

Action

Result

Step1:

Check the machine fuel system and engine fuel filters.

Step 2:

Check the condition of the machine batteries.

Step 3:

Cycle machine power, activate the Auto Start input so the

machine will make another start attempt. Machine will go

through 3 crank cycles to attempt start before a Code 11 is

issued.

Book 22893804 (8-31-06) Rev. A

42

COMPRESSOR CODE 29

Engine shut itself down: reason unknown

Explanation:

The engine has shut down. The WEDGE did not shut down the engine.

Effect:

Code 29 is a SHUTDOWN condition and will shutdown the machine.

TROUBLESHOOTING STEPS

Code 29

Action

Result

Step1:

Check the machine fuel system and engine fuel filters. Check

for loose fittings in the fuel piping that could allow air to be

drawn into the fuel system.

Step 2:

Verify the throttle signal from the WEDGE is continuously

supplied to the engine.

A quick drop in the throttle signal

could cause the engine to stop

Step 3:

Verify battery + and – connections to the engine controller,

inspect harness connections and measure voltage drop at

engine ECM.

Step 4:

In the case of the (John Deere) engine, check the

connections for the crank sensor which is mounted at the front

of the engine. Loose pin connections in the connector will

cause code 29.

Book 22893804 (8-31-06) Rev. A

43

COMPRESSOR CODE 31

Low Air End Oil Pressure

Explanation:

The WEDGE received a closed contact from pressure switch S6, located

in the air end on the machine. This indicates a low oil pressure in the

air end.

Effect:

Code 31 is a shutdown condition and will shutdown the machine. The

cause of the low air end oil pressure must be repaired to continue machine

operation.

S6 Pressure Switch Circuit:

WEDGE

CONTROLLER

J1-21

S9

Blu

Circuit Description:

Switch S6 is a 12 psi, normally open pressure switch. If the pressure falls below

12 psi, the switch will close, indicating to the WEDGE controller a low air end oil

pressure.

Component Location:

S6 is located in the back of the air end.

S6

Book 22893804 (8-31-06) Rev. A

44

TROUBLESHOOTING STEPS

Code 31

Action

Result

Step1:

Check the air end oil pressure with a mechanical gauge.

If > 12 psi, replace S6

If not, there is a harness or

WEDGE problem.

Book 22893804 (8-31-06) Rev. A

45

COMPRESSOR CODE 32

RT2, Discharge Temperature Sensor Fault

Explanation:

The WEDGE has received an out of limits reading from the RT2 temperature

sensor. This reading could be on the high or low end of the range. It is

out of the normal range for temperature measurement.

Effect:

Code 32 is a shutdown condition and will shutdown the machine.

RT2 Temperature Sensor Circuit:

R

T

2

T

e

m

p

e

r

a

t

u

r

e

S

e

n

s

o

r

WEDGE

CONTROLLER

1

2

J1-5

J1-6

Yel

Brn

W066

W025

Circuit Description:

The thermistor temperature sensor connects to the WEDGE controller as shown

in the schematic above. The temperature range of RT2 is –30 to 255 degrees F.

The thermistor is a 10K ohm device.

Component Location:

RT2 thermistor is located in the airend discharge pipe.

W003

W

00

4

Book 22893804 (8-31-06) Rev. A

46

TROUBLESHOOTING STEPS

Code 32

Action

Result

Step1:

Substitute the thermistor simulator (PN # 22073878) for RT2

Use the WEDGE service diagnostics to read the value for RT2

It should be approximately 32 degrees F.

Should read approx. 32 Deg F

If not, there is a harness or

WEDGE problem.

Book 22893804 (8-31-06) Rev. A

47

COMPRESSOR CODE 33

PT1 Pressure Transducer Sensor Fault

Explanation:

The WEDGE has received an out of limits reading from the PT1 pressure

transducer. This reading could be on the high or low end of the range. It is

out of the normal range for pressure.

Effect:

Code 33 is an ALERT condition and will not shutdown the machine. If the

Transducer is defective, the machine could shutdown due to an out of

range pressure

PT1Pressure Transducer Circuit:

P

T

1

P

r

e

s

s

u

r

e

T

r

a

n

s

d

u

c

e

r

WEDGE

CONTROLLER

Gnd

Sig

+5 VDC

A

C

B

J1-8

J1-7

Brn

Orn

Vio

W099

W098

W101

J1-10

Circuit Description:

The pressure transducer is a 3-wire device that connects to the WEDGE

controller as shown in the schematic above. The violet wire (W013) is the 5 VDC

excitation supply. This is spliced in the harness near the breakout for the

harness branch that goes to the separator tank. The “sig” wire is the output

signal that has a range o .45 to 4.5 volts DC. The pressure range of this

transducer is 0 – 225 psig.

Component Location:

PT1 pressure transducer is located in the top of the separator tank.

W

0

11

W

00

7

W

0

1

3

Book 22893804 (8-31-06) Rev. A

48

TROUBLESHOOTING STEPS

Code 33

Action

Result

Step1:

Substitute the pressure transducer simulator (PN # 22168868)

for PT1. Use the WEDGE service diagnostics to read the value

for PT1. It should be approximately 30 – 50 psi.

Should read 30 – 50 psi.

If not, there is a harness or

WEDGE problem.

Book 22893804 (8-31-06) Rev. A

49

COMPRESSOR CODE 34

Separator Tank Pressure Greater Than 20 psi at Crank

Explanation:

The WEDGE has received a pressure from PT1 that is greater than 20 psi at

The time of engine crank.

Effect:

Code 34 is a shutdown condition and will not allow the engine to crank. Once

The separator tank bleeds down below 20 psi, engine crank will be allowed.

Book 22893804 (8-31-06) Rev. A

50

COMPRESSOR CODE 35

Machine Over Pressure Condition

Explanation:

The WEDGE has received a pressure from PT1 that is greater than the limit.

Effect:

Code 35 is a shutdown condition and will shutdown the machine. The separator

tank high pressure has been exceeded.

TROUBLESHOOTING STEPS

Code 35

Action Result

Verify PT1 pressure transducer is reading

correctly.

The pressure simulator (PN#2216868) can

be substituted for PT1. This will verify

operation of harness and WEDGE controller.

Using the simulator, PT1 on the WEDGE

Diagnostics should read 30-50 psi.

Book 22893804 (8-31-06) Rev. A

51

COMPRESSOR CODE 50

Separator Tank Temperature

Explanation:

The WEDGE has received a separator tank temperature from RT1 that is

greater than 247 degrees F.

Effect:

Code 50 is a shutdown condition and will shutdown the machine.

TROUBLESHOOTING STEPS

Code 50

Action

Result

Step1:

Check for package air inlet restrictions.

Step 2:

Check for dirty or clogged coolers.

Book 22893804 (8-31-06) Rev. A

52

COMPRESSOR CODE 51

Machine ID Not Valid

Explanation:

The WEDGE has not received a reading from the machine ID.

Effect:

Code 51 is a shutdown condition and since a valid machine ID has not been

received the machine will shutdown.

Book 22893804 (8-31-06) Rev. A

53

COMPRESSOR CODE 53

RT1, Separator Tank Sensor Fault

Explanation:

The WEDGE has received an out of limits reading from the RT1 temperature

sensor. This reading could be on the high or low end of the range. It is

out of the normal range for temperature measurement.

Effect:

Code 53 is a shutdown condition and will shutdown the machine.

RT1 Temperature Sensor Circuit:

R

T

1

T

e

m

p

e

r

a

t

u

r

e

S

e

n

s

o

r

WEDGE

CONTROLLER

1

2

J1-4

J1-6

Yel

Brn

W067

W024

Circuit Description:

The thermistor temperature sensor connects to the WEDGE controller as shown

in the schematic above. The temperature range of RT1 is –30 to 255 degrees F.

The thermistor is a 10K ohm device.

Component Location:

RT1 thermistor is located in the side of the separator tank.

W002

W006

Book 22893804 (8-31-06) Rev. A

54

TROUBLESHOOTING STEPS

Code 53

Action

Result

Step1:

Substitute the thermistor simulator (PN # 22073878) for RT1

Use the WEDGE service diagnostics to read the value for RT1

It should be approximately 32 degrees F.

Should read approx. 32 Deg F

If not, there is a harness or

WEDGE problem.

Book 22893804 (8-31-06) Rev. A

55

COMPRESSOR CODE 54

PT2 Regulation System Sensor Fault

Explanation:

The WEDGE has received an out of limits reading from the PT2 pressure

transducer. This reading could be on the high or low end of the range. It is

out of the normal range for pressure.

Effect:

Code 54 is an ALERT condition and will not shutdown the machine.

PT2 Pressure Transducer Circuit:

P

T

2

P

r

e

s

s

u

r

e

T

r

a

n

s

d

u

c

e

r

WEDGE

CONTROLLER

Gnd

Sig

+5 VDC

A

C

B

J1-8

J1-9

Brn

Orn

Vio

W21

W100

W101

J1-10

Circuit Description:

The pressure transducer is a 3-wire device that connects to the WEDGE

controller as shown in the schematic above. The violet wire (W014) is the 5 VDC

excitation supply. This is spliced in the harness near the breakout for the

harness branch that goes to the separator tank. The “sig” wire is the output

signal that has a range o .45 to 4.5 volts DC. The pressure range of this

transducer is 0 – 100 psig.

Component Location:

PT2 pressure transducer is located in the pneumatic circuit near the compressor

inlet valve.

W

0

12

W

009

W

0

14

Book 22893804 (8-31-06) Rev. A

56

TROUBLESHOOTING STEPS

Code 54

Action

Result

Step1:

Substitute the pressure transducer simulator (PN # 22168868)

for PT2. Use the WEDGE service diagnostics to read the value

for PT2. It should be approximately 30 – 50 psi.

Should read 30 – 50 psi.

If not, there is a harness or

WEDGE problem.

57

COMPRESSOR CODE 55

Estop Button

Explanation:

The WEDGE has received an indication that the emergency stop button has

been pressed.

Effect:

Code 55 is a shutdown condition and will shutdown the machine. If the machine

Is in the cranking mode when estop is pressed, the starter will be disengaged

simultaneously with engine key switch signal turn off.

Emergency Stop Button Circuit:

WEDGE

CONTROLLER

CUMMINS

ENGINE

CONTROLLER

S4

J1-28

J1-24

K1

J2-38

2

34

1

Yel

Vio

J1-22

Vio

WEDGE

CONTROLLER

CAT

ENGINE

CONTROLLER

S4

J1-28

J1-24

K1

J2-26

2

34

1

Yel

Vio

J1-22 Vio

S7

S7

J2-70

Pnk

Pnk

1

2

Pnk

Pnk

J4-39

1

2

3

4

Book 22893804 (8-31-06) Rev. A

58

Circuit Description:

The estop button is in series with the engine key switch signal and the auxiliary

start relay, K1. Pressing the button opens both of these circuits simultaneously.

The WEDGE reads a sense input that is connected to the estop button to

determine if the estop button is pressed.

Component Location:

The estop button is located above the machine control panel on the front of the

machine.

TROUBLESHOOTING STEPS

Code 55

Action

Result

Step1:

If the estop button is installed, determine if it is pressed.

Release the estop button to

operate the machine.

Step 2:

If the estop button is not installed, a jumper plug will be

installed in the harness at the connection point for the estop

button, P8.

Verify the jumper plug is functional

Step 3:

Perform a continuity check of the harness wires from the

WEDGE through the jumper plug to the engine connector.

Book 22893804 (8-31-06) Rev. A

59

COMPRESSOR CODE 56

Minimum Pressure Not Met

Explanation:

The separator tank has not reached 50 psi within 20 seconds from time engine

starts.

Effect:

Code 56 is an ALERT condition and will not halt machine operation.

TROUBLESHOOTING STEPS

Code 56

Action

Result

Step1:

Check air piping system for restriction.

Step 2:

Verify engine speed has increased to full speed when Service

Air switch is pressed.

Book 22893804 (8-31-06) Rev. A

60

COMPRESSOR CODE 70

Serial Communications

Explanation:

The WEDGE controller cannot communicate with an external computer over the

RS232 serial link.

Effect:

This code can only occur when a laptop computer or PDA Service Tool is

Connected to the WEDGE. The WEDGE may otherwise be functional and

This event may not be mission disabling.

RS232 Communications Circuit:

J

5

R

S

2

3

2

C

o

n

n

e

c

t

o

r

WEDGE

CONTROLLER

J5-B

J5-A

J1-33

J1-32

TXD

RXD

Circuit Description:

The RS232 serial communications link is used for re-programming the WEDGE controller and is

the communications port used with the PDA Service Tool. The J10 connector contains the

RS232 port. It is normally located very close to the WEDGE. There are two signals associated

with the RS232, TXD and RXD. TXD is the transmit signal and RXD is the received signal.

Component Location:

The J10 harness connector is located near the WEDGE controller.

J

1

0

-B

J10-

A

J10

Book 22893804 (8-31-06) Rev. A

61

TROUBLESHOOTING STEPS

Code 70

Action

Result

Step1:

If the current RS232 device (laptop computer, etc.) will not

communicate with the WEDGE, substitute another RS232

device. Note: The second device must have proper software

loaded to communicate with the WEDGE.

If second device will not

communicate with WEDGE,

replace the WEDGE

Book 22893804 (8-31-06) Rev. A

62

COMPRESSOR CODE 71

CAN Communications

Explanation:

The WEDGE controller cannot communicate with the engine controller. The

J1939 CAN (Controller Area Network) broadcast of engine parameters cannot

be received.

Effect:

The WEDGE will not be able to display engine parameters using the diagnostic

Display function. The compressor will continue to operate since Code 71 is an

ALERT condition.

CAN Communications Circuit:

C

U

M

M

I

N

S

E

N

G

I

N

E

C

O

NT

R

O

L

L

E

R

WEDGE

CONTROLLER

CANH

CANL

SHLD

J2-46

J2-37

J2-36

J1-35

J1-34

J1-1

Yel

Grn

Gry

W151

W152

W199

C

AT

E

N

G

I

N

E

C

O

NT

R

O

L

L

E

R

WEDGE

CONTROLLER

CANH

CANL

SHLD

J2-17

J2-18

J2-16

J1-35

J1-34

J1-1

Yel

Grn

Gry

W151

W152

W150

J4-46 W150

J4-47

J4-37 W154

J2-50

J2-34

J2-42

Book 22893804 (8-31-06) Rev. A

63

J

o

h

n

D

e

e

r

e

E

N

G

I

N

E

C

O

NT

R

O

L

L

E

R

WEDGE

CONTROLLER

CANH

CANL

SHLD

J50-G1

J50-F1

J1-35

J1-34

J1-1

Yel

Grn

Gry

Circuit Description:

The CANH, CANL and SHLD wires are a cable that is located in the main harness. CANH refers

to CAN HI and CANL refers to CAN LO and SHLD is the shield of the CAN cable. This is the

cable that carries the communications between the engine and WEDGE controller and any other

devices that are connected to the CAN cable. This cable is also referred to as the CAN Network

since it may have multiple devices connected to it.

The CAN network has two terminating resistors, one located near the engine controller and one

near the WEDGE controller. The value of each of these resistors is 120 ohms. They are

connected in parallel, as shown below, across the network. The resistors are mounted in a

special Deutsch connector.

CUMMINS

ENGINE

CONTROLLER

WEDGE

CONTROLLER

R4

R5

CANH

CANL

Component Location:

The Cummins engine controller is located on the left side of the engine. Connector J4 is located

on the left side of the controller and is the OEM connector. The machine harness (P4) plugs into

the J4 connector. The CAT controller is located on the left side of the engine. The harness P4

connector plugs into the CAT J61 customer connector located near the controller.

The WEDGE controller is mounted to the machine control panel on the back side. Resistor TR2

is stubbed out of the harness near the engine controller and resistor TR1 is stubbed out of the

harness near the WEDGE controller.

TR2

TR1

Book 22893804 (8-31-06) Rev. A

64

TROUBLESHOOTING STEPS

Code 71

Action Result

Step 1:

Verify P1 harness connector pins 34, 35, and 1 are firmly seated into

The connector at the WEDGE controller.

Step 2:

Verify P4 harness connector pins 46, 47, and 37 for Cummins engine

or pins 50, 34, and 42 for CAT engine are firmly seated into the

connector at the engine electronic controller.

Step 3:

Setup the digital multimeter to read ohms. (Refer to the section in this

manual on how to use the multimeter). Disconnect P1 harness

connector from the WEDGE controller. If the engine is a Cummins,

disconnect the P4 harness connector from the engine controller.

If the engine is a CAT engine, leave P2 connected to the engine

Controller.

Connect one of the multimeter test leads to P1-34 and the other test

Lead to P1-35.

Meter should read

approximately 60 ohms. If so,

go to Step 5. If not, go to Step

4.

Step 4:

If you did not get the results of Step 3, there is a problem with the wiring

harness. This problem could be a defective splice, broken wire or

defective wire connection at a pin. The CANH and CANL wires should

be tested for continuity from P1 to P2. The resistor stub outs should be

tested for continuity.

Make harness repairs as

necessary.

Step 5:

Setup the multimeter to read DC volts. (Refer to the section in this

manual on how to use the multimeter). The harness should be

connected to the engine controller and the WEDGE controller.

Turn the machine power to the “ON” position, but do not start the

engine. Using insulation piercing probes (P/N 22216725),

connect the red multimeter lead to P1-34 wire and connect the black

multimeter lead to the battery negative post or one of the brown wires

on the back of the control panel.

Book 22893804 (8-31-06) Rev. A

65

Disconnect the test lead from P1-34 wire and connect to P1-35 wire.

Multimeter should read

approximately 2.5 volts DC.

Multimeter should read

approximately 2.5 volts DC.

If 2.5 volts cannot be read,

replace WEDGE controller. If

WEDGE controller is OK,

harness should be checked as

outlined in Step 4.

Book 22893804 (8-31-06) Rev. A

66

COMPRESSOR CODE 73

Auto Start Stop Controller Communications Failure

Explanation:

The WEDGE has not been able to communicate with the Auto Start Stop

controller for 17 seconds. A communications failure is determined.

Effect:

Code 73 is an ALERT condition and will not stop the machine. The Auto Start

system may not function properly due to communications failure.

TROUBLESHOOTING STEPS

Code 73

Action

Result

Step1:

If CAN communications is OK with the engine, check the CAN-

power stub connection for the Auto Start module. If CAN with

the engine is not working, check CAN wiring in harness.

Step 2:

Verify the Auto Start controller has power and ground.

Step 3:

Replace the Auto Start module.

67()

SECTION 5

SYSTEM SCHEMATIC DIAGRAMS

72()

SECTION 6

ELECTRONIC COMPONENT

LOCATION DRAWINGS

73()

HARNESS CONNECTOR LOCATIONS

J1: Located on back of WEDGE controller

J4: 50 pin connector located on engine electronic controller

P5: 4 pin connector located on engine electronic controller

P13: 3 pin connector for termination resistor on CAN backbone near Engine electronic controller

J11: 9 pin connector for Cummins datalink service, located near engine controller

P15: 3 pin connector for termination resistor on CAN backbone nearWEDGE controller

P7: 4 pin connector for IQ System option located inside instrument panel

J10: 9 pin connector for RS232 communications, located behind control panel

P14: 6 pin CAN buss acc. option located inside front door on left side

74()

SECTION 7

INDIVIDUAL CIRCUIT DIAGRAMS

75()

J1--28

YEL

K1

STARTER

B1

24VDC

M

S

B+

BRN

YEL

-- -- -- -- -- -- -- --

CHART A1

ENGINE START CIRCUIT

P1--28

WEDGE

W070 Red--Yel

W076

W102

1

2

W071 RED

V1.5

W044

Estop

or

Jumper

W171

Yel

76()

CIRCUIT DESCRIPTION

The WEDGE drives the engine starter through the auxiliary start

relay, K1.

K1 is mounted on the lifting bail near the engine.

K1 has a single set of contacts that connect to the starter solenoid.

The control signal leaving the WEDGE on J1--28 passes through the

W1 harness and through a jumper plug. The jumper plug is replaced

with an ESTOP switch for ESA versions.

If the starter will not engage during a crank cycle, check the voltage

at the coil of K1 during the crank cycle. It should be 14--22VDC. If

voltage is not at K1, check for voltage back through the ESTOP

jumper and to the WEDGE.

If voltage is at K1 coil, verify voltage is sent to the starter solenoid

by K1 contact.

CIRCUIT TROUBLESHOOTING

Voltage available at the starter solenoid during a no--crank condition

indicates a starter problem.

77()

CHART B1

CIRCUIT TROUBLESHOOTING

CIRCUIT

DESCRIPTION

U1 FUEL SENDER CIRCUIT

The fuel sender is a resistive device that sends a 10--180 ohm signal to the fuel gauge

indicating fuel level. It also contains two switches, one for low fuel level and another

that will shutdown the machine when the fuel reaches this level. These two switch

inputs connect to the WEDGE controller.

If the fuel reading appears incorrect, check the fuel level in the tanks to see if it

corresponds with the gauge. If not, remove the fuel sender and disconnect t he

harness plug. Connect an ohmeter across terminals A and B on the Packard

Weather--Pack connector. Tilting the sender tube should produce resistance

reading between 10 and 180 ohms. If not, replace the sender.

The two switches can be checked with the sender removed from the tank. Use an

ohmeter to verify switch operation. Tilting the sender tube back and forth should

activate the switches.

o

C

o

D

o

E

o

F

ALERT

SHUTDOWN

U1

Fuel Level Sender

W098

BRN

W099

BRN

WEDGE

J1--17

P1--17

W016

BLU

W017

BLU

P1--18

J1--18

WEDGE

B

A

→

→

to control panel fuel level

to ground

W027

W100

78()

CHART C1

CIRCUIT TROUBLESHOOTING

CIRCUIT

DESCRIPTION

RT1 SEPARATOR TANK TEMPERATURE

CIRCUIT

J1--4

P1--4

YEL

1

2

BRN

P1--6

J1--6

RT1

SEPARATOR TANK

TEMP SENSOR

Separator tank temperature is read by RT1 thermistor. It is mounted in the side of the

separator tank and connects to the W1 harness. The temperature range is --30 to

255_F.

If the WEDGE Controller has an incorrect reading for the RT1 channel, disconnect the

thermistor and install the Thermistor Simulator Plug (PN# 22073878) into the harness

connector. Read the channel again and it should read 32 degrees F ± 5 degrees

(0C ± 3C). If the reading is correct, replace the thermistor. If not, disconnect the

WEDGE Controller P1 connector. Connect an ohmmeter between pins P1--4 and

P1--6. The ohmmeter should read 33.2K ohms ±1%. If the reading is correct, replace

the WEDGE Controller. If not, there is a problem with the W1 harness or the P1--4,

P1--6 connector pins.

W002

W006

WEDGE

CONTROLLER

WEDGE

CONTROLLER

--20 --4 25,490

--10 14 18,088

--5 23 12,221

0 32 9,369

5 41 7,240

15 59 4,427

25 77 2,786

40 104 1460

60 140 668.7

70 158 467.2

90 194 241.0

100 212 177.5

105 221 153.1

110 230 132.8

Tem p_C

Tem p_F

Resistance

(Ohms)

79()

CHART D1

CIRCUIT TROUBLESHOOTING

CIRCUIT

DESCRIPTION

RT2 AIREND DISCHARGE TEMP

J1--5

W1 P1--5

YEL

1

2

BRN

P1--6

J1--6

RT2

AIREND DISCHARGE

TEMP SENSOR

Airend discharge temperature is read by RT2 thermistor. It is mounted in the airend

discharge piping and connects to the W1 harness. The temperature range is --30 to

255_F.

If the WEDGE Controller has an incorrect reading for the RT2 channel, disconnect the

thermistor and install the Thermistor Simulator Plug (PN# 22073878) into the harness

connector. Read the channel again and it should read 32 degrees F ± 5 degrees

(0C ± 3C). If the reading is correct, replace the thermistor. If not, disconnect the

WEDGE Controller P1 connector. Connect an ohmmeter between pins P1--5 and

P1--6. The ohmmeter should read 33.2K ohms ±1%. If the reading is correct, replace

the WEDGE Controller. If not, there is a problem with the W1 harness or the P1--5,

P1--6 connector pins.

W003

W005

WEDGE

CONTROLLER

WEDGE

CONTROLLER

--20 --4 25,490

--10 14 18,088

--5 23 12,221

0 32 9,369

5 41 7,240

15 59 4,427

25 77 2,786

40 104 1460

60 140 668.7

70 158 467.2

90 194 241.0

100 212 177.5

105 221 153.1

110 230 132.8

Tem p_C

Tem p_F

Resistance

(Ohms)

80()

CHART E1

CIRCUIT TROUBLESHOOTING

CIRCUIT DESCRIPTION

PT1

SEPARATOR TANK

PRESSURE TRANSDUCER

P1--8 BRN

P1--7 ORN

PT1 SEPARATOR TANK

PRESSURE CIRCUIT

J1--8

J1--7

J1--10

P1--10 VIO

A

C

B

5VDC+

SIG (+)

GND

The WEDGE reads separator tank pressure from PT1. It is a gauge pressure

transducer mounted on the separator tank. The WEDGE provides 5 VDC excitation

voltage to pin B (+5) and pin A (GND). The pressure signal on pin C connects to the

WEDGE input. The signal range is .45 to 4.5 volts. The transducer range is 0 to 225

psig, or 0--500 psig.

To verify the operation of PT1, connect a gauge in parallel with it. The test gauge

should be at least 1% accuracy to match the accuracy of PT1. Use the WEDGE

diagnostics to display the readings of PT1. If PT1 does not track the test gauge,

replace it.

WEDGE

CONTROLLER

W008

W007

W010

W1

HARNESS

81()

CHART F1

CIRCUIT TROUBLESHOOTING

CIRCUIT

DESCRIPTION

PT2

REGULATION SYSTEM

PRESSURE TRANSDUCER

P1--8 BRN

P1--9 ORN

PT2 REGULATION SYSTEM

PRESSURE CIRCUIT

J1--8

J1--9

J1--10

P1--10 VIO

A

C

B

5VDC+

SIG (+)

GND

The WEDGE reads regulation system pressure from PT2. It is a gauge pressure

transducer mounted near the inlet unloader. The WEDGE controller provides 5 VDC

excitation voltage to pin B (+5) and pin A (GND). The pressure signal on pin C

connects to the WEDGE input. The signal range is .45 t o 4.5 volts. The transducer

range is 0 to 100 psig.

To check the operation of PT2, connect a gauge in parallel with it. The test gauge

should be at least 1% accuracy to match the accuracy of PT2. Use the WEDGE

diagnostics to display the readings of PT2. If PT2 does not track the test gauge,

replace it.

W008

W009

W010

WEDGE

CONTROLLER

W1

HARNESS

82()

CIRCUIT DESCRIPTION

DC HEATER CIRCUIT

A DC heater system is provided to prevent the orifices from freezing in cold tem-

peratures. It is turned on by control panel switch, S3. Fuse F1, a 20 amp fuse,

supplies power to the heaters.

+24V

“Heaters” switch on control panel

S3

W021

BLU

HR1--1

HR1

HR1--2

W097

BRN

GND

HR1 = Regulation Heater

CHART G1

83()

CIRCUIT DESCRIPTION

S4, S5 AIR FILTER SWITCHES

CHART I1

The WEDGE reads the air filter switches, S4 and S5. S5 is connected to the com-

pressor air filter and S4 is connected to the engine air filter. These are normally open

switches and close when the air filter restriction reaches 20 inches of water. The

switches provide a ground connection to an opto coupler input on the WEDGE con-

troller.

WEDGE

CIRCUIT TROUBLESHOOTING

To verify the circuit operation, another type of switch can be substituted for the filter

switch, or a wire jumper can be used to activate the circuit. Disconnect S4 and S5

and install the test switch or jumper. Closing the test switch or installing the jumper

should activate the circuit, and the “Air Filter” alarm light on the control panel should

light. Forcing the alarm lamp to turn on and off will verify proper circuit operation.

W001 BLU

P1--2 J1--2

W028

BLU

S5--1

S5

W029

BRN

S4--1

W093

BRN

S4

84()

CIRCUIT DESCRIPTION

U2 ENGINE COOLANT LEVEL SENSOR

CHART K1

Pin

OutOfWater

In Water

U2

Coolant Sensor

P4

21 28 32

W1 Harness

W057 blu

W058 blu

W059 blu

AB C

The engine coolant level sensor is an impedance probe mounted in the radiator top

tank. The probe connects to the engine controller. The sensor is powered by a 5VDC

supply from the engine controller. The sensor connects to the engine controller at the

J4 connector, near the engine controller.

CIRCUIT

TROUBLESHOOTING

If the probe fails shorted, it can pull down the 5VDC supply and cause other sensors

to not function properly. If a sensor problem is suspected, check to see if engine

fault codes have been set.

The probe can be tested, using a container of water. Pin A connects to +5VDC, Pin

C to ground. Pin B is the output. Using a container of water, they should operate as

follows:

B5.0V

0V

85()

SECTION 8

ELECTRICAL CONNECTOR INFORMATION

86()

CONNECTOR PARTS INFORMATION

The following is a list of the connector parts used with the harnesses and devices on the machine. Most connectors

consist of 1 to 4 items per side (harness or device). The devices can be located on the schematics and then refer-

enced to this list. A connector repair kit, P/N 54749635, containing terminals and housings, is available for

repairs.

PART

Manufacturer Part No.

RT1, RT2

Plug, 2 Way Packard 22869515

TPA, 2 Way Packard 22969523

Seal, Cable Packard 54750567

Contact, Female Packard 22869531

PT1,PT2

Plug, 3 Way Packard 22869499

TPA, 3 Way Packard 22869754

Seal, Cable Packard 22869762

Contact, Female; 18AWG Packard 22869507

U1, Fuel Level

Plug, 6 Way Packard 22869416

Seal, Cable Packard 54750567

Contact, Female Packard 54750526

P1, Wedge Controller

Plug, 40 Way Deutsch 22868939

Socket, 16 AWG, Tin Stamp Deutsch 22869044

Socket, 16 AWG, Gold Stamp Deutsch 22869069

Socket, 14 AWG, Tin Stamp Deutsch 22868947

P4, Cummins Engine Control

Plug, 50 Way Deutsch 22869580

Backshell, 50 Way Deutsch 22870026

Seal Cavity, Size 20 Deutsch 22870018

Socket, 20 AWG, Gold Stamp Deutsch 54699608

U2, Coolant Level Sensor

Plug, 3 Way Packard 22880926

TPA, 3 Way Packard 22870067

Seal, Cable Packard 54750682

Plug, Sealing Packard 22869465

Contact, Female Packard 54750674

P5, Cummins Power Connect

Plug, 4 Way Deutsch 22869986

Wedge, Lock, 4 Way Socket Deutsch 22870042

Socket, Size 12, Tin Stamp Deutsch 22880710

87()

P2 Control Panel

Plug, 12 Way Deutsch 22871842

Wedge Lock, 12 Way Deutsch 22871859

Socket Size 16, Tin Stamp Deutsch 22869044

P3 Control Panel: P14, Accessory Connector

Plug6Way Deutsch 22868988

Wedge Lock 6 Way Deutsch 22868996

Socket, Size 14, Tin Stamp Deutsch 22868947

Socket, Size 16, Gold Stamp Deutsch 22869069

Socket, Size 16, Tin Stamp Deutsch 22869044

P7, IQ Option: P8, Emergency Stop Option

Plug, 4 Way Deutsch 22869002

Wedge Lock, 4 Way Deutsch 22869028

Socket, Size 16, Tin Stamp Deutsch 22869044

Socket, Size 16, Gold Stamp Deutsch 22869069

P13, P15: Can Buss

Plug, 3 Way Deutsch 22869150

Wedge Lock, 3 Way Deutsch 22870000

Socket, Size 16, Gold Stamp Deutsch 22869069

TR1, TR2: Can Terminator

Resister Plug Assembly Deutsch 54750633

J10 Wedge Comms

Receptacle, 9 Way Deutsch 22871875

Cap, Dust w/Lanyard Deutsch 22869085

Seal, Cavity, 12--16 AWG Deutsch 22868954

Pin, Size 16, Gold Stamp Deutsch 22869093

J11 Data Link Service

Receptacle, 9 Way Deutsch 22869994

Cap, Dust, w/Lanyard Deutsch 22869085

Pin, Size 16, Gold Stamp Deutsch 22869093

J8

Receptacle, 4 Way Deutsch 22869036

Wedge Lock, 4 Way, Pin Deutsch 22880876

Pin, Size 16, Gold Stamp Deutsch 22869093

G1, Engine Alternator

Plug, 4 Way Packard 22880918

TPA, 4 Way Packard 22870083

Seal, Cable Packard 54750682

Terminal, Female Packard 54750674

Seal, Cavity Packard 22869465

88()

F1, F2; Fuse Connectors

Connector, 2 Way; Fuse Packard 22871677

Cover, Fuse Packard 22871735

Terminal, Female; 12--10 AWG Packard 22869432

D1--D2; Diodes

Diode, Molded M/F Doosan 35376169

Connector, Over Mold; M/F Doosan 36882694

Shur RCPT .180 dia. AMP 22869606

Shur Plug .180 dia. AMP 22869598

M2 Control Panel

Housing, Connector; 3 Way Siemens VDO 22972089

Pin, Connector, 14--18 AWG AMP 22872097

J2 Control Panel

Receptacle, 12 Way Deutsch 22880942

Wedge Lock, 12 Way Deutsch 22880934

Seal, Cavity; Size 12--16 Deutsch 22868954

Pin, Size 16, Tin Stamp Deutsch 22880405

J3 Control Panel

Receptacle, 6 Way Deutsch 22869051

Wedge Lock, 6 Way Deutsch 22880959

Pin, Size 16, Tin Stamp Deutsch 22880405

Seal, Cavity; Size 12--16 Deutsch 22868954

S1 -- Key Switch

Plug, 4 Way Packard 22881966

TPA, 4 Way Packard 22871974

Terminal, Female Packard 22871982

89()

REMOVAL TOOL USAGE

Terminal

Part Number Manufacturer Removal Tool No.

54699525 Deutsch 54699624

22869044 Deutsch 54699632

22869069 Deutsch 54699632

22868947 Deutsch 54699624

22869093 Deutsch 54699632

22880405 Deutsch 54699632

22880413 Deutsch 54699624

54699608 Deutsch 54699640

22880710 Deutsch 54699624

22869531 Packard 54749643

22869507 Packard 54749643

54750526 Packard 54749643

54750674 Packard 54749643

54699525 Packard 54749643

22869044 Packard 54749643

22869432 Packard 54749643

22869424 Packard 54749643

22871982 Packard 54749643

90()

Deutsch DT Series Connector

(Note the orange wedgelock)

Packard Metri Pack Series Connector

(Note the green wire seals and blue Terminal

Position Assurance Connection)

Deutsch HD Series Connector

Deutsch DRC Series Connector

It is very important that connectors be properly

assembled. Use of the correct pin crimp tool is

required to ensure high quality terminations. The

manufacturer’s instructions must be followed as to

selection and use of crimp tools. Improper crimps

not only provide unreliable connections but can

damage the connector housing.

Troubleshooting Harnesses -- For extensive har-

ness troubleshooting, a detailed schematic will be

required. Splice location details can be very useful

since problems do occur at splices.

The proper test adapters are recommended for

harness troubleshooting. Some examples of these

are s hown in Section 2 concerning multimeters.

Use of these adapters will prevent harness dam-

age during testing.

The first item to perform during harness trouble-

shooting is a physical inspection of the harness

for damage. Look for cut or frayed conductors,

melted insulation and conductors pulled from con-

nectors.

The next item to check is connector pin seating.

Ensure the connector pins in the circuit under test

are properly seated in the connector housing. A

tug on the wire should confirm this.

If the harness is not physically damaged and all

connector pins are seated, perform a continuity

check of the circuit conductors. The ohmeter func-

tion of the multimeter can be used for this test.

Check to ensure there are not any ground

faults or conductor shorts to ground.

Finally, measure the signals on the circuit

under test. Start at the point of origin of the

signal and verify at as many points along the

harness as possible, ending at the termination

point.

91()

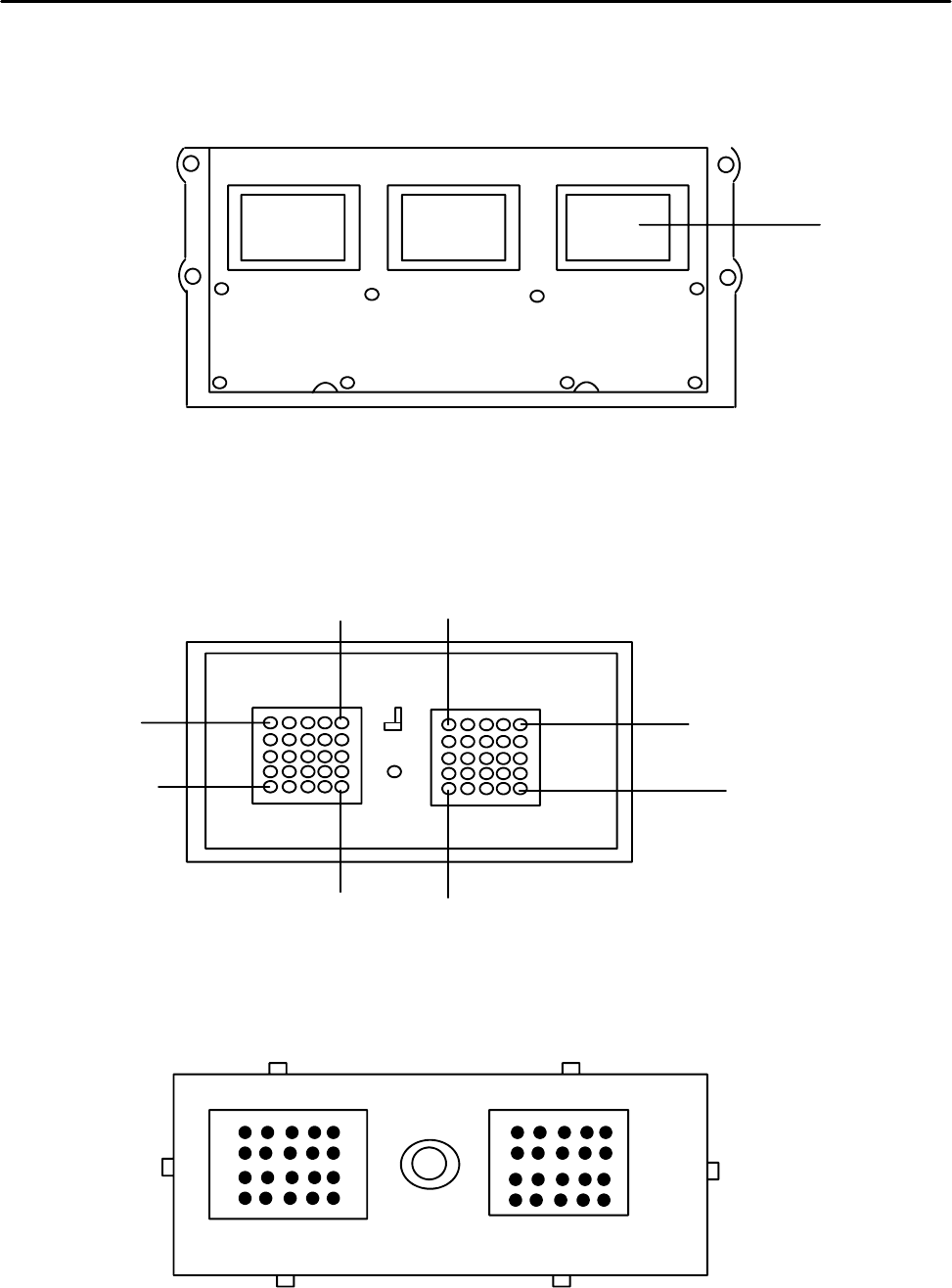

Use of Harness Tools

These pictures describe the proper methods of

use of harness tools.

Proper removal tool usage is shown in the above

picture. The removal tools are color coded as to

wire size. The Table below lists the colors and

wire sizes.

Removal

Tool Color Wire Size

P/N

Red 20--24 54699640

Blue 16--18 54699632

Yellow 12--15 54699624