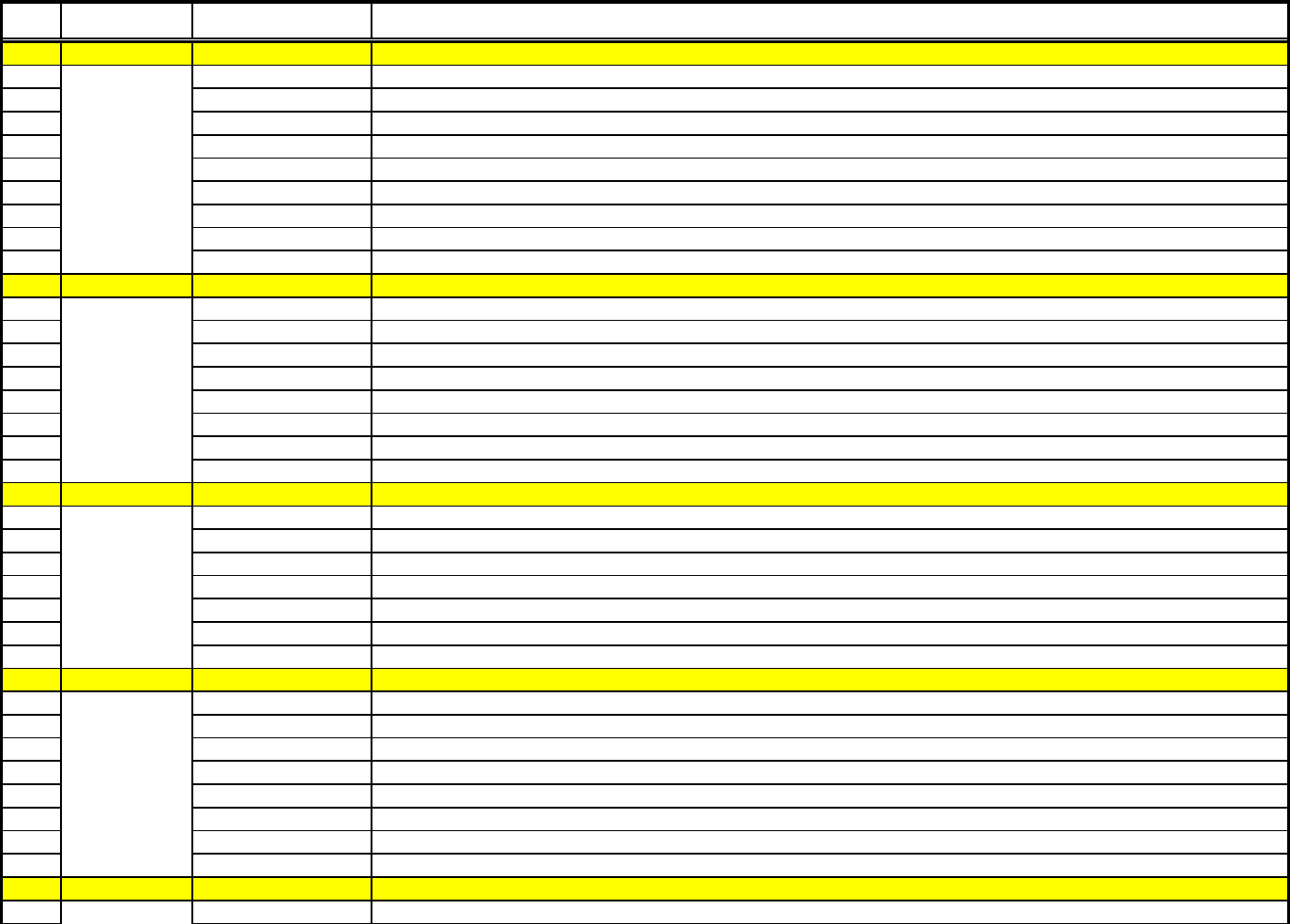

Regulatory Code Quick Reference

Item #

Part

TFER Regulation Code

TFER Quick Reference

Priority Items

1

228.75(d)(1)(A)

Cooling -- within 2 hours, 135-70°F

1

228.75(d)(1)(B)

Cooling -- total 6 hours, 135-41°F

1

228.75(d)(2)

Cooling -- ingredients from ambient within 4 hours to 41°F

1

228.75(d)(3)

Food received cooled within 4 hours to 41°F

1

228.75(d)(4)

Raw shelled eggs immediately placed at 41°F

1

228.77(4)(B)(v)

Cook-Chill or Sous Vide. Sealed package/bag cooled to 41°F

1

228.71(d)(2)

Non-continuous cooking process immediately cooled after initial heating

2

228.75(f)(1)(B)

Cold Hold (41°F/45°F or below)

2

228.75(f)(2)

Eggs not treated to destroy Salmonellae stored in refrigerator maintains an ambient air temperature 7°C (45°F) or less.

2

228.77(4)(B)(v)(I)

Cold Hold (41°F/45°F or below)--Cook-Chill or Sous Vide (30 Day)

2

228.77(4)(B)(v)(II)

Cold Hold (41°F/45°F or below)--Cook-Chill or Sous Vide (7 Day)

2

228.77(4)(B)(v)(III)

Cold Hold (41°F/45°F or below)--Cook-Chill or Sous Vide--frozen

2

228.71(d)(3)

Cold Hold (41°F/45°F or below)--non-continuous cooking

2

228.106(k)(1)(A)

Machine vending--Cold Hold (41°F/45°F or below) criteria

2

228.106(k)(2)(A)

Machine vending--automatic shut off-- Cold Hold (41°F/45°F or below)

3

228.75(f)(1)(A)

Hot Hold (135°F or higher)

3

228.77(4)(B)(iv)

COOK-CHILL/SOUS VIDE. Sealed

3

228.71(d)(5)

NON-CONTINUOUS COOKING. Hot Hold (135°F or higher)

3

228.106(k)(2)(B)

Vending Machine. Hot Hold (135°F or higher)

4

228.71(a)(1)(A)(i)

Raw eggs prepared for immediate service cooked to 145°F for 15 seconds

4

228.71(a)(1)(B)

Is Comminuted meats (tenderized, injected) cooked to 68°C (155°F) for 15 seconds

4

228.71(a)(2)(B)

Pork roasts and beef roasts cooked to 130°F for 112 minutes or according to oven parameters per chart

4

228.71(a)(1)(C)

Is Poultry; stuffed fish/meat/pasta/poultry/ratites cooked to 165°F for 15 seconds

4

228.71(a)(3)(C)

Is whole-muscle, intact beef steaks cooked to surface temperature of 145°F on top and bottom

4

228.71(a)(1)(A)(ii)

Are all other raw animal foods (such as seafood, pork) cooked to 145°F for 15 seconds

4

228.71(b)(3)

Microwave cooking criteria (heated to 165°F)

4

228.71(d)(1)

Non-continuous cooking process > 60 minute duration

4

228.71(d)(4)

Non-continuous cooking process -- time/temperature requirements

4

228.77(4)(B)(ii)

Cook-Chill or Sous Vide process -- cooking time/temperature requirements

4

228.71(c)

Fruits, vegetables or other plant based foods cooked to a minimum of 135°F for hot holding

4

228.223(d)(3)

OUTFITTER OPERATION-- onsite cook and serve requirements

5

228.73(a)

Rapidly reheat 165°F for hot holding

5

228.73(b)

Reheat 165°F--microwave

5

228.73(c)

Commercially processed ready-to-eat (RTE) food reheat 135°F or above

Proper Cooling

Time and

Temperature

Proper Cold

Holding

temperature(41°F

/45°F)

Proper Hot

Holding

temperature(135°

F)

Proper Cooking

Time and

Temperature

Proper Reheating

Procedure for Hot

Holding

Regulatory Code Quick Reference

Item #

Part

TFER Regulation Code

TFER Quick Reference

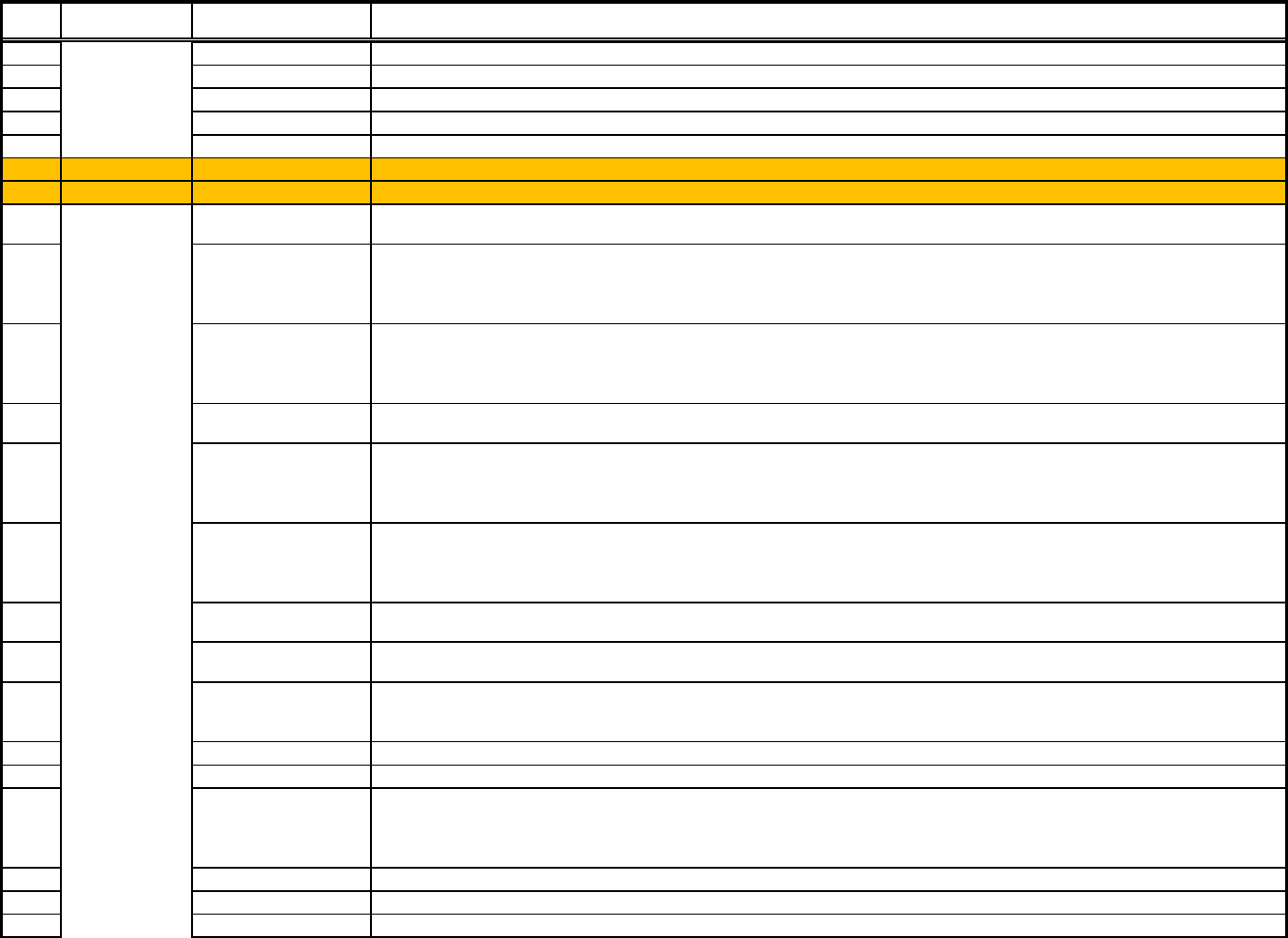

5

228.73(d)

Reheat from 41°F to 165°F within 2 hours and/or Commercially processed RTE foods reheated from 41°F to 135°F within 2

hours?

5

228.73(e)

Roasts reheat for hot holding

6

228.75(i)(1)

Written procedures shall be prepared in advance, maintained in the establishment

6

228.75(i)(2)

Cooked and served, within 4 hours, exceed a 4-hour limit shall be discarded

6

228.75(i)(3)

Maximum 6 hours, initial 41°F, may not exceed 70°F within 6 hours

6

228.75(h)(1)(A)

Discarded if exceed either temperature and time combinations

6

228.75(h)(1)(B)

Discarded if in a container or package that does not bear a date or day

6

228.75(h)(1)(C)

Discarded if appropriately marked with a date or day that exceeds a temperature and time combination

6

228.75(h)(2)

Dispensed through a vending machine, discarded if it exceeds a temperature and time combination

6

228.77(2)(D)

Shelf life no more than 30 days from packaging to consumption

6

228.224(d)(5)

OUTFITTER OPERATION, TCS complex preparation, served within the first 24 hours excursion departure time

6

228.225(d)

Self-Service Food Market, discard TCS if date mark exceeds the time limit or does not bear an expiration date

7

228.61

Food safe, good condition, unadulterated, and honestly presented

7

228.62(a)(1)

Food obtained from sources that comply with applicable laws

7

228.62(a)(2)

Food prepared in a private home, unlicensed food manufacturer, wholesaler, may not use in a establishment

7

228.174(k)

No living or sleeping quarters may be used for conducting establishment operations

7

228.62(a)(3)

Packaged food shall be labeled as specified in law

7

228.62(b)

Food hermetically sealed shall be obtained from food processing plant regulated by the regulatory agency

7

228.62(c)

Fluid milk and milk products shall be obtained from sources that comply with Grade A standards

7

228.63(f)

Ice use as food or cooling medium shall be made from drinking water

7

228.222(a)(1)

TEMPORARY, Foods not prepared on site, require preparation, or cooking prepared at licensed establishment

7

228.222(c)

TEMPORARY, Ice consumed or contacts food shall have been made under rules (pertaining to Food).

7

228.223(c)

B&B, Food shall be obtained from approved sources

7

228.224(b)

OUTFITTER, Food supplies, ice, shall be obtained from approved sources

7

228.224(d)(2)

OUTFITTER, commercially prepackaged or packaged ready to eat food no cooking may be served

7

228.62(d)(1)(A)

Fish that are received for sale or service shall be commercially and legally caught or harvested

7

228.62(d)(1)(B)

Fish that are received for sale or service shall be approved for sale or service

7

228.72(a)(1)(A)

Parasite destruction, shall be frozen and stored at a temperature of -4°F or below for (7 days) in a freezer

7

228.72(a)(1)(B)

Parasite destruction, shall be frozen at -31°F or below and stored -31°F for 15 hours

7

228.72(a)(1)(C)

Parasite destruction, shall be frozen at -31°F or below and stored -4°F or below for minimum of 24 hours

7

228.63(g)

Pre-packaged juice shall be obtained pasteurized or otherwise treated to attain a 5-log reduction

7

228.63(c)

Eggs received clean and sound and may not exceed the restricted egg tolerances for U.S. Consumer Grade B

7

228.63(d)(1)

Eggs pasteurized shall be obtained pasteurized

7

228.66(c)

Pasteurized eggs or egg products shall be substituted for raw shell eggs in prep of foods that are not cooked

7

228.63(d)(2)

Fluid, dry, and milk products shall be obtained pasteurized & comply grade A standards as specified in law

7

228.63(d)(3)

Frozen milk products, as ice cream, shall be obtained pasteurized

Food and Ice

obtained from

Approved

Source; Food in

Good Condition,

Safe, and

Unadulterated

Time as a Public

Health Control;

Procedures &

Records

Proper Reheating

Procedure for Hot

Holding

Regulatory Code Quick Reference

Item #

Part

TFER Regulation Code

TFER Quick Reference

7

228.63(d)(4)

Cheese shall be obtained pasteurized unless alternative procedures to pasteurization are specified

7

228.77(5)(A)

Cheese packaged in establishment using ROP method shall limit the cheeses packaged

7

228.62(f)(1)

Wild mushrooms species picked in the wild shall not be offered for sale or service by a establishment

7

228.62(g)

Exotic animals approved by regulatory authority

7

228.62(g)(2)

Game animals approved by regulatory authority

7

228.62(e )

Molluscan shellfish from an approved source (NSSP listed sources)

7

228.62(d)(2)

Molluscan shellfish that are recreationally caught may not be received for sale or service

7

228.69(c)

TCS food dispensed through a vending machine shall be in original container

8

228.63(a)(1)

Specifications for Receiving temperature at 41°F or less

8

228.63(a)(3)

Raw shell eggs received at 45°F or less

8

228.63(a)(4)

Grade A Milk received at 45°F or less

8

228.63(a)(5)

Molluscan shellfish received at 45°F or less

8

228.63(a)(6)

Cooked TCS foods received at 135°F or less

8

228.63(a)(7)

A food labeled frozen and shipped frozen shall be received frozen

8

228.63(a)(8)

Upon receipt, TCS food shall be free of evidence of previous temperature abuse, such as but not limited to odors, ice crystals,

frost or discoloration.

8

228.106(k)(1)(B)

TCS Foods for Vending Machine received at proper temperature

9

228.65(b)

Food employee may not use a utensil more than once to taste food that is to be sold or served

9

228.66(a)(1)(A)

Food protected from cross contamination by separating, storage, preparation, holding, and display

9

228.66(a)(1)(B)(i)

Food protected cross contamination separating types of raw animal food storage, preparation, holding, display

9

228.66(a)(1)(B)(ii)

Food protected cross contamination arrange each type food in equipment so cross is prevented

9

228.66(a)(1)(B)(iii)

Food protected cross contamination by preparing each type of food at different times or in separate area

9

228.67(a)

Ice used as exterior coolant, prohibited as ingredient and may not be used as food

9

228.68(a)

Food shall only contact clean surfaces of equipment, linen, single service articles

9

228.70(a)

Food on display shall be protected from contamination

9

228.70(c )(2)

Consumer self-service ready-to-eat food provided with suitable utensils that protect food from contamination

9

228.70(c)(1)

Raw unpackaged animal food, beef, lamb, pork, poultry, and fish may not be offered for consumer self-service

9

228.106(j)(1)

Molluscan shellfish life support system display tanks may not be used for human consumption

9

228.222(g)

TEMPORARY, Packaged food not stored in direct contact with ice or water if food is subject to entry of water.

9

228.223(d)(1)

B&B, Food shall be prepared and protected

9

228.224(d)(1)

OUTFITTER, All food shall be prepared and protected in Central Preparation Facility

9

228.224(d)(4)

OUTFITTER, All food must be stored to protect from contamination

9

228.224(f)(1)

OUTFITTER, Ice that is used for cooling food may not be used for human consumption

9

228.77(1)

ROP, firm that packages TCS food using ROP method shall control growth and toxin formation of bacteria

9

228.77(3)

An establishment may not package fish using a reduced oxygen packaging method

9

228.77(4)(B)(iii)

Establishment that packages TCS food cook-chill or sous vide process ensure food is protected before and after cooking

9

228.74(a)

Juice packaged in retail under HACCP plan and obtain 5-log reduction

Food and Ice

obtained from

Approved

Source; Food in

Good Condition,

Safe, and

Unadulterated

Food Separated

& Protected,

Prevented during

food preparation,

storage, and

display

Food Received at

Proper

Temperature

Regulatory Code Quick Reference

Item #

Part

TFER Regulation Code

TFER Quick Reference

10

228.113(1)

Food-contact surfaces clean to sight and touch

10

228.114(a)(1)(A)

Food-contact surfaces cleaned before each use with different type of raw animal food

10

228.114(a)(1)(B)

Equipment food-contact surfaces & utensils cleaned each time change from working raw to ready-to-eat foods

10

228.114(a)(1)(C)

Equipment food-contact surfaces & utensils shall be cleaned between uses with raw produce and TCS food

10

228.114(a)(1)(D)

Food-contact surfaces cleaned before using or storing a food temperature device

10

228.114(a)(1)(E)

Food-contact surfaces cleaned any time when contamination may occur

10

228.114(a)(3)

TCS food equipment food-contact surfaces & utensils shall be cleaned at least every four hours

10

228.117

Utensils and food-contact surfaces of equipment shall be sanitized before use after cleaning

228.111(k)

Water maintained at 171°F or above for manual ware washing equipment,using hot water sanitization temperatures

10

228.118(1)

Manual ware washing equipment, hot water sanitization temperatures maintained at 171°F or above for at least 30 seconds

10

228.118(2)

Hot water mechanical sanitization achieving surface temperature of 160°F

10

228.118(3)(A)

After being cleaned food-contact surfaces shall be sanitized an exposure time of at least 10 seconds for a CHLORINE

SOLUTION

10

228.118(3)(B)

After being cleaned, food-contact surfaces shall be sanitized in a contact time of at least 7 seconds for a CHLORINE SOLUTION

of 50 mg/L

10

228.118(3)(C)

After being cleaned, food-contact surfaces sanitized contact of at least 30 seconds for other chemical sanitizing solutions

10

228.118(3)(D)

After being cleaned, equipment food-contact surfaces and utensils shall be sanitized in an exposure time used in relationship

with a combination of temperature, concentration, and pH that, when evaluated for efficacy, yields sanitization as defined in

§228.2(125) of this title (relating to Definitions)

10

228.111(n)(1)

Chlorine sanitizing solution shall have a minimum temperature based on the concentration and pH of the solution as listed in the

following chart

10

228.111(n)(2)

Iodine solution concentration between 12.5 mg/L and 25 mg/L

10

228.111(n)(3)

Quaternary ammonium compound solution concentration indicated by the manufacturer's instructions

10

228.111(n)(4)

A chemical sanitizer used contact times criteria

10

228.111(n)(5)

Other chemical sanitizer used in accordance with the EPA-approved manufacturer's label use instructions

10

228.111(n)(6)

Chemical sanitizer generated on-site, criteria

10

228.112(b)

Single-service and single-use articles, required use

10

228.68(g)(1)

Refilling returnables cleaned and refilled in a regulated food processing plant

10

228.68(g)(2)

A take-home food container returned and refilled

11

228.70(d)(1)

Food not re-served after being served or sold to consumer

11

228.224(d)(6)

Food not re-served or re-heated. OUTFITTER OPERATION

11

228.81(1)

Unsafe, adulterated or contaminated Food--discarded, reprocessed or reconditioned

11

228.81(2)

Unapproved source food--discard

11

228.81(3)

Contaminated RTE food discard

11

228.81(4)

Contaminated food discard

11

228.83(a)

Food not donated after served/sold to customer

11

228.83(b)(1)

Donated TCS food hot holding at or above 135°F

Food Contact

Surfaces;

Cleaned and

Sanitized

Proper

Disposition of

Returned,

Previously

Served,

Reconditioned, &

Unsafe Food

Regulatory Code Quick Reference

Item #

Part

TFER Regulation Code

TFER Quick Reference

11

228.83(b)(2)

TCS food may be donated if the donor can substantiate that the food recipient has the facilities to meet the transportation,

storage, and reheating requirements of these rules

11

228.83(b)(3)

Donated TCS food cold hold 41°F

11

228.83(b)(4)

Donated TCS food transported directly to a consumer, meet transportation requirements, including holding temperatures,

11

228.83(c)

Donated foods labeling criteria

11

228.83(d)

Shelf life. Donated TCS foods

11

228.83(e)

Damaged foods. Heavily rim/seam-dented canned foods, or without the manufacturer’s complete labeling

11

228.83(f)

Distressed foods.

11

228.184

Products held for credit, redemption, return --- separated

12

228.35(a)(1)

Responsibility of Permit Holder, Person in Charge, and Conditional Employees.

12

228.35(a)(1)(E)

Lesions

12

228.35(a)(2)

Has an illness diagnosed by a Health Practitioner due to NOROVIRUS; Hepatitis A virus; Shigella spp.; Shiga toxin-producing

Escherichia coli; Salmonella typhi; or non-typhoidal salmonella

12

228.35(a)(3)

Had a previous illness, diagnosed by a Health Practitioner, within the past 3 months due to Salmonella typhi, without having

received antibiotic therapy, as determined by a Health Practitioner

12

228.35(a)(4)

Has been exposed to, or is the suspected source of, a confirmed disease outbreak, because the food employee or conditional

employee implicated in the outbreak, or consumed food at an event prepared by a person who is infected or ill with NOROVIRUS

within the past 48 hours of the last exposure, Shiga Toxin-Producing Escherichia coli or Shigella ssp. within the past 3 days of

the last exposure, Salmonella typhi within the past 14 days of the last exposure, or hepatitis A virus within the past 30 days of

the last exposure

12

228.35(a)(5)

Has been exposed by attending or working in a setting where there is a confirmed disease outbreak, or living in the same

household as, and has knowledge about, an individual who works or attends a setting where there is a confirmed disease

outbreak, or living in the same household as, and has knowledge about, an individual diagnosed with an illness caused by

NOROVIRUS within the past 48 hours of the last exposure, Shiga Toxin-Producing Escherichia coli or Shigella spp. within the

past 3 days of the last exposure, Salmonella typhi within the past 14 days of the last exposure, or hepatitis A virus within the

past 30 days of the last exposure

12

228.35(b)

PIC notify regulatory authority when a food employee is jaundiced or diagnosed with an illness

12

228.35(c)

PIC ensure conditional employee who exhibits or reports a symptom, or who reports diagnosed illness prohibited from becoming

a food employee until

12

228.35(d)

Licensures food employee exhibits or reports a symptom, or diagnosed illness EXCLUDED or RESTRICTED

12

228.35(e)

A food employee or conditional employee shall report to PIC the information as specified under (a) of this section

12

228.35(f )

A food employee shall comply with an exclusion or RESTRICTION

12

228.252(a)(1)

Ceasing operations and reporting

13

228.36

EXCLUSION/RESTRICTION

13

228.37

Conditions of exclusion/restriction

13

228.42(b)

Discharges from the Eyes, Nose, and Mouth

Management,

Food Employees

and Conditional

Employees;

Knowledge,

Responsibilities,

and Reporting

Proper use of

restriction and

exclusion; No

discharge from

eyes, nose, and

mouth

Proper

Disposition of

Returned,

Previously

Served,

Reconditioned, &

Unsafe Food

Regulatory Code Quick Reference

Item #

Part

TFER Regulation Code

TFER Quick Reference

14

228.38(a)

Clean Condition--hands and arms

14

228.38(b)(1)

Cleaning procedure--time frame (20 seconds)

14

228.38(b)(2)

Cleaning procedure--steps

14

228.147(a)(3)

Chemically treated towelettes for handwashing-Limited

14

228.38(d)

When to wash

14

228.68(e)(1)

Gloves single use

14

228.68(e)(2)

Slash-resistant--use

14

228.68(e)(3)

Slash-resistant--characteristics

14

228.68(e)(4)

Cloth glove--use

15

228.65(a)(2)

Bare hands contact with ready-to-eat foods

15

228.65(a)(3)

Limit bare hand contact with all other foods

15

228.65(a)(5)(A)

Highly susceptible population--bare hand contact prohibited

15

228.65(a)(5)(B)

Written procedures maintained for bare hand contact

15

228.65(a)(5)(C)

A written employee health policy

15

228.65(a)(5)(F)

Documentation--2 or barrier, incentive program

15

228.65(a)(5)(E)

Documentation--hands washed

15

228.65(a)(5)(G)

Documentation--corrective action taken

16

228.82(1)(B)

Only pasteurized prepackaged juice served

16

228.82(1)(C)

Unpackaged juice made on site prohibited

16

228.82(2)

Only pasteurized eggs used

16

228.82(3)

Raw or partially cooked animal food and raw seed sprouts not offered

16

228.71(a)(4)(B)

Raw or partially cooked animal food and raw seed sprouts not served

16

228.82(4)

No bare hand contact

16

228.82(5)

No 'time only' used for raw eggs

228.63(b)

Food may not contain unapporved additives or additives that don't exceed CFR criteria

17

228.66(d)(1)

Unapproved food or color additives. Prohibited

17

228.66(d)(2)

Sulfites prohibited

17

228.206(b)(1)

Chemical for Washing, Treatment, Storage, and Processing Fruits and Vegetables, Criteria

17

228.206(b)(2)

Ozone, criteria

17

228.206(c)

Boiler water additives, criteria

17

228.206(d)(1)

Drying agents, criteria

17

228.206(d)(2)

Chemical sanitization, criteria

18

228.201

Poisonous/toxic materials or chemicals have manufacture label

Toxic Substances

Properly

Identified, Stored

and Used

Food Additives;

Approved and

Properly Stored;

Washing Fruits &

Vegetables

HIGHLY

SUSCEPTIBLE

POPULATIONS.

Hands Cleaned

and Properly

Washed/ Gloves

Used Properly

No Bare Hand

Contact with RTE

foods or

Approved

Alternate Method

Regulatory Code Quick Reference

Item #

Part

TFER Regulation Code

TFER Quick Reference

18

228.202

Poisonous/toxic materials or chemicals not in original container labeled

18

228.203

Poisonous/toxic materials or chemicals stored properly

18

228.204(a)(1)

Approved Poisonous/toxic materials or chemicals

18

228.204(b)(1)

Poisonous/toxic materials or chemicals used properly

18

228.204(b)(2)(A)

Poisonous/toxic materials or chemicals doesn’t cause hazard

18

228.204(b)(2)(B)

Poisonous/toxic materials or chemicals applied properly

18

228.204(b)(3)

RESTRICTED use pesticide applied only by an certified applicator

18

228.205

Chemical container not used for food

18

228.206(a)

Sanitizers, criteria

18

228.207

Lubricant criteria

18

228.208(a)

RESTRICTED use pesticides, criteria

18

228.208(b)

Rodent Bait station criteria

18

228.208(c)(1)

Tracking powders prohibited

18

228.223(k)(2)

Pesticides and rodenticides application criteria

18

228.209(a)(1)

Employee Medication

18

228.209(a)(2)

Medicine storage and labeling

18

228.209(b)

Refrigerated medicines, storage

18

228.211

First Aid Supplies, Storage and labeling

18

228.111(n)(6)(A)

Chemical sanitizer generated onsite, device criteria

18

228.111(n)(6)(B)

Chemical sanitizer generated onsite, chemical criteria

18

228.213

Stock and retail sale of poisonous or toxic materials

18

228.101(a)(1)

Materials used for food contact surfaces safe

18

228.102

Materials used for single service/use safe

18

228.101(c)(1)

Lead use limitation--lead free

18

228.101(c)(2)

Lead use limitation--Pewter alloy < 0.05% lead

18

228.101(d)

Copper, use limitation

18

228.101(e)

Galvanized metal, use limitation

19

228.141(a)(1)

Drinking water obtained from an approved source( public water system)

19

228.141(a)(2)

Drinking water obtained from an approved source (nonpublic water system)

19

228.141(b)

System flushing and disinfection

19

228.141(c)

Bottled drinking water approved source

19

228.142(a)(1)

Public and private water system meet National Primary Drinking Water Regulations, state drinking water quality standards

19

228.142(a)(2)

Nonpublic water system shall meet the requirements in Subchapter J of this chapter, Private Water Systems

19

228.142(b)(1)

A nondrinking water supply shall be used only if its use is approved by the regulatory authority

19

228.142(b)(2)

Nondrinking water shall be used only for nonculinary purposes such as air conditioning, nonfood equipment cooling, and fire

protection

19

228.142(c)

Nonpublic water system sampled and tested, criteria

19

228.142(d)

Sample report maintained

Toxic Substances

Properly

Identified, Stored

and Used

Water from

Approved

Source; Plumbing

Installed; Proper

Backflow Device

Regulatory Code Quick Reference

Item #

Part

TFER Regulation Code

TFER Quick Reference

19

228.222(f)

Water from an approved source shall be made available in a TEMPORARY FOOD ESTABLISHMENT

19

228.223(o)(1)

Water supply. shall be from an approved source that meets the standards in accordance with: state drinking water quality

standards in accordance with 30 TAC §§290.38 – 290.47(Rules and Regulations for Public Water Systems), and 30 TAC

§§290.101 - 290.114, 290.117 - 290.119, 290.121, and 290.122 (Drinking Water Standards Governing Drinking Water Quality

and Reporting Requirements for Public Water Systems)

19

228.223(o)(2)

Water supply. shall be from an approved source that meets the standards in accordance with: private water system standards as

provided in Subchapter J , Private Water Systems

19

228.224(g)(1)

Potable water shall be used on excursions for human consumption, food preparation, handwashing, and for cleaning and

sanitizing utensils and equipment

19

228.272(a)(1)

Private water systems serving food service facilities shall submit a minimum of one water sample for testing for total coliform,

fecal coliform, E. coli, or other fecal indicator organisms, for the month prior to opening and each month the facility is in

operation. The sample shall be collected from a designated location within the Food Service Establishment

228.272(a)(2)

water sampled every 6 months and have negative result

228.272(a)(3)

If test is postive-- water smapled every month for 24 months, must have negative result for 12 consecutive months

19

228.272(a)(5)

If a routine distribution coliform sample is E.coli-positive, then the facility shall issue a written boil water notification.

228.272(a)(6)

boil water notification in effect until repeat coliform sample is negative

19

228.272(b)

Water Chemical properties.

19

228.272(c)

Minimum residual disinfectant concentrations and maximum residual disinfectant levels (MRDLs). (1) The minimum residual

disinfectant concentration in the water entering the distribution system and the water within the distribution system shall be 0.2

milligrams per liter (mg/L) free chlorine. (2) The MRDL of free chlorine in the water within the distribution system shall be 4.0

mg/L based on a running annual average

19

228.274(c)

A sample of water from the new or repaired main shall be submitted to a TCEQ Accredited laboratory for bacteriological

examination so as to be assured that the disinfection procedure was effective

19

228.275

Flushing of Water System Mains.

19

228.274(a)

Disinfection of New or Repaired Water System Facilities. When repairs are made to existing mains or when new main extensions

are installed, they shall be disinfected using such amounts of chlorine compounds as to fill the repaired or new mains and

appurtenances with water containing 50 mg/L chlorine.

19

228.274(b)

Disinfection of New or Repaired Water System Facilities. After the water containing this amount of chlorine, which is greater

than that normally present in drinking water, has been in contact with the pipe and appurtenances for at least 24 hours, the main

shall be flushed until the free chlorine or chloramine in the water within the new or repaired distribution system is less than 4.0

mg/L.

19

228.145(a)

Construction. A plumbing system and hoses conveying water shall be constructed and repaired with approved materials

according to the Plumbing Code

19

228.145(b)

Water filter. A water filter shall be made of safe materials

19

228.146(a)(1)

Approved system and cleanable fixtures

19

228.149(d)(1)(A)

A reservoir that is used to supply water to a device such as a produce fogger shall be maintained in accordance with

manufacturer's specifications

19

228.149(d)(1)(B)

A reservoir that is used to supply water to a device such as a produce fogger shall be cleaned in accordance with manufacturer's

specifications or according to the procedures specified under paragraph (2) of this subsection, whichever is more stringent

Water from

Approved

Source; Plumbing

Installed; Proper

Backflow Device

Regulatory Code Quick Reference

Item #

Part

TFER Regulation Code

TFER Quick Reference

19

228.149(d)(2)

Cleaning procedures shall include at least the following steps and shall be conducted at least once a week: (A) draining and

complete disassembly of the water and aerosol contact parts; (B) brush-cleaning the reservoir, aerosol tubing, and discharge

nozzles with a suitable detergent solution; (C) flushing the complete system with water to remove the detergent solution and

particulate accumulation; and (D) rinsing by immersing, spraying, or swabbing the reservoir, aerosol tubing, and discharge

nozzles with at least 50 mg/L hypochlorite solution

19

228.149(e)(1)

A plumbing system shall be repaired according to the Plumbing Code

19

228.149(f)(1)(A)

Materials, approved. Materials that are used in the construction of a MOBILE water tank, MOBILE FOOD UNIT water tank, and

appurtenances shall be safe

19

228.149(f)(7)(A)

Tank hose, construction and identification. A hose used for conveying drinking water from a water tank shall be safe

19

228.149(f)(8)

Tank filter, compressed air

19

228.149(f)(13)

Operation and maintenance, system flushing and disinfection

19

228.149(f)(16)(A)

Tank, pump, and hoses, dedication. Except as specified in subparagraph (B) of this paragraph, a water tank, pump, and hoses

used for conveying drinking water shall be used for no other purpose

19

228.146(c)

Backflow prevention, air gap

19

228.146(d)

Backflow prevention device, design standard

19

228.147(d)

Backflow prevention device, when required

19

228.147(e)(1)

If not provided with an air gap as specified under§228.146(c) of this title, a dual check valve with an intermediate vent preceded

by a screen of not less than 100 mesh to 25.4mm (100 mesh to 1 inch) shall be installed upstream from a carbonating device and

downstream from any copper in the water supply line

19

228.149(b)(1)

A person may not create a cross connection by connecting a pipe or conduit between the drinking water system and a

nondrinking water system or a water system of unknown quality

19

228.273(a)

Backflow Prevention. The plumbing system shall preclude backflow of a solid, liquid, or gas contaminant into the water supply

system at each point of use, including on a hose bib, by: providing an air gap between the water supply inlet and the flood level

rim of a plumbing fixture, equipment, or nonfood equipment that is at least twice the diameter of the water supply inlet and not

less than 25 mm (1 inch)

19

228.273(b)

Backflow Prevention. The plumbing system shall preclude backflow of a solid, liquid, or gas contaminant into the water supply

system at each point of use, including on a hose bib, by: installing an approved backflow prevention device that meets the

American Society of Sanitary Engineering (ASSE) standards for construction, installation, maintenance, inspection, and testing

for that specific application and type of device

19

228.278

No physical connection between the distribution system of a food service facility water supply and that of any other water supply

shall be permitted. Unless that water supply meets all applicable requirements of 30 TAC 290

20

228.150(e)

Conveying sewage

20

228.151(a)(1)

Sewage disposed through public sewer system

20

228.151(a)(2)

Capacity and drainage

20

228.150(c)(1)

A direct connection may not exist between the sewage system and a drain originating from equipment in which food, portable

equipment, or utensils are placed

20

228.186(e)

Cleaning maintenance tools, preventing contamination

20

228.221(a)(9)(D)

MOBILE FOOD UNIT--liquid waste discharge prohibited

20

228.221(a)(9)(E)

Flushing a waste retention tank

20

228.221(a)(9)(F)

MOBILE FOOD UNIT--approved waste disposal system

20

228.221(c)(1)(B)

MOBILE FOOD UNIT--waste disposal location

Approved

Sewage/Wastew

ater Disposal

System, Proper

Disposal

Water from

Approved

Source; Plumbing

Installed; Proper

Backflow Device

Regulatory Code Quick Reference

Item #

Part

TFER Regulation Code

TFER Quick Reference

20

228.222(h)(1)

Sewage and waste water disposed properly--Temporary Event

20

228.223(n)

Sewage and waste water disposed properly BED AND BREAKFAST

20

228.276(a)

Sewer or septic tank location criteria

20

228.276(b)

Storm sewer criteria

20

228.276(c)

Sewer/ Water line location criteria

Priority Foundation

21

228.31(a)

Except as specified in (b), the permit holder shall be the person in charge or shall designate a person in charge and shall ensure

that a person in charge is present at the establishment during all hours of operation

21

228.31(b)

In a establishment with two or more separately permitted departments that are the legal responsibility of the same permit holder

that are located on the same premises, the permit holder may, during specific time periods when food is not being prepared,

packaged, or served, designate a single person in charge who is present on the premises during all hours of operation, and who

is responsible for each separate permitted establishment on the premises

21

228.32(1)

Based on the risks inherent to the food operation, during inspections and upon request the person in charge shall demonstrate to

the regulatory authority knowledge of foodborne disease prevention, application of the Hazard Analysis Critical Control Point

principles, and the requirements of this rule. The person in charge shall demonstrate this knowledge by complying with these

rules by having no critical violations/priority items during the current inspection

21

228.31(a)

Except as specified in (b), the permit holder shall be the person in charge or shall designate a person in charge and shall ensure

that a person in charge is present at the establishment during all hours of operation

21

228.31(b)

In a establishment with two or more separately permitted departments that are the legal responsibility of the same permit holder

that are located on the same premises, the permit holder may, during specific time periods when food is not being prepared,

packaged, or served, designate a single person in charge who is present on the premises during all hours of operation, and who

is responsible for each separate permitted establishment on the premises

21

228.32(1)

Based on the risks inherent to the food operation, during inspections and upon request the person in charge shall demonstrate to

the regulatory authority knowledge of foodborne disease prevention, application of the Hazard Analysis Critical Control Point

principles, and the requirements of this rule. The person in charge shall demonstrate this knowledge by complying with these

rules by having no critical violations/priority items during the current inspection

21

228.32(2)

Being a certified food protection manager who has shown proficiency of required information through passing a test that is part of

an Accredited Program

21

228.32(3)

Responding correctly to the inspector’s questions as they relate to the specific food operation. The areas of knowledge include:

§228.32(3) (A-Q) are met

21

228.33(a)

At least one employee that has supervisory and management responsibility and the authority to direct and control food

preparation and service shall be a certified food protection manager who has shown proficiency of required information through

passing a test that is part of an accredited program

21

228.33(c)

At least one certified food protection manager must be employed by each establishment

21

228.34

Person in charge. The person in charge shall ensure that §228.34 (1-15) Relating to Duties of PIC are met

21

228.45

A establishment shall have written procedures for employees to follow when responding to vomiting or diarrheal events that

involve the discharge of vomitus or fecal matter onto surfaces in the establishment the procedures shall address the specific

actions employees must take to minimize the spread of contamination and the exposure of employees, consumers, food, and

surfaces to vomitus or fecal matter

21

228.221(a)(4)(A)

Initial Permitting Inspection. MOBILE FOOD UNIT criteria

21

228.222(a)(2)

TEMPORARY FOOD ESTABLISHMENT certified food manager or food handler certification criteria

21

228.223(b)

Bed and Breakfast Certified food protection manager

Person in Charge

Present,

Demonstration of

Knowledge, and

Perform Duties/

Certified Food

Manager (CFM)

Approved

Sewage/Wastew

ater Disposal

System, Proper

Disposal

Regulatory Code Quick Reference

Item #

Part

TFER Regulation Code

TFER Quick Reference

21

228.224(l)

Outfitter Certified food protection manager

22

228.33(d)

Food Handler Training criteria

22

228.34(2)

Unauthorized persons prohibited

22

228.38(e)

Washing hands only at a designated hand sink

22

228.39(a)

Fingernail maintenance

22

228.39(b)

Nail polish, fake nails, criteria

22

228.223(f)

BED AND BREAKFAST. Personal hygiene practices. Criteria

22

228.44(a)

Food employees may not care for or handle animals that may be present

22

288.70(c)(3)

Consumer self-service operations (buffets and salad bars) shall be monitored by food employees

23

228.143(a)

Water capacity

23

228.143(b)

Water pressure

23

228.223(o)

BED AND BREAKFAST -- Water supply

23

228.143(c)

Does the establishment have sufficient capacity to meet peak hot water demands?

23

228.144(a)(1)

Public water delivery system, criteria

23

228.144(a)(2)(A)

Nonpublic water delivery system, criteria

23

228.144(a)(2)(B)

Water transport vehicle criteria

23

228.144(a)(2)(C)

Water container, criteria

23

228.144(b)

Alternate water supply criteria

23

228.144(b)(5)

Alternate water supply criteria without paramount water supply

23

228.149(b)(2)

Identify nondrinking water pipes to distinguish from drinking water pipes

23

228.149(c)

Scheduled inspection and service of water system device

23

228.149(f)(12)

Water sampling --Mobile Food unit

23

228.271(1)

Water capacity specifications

23

228.271(2)

Water pressure specifications

24

228.63(h)(1)

Raw shucked shellfish, including individual quick frozen oysters, shall be obtained in nonreturnable packages which bear a

legible label that identifies the: name, address, and certification number of the shucker-packer or repacker of the molluscan

shellfish; and the “sell by” or “best if used by” date for packages with a capacity of less than 1.89 L (one-half gallon) or the date

shucked for packages with a capacity of 1.89 L (one-half gallon) or more

24

228.63(i)

Shellstock identification. §228.63(i)(1)(A)-(B) Shellstock tags or labels bear legible source identification information is being met.

24

228.64(e)(1)

Shellstock tags shall remain attached to the container

24

228.64(e)(2)

The date when the last shellstock from the container is sold or served shall be recorded on the tag or label

24

228.64(e)(3)

The identity of the source of shellstock that are sold or served shall be maintained by retaining shellstock tags or labels for 90

calendar days from the date that is recorded on the tag or label

24

228.72(b)(1)

If raw, raw-marinated, partially cooked, or marinated-partially cooked fish are served or sold in ready-to-eat form, the person in

charge shall record the freezing temperature and time to which the fish are subjected and shall retain and have accessible the

records of the establishment for 90 calendar days beyond the time of service or sale of the fish

Person in Charge

Present,

Demonstration of

Knowledge, and

Perform Duties/

Certified Food

Manager (CFM)

Food Handler/No

Unauthorized

Persons/

Personnel

Required

Records

Available

(shellstock tags;

parasite

destruction);

Food Properly

Labeled

Hot and Cold

Water available;

Adequate

Pressure; Safe

Water

Regulatory Code Quick Reference

Item #

Part

TFER Regulation Code

TFER Quick Reference

24

228.72(b)(3)

If raw, raw-marinated, partially cooked, or marinated-partially cooked fish are served or sold in ready-to-eat form, and the fish are

raised and fed as specified in subsection (a)(2)(C), a written agreement or statement from the supplier or aquaculturist stipulating

that the fish were raised and fed as specified in subsection (a)(2)(D) shall be obtained by the person in charge and retained in the

records of the establishment for 90 calendar days beyond the time of service or sale of the fish

24

228.79(a)(1)

Food packaged in a establishment, shall be labeled as specified in law

24

228.79(a)(2)(A)

Label include the common name of the food, an adequately descriptive identity statement

24

228.79(a)(2)(B)

Label include if made from two or more ingredients, a list of ingredients and sub-ingredients in descending order

24

228.79(a)(2)(C)

Label information shall include an accurate declaration of the quantity of contents

24

228.79(a)(2)(D)

Label include the name and place of business of the manufacturer, packer, or distributor

24

228.79(a)(2)(F)

Label include nutrition labeling

25

228.76(1)

Obtain a variance from the regulatory authority for Smoking food

25

228.76(2)

Curing food obtain variance

25

228.76(3)(A)

Obtain Variance: using food additives or adding components such as vinegar: as a method of food preservation

25

228.76(3)(B)

Obtain Variance: render a food non TCS

25

228.76(4)

Obtain Variance: reduce oxygen packaging

25

228.76(5)

Obtain variance: Molluscan shellfish life-support system display tank

25

228.76(6)

Obtain variance: custom processing animals

25

228.76(7)

Preparing food determined by the regulatory authority to require a variance

25

228.76(8)

Obtain variance: sprouting seeds or beans, such as wheat grass and Alfa spouts

25

228.77(2)(A)

Have HACCP plan: reduced oxygen packaging

25

228.77(2)(B)

Except as specified under paragraphs (3) - (6) of this section, requires that the packaged food shall be maintained at 5 degrees

Celsius (41 degrees Fahrenheit) or less and meet at least one of the following criteria: has an aw of 0.91 or less; has a pH of 4.6

or less; is a meat or poultry product cured at a food processing plant regulated by the USDA or the department using substances

specified in 9 CFR §424.21, use of food ingredients and sources of radiation, and is received in an intact package; or is a food

with a high level of competing organisms such as raw meat, raw poultry, or raw vegetables

25

228.77(2)(C)

Describes how the packages shall be prominently and conspicuously labeled on the principal display panel in bold type on a

contrasting background, with instructions to: maintain the food at 5 degrees Celsius (41 degrees Fahrenheit) or below; and

discard the food if within 30 calendar days of its packaging it is not served for on-premises consumption, or consumed if served

or sold for off-premises consumption

25

228.77(2)(E)

Includes operational procedures that: prohibit contacting ready-to-eat food with bare hands as specified under §228.65(a)(2) of

this title; identify a designated area and the method by which: physical barriers or methods of separation of raw foods and ready-

to-eat foods minimize cross contamination; and access to the processing equipment is limited to responsible trained personnel

familiar with the potential hazards of the operation; and delineate cleaning and sanitization procedures for food-contact surfaces

25

228.77(2)(F)

Describes the training program that ensures that the individual responsible for the reduced oxygen packaging operation

understands the: concepts required for a safe operation; equipment and facilities; and procedures specified under paragraph

(2)(E) of this subsection and §228.244(d)(2) and (4) of this title

25

228.77(2)(G)

Is provided to the regulatory authority prior to implementation as specified under §228.244(c)(3) of this title

Compliance with

Variance,

Specialized

Process, and

HACCP plan;

Variance

obtained for

Specialized

Processing

Methods;

Manufacturer

Instructions

Required

Records

Available

(shellstock tags;

parasite

destruction);

Food Properly

Labeled

Regulatory Code Quick Reference

Item #

Part

TFER Regulation Code

TFER Quick Reference

25

228.77(4)(A)

Cook-Chill or Sous Vide. Except as specified under paragraphs (3) and (6) of this subsection, a establishment that packages

time/temperature controlled for safety food using cook-chill or sous vide process shall: provide to the regulatory authority prior to

implementation, a HACCP plan that contains the information specified under §228.244(d)(2) and (4) of this title;

25

228.77(4)(B)(i)

Cook-Chill or Sous Vide. Except as specified under paragraphs (3) and (6) of this subsection, a establishment that packages

time/temperature controlled for safety food using cook-chill or sous vide process shall: ensure the food is: prepared and

consumed on the premises, or prepared and consumed off the premises but within the same business entity with no distribution

or sale of the packaged product to another business entity or the consumer;

25

228.77(4)(B)(vi)

Held in a refrigeration unit that is equipped with an electronic system that continuously monitors time and temperature and is

visually examined for proper operation twice daily,

25

228.77(4)(B)(vii)

If transported off-site to a satellite location of the same business entity, equipped with verifiable electronic monitoring devices to

ensure that times and temperatures are monitored during transportation

25

228.77(4)(B)(viii)

Labeled with the product name and the date packaged;

25

228.77(4)(C)

Maintain the records required to confirm that cooling and cold holding refrigeration time/temperature parameters are required as

part of the HACCP plan and make such records available to the regulatory authority upon request, and hold such records for at

least 6 months

25

228.77(4)(D)

Implement written operational procedures as specified under paragraph (2)(E) of this section and a training program as specified

under paragraph (2)(F) of this section.

25

228.77(5)(B)

Cheese using a Reduced Oxygen Packaging method have a HACCP plan

25

228.77(5)(C)

Labels the package on the principal display panel with a “use by” date that does not exceed 30 days from its packaging or the

original manufacturer’s “sell by” or “use by” date, whichever occurs first

25

228.77(5)(D)

Discards the reduced oxygen packaging cheese if it is not sold for off-premises consumption or consumed within 30 calendar

days of its packaging

25

228.243(b)

Documentation of proposed variance and justification

25

228.243(c)(1)

Conformance with approved procedures. If the regulatory authority grants a variance as specified in subsection (a) of this

section, or a HACCP plan is otherwise required as specified in §228.244(c) of this title, the establishment shall comply with the

HACCP plans and procedures that are submitted and approved as specified in §228.244(d) of this title as a basis for the

modification or waiver

25

228.243(c)(2)

Conformance with approved procedures. If the regulatory authority grants a variance as specified in subsection (a) of this

section, or a HACCP plan is otherwise required as specified in §228.244(c) of this title, the establishment shall maintain and

provide to the regulatory authority, upon request, records specified in §228.244(d)(4) and (5) of this title that demonstrate that the

following are routinely employed: procedures for monitoring critical control points; monitoring of the critical control points;

verification of the effectiveness of an operation or process; and necessary corrective actions if there is failure at a critical control

point

25

228.244(a)

When plans are required

25

228.244(d)(1)

Contents of a HACCP plan

25

228.106(j)(2)

Have HACCP Plan: Molluscan shellfish life-support system display tanks

25

228.71(d)(6)

Non-continuous Cooking obtained prior approval from the regulatory authority

25

228.71(a)(2)(A)

Roasts weight and temperature requirements for cooking in oven

25

228.66(e)(3)

Devices used for on-site generation of chemicals used in the washing/peeling of fruits and vegetables used in accordance with

the manufacturer’s instructions

25

228.111(n)(6)(C)

Chemical sanitizer generated by a device on-site shall be produced by a device that displays the EPA device manufacturing

facility registration number on the device

Compliance with

Variance,

Specialized

Process, and

HACCP plan;

Variance

obtained for

Specialized

Processing

Methods;

Manufacturer

Instructions

Regulatory Code Quick Reference

Item #

Part

TFER Regulation Code

TFER Quick Reference

25

228.111(n)(6)(D)

Chemical sanitizer generated by a device located on-site shall be produced by a device that is operated and maintained in

accordance with manufacturer’s instructions

25

228.186(k)(3)

Controlling pests. The presence of insects, rodents, and other pests shall be controlled to eliminate their presence on the

premises by using methods, if pests are found, such as trapping devices or other means of pest control as specified under

§228.204(b) and§228.208(b) and (c) of this title

26

228.74(b)

Non Pasteurized Juice properly labeled

26

228.80(a)

Consumer Advisory--when needed

26

228.80(b)(1)

Consumer Advisory--Disclosure--description criteria

26

228.80(b)(2)

Consumer Advisory Disclosure---asterisking

26

228.80(c)

Consumer Advisory--Reminder specifications

26

228.68(f)(2)

Consumer Advisory--salad bar or buffet --- use of clean tableware to return

26

228.79(a)(2)(E)

Allergen Labeling

26

228.62(a)(5)

Consumer Advisory--whole-muscle, intact beef steaks, criteria

26

228.79(b)(1)

Labeling -bulk food additional information

27

228.75(e)(1)

Cooling method, criteria

27

228.107(a)

Cooling, heating, and holding capacities. Equipment

27

228.221(a)(6)(A)

MOBILE FOOD UNIT--Cooling, heating, and holding capacities. Equipment

27

228.222(d)(3)

TEMPORARY ESTABLISHMENTS -- Hot and cold holding equipment. Equipment

27

228.223(l)

BED AND BREAKFAST -- Equipment capacity

27

228.225(e)

Self-Service Food Market--automatic shut-off control

27

228.225(f)

Self-Service Food Market--cold hold capacity

27

228.225(g)

Self-Service Food Market--self closing door

28

228.75(g)(1)

Date marking prepare on site RTE/ TCS food

28

228.75(g)(2)

Date marking commercially prepared RTE/ TCS food

28

228.75(g)(3)

Date marking combined ingredients for RTE/ TCS food

29

228.105(a)

Food thermometers--accurate, ±2 degrees Fahrenheit

29

228.105(b)

Food thermometers--easily readable

29

228.108(b)

Food thermometers provided and accessible

29

228.108(c)

Food thermometers--small diameter probe

29

228.103(b)

Food thermometers--glass limited

29

228.112(a)(2)

Food thermometers--calibrated

29

228.112(a)(3)

Food thermometers--maintained, good repair

29

228.224(j)

OUTFITTER OPERATION -- Thermometers

29

228.106(l)(5)

Food/ water temperature measuring device--numerical scale in increments no greater than 1°C or 2°F

29

228.106(l)(1)

Mechanically refrigerated or hot food storage unit, temperature measuring device located at warmest part

Posting of

Consumer

Advisories; Raw

or Undercooked

Foods

(Disclosure/Remi

nder/Buffet

Plate)/ Allergen

Labeling

Compliance with

Variance,

Specialized

Process, and

HACCP plan;

Variance

obtained for

Specialized

Processing

Methods;

Manufacturer

Instructions

Proper Cooling

Method used;

Equipment

Adequate to

Maintain Product

Temperature

Proper Date

Marking and

Disposition

Thermometers

Provided,

Accurate, and

Calibrated;

Chemical/

Thermal Test

Strips

Regulatory Code Quick Reference

Item #

Part

TFER Regulation Code

TFER Quick Reference

29

228.106(l)(2)

Cold or hot holding equipment include temperature measuring device located to allow easy viewing

29

228.106(l)(4)

Temperature measuring devices shall be designed to be easily readable

29

228.108(d)

Hot water mechanical ware washing operations, an irreversible registering temperature indicator shall be provided

29

228.106(o)(1)

Ware washing machine shall be equipped with a temperature measuring device that indicates the temperature of the water in

each wash and rinse tank

29

228.106(o)(2)

Ware washing machine equipped with temperature measuring device water enters the hot water sanitizing final rinse

manifold/chemical sanitizing solution tank

29

228.108(e)

Sanitizing solutions, testing devices

29

228.111(p)

Concentration of the sanitizing solution shall be accurately determined by using a test kit or other device

30

228.247

Does Establishment have a current valid permit posted?

30

228.221(a)(3)

MOBILE FOOD UNIT. Readily moveable

30

228.223(a)(2)

BED AND BREAKFAST criteria

30

228.225(b)

Self-Service Food Markets criteria

31

228.146(b)(1)

Hand washing facility provide water at a temperature of at least 38 degrees Celsius (100 degrees Fahrenheit) through a mixing

valve or combination faucet

31

228.147(a)(1)

Hand washing facilities. at least one hand washing lavatory, a number of hand washing lavatories necessary for their convenient

use by employees in areas, and not fewer than the number of hand washing lavatories required by the Plumbing Code shall be

provided

31

228.148(a)

Hand washing facilities. A hand washing facility shall be located: to allow convenient use by employees in food preparation, food

dispensing, and ware washing areas; and in, or immediately adjacent to, toilet rooms

31

228.149(a)

Using a hand washing facility. accessible at all times for employee use; not be used for purposes other than hand washing

31

228.146(b)(2)

A steam mixing valve may not be used at a handwashing sink

31

228.146(b)(3)

A self-closing, slow-closing, or metering faucet shall provide a flow of water for at least 15 seconds without the need to reactivate

the faucet

31

228.146(b)(4)

An automatic handwashing facility shall be installed in accordance with manufacturer's instructions

31

228.221(a)(6)(C)

MOBILE FOOD UNIT-- At least one handwashing sink

31

228.222(i)

TEMPORARY ESTABLISHMENT--Handwashing facilities criteria

31

228.223(i)

BED AND BREAKFAST -- Hand sinks

31

228.224(h)

OUTFITTER OPERATION -- Handwashing facility criteria

31

228.175(b)

Hand washing cleanser, availability

31

228.38(f)(1)

A hand antiseptic (sanitizer) criteria

31

228.38(f)(2)

If a hand antiseptic or a hand antiseptic solution used as a hand dip does not meet the criteria specified under paragraph (1)(B)

of this subsection, use shall be:(A) followed by thorough hand rinsing in clean water before hand contact with food or by the use

of gloves; or (B) limited to situations that involve no direct contact with food by the bare hands

31

228.38(f)(3)

HAND DIP: hand antiseptic solution strength at least 100 mg/L chlorine

31

228.38(b)(4)

Automatic hand washing facility may be used if approved

31

228.175(c)

Hand drying provision.

31

228.38(b)(3)

Disposable paper towels used to avoid re-contaminating hands if manually operated faucet handles on a hand washing sink or

the handle of a restroom door

Establishment

Permit

Thermometers

Provided,

Accurate, and

Calibrated;

Chemical/

Thermal Test

Strips

Adequate Hand

Washing

Facilities:

Accessible and

Properly Supplied

Regulatory Code Quick Reference

Item #

Part

TFER Regulation Code

TFER Quick Reference

32

228.104(a)

Cleanability. Food-contact surfaces.

32

228.101(a)(2) -(5)

Materials that are used in the construction of utensils and food-contact surfaces of equipment may not allow the migration of

deleterious substances or impart colors, odors, or tastes to food and under normal use conditions shall be: durable, corrosion-

resistant, and nonabsorbent; sufficient in weight and thickness to withstand repeated ware washing; finished to have a smooth,

easily cleanable surface; and resistant to pitting, chipping, crazing, scratching, scoring, distortion, and decomposition

32

228.106(c)(5)

Dispensing equipment in which Time/Temperature Control for Safety (TCS) food in a homogenous liquid form is maintained

outside of the temperature control requirements as specified under §228.75(f)(1) shall: be specifically designed and equipped to

maintain the commercial sterility of aseptically packaged food in a homogenous liquid form for a specified duration from the time

of opening the packaging within the equipment; and conform to the requirements for this equipment as specified in NSF/ANSI 18-

2006- manual food and beverage dispensing equipment

32

228.63(e)

Package integrity

32

228.104(c)

Cleaned in place (CIP) equipment. CIP equipment shall meet the characteristics specified under subsection (a) of this section

and shall be designed and constructed so that: cleaning and sanitizing solutions circulate throughout a fixed system and contact

all interior food-contact surfaces; and the system is self-draining or capable of being completely drained of cleaning and

sanitizing solutions; and CIP equipment that is not designed to be disassembled for cleaning shall be designed with inspection

access points to ensure that all interior food-contact surfaces throughout the fixed system are being effectively cleaned

32

228.103(a)

Equipment and utensils. Equipment and utensils shall be designed and constructed to be durable and to retain their characteristic

qualities under normal use conditions

32

228.110(b)(1)

Except as specified in paragraphs (2) and (3) of this subsection, floor-mounted equipment that is not easily movable shall be

sealed to the floor or elevated on legs that provide at least a 15-centimeter (6-inch) clearance between the floor and the

equipment

32

228.110(b)(4)

Except as specified in paragraph (5) of this subsection, counter-mounted equipment that is not easily movable shall be elevated

on legs that provide at least a 10- centimeter (4-inch) clearance between the table and the equipment

32

228.112(a)(1)

Utensils shall be maintained in a state of repair or condition that complies with the requirements specified under §§228.101 -

228.106 of this title or shall be discarded

32

228.101(b)(1)

Cast iron, use limitation. Except as specified in paragraphs (2) and (3) of this subsection, cast iron may not be used for utensils

or food-contact surfaces of equipment

32

228.101(f)

Sponges, use limitation. Sponges may not be used in contact with cleaned and sanitized or in-use food-contact surfaces

32

228.101(g)

Wood, use limitation. Except as specified in paragraphs (2) - (4) of this subsection, wood and wood wicker may not be used as a

food-contact surface

32

228.101(h)

Nonstick coatings, use limitation. Multiuse kitchenware such as frying pans, griddles, sauce pans, cookie sheets, and waffle

bakers that have a perfluorocarbon resin coating shall be used with nonscoring or nonscratching utensils and cleaning aids

32

228.104(c)(1)(A)

Clean in place equipment design and constructed criteria

32

228.104(d)

“V” threads, use limitation

32

228.104(e)

Hot oil filtering equipment

32

228.104(f)

Can openers

32

228.104(g)

Nonfood-contact surfaces. Nonfood-contact surfaces shall be free of unnecessary ledges, projections, and crevices, and

designed and constructed to allow easy cleaning and to facilitate maintenance

32

228.106(b)(1)

A cover or lid for equipment shall overlap the opening and be sloped to drain

Food and Non-

food Contact

surfaces

Cleanable,

Properly

Designed,

Constructed, and

Used

Regulatory Code Quick Reference

Item #

Part

TFER Regulation Code

TFER Quick Reference

32

228.106(b)(2)

An opening located within the top of a unit of equipment that is designed for use with a cover or lid shall be flanged upward at

least 5 millimeters (two-tenths of an inch)

32

228.106(b)(3)

Fixed piping, temperature measuring device, rotary shafts, and other parts extending into equipment shall be provided with a

watertight joint at the point where the item enters the equipment

32

228.149(f)(1)(B)-(C)

Materials, approved. Materials that are used in the construction of a MOBILE water tank, MOBILE FOOD UNIT water tank, and

appurtenances shall be: (B) durable, corrosion-resistant, and nonabsorbent; and (C) finished to have a smooth, easily cleanable

surface

32

228.149(f)(2)

Tank design and construction

32

228.149(f)(3)

Tank inspection and cleaning port, protected and secured

32

228.149(f)(7)(B)- (E)

Tank hose, construction and identification

32

228.149(f)(10)

MOBILE FOOD UNIT tank inlet criteria--same as 228.221(a)(8)

32

228.221(a)(8)

MOBILE FOOD UNIT tank inlet criteria-- same as 228.149(f)(10)

32

228.221(c)(1)(E)

Potable water servicing equipment shall be installed in the servicing area according to the Plumbing Code and shall be stored

and handled in a way that protects the water and equipment from contamination

32

228.222(d)(1)

Design and construction. Equipment/utensils durable

32

228.223(h)

Equipment and utensil design and construction. safe materials and maintained in good repair

32

228.223(j)

Food-contact surfaces. smooth, non-absorbent and easily cleanable

32

228.224(f)(2)

Ice storage container criteria

32

228.224(g)(2)

Potable water storage criteria

32

228.224(i)

Equipment and utensils approved for food use.

33

228.106(p)(1)

Manual ware washing equipment, heaters and baskets. If hot water is used for sanitization in manual ware washing operations,

the sanitizing compartment of the sink shall be: designed with an integral heating device that is capable of maintaining water at a

temperature not less than 77 degrees Celsius (171 degrees Fahrenheit)

33

228.106(p)(2)

Manual ware washing equipment, heaters and baskets. If hot water is used for sanitization in manual ware washing operations,

the sanitizing compartment of the sink shall be: provided with a rack or basket to allow complete immersion of equipment and

utensils into the hot water

33

228.107(b)(1)

Manual ware washing, sink compartment requirements

33

228.107(b)(2)

Sink compartments shall be large enough to accommodate immersion of the largest equipment and utensils.

33

228.111(i)

Manual ware washing equipment, wash solution temperature

33

228.107(c)

Drain boards

33

228.221(a)(6)(B)

MOBILE FOOD UNIT -- Manual warewashing, sink compartment requirements

33

228.223(e)(1)

Bed and Breakfast -- Manual. A three compartment sink shall be used if washing, rinsing and sanitizing of utensils and equipment

is done manually; or a two compartment sink may be utilized if single service tableware is provided, and if an approved detergent

sanitizer is used

33

228.115(d)

Wet cleaning

33

228.115(f)

Rinsing procedures

33

228.125(d)

Rinsing Equipment and Utensils after Cleaning and Sanitizing

33

228.111(d)

Warewashing equipment, cleaning frequency

Warewashing

Facilities;

Installed,

Maintained,

Used; Service

sink or Curbed

Cleaning Facility

Provided

Food and Non-

food Contact

surfaces

Cleanable,

Properly

Designed,

Constructed, and

Used

Regulatory Code Quick Reference

Item #

Part

TFER Regulation Code

TFER Quick Reference

33

228.111(f)(2)

If a warewashing sink is used to wash wiping cloths, wash produce, or thaw food, the sink shall be cleaned as specified under

subsection (d) of this section before and after each time it is used to wash wiping cloths or wash produce or thaw food. Sinks

used to wash or thaw food shall be sanitized as specified under §228.116 - 228.118 of this title before and after using the sink to

wash produce or thaw food

33

228.111(g)

Warewashing equipment, cleaning agents

33

228.111(h)

Warewashing equipment, clean solutions. The wash, rinse, and sanitize solutions shall be maintained clean

33

228.106(q)(1)

Ware washing machines, automatic dispensing of detergents and sanitizers. A ware washing machine that is installed after

adoption of these rules by the regulatory authority, shall be equipped to automatically dispense detergents and sanitizers

33

228.106(q)(2)

Ware washing machines, automatic dispensing of detergents and sanitizers. A ware washing machine that is installed after

adoption of these rules by the regulatory authority, shall be equipped to incorporate a visual means to verify that detergents and

sanitizers are delivered or a visual or audible alarm to signal if the detergents and sanitizers are not delivered to the respective

washing and sanitizing cycles

33

228.111(j)

Mechanical warewashing equipment, wash solution temperature

33

228.106(m)

Warewashing machine, data plate operating specifications

33

228.106(n)

Warewashing machines, internal baffles

33

228.106(r)

Warewashing machines, flow pressure device

33

228.106(s)

Warewashing sinks and drain boards, self-draining. Sinks and drain boards of warewashing sinks and machines shall be self-

draining

33

228.111(e)

Warewashing machines, manufacturers’ operating instructions

33

228.115(c)

Loading of soiled items, warewashing machines

33

228.223(e)(2)

``

33

228.111(l)

Mechanical warewashing equipment, hot water sanitization temperatures.

33

228.111(m)

Mechanical warewashing equipment, sanitization pressure.

33

228.111(o)

Manual warewashing equipment, chemical sanitization using detergent-sanitizers

33

228.115(e)

Washing, procedures for alternative manual warewashing equipment.

33

228.107(b)(4)

Before a two-compartment sink is used criteria

33

228.107(b)(5)

A two-compartment sink may not be used for warewashing operations where cleaning and sanitizing solutions are used for a

continuous or intermittent flow of kitchenware or tableware in an ongoing warewashing process

33

228.222(d)(5)

Alternative manual warewashing

33

228.224(e)

Warewashing. Alternative manual warewashing equipment

33

228.147(c)(1)

Service sink or one curbed cleaning facility provided

Core Items

34

228.174(c)

Insect control devices, design and installation

34

228.174(e)(1)

Outer openings, protected

34

228.174(e)(3)

Exterior doors used as exits need not be self-closing if they are solid and tight-fitting

34

228.174(e)(4)

Windows or doors protected against the entry criteria

34

228.174(f)

Exterior walls and roofs, protective barrier

34

228.186(k)(1)

Controlling pests. Routine check shipments of food and supply

34

228.186(k)(2)

Controlling pests. Check premises

Warewashing

Facilities;

Installed,

Maintained,

Used; Service

sink or Curbed

Cleaning Facility

Provided

No Evidence of

Insect

Contamination,

Rodent/other

Animals

Regulatory Code Quick Reference

Item #

Part

TFER Regulation Code

TFER Quick Reference

34

228.186(k)(4)

Controlling pests. Eliminating harborage conditions

34

228.186(l)

Removing dead or trapped birds, insects, rodents, and other pests

34

228.222(k)(2)

Outer openings

34

228.223(k)(1)

BED AND BREAKFAST Construction

34

228.186(o)(1)

Live animals may not be allowed on the premises of a establishment

34

228.186(o)(2)(A)

Edible fish or decorative fish in aquariums, shellfish or crustacea on ice or under refrigeration, and shellfish and crustacea in

display tank systems

34

228.186(o)(2)(B)

Patrol dogs accompanying police or security officers

34

228.186(o)(2)(C)

Service animals

34

228.186(o)(2)(D)

Pets in the common dining areas criteria

34

228.186(o)(2)(E)

Displayed or Caged animals or animals that are similarly confined

34

228.186(o)(3)

Live or dead fish bait storage

35

228.42(a)(1)

Eating food, chewing gum, drinking beverages, or using tobacco

35

228.43(a)

Hair Restraints effective

35

228.40

Jewelry Prohibition

35

228.41

Outer Clothing, Clean Condition

36

228.68(d)(1)(A)

Cloths in-use maintained dry

36

228.68(d)(1)(B)

Cloths in-use for wiping food spills used for no other purpose

36

228.68(d)(2)(A)

Cloths in-use for wiping between uses stored

36

228.68(d)(2)(B)

Cloths in-use for wiping laundered daily

36

228.68(d)(3)

Cloths in-use for wiping raw animal foods shall be kept separate

36

228.68(d)(4)

Dry wiping cloths and the chemical sanitizing solutions free of food debris and visible soil

36

228.68(d)(5)

Containers of chemical sanitizing solutions stored off the floor and used in a manner that prevents contamination

36

228.68(d)(6)

Single-use disposable sanitizer wipes used in accordance with EPA-approved manufacturer’s instructions

36

228.120(d)

Wet wiping cloths shall be laundered daily

36

228.120(e)

Dry wiping cloths shall be laundered as necessary to prevent contamination of food and clean serving utensils

36

228.121(b)(2)

Where Wiping cloths laundered criteria

36

228.122(b)

Wiping cloths, air-drying locations

37

228.69(a)(1)(A)

Food shall be protected from contamination by storing the food in a clean, dry location