www.DuxxBakDecking.com APRIL, 2021 V13.8 Page 1 of 16

DUXXBAK DEKK WATER SHEDDING DECK SYSTEM

INSTALLATION INSTRUCTIONS

DuxxBak DekkWater Shedding Deck System

• The DuxxBak Dekk Water Shedding Deck System is an innovave product designed to shed water in any

environment. Properly installed, DuxxBak Dekk will provide a funconal, dry underdeck area, without the moisture

buildup and structural compromise associated with convenonal underdeck drainage systems. Installaon of this

product is vastly dierent from our other quality oerings. Strict adherence to these installaon instrucons will

ensure delivery of an aracve, funconal system.

By DuxxBak Composite Decking

A Division of Green Bay Decking, LLC

www.DuxxBakDecking.com APRIL, 2021 V13.8 Page 2 of 16

TABLE OF CONTENTS

Important Installaon Tips 3

General Informaon 4

Product Informaon 4

DuxxBak Dekk Product Proles 4

Storing and Handling 4

Sucient Pitch 4

Substructure Framing 4

Proper Caulk and Flashing System 5

Caulk and Flashing On Masonry 5

Fasteners Installaon 5

Fascia Installaon 6

Special Design Concepts 6

Installaon Hints 6

Final Preparaon 7

Proper Endcap Selecon 7

Parts of DuxxBak Dekk Board 7

Installaon Guide 8

Step 1: Install The First Deck Board 8

Step 2: Install The Second and Subsequent Deck Boards 9

Step 3: Install The Final Deck Board 9

Step 4: Install Seal and Flashing 10

Step 5: Install Endcaps on Exposed Boards 11

Step 6: Install Guers 11

Step 7: Compleon 11

DuxxBak Dekk End Cap Installaon On A 45 Degree Angle Deck 12

Installaon of Replacement Board 13

Stair Installaon 14

Care and Maintenance 14

Warranty 14

Fasteners 15

Product Features 16

List of Revisions 16

www.DuxxBakDecking.com APRIL, 2021 V13.8 Page 3 of 16

DuxxBak Dekk WATER SHEDDING DECK SYSTEM

IMPORTANT INSTALLATION TIPS

• If quesons arise during installaon for which you can nd no answer, or for general product or installaon quesons, please call

us toll-free at 1-877-804-0137.

• All composite decking will expand and contract as temperatures change. To minimize potenal system failure resulng from these

movements, avoid installing your decking during extreme temperatures.

• DuxxBak Dekk is designed for use as weather protecon above an outdoor living area. DuxxBak Dekk is not designed or approved

to be used over a temperature-controlled, enclosed living space.

• An unrestricted minimum pitch of 1/8” per foot in the direcon of intended water ow (along the length of the deck board) is

required.

• A gap of at least 3/16” must be provided where the deck boards meet the house or other structure. A gap of 3/16” must be

provided at each side of posts or other obstrucons.

• See important board-gapping informaon in step 2 of installaon instrucons, page 9.

• Use genuine DuxxBak Composite Decking screws, or equivalent.

• All fasteners must be located a minimum of 3/4” from the ends of the deck boards. Addionally, any necessary face fasteners

should be placed near the deck board structural septum, but not directly through the septum. Avoid over penetraon of the

fastener heads.

• DuxxBak Dekk should be installed on an open structure that allows venlaon through the deck structure. If installing a ceiling

below a DuxxBak Dekk, installers should defer to the venlaon requirements of the structural component manufacturer.

• As with any manufactured decking product, be aware of condions where reecve heat buildup from “Low-E” glass may cause

damage to your deck.

• No special tools are required to work with DuxxBak Composite Decking products. Typical wood-working tools are recommended.

• It is always good idea to wear personal protecve equipment, such as safety glasses, hearing protecon, and a dust mask when

working with any construcon materials.

• Composite decking is not designed to act as a structural element. Avoid placing weight bearing loads, such as roof-support

columns, on top of a composite decking surface.

• Installaon and care instrucons & videos can also be found on our website at www.duxxbakdecking.com

• An numeric superscript is used at various locaons in this document to reference a revision from V13.7. All revisions can be found

on the “List of Revisions” document.

Thank you for choosing the DuxxBak Dekk Water Shedding Deck System

®

www.DuxxBakDecking.com APRIL, 2021 V13.8 Page 4 of 16

GENERAL INFORMATION

PRODUCT INFORMATION

DuxxBak Dekk boards have laser-engraved idencaon

informaon on the board edge, including a code-

compliance report number.

DuxxBak Dekk boards are made from a formulaon of

BioDac®, rice hulls (a rapidly renewable resource), HDPE,

and other high-quality materials. Its properes are an

innovave deviaon from those of other manufactured-

decking opons. Therefore, DuxxBak Dekk has dierent

handling and installaon requirements which must be

considered during planning and installaon.

Typical woodworking tools are recommended. No special

tools are required.

If quesons arise during installaon for which you can nd

no answer, or for general product or installaon

quesons, please call us toll-free at 1-877-804-0137.

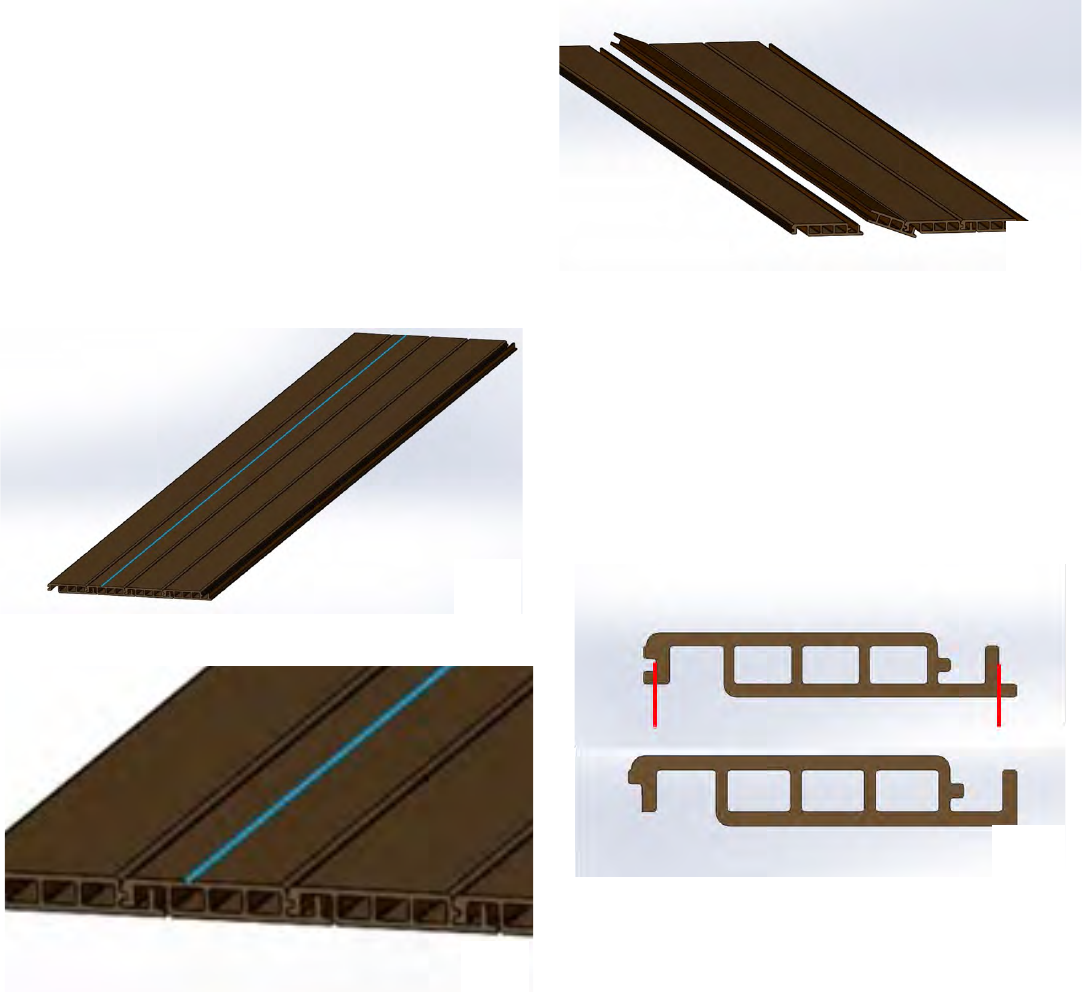

DUXXBAK DEKK PRODUCT PROFILES

DuxxBak Dekk Product Proles

• DuxxBak Dekk

Descripon: 5/4” x 7-1/4”

Height: 1-1/4”

Width: 5-3/4” Coverage

Lengths: 12’, 16’,20’ and 24’

Weight: Approx. 2.1 lbs./.

• DuxxBak Dekk End Cap (Right & Le)

Height: 1-1/4”

Width: 5-3/4”

Weight: Approx. 0.06 lbs.

To determine end cap direcon for DuxxBak Dekk or I.Dekk®

T&G: While looking at the open end of installed deck boards,

simply refer to the side of the deck at which you began

installaon—LEFT or RIGHT. (See illustraon on pg 7).

• Fascia Board

Height:12”

Thickness: 7/16”

Length: 12’

Weight: Approx. 2.6 lbs./.

SUFFICIENT PITCH

Before installing DuxxBak Dekk, be sure your deck structure

has an unrestricted minimum pitch of 1/8” per foot to help

shed water from the deck surface. Remember: Pitch must

run lengthwise direcon of the DuxxBak Dekk boards.

SUBSTRUCTURE FRAMING

Plan your deck substructure to use current framing

techniques as outlined in the Internaonal Residenal Code

(IRC) and your local building codes.

Remember that the deck pitch must be unrestricted. The

deck structure must be constructed such that the top of the

structure is in plane, avoiding the introducon of a high point

or a low point along the pitch of the deck.

DuxxBak Dekk is designed for installaon on joists that are

spaced at 24”, or less, on center. Each joist longer than 6’

should be installed with at least three points of aachment.

If a joist is aached or supported only at each end, and is

longer than 6’, internal blocking must be installed at 6’

intervals to stabilize the structure. The mid-joist beam or

blocking will also enable the installer to bring the enre deck

structure into plane.

Support blocking should be installed to support the full width

of every deck board where it is cut around obstrucons such

as railing posts.

I.Dekk® or I.Dekk HD S4S or OPTIMA® Dekk Square Edge deck

boards can be used as stair treads, to complement the

DuxxBak Dekk system.

STORING & HANDLING DUXXBAK®

DuxxBak Dekk should be stored on a at surface with

supports every 48”. Do not stack decking more than four

units (bundles) high. Trim boards should have supports every

24”, to avoid sagging, which could make proper installaon

challenging.

It is always a good idea to wear personal protecve

equipment, such as safety glasses, hearing protecon, and a

dust mask when working with construcon materials.

www.DuxxBakDecking.com APRIL, 2021 V13.8 Page 5 of 16

PROPER CAULK AND FLASHING SYSTEM

Successful installaon of your deck is dependent on proper

sealing and ashing at the surfaces where the deck meets

your home or other structure. Water must be properly

directed to avoid leakage.

• Sealants: Use LEXEL Adhesive Sealant or equivalent to

form water barriers where a sealant is recommended.

• Sealing Tape: Use the best sealing tape available from

your supplier to form a waterproong barrier at the

point where the ashing and house wrap are joined.

• Butyl Tape: Use butyl tape to form a waterproong

barrier at those points where structural objects

penetrate the deck, to form a waterproong seal.

• Flashing: Use exterior-grade vinyl, coated aluminum, or

galvanized ashing rated for contact with your deck’s

structural components.

Counterashing is a piece of metal or vinyl designed to shed

water away from the wall of a building, and is an essenal

step when installing DuxxBak No Drip Through Decking on a

deck structure that is aached to a masonry wall where tra-

dional ashing cannot be achieved. This approved method

of counterashing for masonry walls is called Reglet counter-

ashing.

CAULK AND FLASHING ON MASONRY

Counterashing

Wall

Sealant

Sealant

Counter Flashing Wedge

or Copper Wool

Deck

Reglet Counterashing is done by using a masonry saw or

grinder to cut a 3/4” to 1-1/2” Reglet in the masonry. The

Reglet can be cut into a joint, or into the stone itself. The

ashing is then inserted into the Reglet, and held in place

with a lead wedge or copper wool, or ashing wedge. A bead

of caulk is then used to ll the reglet opening. Sealant should

also be installed where the deck meets the wall, and where

the ashing meets the deck boards.

FASTENERS INSTALLATION

General Notes

• DuxxBak Composite Decking screws, or equivalent, are

recommended.

• Avoid the use of “composite screws”—those with re-

verse threads near the top end of the screw—as the re-

verse threads displace too much material, compromising

the aachment of decking to structure. Ideally, a screw

with a smooth (non-threaded) sha at its top should be

used.

• Make sure the fastener coang is approved for use in

your structural material.

• Stainless steel screws are recommended for use near

salt water.

• Addional fastener informaon can be found on the

Fasteners page at end of this instrucon manual.

DuxxBak Dekk

• Use 1-1/4” (or longer) DuxxBak Composite Decking

screws to aach the decking through the fastening wing.

Insert fasteners at an angle of 55-60 degrees. (Please

see illustraon, above)

• Use 2-1/4” (or longer) DuxxBak Composite Decking

screws to aach decking when it is necessary to insert a

fastener through the face of the deck board.

I.Dekk® Fascia

• Use 1-1/2” (or longer) DuxxBak Composite Decking

screws to aach fascia.

• Use a minimum of three fasteners every 12” to secure

the connecon.

DuxxBak Dekk End Cap

• End caps can be secured using an adhesive sealant ap-

plied to the legs of each cap before inseron.

• Alternavely, a 1/8” hole may be drilled through the

underside of the decking and through 2 legs of the end

cap, into which a #6 x 1” truss-head or pan-head screw

can be inserted.

www.DuxxBakDecking.com APRIL, 2021 V13.8 Page 6 of 16

FASCIA INSTALLATION

Install fascia to the outer joists (rim joists and end joists) of

the deck substructure.

• Use a minimum of three evenly spaced screws every

12” (or two every 12” if the fascia has been ripped to 6”

or less).

• End-to-end “bu-joints” must have a 3/16” minimum

gap to allow for expansion and contracon with

variaons in temperature. There are several methods of

concealing the gaps in fascia bu-joints, as follow:

Leave a wider gap and cover with a ripped piece

of fascia installed vercally. Be sure the screws

that aach the cover do not limit movement of

the boards being bued together (see below

illustraon).

Apply a dark wood stain (similar to the color of

the fascia) to the joist 1”-2” in each direcon

from where the bu-joint will lie. As the fascia

opens and closes, the wood stain will render

the gap praccally invisible.

• The same 3/16” gap should be allowed at corners to

allow for expansion and contracon. A corner molding

can be ripped from a spare piece of decking or post

sleeve. This cover should only be aached through one

side to allow for expansion and contracon. (Please see

illustraon below) Alternavely, the wood-stain process

described above can be used here to conceal the

required gap (see below illustraon.

SPECIAL DESIGN CONCEPTS

Special design concepts may require that you and your

designer consider how to best implement those concepts,

prior to construcon, to avoid problems during or aer

installaon. The following may be such situaons:

• DuxxBak Dekk is available in 12’, 16’, 20’, and 24’ lengths.

Custom lengths are available subject to restricons.

Design concepts must be considered if condions require

longer spans to assure that water can properly shed from

the deck.

• Deck boards should not be bued end to end, as this

would compromise the waterght integrity of the DuxxBak

Dekk installaon.

• Contact DuxxBak Composite Decking for technical

guidance for special design consideraons relave to your

specic project.

INSTALLATION HINTS

• Lay the deck boards out prior to installaon to determine

the most pleasing eect of the grain paern.

• It is best to mark, cut, and install deck boards when they

are all at similar temperature.

• Cut boards to length, aer installaon, allowing a 1-7/16”

overhang past the deck structure. This will allow for the

installaon of a 7/16” fascia board and a nal overhang of

1”.

• Fascia may be installed before or aer decking installaon.

• A guer apron (drip edge) should be installed on top of

the outermost framing member, or fascia, to divert

drainage away from the deck structure and fascia, and to

prevent water from wicking back on the underside of deck

boards. A bead of adhesive sealant should be installed

between the deck boards and the top of the apron.

• It is possible to conceal the heads of GBD trim head

screws in both decking and trim boards. Simply drive the

screws just below the surface of the board. Then, gather

the material (which has been displaced by the screw) on

top of the screw head, and tap with a hammer.

www.DuxxBakDecking.com APRIL, 2021 V13.8 Page 7 of 16

FINAL PREPARATION

Here are a few nal steps to take before beginning actual in-

stallaon of the DuxxBak Dekk deck boards.

Step 1: Determine Your Starng Point

Determine which side of the substructure will be the starng

point for your deck. If aaching to an inside corner of a house,

start on the end of the deck away from the house, and work

toward the house. For a deck aached only at one edge, you

can choose either side as a starng point. For the purposes of

this installaon guide, we’ll assume we’re working with an in-

side-corner deck, and we’ll start the decking on the le side as

we are looking at the back of the house from the rear yard.

Step 2: Assure most desired appearance

Lay the deck boards out on the structure, and look from dier-

ent perspecves, to determine how the deck will best show its

aesthec features.

Step 3: Prepare for ashing

If possible, remove the boom course of siding, to ease instal-

laon of ashing & sealant as decking installaon progresses.

Be sure to mark each piece of siding so that it can be reinstalled

in the same place from which it was removed.

PROPER ENDCAP SELECTION

Right End Cap needed.

Le End Cap needed.

Parts of a DuxxBak Dekk Board

To determine end cap direcon for DuxxBak Dekk or I.Dekk

T&G: While looking at the open end of the installed deck

boards, simply refer to the side of the deck at which you be-

gan installaon—Le or Right.

www.DuxxBakDecking.com APRIL, 2021 V13.8 Page 8 of 16

Installaon Guide

Step 1: Install the rst deck board

Cut the enre groove wing (1-9/16” cut) away from the rst

board to leave a smooth outer surface. A sander or router can

be used to make the cut edge more uniform in appearance,

and to round over the cut edge. (see Fg1)

Posion the rst board on the deck with the fastening wing to

the right, with the board overhanging the edge of the structure

1 7/16” (or past the installed fascia board 1”).

(Not shown in these illustraons is a recommended guer

shroud, or drip edge, which should be installed between the

deck boards and the outermost structural members or fascia).

A 3/16” gap must be allowed where the end of the board

meets the house, as well at any point where the deck board

meets an abutment.

Notch the rst and second boards, if necessary, to allow for any

obstrucon that will penetrate the decking surface, such as

wooden railing posts. Cut the notches to allow for a clearance

of 3/16” on all sides of obstrucons.

Before installing the rst and all subsequent DuxxBak Dekk

boards, a bead of sealant (LEXEL is recommended) should be

installed on top of the outermost structural members (or on

top of the guer shroud) to act as a water-stop to prevent

drainage from wicking back on the underside of the deck

board.

12

Aer notching the second board to allow penetraon of

obstrucons, place a connuous bead of sealant into the enre

length of the interlocking groove of the second board, to

prevent water penetraon into the now-interrupted drainage

channel below. Because the railing post will interrupt the

channel, any water entering the channel could become trapped

without introducon of sealant in the interlocking groove. (See

Fg2)

Assure that the rst deck board is properly posioned and is

square to the structure.

Secure the deck board to the joists by inserng one 2 1/4” (or

longer) trim head screw through the face of the board at each

joist, with the screw being placed near a septum of the deck

board to take advantage of the points of highest strength. Set

the screw heads just below the top surface of the board to

avoid pullout, and to parally conceal the screw head.

Complete the installaon of the rst board by inserng a 1-

1/4” (or longer) trim screw through the fastening wing at each

joist. Insert the screw at ≥ 55 degree angle. (See Fg3)

Note: If there are no obstrucons, such as wooden railing posts,

there is no need to insert sealant in the interlocking groove

between the courses.

Step 1: (connued)

Fg1

Fg2

Fg3

www.DuxxBakDecking.com APRIL, 2021 V13.8 Page 9 of 16

Step 2: Install the second and subsequent deck boards.

With the rst and each subsequent board, insert a bead of

sealant onto the end joist, under where the board will be

installed closest to the house. (See Fg4)

And apply a generous dollop

of sealant into the drainage

channel, closest to the

house, to prevent wind-

driven rain from being blown

backward through the

channel toward the house.

(See Fg5) This dollop should

also act as a water-stop,

compressed between the

deck boards as they are

being installed.

Posion the second and subsequent boards by engaging the

interlocking grooves of each board to lock the boards together,

allowing a minimum 3/16” from the board ends to the wall.

Using a 1/32” gapping tool (typical credit card thickness),

secure each board using the prescribed fasteners (See Fg6). Do

not introduce a gap between deck boards that are to be sealed

at the interlocking groove to prevent water penetraon

because of a drainage channel interrupon. (You may use any

gapping mechanism that measures 1/32” [.03” or 1 mm] to

introduce this gap). Do not allow the gapping tool to drop

between the interlocking groove interface. GBD recommends

Perfect Level Reuseable Crosses.

NOTE: For installaons over a pre-exisng Pressure Treated or

a metal structure or if the air temperature at me of

installaon is 80°F or greater, the introducon of a gap

between the boards is not recommended.

Note: The gap between deck boards will allow the deck struc-

ture to move without compromising the integrity of the deck

surface.

Notch each subsequent board as necessary to allow for ob-

strucons that may penetrate the deck substructure at the

point where the board is being installed. Remember to install

support blocking to ensure rigidity across the deck surface

where boards have been notched.

Allow for a clearance of 3/16” on all sides of posts or other

structure obstrucons when installing the deck board.

And once again, at any point where an obstrucon interferes

with the ow of water through the channel, place a connuous

bead of sealant in the enre length of the interlocking groove

so that water will not nd its way through the deck surface,

into the drainage channel, where it may become trapped. (See

Fg2, page 8)

Step 3: Install the nal deck board.

Measure the area to be covered by the nal deck board.

If the nal board will be against the house, rip the board to at

least 3/16” less than the distance to the house.

If the nal board will overhang the deck, rip the board back to

a septum to overhang the fascia an acceptable distance. As in

preparaon of the rst board, clean up the ripped edge using a

sander or router.

Step 2: (connued)

Fg4 Fg6

Fg5

Installaon Guide (cont’d)

www.DuxxBakDecking.com APRIL, 2021 V13.8 Page 10 of 16

Secure the last deck board to the joists by inserng one trim

head screw through the face of the board at each joist, with

the fastener being placed near a septum of the deck board to

take advantage of the points of strength. Assure that the

screw heads are seated just below the top surface of the

board. (See Fg8)

Step 3: (connued)

Notch the board as necessary to allow for obstrucons that

may penetrate the deck substructure at the point where the

board is being installed. Allow for a clearance of 3/16” on all

sides of posts or other structure obstrucons when installing

the deck board. Be sure that support blocking is installed to

support the deck board where notched around obstrucons.

As with all obstrucon-based notches, place a connuous bead

of sealant in the enre length of the interlocking groove if the

board seam will intersect an obstrucon, to assure that water

will not nd its way through the deck to the surface below.

Place a bead of sealant along any joist where the deck board

will rest, on all sides of the deck. (See Fg7)

Step 4: Install seal and ash

Cut and dry-t a piece of corrosion-resistant ashing to be

installed behind the house-wrap membrane and on top of the

decking. The ashing should be bent so that when installed it

will naturally compress against the wall and the deck, and will

shed water away from the house.

Set the ashing aside unl the sealant, described below, is in

place.

Place a generous, connuous bead of sealant on top of the

DuxxBak Dekk boards approximately 3/4” away from the

house. This sealant will create a barrier to keep wind-driven

water from being blown back underneath the ashing. (See

Install your pre-bent ashing at the house-to-deck connecon,

holding the ashing ght against the house and sliding it down

onto the decking, thereby compressing the sealant installed in

the previous step. Be sure that a connuous seal is formed be-

tween the ashing and the decking. (See Fg10)

Fg7

Fg8

Fg9

Fg10

Installaon Guide (cont’d)

www.DuxxBakDecking.com APRIL, 2021 V13.8 Page 11 of 16

Step 4: (connued)

Secure the ashing to the wall behind the house wrap, using a

roong nail, staple, or other appropriate fastener.

Secure the house wrap to the face of the ashing using an

appropriate sealing tape. (See Fg11)

Install or reinstall siding if it has been removed for the deck

installaon.

Install waterproong butyl tape to the deck board (7/8”) and

obstrucon at all locaons where an obstrucon penetrates

the deck, so that water does not nd its way through the deck

to the area below. (See Fg12)

Step 4: (connued)

The waterproong butyl tape will be concealed by the post

sleeve and base trim when the rail system is installed. (See

Fg13)

If the railing posts are not sleeved, a trim piece can be created

to conceal the butyl tape. Be sure to only fasten the trim piece

to the wood post, and not to or through the decking.

If installing structural railing posts,

• Adhere to post manufacturer’s installaon guidance.

• Seal interlocking groove if fastener penetrates through

drainage channel (Step 1, page 8)

• Apply a generous amount of Lexel (or equivalent) around

base of post and around each fastener head to prevent

water penetraon.

Step 5: Install end caps to exposed board ends

Install the appropriate end caps, detailed on page 7.

Insert the end cap with the drain slots down and the arrow

poinng up.

End caps can be secured using an adhesive sealant applied to

the legs of each cap before inseron. Alternavely, a 1/8” hole

may be drilled through the underside of the decking and

through 2 legs of the end cap, into which a #6 x 1” truss-head

or pan-head screw can be inserted.

Step 6: Install guers

Install system per your design concept.

Step 7: Compleon

Install rail system to assure the safety of those who will use

your deck.

Enjoy your new deck!!!

Fg11

Fg12

Fg13

Installaon Guide (cont’d)

www.DuxxBakDecking.com APRIL, 2021 V13.8 Page 12 of 16

DuxxBak Dekk End Cap Placement On A 45 Degree Angle

15

End Caps for the GBD products are primarily designed for

square end applicaons. Occasionally, it is necessary to install

an end cap on a DuxxBak installaon that is at 45° angle. The

following informaon will allow easy and aracve applica-

on of end caps into a 45° angle applicaon. Please note, this

will require 2 (two) end caps per board.

Step 1:

Cut your rst end cap as shown below. Fg14

Step 2:

Remove the lleted edge of the end cap as shown. Fg15

Step 3:

Posion the rst end cap while being sure to align the hole of

the end cap with the drainage channel of the deck board. Use

LEXEL brand adhesive or equivalent to secure the end cap.

(See Fg16)

Step 4:

Cut the second end cap as shown below. Fg17

Step 5:

Posion the second end cap as shown and mark where the cap

must be cut to sit ush with the rst. Fg18

Step 6:

Cut the second end cap and insert it into the end of the

DuxxBak board. Use LEXEL brand adhesive or equivalent to

beer secure the end cap if necessary. When done properly,

only a small seam will be visible where the two end caps meet.

Fg19

Step 6:

Repeat this process for the remaining boards. See Fg20

Split and Remove Inserts as Shown

Remove Inserts

Cut As Shown

Remove Inserts Cut As Shown

Fg14

Fg15

Fg16

Fg17

Fg18

Fg19

Fg20

www.DuxxBakDecking.com APRIL, 2021 V13.8 Page 13 of 16

DuxxBak Dekk Replacement Board Guide

Step 1:

Determine the number of DuxxBak dekk board(s) that must

be replaced. If replacing more than one board, the DuxxBak

Replacement Board Guide will only apply to the last board

installed. All other adjacent boards will be replaced in accord-

ance with the normal installaon guidelines, above.

Step 2:

If you are replacing more than one board, remove the boards

in the opposite direcon of the original installaon, which will

allow the fasteners to be exposed for easy removal of the

second and subsequent boards.

Step 3:

Place a chalk line or other mark along the length of the board

to be removed as shown (see Fg 21), near the groove edge of

the board as shown (see Fg 22).

Step 4:

Using a circular saw set to a depth of 1 1/4”, cut the length of

the board to divide the board into two pieces. Avoid cung

into the structural component beneath the board. It may be

necessary to use an oscillang tool or other tool that can

work in close quarters to complete the cut near a wall or oth-

er obstrucon.

Step 5:

Aer the board has been separated into two secons, maneu-

ver the unfastened groove secon of the board out of its posi-

on and discard. Some eort may be necessary to remove the

secon.

Step 6:

Aer the loose secon has been removed, the remaining se-

cured secon can be removed by using a pry bar to li at each

joist to break the fastening wing at the points where its fasten-

ers are located (see Fg23). The fasteners can then be removed

using a reciprocang saw or oscillang tool equipped with the

appropriate blade, using cauon to not damage adjacent deck-

ing.

Step 7:

To prepare the new board for installaon, cut away the fas-

tening wing along the enre length of the board. Also cut away

the boom lip of the groove along the enre length of the

board (see Fg24). Note that if more than one deck board is be-

ing replaced, only the last one to be installed will have to be

modied.

Fg21

Fg23

Fg22

Fg24

www.DuxxBakDecking.com APRIL, 2021 V13.8 Page 14 of 16

DuxxBak Dekk Replacement Board Guide (cont’d)

Step 8:

Prepare the substructure to accept the replacement board or

boards. Assure that there are no interference points.

• Place a bead of sealant on the joists where the ends of

the deck boards will rest (See Fg 4 on Page 9). Assure

that all points of potenal water entry are properly

sealed as the board replacement proceeds.

• Apply a generous dollop of sealant into the drainage

channel, closest to the house, to prevent wind-driven

rain from being blown backward through the channel

toward the house (see Fg 5 on Page 9)

• Posion the prepared deck board and secure it to the

joists by inserng two trim head screws through the face

of the board at each joist. Assure that the fasteners are

placed near the septum of the deck board to take ad-

vantage of the points of strength. Set the screw heads

just below the top surface of the board to avoid pullout,

and to parally conceal the screw head.

Occasional cleaning will help to keep your deck looking fresh.

A nylon bristle brush or broom will make the task easier.

A pressure washer with a fan p may be carefully used to

clean your deck if it is guided along in the direcon of the

grain at a consistent height above the deck. A Water-Broom

can be used to assure even coverage and a consistent result.

Always test a small area to assure that the surface texture is

not damaged. Always follow safety precauons.

Although your DuxxBak Dekk Water Shedding Deck System is

durable, care should be taken to avoid scratching. If scratch-

es appear in brushed-surface DuxxBak®, it is possible to

carefully draw a stainless steel brush across the scratches in the

direcon of the grain to remove or reduce the scratches. Al-

ways test a small area before proceeding. (Do not use a wire

brush on OPTIMA-nish DuxxBak®).

Many household spills can be removed with an all-purpose

household cleaner, concentrated dish soap, laundry detergent,

degreaser, or deck cleaner. Fresh spills are more easily re-

moved, and a nylon bristle brush will help achieve the best re-

sults. Always test a small area before proceeding.

Mold and mildew that may form on the surface of your deck are

environmentally generated and will not damage your deck.

These can generally be removed with cleaners that are designed

to remove mold and mildew along with the use of a pressure

washer and nylon bristle brush as described above. Always test

a small area before proceeding.

Always make necessary repairs to maintain a safe and enjoyable

deck.

Your DuxxBak Dekk Water Shedding Deck System comes with a

lifeme limited warranty that provides coverage against splin-

tering and spling, rot and decay, and termite damage.

Your deck is designed to shed water and will keep the under

deck area dry when properly installed.

Every material expands and contracts with temperature varia-

ons, and engineered decking is no excepon. Avoid potenal

problems by allowing me for proper acclimaon of your deck-

ing to local temperatures prior to installaon. Expansion and

contracon is not a product defect and is not covered under the

DuxxBak Dekk Water Shedding Deck System warranty.

You will nd the complete Warranty Agreement and Warranty

Registraon at www.duxxbakdecking.com.

It is the responsibility of the Homeowner to register

the warranty for your new deck when the deck has

been completed.

16

STAIR INSTALLATION

Use I.Dekk or I.Dekk HD S4S or OPTIMA Dekk boards for the

construcon of stair treads for a safe installaon. Use

appropriate fastener as for each product per the Fastener

Page.

Stair tread installaon should be made on stair stringers that

are no more than 12” on center.

Leave a 3/16” gap between the stair tread boards.

Install according to local codes and acceptable construcon

CARE AND MAINTENANCE

WARRANTY

www.DuxxBakDecking.com APRIL, 2021 V13.8 Page 15 of 16

www.DuxxBakDecking.com APRIL, 2021 V13.8 Page 16 of 16

Product Features

• Unique water shedding board eliminates the need for a secondary drainage system

• DuxxBak Dekk prole contains inherent hidden fastener system

• Outdoor furniture can be safely stored under the deck

• Outdoor acvies can connue during periods of rainfall

• Resistant to decay and mold

• Strong and durable

• Less maintenance

• Eco-friendly

• Lifeme limited warranty

• Fast, easy installaon

• DuxxBak Dekk decking can be installed on joists spaced at 24”

1518 South Broadway

Green Bay, WI 54304

(877) 804-0137

List of Revisions

When accessing the installaon instrucons on www.duxxbakdecking.com, clicking on the applicable revision will bring you to the

details of what was revised, and why the revision was important.

2020DB13.7—Revisions to document made Oct of 2020

2021DB13.8—Revisions to document made April of 2021

For the most up-to-date installation instructions, please visit

www.duxxbakdecking.com

By DuxxBak Composite Decking

A Division of Green Bay Dec LLC