Evaluation of Worker

Exposures to Peracetic

Acid-Based Sterilant

during Endoscope

Reprocessing

David Sylvain, MS, CIH

John Gibbins, DVM, MPH

Health Hazard Evaluation Report

HETA 2006-0298-3090

Kaleida Health–Buffalo General Hospital

Buffalo, New York

August 2009

DEPARTMENT OF HEALTH AND HUMAN SERVICES

Centers for Disease Control and Prevention

Workplace

Safety and Health

National Institute for Occupational

Safety and Health

This Health Hazard Evaluation (HHE) report and any recommendations made herein are for the specific

facility evaluated and may not be universally applicable. Any recommendations made are not to be

considered as final statements of NIOSH policy or of any agency or individual involved. Additional HHE

reports are available at http://www.cdc.gov/niosh/hhe/

The employer shall post a copy of this report

for a period of 30 calendar days at or near

the workplace(s) of affected employees. The

employer shall take steps to insure that the

posted determinations are not altered, defaced,

or covered by other material during such

period. [37 FR 23640, November 7, 1972, as

amended at 45 FR 2653, January 14, 1980].

Page i

Health Hazard Evaluation Report 2006-0298-3090

Re p o R t

Abbreviations .......................................................................ii

Highlights of the NIOSH Health Hazard Evaluation ............ iii

Summary .............................................................................v

Introduction ..........................................................................1

Assessment .........................................................................4

Results .................................................................................5

Discussion ...........................................................................7

Conclusions .........................................................................9

Recommendations .............................................................10

References ........................................................................12

Co n t e n t s

Acknowledgments and Availability of Report .....................15

AC k n o w l e d g m e n t s

Page ii

Health Hazard Evaluation Report 2006-0298-3090

ACGIH® American Conference of Governmental Industrial Hygienists

BGH Buffalo General Hospital

CDRH Center for Devices and Radiological Health

CFR Code of Federal Regulations

FDA United States Food and Drug Administration

HVAC Heating, ventilating, and air-conditioning

HHE Health hazard evaluation

LOD Limit of detection

mL/min milliliters per minute

NAICS North American Industry Classification System

NIOSH National Institute for Occupational Safety and Health

OEL Occupational exposure limit

OPA ortho-Phthalaldehyde

OSHA Occupational Safety and Health Administration

PAA Peracetic acid

PBZ Personal breathing zone

PPE Personal protective equipment

ppm Parts per million

REL Recommended exposure limit

RH Relative humidity

SS1 Steris SYSTEM 1® Processing System

TWA Time-weighted average

Ab b R e v i A t i o n s

Page iii

Health Hazard Evaluation Report 2006-0298-3090

What NIOSH Did

We met with management, employees, and a union ●

representative to discuss employee concerns.

We toured the A2 GI Lab Steris Room and observed staff at ●

work.

We collected area and personal air samples for acetic and ●

peracetic acids.

We measured temperature and relative humidity. ●

We used smoke tubes to observe airflow patterns in the A2 ●

GI Lab Steris Room.

We spoke with employees confidentially about possible work- ●

related symptoms, safety and health training, use of personal

protective equipment (PPE), chemical exposure incidents,

and indoor environmental quality.

We looked at Food and Drug Administration reports ●

of sterilant spills, worker exposures, and injuries during

endoscope reprocessing at other hospitals to identify possible

causes of problems reported at this facility.

What NIOSH Found

Concentrations of peracetic acid are thought to be low, ●

although we could not measure current levels.

Latex gloves worn while handling peracetic acid sterilant ●

containers do not provide adequate protection.

Some workers reported not using all available PPE (aprons ●

and sleeve protectors) due to high temperatures in the A2 GI

Lab Steris Room.

Two workers reported prior chemical burns from contact ●

with Steris 20 Sterilant Concentrate.

Employees did not receive adequate training in chemical ●

hazard communication and in standard operating procedures

for chemical spills, leaks, and processor malfunctions.

Ventilation in the A2 GI Lab Steris Room was inadequate. ●

Exposure to peracetic acid sterilant is unlikely when Steris ●

processors are maintained and operated properly and when

technicians follow the manufacturer’s operating procedures.

In July 2006, the National

Institute for Occupational

Safety and Health (NIOSH)

received a confidential

health hazard evaluation

(HHE) request from

employees at Kaleida

Health-Buffalo General

Hospital in Buffalo, New

York. The HHE request

stated that inadequate

ventilation was provided

in the A2 GI Lab Steris

Room where five

employees clean and

sterilize endoscopes

using Klenzyme®

Enzymatic Cleaner and

Steris® 20 Sterilant

Concentrate. Health

problems identified in the

request were headache,

shortness of breath, eye

irritation, and diminished

sense of smell. We

conducted a site visit on

December 18–19, 2006.

Hi g H l i g H t s o f t H e

niosH He A l t H

HA z A R d ev A l u A t i o n

Page iv

Health Hazard Evaluation Report 2006-0298-3090

Hi g H l i g H t s o f t H e

niosH He A l t H

HA z A R d ev A l u A t i o n

(C o n t i n u e d )

What Hospital Managers Can Do

Require use of appropriate PPE to prevent eye, face, hand, ●

arm, and body contact with concentrated peracetic acid

as well as other cleaning chemicals and contaminated

equipment.

Provide hazard communication training for A2 GI Lab Steris ●

Room employees.

Train employees in standard operating procedures for spills, ●

leaks, and processor malfunctions.

Ask Steris Corporation to provide new employee and annual ●

refresher inservice training.

Make sure that processors are inspected periodically for worn ●

parts that can cause leaks.

Notify Steris Corporation of leaks and equipment problems. ●

Increase ventilation in the A2 GI Lab Steris Room for odor ●

control and the comfort of the workers.

What Steris Room Employees Can Do

Wear tight-fitting splash-resistant goggles and acid-resistant ●

gloves, sleeves, and apron when handling sealed Steris cups

during normal operations.

Wear a face shield over eye protection along with routine ●

PPE when handling or disposing of a cup that is not

completely empty.

Follow the manufacturer’s instructions for handling Steris ●

cups and operating processors.

Tell management about problems with processors or Steris ●

cups, or if you notice worn processor seals or other parts.

Follow standard operating procedures for processor ●

problems, leaks, and sterilant spills.

Participate in training when provided. ●

Page v

Health Hazard Evaluation Report 2006-0298-3090

In July 2006, NIOSH received a confidential HHE request from

employees at Kaleida Health-Buffalo General Hospital in Buffalo,

New York. The HHE request stated that inadequate ventilation was

provided in the A2 GI Lab Steris Room where five employees clean

and sterilize endoscopes with Klenzyme® Enzymatic Cleaner and

Steris® 20 Sterilant Concentrate. Health problems identified in

the request were headache, shortness of breath, eye irritation, and

diminished sense of smell.

On December 18–19, 2006, we conducted a site visit that included

an opening conference, a walk-through of the A2 GI Lab Steris

Room, air sampling for peracetic and acetic acids, measurements

of temperature and RH, smoke tube visualization of airflow, and

confidential informal interviews with several employees.

Air samples did not contain detectable concentrations of acetic

acid. Sampling results and our onsite observations indicate very

little, if any, airborne exposure to peracetic acid sterilant on the

sampling date. The temperature was 74ºF to 76ºF, and the RH was

17% to 20%. Smoke tube visualization of airflow at the ceiling-

mounted ventilation supply diffusers and return grilles in the

Steris room indicated that the HVAC system provided insufficient

airflow. Ventilation in the Steris room appeared to be inadequate

for providing reliable odor control and maintaining the work

environment within an acceptable range of temperature and RH.

Employees reported periodic headaches and burning eyes that

were more noticeable when SS1 processors malfunctioned and

leaked. Poor ventilation and high environmental temperatures

were noted by workers. Although gloves, sleeves and aprons are

provided, some workers reported not using all available PPE due

to high environmental temperatures. Two workers reported prior

chemical burns from occupational exposure to Steris 20 Sterilant

Concentrate. Several workers reported that they had not received

formal chemical hazard communication training for Steris room

operations.

A review of FDA CDRH data files indicated that occupational

exposure to peracetic acid sterilant should be unlikely when

SS1 processors are maintained and operated properly and when

technicians follow the manufacturer’s operating procedures.

However, processor malfunctions and improper handling and

disposal of Steris 20 Sterilant Concentrate containers can result

in dermal or inhalation exposures. Appropriate employee training,

Exposure to peracetic

acid sterilant is unlikely

when SS1 processors

are maintained and

operated properly and

when technicians follow

the manufacturer’s

operating procedures.

Processor malfunctions,

and improper handling

and disposal of Steris

20 Sterilant Concentrate

containers can result

in dermal or inhalation

exposures.

su m m A R y

Page vi

Health Hazard Evaluation Report 2006-0298-3090

su m m A R y

(C o n t i n u e d )

use of adequate PPE, and routine maintenance of processors

should help reduce the likelihood of worker exposures, as well as

the risk of employee illness or injury if a spill or leak does occur.

Keywords: NAICS 622110 (General Medical and Surgical

Hospitals), endoscope reprocessing, endoscope sterilization,

peracetic acid, anosmia, chemical burns, dyspnea, eye irritation,

sense of smell, shortness of breath.

Page 1

Health Hazard Evaluation Report 2006-0298-3090

in t R o d u C t i o n

In July 2006, NIOSH received a confidential HHE request from

employees at Kaleida Health-Buffalo General Hospital in Buffalo,

New York. The HHE request stated that inadequate ventilation was

provided in the A2 GI Lab Steris Room where five employees clean

and sterilize endoscopes using Klenzyme® Enzymatic Cleaner and

Steris® 20 Sterilant Concentrate. Health problems identified in

the request were headache, shortness of breath, eye irritation, and

diminished sense of smell.

Background

Management representatives told us that SS1 had been used

at BGH for approximately 10 years prior to our site visit. SS1

was introduced into BGH as a replacement for ethylene oxide

sterilization. During the opening conference, management noted

that health complaints from employees in the A2 GI Lab Steris

Room began in approximately May 2006, following renovations

in that area. Full-shift air sampling conducted by a consultant

in June 2006 indicated that airborne concentrations of acetic

acid were less than 0.2 ppm. Although management was not

aware of spills involving SS1 processors, employees had reported

occasional leaks. In November 2006, SS1 processors were inspected

by a representative from Steris Corporation who identified no

problems.

The A2 GI Lab Steris Room is one of several Steris rooms at BGH.

Although referred to as a single room, the A2 GI Lab Steris Room

is divided into two small rooms (“dirty side” and “clean side,”

which are separated by a floor-to-ceiling wall with a sliding window.

The dirty side adjoins a hospital corridor along a 6-foot wall, which

has a single doorway for entry. The length of the room extends

approximately 15 feet from the corridor. The dirty side contains a

stainless steel counter and sink along the 15-foot wall that separates

the dirty and clean sides. The window between these rooms is

located a few feet from the most interior wall. Each of these rooms

has a plumbed eyewash station.

The clean side is approximately 10 feet wide by 15 feet long, with a

single doorway to the corridor. Three SS1 processors are installed

on a stainless steel counter near the window between the dirty and

clean sides. Two processors are located along the back wall and

one along the wall opposite the window. Also along this wall is a

GUS® Model G17HS endoscope immersion unit, which contains

approximately one-half gallon of Cidex® OPA Solution. The GUS

unit is a compact, ductless vapor control system that exhausts into

the room via a carbon filter. It is our understanding that the GUS

Page 2

Health Hazard Evaluation Report 2006-0298-3090

in t R o d u C t i o n

(C o n t i n u e d )

unit is used infrequently for endoscope disinfection; however,

Cidex OPA remains in the unit at all times.

A canopy hood is mounted on the ceiling of the clean side against

the wall separating the two small rooms and the most interior

(back) wall (the hood is open on two sides). The sides of the hood

extend downward to within approximately 4 feet above four of the

six processors. The Steris room is provided with ceiling diffusers

and returns for general ventilation. Facilities staff informed us that

the Steris room is supplied with 100% outside air.

When an endoscopic procedure is completed, the endoscope is

brought to the dirty side where a technician manually cleans it

using Klenzyme® enzymatic cleaner. After cleaning, the endoscope

is passed through the sliding window to a technician in the clean

side. The clean side technician installs the appropriate channel

connectors, places the endoscope in a processing tray in one of

the SS1 processors along with a sealed container of Steris 20

Sterilant Concentrate, closes the processor lid, and starts the

microprocessor-controlled operating cycle. When the approximately

30-minute sterilization cycle is finished, the technician opens the

processor, removes the endoscope, flushes it with 120 milliliters

of isopropyl alcohol, and purges cavities within the endoscope

with forced air to remove the alcohol. This procedure is repeated

for each endoscope that is returned for cleaning and sterilization.

More than one processor may be operating at any given time. The

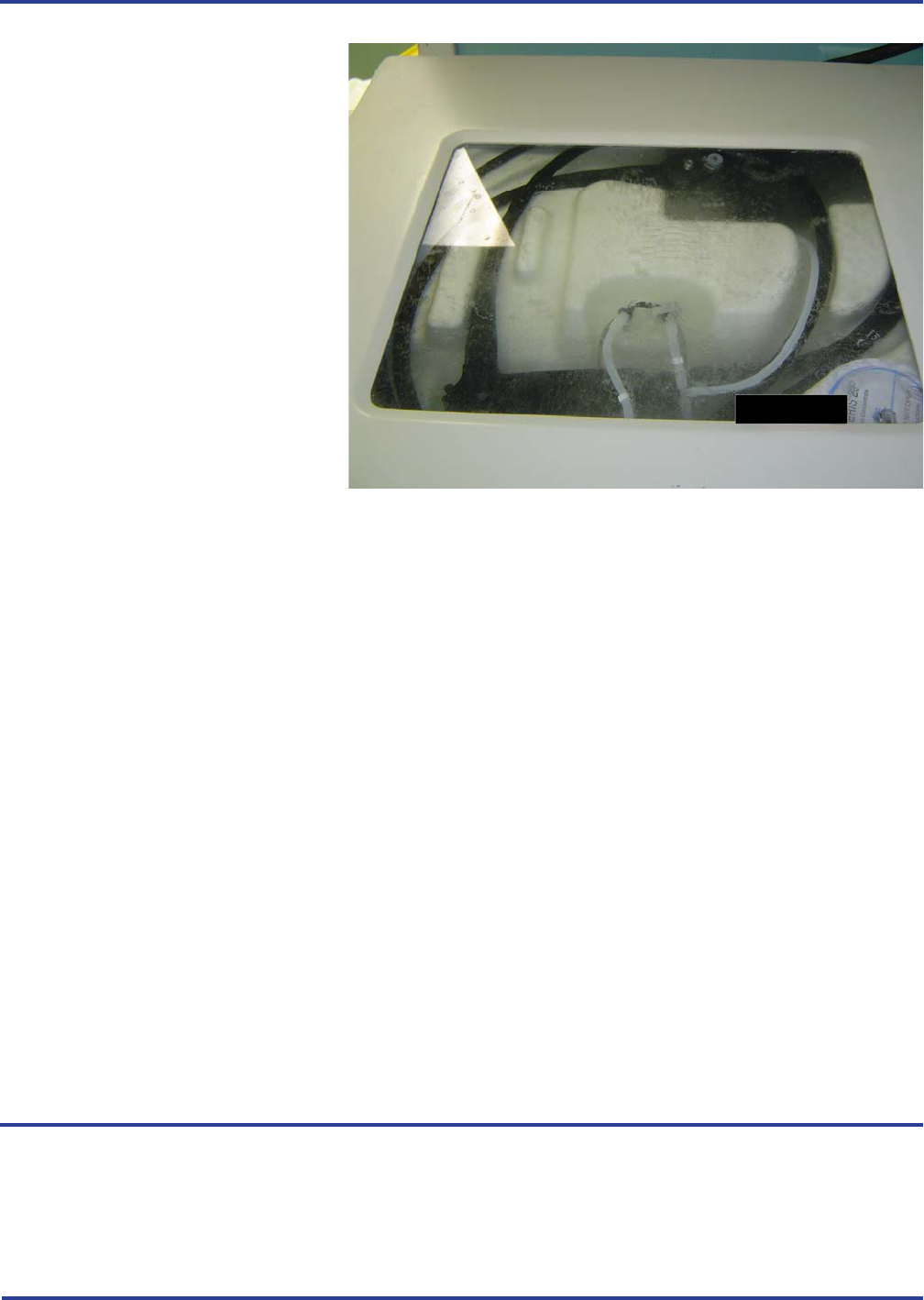

Figure 1. Steris System 1® processor in operation

Page 3

Health Hazard Evaluation Report 2006-0298-3090

in t R o d u C t i o n

(C o n t i n u e d )

only PPE that we observed being worn in the clean side during our

site visit was latex gloves.

Each SS1 processor is a fully-enclosed tabletop unit. Steris 20

Sterilant Concentrate is provided in sealed single-use containers

(“cups”) that hold 2.02 fluid ounces (67.5 grams) of liquid and

163.7 grams of powder. The composition of the liquid (% by

volume) is 35.5% peracetic acid, 40.0% acetic acid, 6.5% hydrogen

peroxide, and 1.0% sulfuric acid [Steris 1995]. The solid powder

consists of proprietary builders and buffers [Alfa 2004; Steris

2007]. During the sterilization cycle, the processor aspirates

the concentrated liquid sterilant, and dilutes it to a working

concentration of 0.2% PAA at a pH of 6.4 and a temperature

of 50ºC to 56ºC [Alfa 2004; Steris 2007]. When diluted, PAA

hydrolyzes to acetic acid and hydrogen peroxide with a half-life

of less than 20 minutes at 50ºC [Steris 1995]. The 0.2 % PAA

solution circulates around and through the endoscope for 12

minutes before being discharged into the sewer system. After the

sterilant has been discharged from the processor, the processor

flushes the endoscope four times with filtered water [Alfa 2004;

Steris 2007; Steris 2008]. The technician can open the processor

after the final rinse water has been discharged down the drain.

Figure 2. Row of Steris System 1® processors

Page 4

Health Hazard Evaluation Report 2006-0298-3090

in t R o d u C t i o n

(C o n t i n u e d )

Contact with Steris 20 Sterilant Concentrate can cause severe

irritation and burns to eyes and skin. Animal studies indicate

that Steris 20 Sterilant Concentrate may be a sensitizer [Steris

1995]. Inhalation of PAA vapor may cause pulmonary edema and

sensitization [IPCS 1994a; Sciencelab.com 2005]. No OELs have

been established for PAA [NJDHSS 1998a].

Contact with acetic acid can cause severe irritation and burns

to the eyes and skin. Inhalation exposure can cause respiratory

irritation, bronchitis, pharyngeal edema, and pulmonary edema

[IPCS 1994b; Hathaway et al. 1996; NJDHSS 1998b]. The NIOSH

REL for acetic acid is 10 ppm for up to 10 hours per workday

during a 40-hour workweek. OSHA and ACGIH have established

8-hour TWA OELs of 10 ppm for acetic acid. In addition, NIOSH

and ACGIH recommend that exposures to acetic acid not exceed

15 ppm during any 15-minute exposure during the course of the

day (short-term exposure limit) [ACGIH 2009; NIOSH 1992]. The

odor threshold for acetic acid is reported to be approximately 0.48

to 1.0 ppm [NJDHSS 1998b].

In response to the HHE request, we conducted a site visit on

December 18–19, 2006. The evaluation included an opening

conference, a walk-through of the A2 GI Lab Steris Room,

Figure 3. Steris System 1® processor in operation showing Steris 20

Sterilant Concentrate container in lower right corner of the processor.

As s e s s m e n t

Page 5

Health Hazard Evaluation Report 2006-0298-3090

As s e s s m e n t

(C o n t i n u e d )

air sampling for peracetic and acetic acids, measurements of

temperature and RH

,

and confidential informal interviews with

several employees.

Full-shift PBZ air samples were collected for each of the three

technicians who were working in the Steris room on December

19. Two area air samples were collected in the clean side. One

area air sample was collected in the dirty side at the open window

between the dirty and clean sides. Air samples were collected on

ORBO™ 53 activated silica gel tubes at a nominal flow rate of 100

mL/min. Samples were analyzed for PAA and acetic acid by high

performance liquid chromatography according to a NIOSH draft

method. Draeger® short-term colorimetric detection tubes were

used to measure the airborne concentration of acetic acid in the

clean side while four processors were in operation. These tubes

have a standard measurement range of 5 to 80 ppm during a 30

second sampling period [Draeger 2009].

Temperature and RH were measured in the clean side using a

hand-held, battery operated, TSI Model 8722 TH-Calc™ Thermal

Hygrometer (TSI Inc., Shoreview, Minnesota). This instrument

measures temperature and RH in the ranges of 32ºF to 140ºF and

5% to 95% RH. A ventilation smoke tube was used to visualize

airflow patterns within the Steris room and to determine if the

clean and dirty sides were under positive or negative pressure

relative to each other and to the adjoining corridor.

Confidential, voluntary interviews were conducted with employees

who work in the A2 GI Lab Steris Room. Employees were asked

about potential work-related health symptoms, safety and health

training, PPE use, chemical exposure incidents, and indoor

environmental quality.

Industrial Hygiene

Air samples did not contain detectable concentrations of acetic

acid. The analytical LOD for acetic acid in the air samples was

approximately 25 micrograms of acetic acid per sample [Neumeister

2009]. Based on the LOD and the average volume of the PBZ

samples (20.1 liters), acetic acid concentrations in these samples

were no greater than 0.5 ppm. The three area air samples, which

had an average sample volume of 43 liters, indicated that acetic

acid concentrations were no greater than 0.24 ppm. Draeger

colorimetric detector tubes did not detect acetic acid in the clean

side.

Re s u l t s

Page 6

Health Hazard Evaluation Report 2006-0298-3090

Re s u l t s

(C o n t i n u e d )

We attempted to quantitate PAA using a draft NIOSH method

originally intended for acetic acid; however, PAA coeluted with

the solvent front during analysis, which prevented separation and

quantitation of PAA. Further efforts to resolve PAA in the samples

were not made because (1) acetic acid (a major component of Steris

20 sterilant) was not detected above the LOD; (2) although PAA

coeleuted with the solvent front, the area of the chromatogram

peak was consistent with the area of the blank samples,

indicating that PAA was not present in large quantity; and (3)

no acid odor was detected during the sampling visit [Neumeister

2009].

Temperatures in the clean side between 8:50 a.m. and 1:15 p.m.

were 74ºF to 76ºF, and RH was between 17% and 20%. Smoke

tube visualization of airflow at the ceiling-mounted ventilation

supply diffusers and return grilles in the clean side indicated that

the HVAC system provided insufficient airflow. No air appeared

to be coming from the supply diffusers. The open doors between

the Steris room and the corridor served as the source of make-

up air for the canopy hood; there was no other source of outside

air. The dirty side appeared to be under slight negative pressure

relative to the corridor, while the clean side was under negative

pressure relative to the corridor and the dirty side, causing air

to flow toward the clean side and out through the canopy hood.

Turbulence beneath the canopy hood in the clean side caused

smoke to drift away from the Steris processors, rather than being

immediately captured and exhausted by the hood.

Interviews

Confidential, voluntary interviews were conducted with four of five

employees who work in the A2 GI Lab Steris Room; one employee

was on extended family leave and not available to participate. The

median length of employment at BGH was 14 years; however, the

median length of employment in the A2 GI Lab Steris Room was

13 months, and three of the four employees had worked in the

department less than 14 months. Workers reported no formalized,

documented initial or refresher hazard communication training

in their current assignment at BGH; however, such training had

been provided when they were employed in other sections of the

hospital. On-the-job training was provided by coworkers with

longer tenure in the department; however, two of four employees

did not know the proper procedures for responding to a chemical

spill or SS1 processor malfunction and overflow.

Page 7

Health Hazard Evaluation Report 2006-0298-3090

Re s u l t s

(C o n t i n u e d )

Three employees reported periodic headaches and burning eyes;

these symptoms were worse when the processors malfunctioned

and overflowed, or when excessive liquid was left in the bottom

of the machine after completion of a sterilization cycle. Poor

ventilation and high environmental temperatures were common

complaints among workers; these conditions were reportedly

worse during the summer. Workers reported leaving the doors

between both sides of the Steris rooms and the corridor open to

improve ventilation, but are instructed by supervisors to keep these

doors closed, reportedly due to odor complaints from patients

and nursing staff. PPE in the form of chemically resistant, sleeve

protectors and aprons are provided by management; however,

some workers reported not using all available PPE due to high

environmental temperatures. Two workers reported having had

chemical burns from prior use of Steris 20 Sterilant Concentrate.

On the day of our site visit, we did not smell an acid odor, which

we would have noticed if airborne acid vapor concentrations had

approached the OELs for acetic acid. This observation is consistent

with air sampling results, which indicate that airborne levels of

acetic acid were below the analytical LOD. Although exposure

limits have not been established for PAA, the sampling results and

our onsite observations indicated little, if any, airborne exposure to

PAA on the sampling date.

Although we do not know the specific sources of odors reportedly

emitted from the Steris room, odor complaints from patients and

nursing staff suggest that the ventilation in the Steris room is

inadequate. Odor complaints, worker reports of uncomfortably

warm temperatures especially during the summer, and our

observations during the site visit point to a need for increasing the

general ventilation in the Steris room.

While Klenzyme Concentrate Plus Enzymatic Cleaner and

Cidex OPA Solution were not the focus of this investigation,

it is important to note hazards associated with these products.

Klenzyme, which can irritate the skin and eyes, contains proteolytic

enzymes, also known as subtilisins. Subtilisins in powder form

are a known respiratory sensitizer. In 2001, researchers reported

a case of extrinsic allergic alveolitis in a hospital worker who was

exposed to subtilisins in Klenzyme that the worker used to wash

surgical instruments and clean operating room surfaces [Tripathi

and Grammer 2001]. OPA is an eye, skin, and respiratory irritant

that may also cause sensitization [Advanced Sterilization Products

2007]. A 2006 article describes a case of occupational asthma and

di s C u s s i o n

Page 8

Health Hazard Evaluation Report 2006-0298-3090

di s C u s s i o n

(C o n t i n u e d )

dermatitis that is believed to be due to exposure to OPA in an

endoscopy unit [Fujita et al. 2006]. BGH employees and managers

should be aware of the hazards associated with these materials.

The FDA CDRH maintains Adverse Event Reporting Data Files

that consist of voluntary reports, user facility reports, distributor

reports, and manufacturer reports of medical devices that may

have malfunctioned or caused a death or serious injury [USFDA

2009]. To better understand workplace hazards during endoscope

reprocessing, we searched the online CDRH data files for adverse

event reports received in 1996 through 2008 that involved SS1.

Reports involving SS1 were reviewed to identify factors related to

worker safety and health at all medical facilities that had submitted

reports, or that were described in reports.

Steris 20 Sterilant Concentrate was involved in approximately

50% of the 63 adverse event reports identified during our review.

Worker exposure was noted in all but one of these reports.

More than 80% of reported exposures to concentrated PAA

sterilant resulted in worker injury; most of these incidents

occurred while handling a sealed Steris 20 Sterilant Concentrate

cup prior to placing the cup into a processor, or while disposing

of incompletely emptied cups at the end of a sterilization cycle.

The most common type of injury was a chemical burn of the skin,

which varied from what appeared to be minor burns, to several

reports of second degree burns, and at least one report of a third

degree burn. Several instances of eye contact that reportedly

resulted in burns and pain were identified. Respiratory exposures

to concentrated PAA sterilant resulted in reports of shortness of

breath; nasal irritation and scabbing of nasal passages; and rare

events, including lung hypertension and pneumonia, and an

asthmatic-like reaction in a hospital receptionist.

Eight reports noted that hospital workers were burned when the

seal on unopened cups ruptured as the workers squeezed the cups

to break up powdered buffers. As reported in three manufacturer

narratives, the manufacturer’s instructions state that “powders

can be broken up by gently squeezing the bottom portion of the

Steris 20 container.” The manufacturer narratives attributed these

incidents to improper handling by the workers. These incidents

resulted in reports of burns on hands, arm, eyes, face, neck,

and abdomen. In one instance, concentrated PAA sterilant was

reportedly splashed onto the eyes, face, and neck of a bystander.

In two instances, a cup lid “popped” or leaked as a cup was being

removed from its carton.

Page 9

Health Hazard Evaluation Report 2006-0298-3090

di s C u s s i o n

(C o n t i n u e d )

Ten reports described incidents involving disposal of cups that

had expired, or that had not been completely emptied during

a sterilization cycle. In most cases, the exposure occurred to

the worker who was disposing of the cup; however, two reports

noted burns due to contact with concentrated sterilant spilled on

work surfaces or furniture, and in one instance, a housekeeping

employee reported shortness of breath that was attributed to

a Steris cup that had been thrown in the trash. Other reports

describe skin and eye contact with concentrated sterilant as a result

of cup leaks, improper sterilant storage, and spray released while

inserting or removing the SS1 aspirator into/from the sterilant

cup.

Only eight reports were identified in which PPE was mentioned.

Of these, five noted that PPE had not been used by the exposed

worker, and two indicated that the PPE was inadequate. Based on

the descriptions of dermal and eye exposures to concentrated PAA

sterilant, it appears that worker injuries could have been prevented

if appropriate PPE had been used.

Twenty-five reports appear to involve releases of 0.2% PAA sterilant

(“use dilution”) from SS1 processors. Failure of the inflatable

processor lid seal was reported as the cause of most processor leaks.

Other leaks occurred when the processor lid opened suddenly

during a sterilization cycle, or when defective endoscope trays

were used. Only six releases of dilute sterilant resulted in reports

of worker exposure. Four reports identified health effects such as

eye, skin, or respiratory irritation. Two reports of exposure during

cleanup of dilute sterilant described respiratory difficulties: in one

instance, a worker was treated with a nebulizer after cleaning a

dilute sterilant spill for 10 minutes, and in the second instance, a

worker was treated for reactive airways dysfunction syndrome after

cleaning a spill for 15 minutes.

Exposure to peracetic acid sterilant is unlikely when SS1 processors

are maintained and operated properly, and technicians follow

the manufacturer’s operating procedures; however, processor

malfunctions, improper handling and disposal of Steris 20

Sterilant Concentrate containers, and nonroutine events can result

in dermal or inhalation exposures. Even though the sterilant cups

are designed to prevent exposure to PAA sterilant, rough handling

and accidental or forceful squeezing can result in exposure to

the concentrated acid. Appropriate employee training, use of

adequate PPE, and routine maintenance of equipment should

help reduce the likelihood that such events will occur, and also

Co n C l u s i o n s

Page 10

Health Hazard Evaluation Report 2006-0298-3090

di s C u s s i o n

(C o n t i n u e d )

Re C o m m e n d A t i o n s

reduce the risk of employee illness or injury if a spill or leak does

occur. Ventilation in the Steris room appears to be insufficient

for providing reliable odor control and maintaining the work

environment within an acceptable range of temperature and RH.

The following recommendations are provided to improve the safety

and health of hospital staff that clean and sterilize endoscopes at in

the A2 GI Lab Steris Room.

Training

Conduct and document hazard communication training ●

required by the OSHA Hazard Communication Standard

(29 CFR 1910.1200). Training should be provided for new

and current employees, and should be designed specifically

for A2 GI Lab Steris Room workers. Training should

address chemical hazards, exposure controls, and PPE for all

chemicals used to process endoscopes, including Steris 20

Sterilant Concentrate, Klenzyme Concentrate Plus Enzymatic

Cleaner and Cidex OPA Solution.

Conduct training for Steris room employees that addresses ●

standard operating procedures in the event of chemical

spills, processor malfunctions, and processor leaks. Training

should include notification procedures for contacting

Environmental Services for spill cleanup.

Contact Steris Corporation to request new employee initial ●

and annual refresher inservice training for SS1 processor

operators. Training should include routine and nonroutine

processor operations, handling of unopened sterilant cups,

and disposal of incompletely aspirated and expired cups.

Annual refresher training would allow a Steris representative

to review technicians’ technique, and to provide instructions

for the proper use and handling of Steris 20 Sterilant

Concentrate.

Personal Protective Equipment

Given the serious nature of injuries that may result from ●

exposure to Steris 20 Sterilant Concentrate, appropriate PPE

should be worn by workers when handling both sealed and

used containers of Steris 20 Sterilant Concentrate.

Page 11

Health Hazard Evaluation Report 2006-0298-3090

Re C o m m e n d A t i o n s

(C o n t i n u e d )

Minimum PPE worn while performing routine tasks ●

involving the handling of sealed Steris cups should include

tight-fitting splash-resistant goggles, acid-resistant sleeves

and apron, and gloves made of butyl rubber, neoprene

rubber, Viton®, or Barrier® [Forsberg and Mansdorf 2007].

Very thin gloves, as typically worn in healthcare settings,

provide poor chemical resistance and mechanical strength,

and should not be the only barrier between the wearer and

a chemical hazard, such as PAA [Forsberg and Mansdorf

2007]. Latex gloves do not provide appropriate protection

and introduce a known allergen into the workplace [NIOSH

1997].

If sterilant remains in a cup at the end of a sterilization ●

cycle, the technician should don additional face protection

(e.g., face shield in addition to gloves, sleeves, apron, and

eye protection used during normal operations). This PPE

should be worn when handling unsealed cups containing

any sterilant concentrate, and when disposing of expired

sterilant.

Preventive Maintenance and Equipment

Malfunctions

SS1 processors should be inspected periodically for ●

components that can fail due to normal wear, resulting in a

leak or worker exposure. These components include aspirator

tubing, processor lid seal, and endoscope trays.

Employees should notify management of all spills, leaks, ●

and equipment malfunctions so that the causes of these

events can be identified and appropriate corrective actions

can be taken. BGH should notify Steris Corporation of

equipment malfunctions and request assistance from Steris

in diagnosing and correcting problems.

Ventilation and Indoor Environmental

Quality

The Steris room must be under negative pressure relative to ●

all surrounding areas in order to control odors. The HVAC

system serving the Steris room should exhaust completely

to the outdoors, i.e., no recirculation. The dirty side should

be under negative pressure relative to the clean side to help

prevent migration of bioaerosols from the dirty side to the

clean side.

Page 12

Health Hazard Evaluation Report 2006-0298-3090

Re C o m m e n d A t i o n s

(C o n t i n u e d )

Re f e R e n C e s

A minimum of 10 air changes per hour should be provided ●

in the Steris room, with a minimum of 2 air changes

of outside air per hour [ASHRAE 2003; ACGIH 2007;

ASHRAE 2007].

Supply diffusers and return grilles need to be located so that ●

supply air reaches room occupants without “short circuiting,”

i.e., flowing directly from supply diffusers to return ducts

without ventilating the occupied space.

ASHRAE recommends maintaining sterilizer equipment ●

rooms between 72ºF and 76ºF, with RH between 30% and

60% [ASHRAE 2007].

Ensure that the GUS Vapor Control System is operating ●

whenever it contains OPA, and that the charcoal filters are

changed every 6 months or as advised by PCI Medical, Inc

[PCI 2009].

ACGIH [2007]. Industrial ventilation: a manual of recommended

practice for design. 26

th

ed. Cincinnati, OH: American Conference

of Governmental Industrial Hygienists.

ACGIH [2009]. 2009 TLVs® and BEIs®: threshold limit values for

chemical substances and physical agents and biological exposure

indices. Cincinnati, OH: American Conference of Governmental

Industrial Hygienists.

Advanced Sterilization Products [2007]. Material safety data sheet,

CIDEX® OPA solution. MSDS-09588-0-001, Rev. F. Irvine, CA:

Advance Sterilization Products. [www.sterrad.com/Customer_

Support/user_resources/msds/cidexopa_msds.pdf]. Date accessed:

March 30, 2009.

Alfa MJ [2004]. SYSTEM 1® Sterile Processing System: liquid

chemical sterilization anthology. [www.steris.com]. Date accessed:

March 23, 2009.

ASHRAE [2003]. HVAC design manual for hospitals and clinics.

Atlanta, GA: American Society of Heating, Refrigerating, and Air-

Conditioning Engineers, Inc.

ASHRAE [2007]. The ASHRAE handbook—HVAC applications.

Atlanta, GA: American Society of Heating, Refrigerating, and Air-

Conditioning Engineers, Inc.

Page 13

Health Hazard Evaluation Report 2006-0298-3090

Re f e R e n C e s

(C o n t i n u e d )

Draeger [2009]. Short-term measurements with Dräger-Tubes.

[www.draeger.com]. Date accessed: March 14, 2009.

Forsberg K, Mansdorf SZ [2007]. Quick selection guide to chemical

protective clothing. 5

th

ed. Hoboken, NJ: John Wiley & Sons, Inc.

Fujita H, Ogawa M, Endo YA [2006]. A case of occupational

bronchial asthma and contact dermatitis caused by ortho-

phthalaldehyde exposure in a medical worker. J Occup Health

48(6): 413–416.

Hathaway GJ, Proctor NH, Hughes JP [1996]. Chemical hazards of

the workplace. 4th ed. New York, NY: Van Nostrand Reinhold.

IPCS [1994a]. International chemical safety cards, peracetic acid

(stabilized). ISCS no. 1031, partial update April 2005. Geneva,

Switzerland: World Health Organization, International Programme

on Chemical Safety. [www.cdc.gov/niosh/ipcsneng/neng1031.

html]. Date accessed: July 23, 2009.

IPCS [1994b]. International chemical safety cards, acetic acid.

ISCS no. 0363, partial update October 2005. Geneva, Switzerland:

World Health Organization, International Programme on

Chemical Safety. [www.cdc.gov/niosh/ipcsneng/neng0363.html].

Date accessed: July 23, 2009.

Neumeister CE [2009]. E-mail communication from C.

Neumeister, Division of Applied Research and Technology,

National Institute for Occupational Safety and Health, Centers for

Disease Control, U.S. Department of Health and Human Services

to D. Sylvain. February 3, 2009.

NIOSH [1992]. Recommendations for occupational safety and

health: compendium of policy documents and statements.

Cincinnati, OH: U.S. Department of Health and Human Services,

Centers for Disease Control, National Institute for Occupational

Safety and Health, DHHS (NIOSH) Publication No. 92-100.

NIOSH [1997]. Preventing allergic reactions to natural rubber latex

in the workplace. Cincinnati, OH: U.S. Department of Health and

Human Services, Centers for Disease Control, National Institute

for Occupational Safety and Health, DHHS (NIOSH) Publication

No. 97-135.

NJDHSS [1998a]. Hazardous substance fact sheet, peroxyacetic

acid. RTK substance no. 1482, revised October 2004. Trenton, NJ:

Page 14

Health Hazard Evaluation Report 2006-0298-3090

Re f e R e n C e s

(C o n t i n u e d )

New Jersey Department of Health and Senior Services.

[http://nj.gov/health/eoh/rtkweb/documents/fs/1482.pdf]. Date

accessed: March 14, 2009.

NJDHSS [1998b]. Hazardous substance fact sheet, acetic acid. RTK

substance no. 0004, revised July 2007. Trenton, NJ: New Jersey

Department of Health and Senior Services.

[nj.gov/health/eoh/rtkweb/documents/fs/0004.pdf]. Date

accessed: March 14, 2009.

PCI [2009]. GUS® vapor control systems for OPA and

glutaraldehyde, frequently asked questions. Deep River, CT: PCI

Medical. [www.pcimedical.com]. Date accessed: March 25, 2009.

Sciencelab.com [2005]. Material safety data sheet, peracetic acid,

35%, updated November 11, 2008. Houston, TX: Sciencelab.com,

Inc. [www.sciencelab.com]. Date accessed: March 30, 2009.

Steris [1995]. Product safety data sheet, Steris 20® Sterilant

Concentrate. MSDS No. 612038, revised January 21, 2009.

Mentor, OH: Steris Corporation. [www.steris.com]. Date accessed:

March 26, 2009.

Steris [2007]. SYSTEM 1® Sterile Processing System in-service

checklist. Document ST1006EN.2007-07, August 2007. [www.

steris.com/]. Date accessed: March 26, 2009.

Steris [2008]. SYSTEM 1® Sterile Processing System technical data

document SD707, revised June 1, 2008 [www.steris.com]. Date

accessed: March 30, 2009.

Tripathi A, Grammer LC [2001]. Extrinsic allergic alveolitis from a

proteolytic enzyme. Ann Allergy Asthma Immunol 86(4):425–427.

USFDA [2009]. Adverse event reporting data files. Center

for Devices and Radiological Health, U.S. Food and Drug

Administration, Department of Health and Human Services.

[www.fda.gov/cdrh/mdr/mdr-file-general.html]. Date accessed:

March 24, 2009.

Page 15

Health Hazard Evaluation Report 2006-0298-3090

AC k n o w l e d g m e n t s A n d

AvAilAbility o f Re p o R t

The Hazard Evaluation and Technical Assistance Branch (HETAB)

of the National Institute for Occupational Safety and Health

(NIOSH) conducts field investigations of possible health hazards

in the workplace. These investigations are conducted under the

authority of Section 20(a)(6) of the Occupational Safety and

Health (OSHA) Act of 1970, 29 U.S.C. 669(a)(6) which authorizes

the Secretary of Health and Human Services, following a written

request from any employer or authorized representative of

employees, to determine whether any substance normally found

in the place of employment has potentially toxic effects in such

concentrations as used or found. HETAB also provides, upon

request, technical and consultative assistance to federal, state, and

local agencies; labor; industry; and other groups or individuals to

control occupational health hazards and to prevent related trauma

and disease.

The findings and conclusions in this report are those of the

authors and do not necessarily represent the views of NIOSH.

Mention of any company or product does not constitute

endorsement by NIOSH. In addition, citations to websites

external to NIOSH do no constitute NIOSH endorsement of

the sponsoring organizations or their programs or products.

Furthermore, NIOSH is not responsible for the content of these

websites. All Web addresses referenced in this document were

accessible as of the publication date.

This report was prepared by David Sylvain and John Gibbins of

HETAB, Division of Surveillance, Hazard Evaluations and Field

Studies. Analytical support was provided by Charles Neumeister

of the Division of Applied Research and Technology. Health

communication assistance was provided by Stefanie Evans.

Editorial assistance was provided by Ellen Galloway. Desktop

publishing was performed by Robin Smith.

Copies of this report have been sent to employee and management

representatives at Kaleida Health-Buffalo General Hospital, the

state health department, and the OSHA Regional Office. This

report is not copyrighted and may be freely reproduced. The report

may be viewed and printed at

www.cdc.gov/niosh/hhe. Copies may

be purchased from the National Technical Information Service at

5825 Port Royal Road, Springfield, Virginia 22161.

Below is a recommended citation for this report:

NIOSH [2009]. Health hazard evaluation report: evaluation of worker exposures

to peracetic acid-based sterilant during endoscope reprocessing, Buffalo, NY.

By Sylvain D, Gibbins J. Cincinnati, OH: U.S. Department of Health and Human

Services, Centers for Disease Control and Prevention, National Institute for

Occupational Safety and Health, NIOSH HETA No. 2006-0298-3090.

To receive NIOSH documents or information about

occupational safety and health topics, contact NIOSH at:

1-800-CDC-INFO (1-800-232-4636)

TTY: 1-888-232-6348

E-mail: [email protected]

or visit the NIOSH web site at: www.cdc.gov/niosh.

For a monthly update on news at NIOSH, subscribe to

NIOSH eNews by visiting www.cdc.gov/niosh/eNews.

Delivering on the Nation’s promise:

Safety and health at work for all people

through research and prevention.

National Institute for Occupational

Safety and Health