Machine Automation Controller

NJ/NX-series

Motion Control

Instructions Reference Manual

W508-E1-15

NX701-17

NX701-16

NX1P2-11

NX1P2-10

NX1P2-90

NJ501-5

NJ501-4

NJ501-3

NJ301-12

NJ301-11

NJ101-10

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Neverthe-

less, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and other

countries for OMRON factory automation products.

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or trademarks of

Microsoft Corporation in the United States and other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD and SDHC logos are trademarks of SD-3C, LLC.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Trademarks

Copyrights

NOTE

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

1

Introduction

NJ/NX-series Motion Control Instructions Reference Manual (W508)

Introduction

Thank you for purchasing an NJ/NX-series CPU Unit.

This manual describes the motion control instructions. Please be sure you sufficiently understand the

operations and handling procedures, and use the Motion Control Function Module (abbreviated as “MC

Function Module”) correctly.

Use this manual together with the user’s manuals for the NJ/NX-series CPU Unit.

When you have finished reading this manual, keep it in a safe location where it will be readily available

for future use.

This manual is intended for the following personnel, who must also have knowledge of electrical sys-

tems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

For programming, this manual is intended for personnel who understand the programming language

specifications in international standard IEC 61131-3 or Japanese standard JIS B 3503.

This manual covers the following products.

NX-series CPU Units

• NX701-17

• NX701-16

• NX1P2-11

• NX1P2-111

• NX1P2-10

• NX1P2-101

• NX1P2-90

• NX1P2-901

NJ-series CPU Units

• NJ501-5

• NJ501-4

• NJ501-3

• NJ301-12

• NJ301-11

• NJ101-10

Part of the specifications and restrictions for the CPU Units are given in other manuals. Refer to Rele-

vant Manuals on page 2 and Related Manuals on page 26.

Intended Audience

Applicable Products

Relevant Manuals

2

NJ/NX-series Motion Control Instructions Reference Manual (W508)

Relevant Manuals

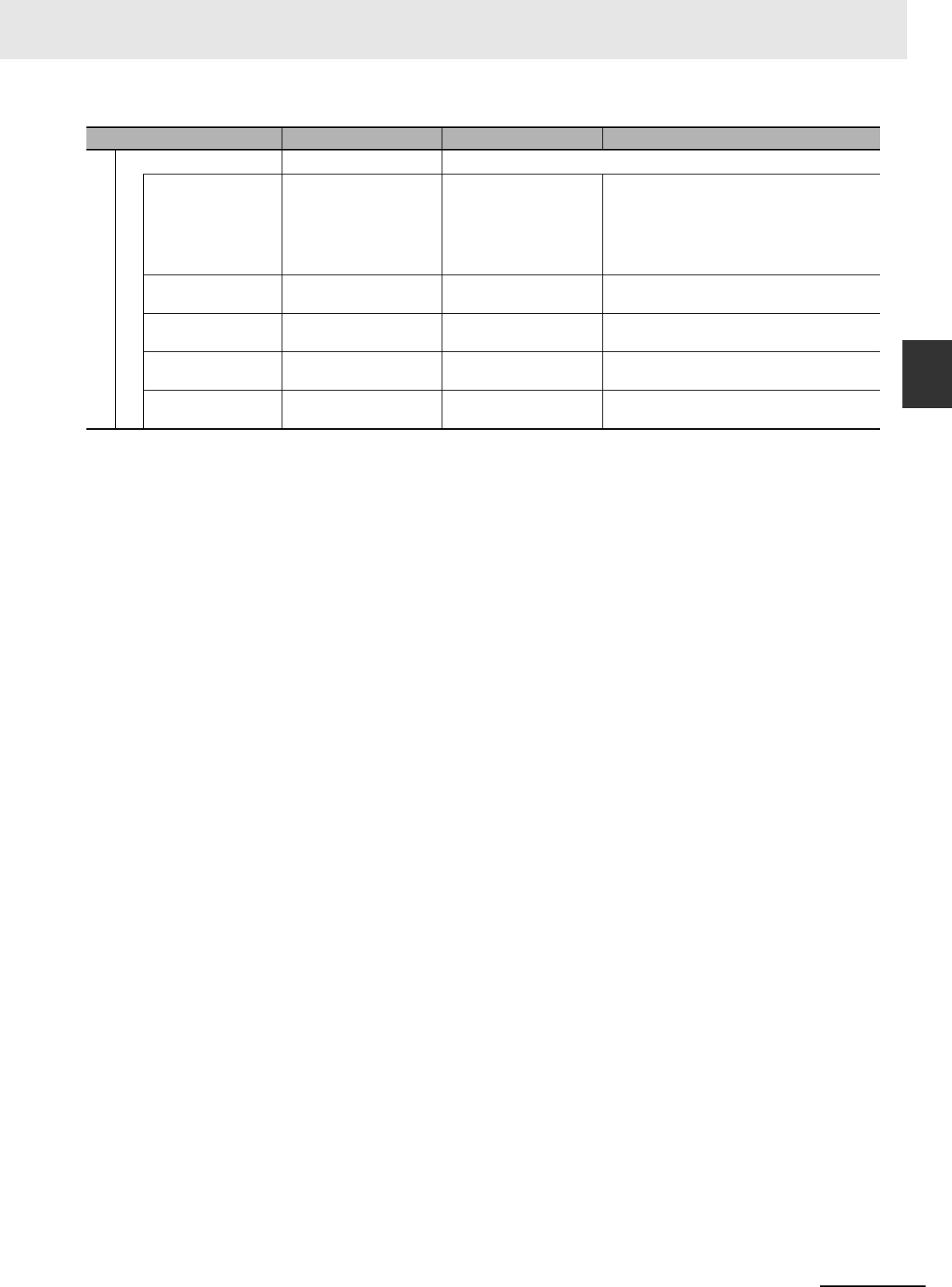

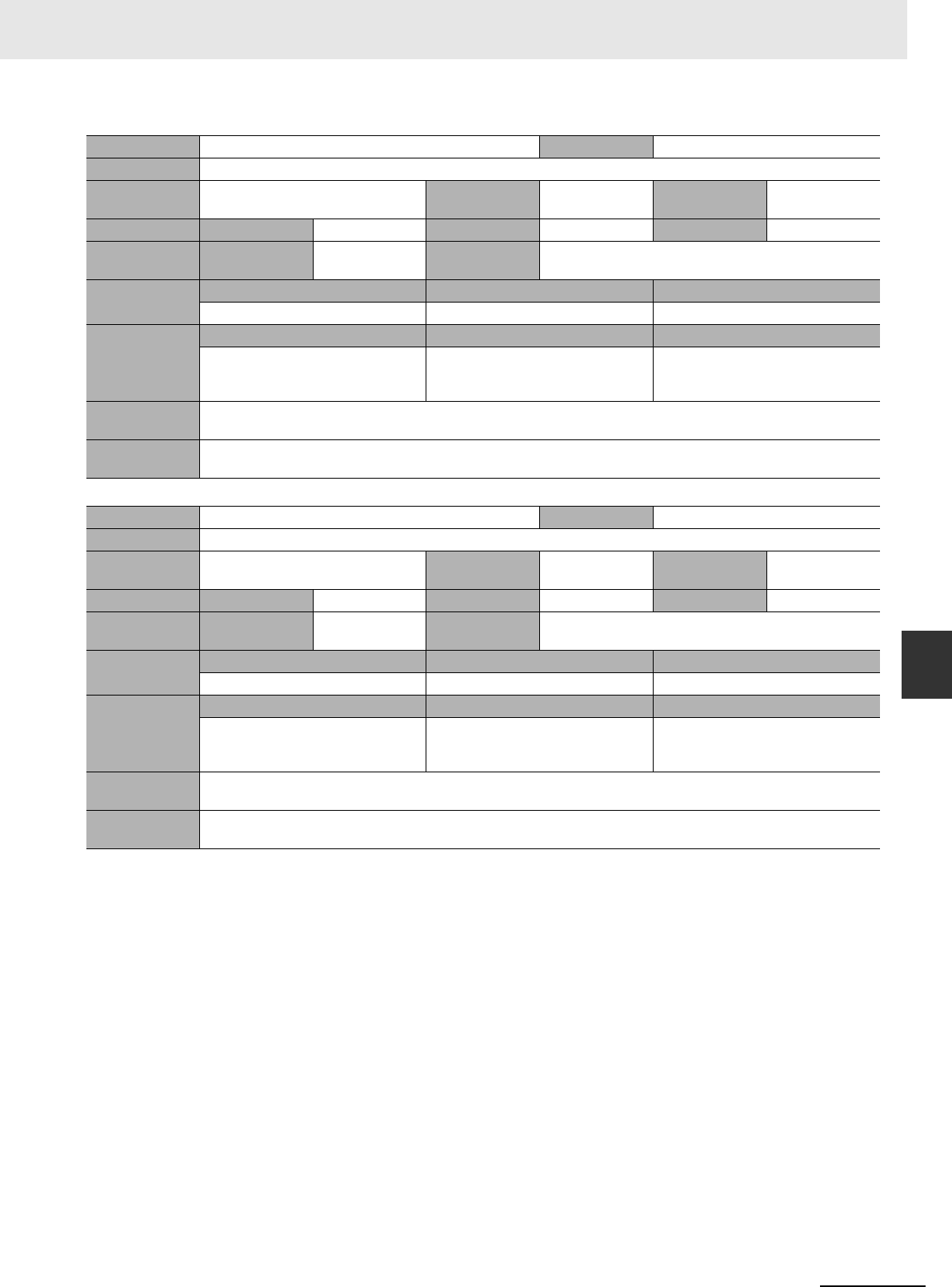

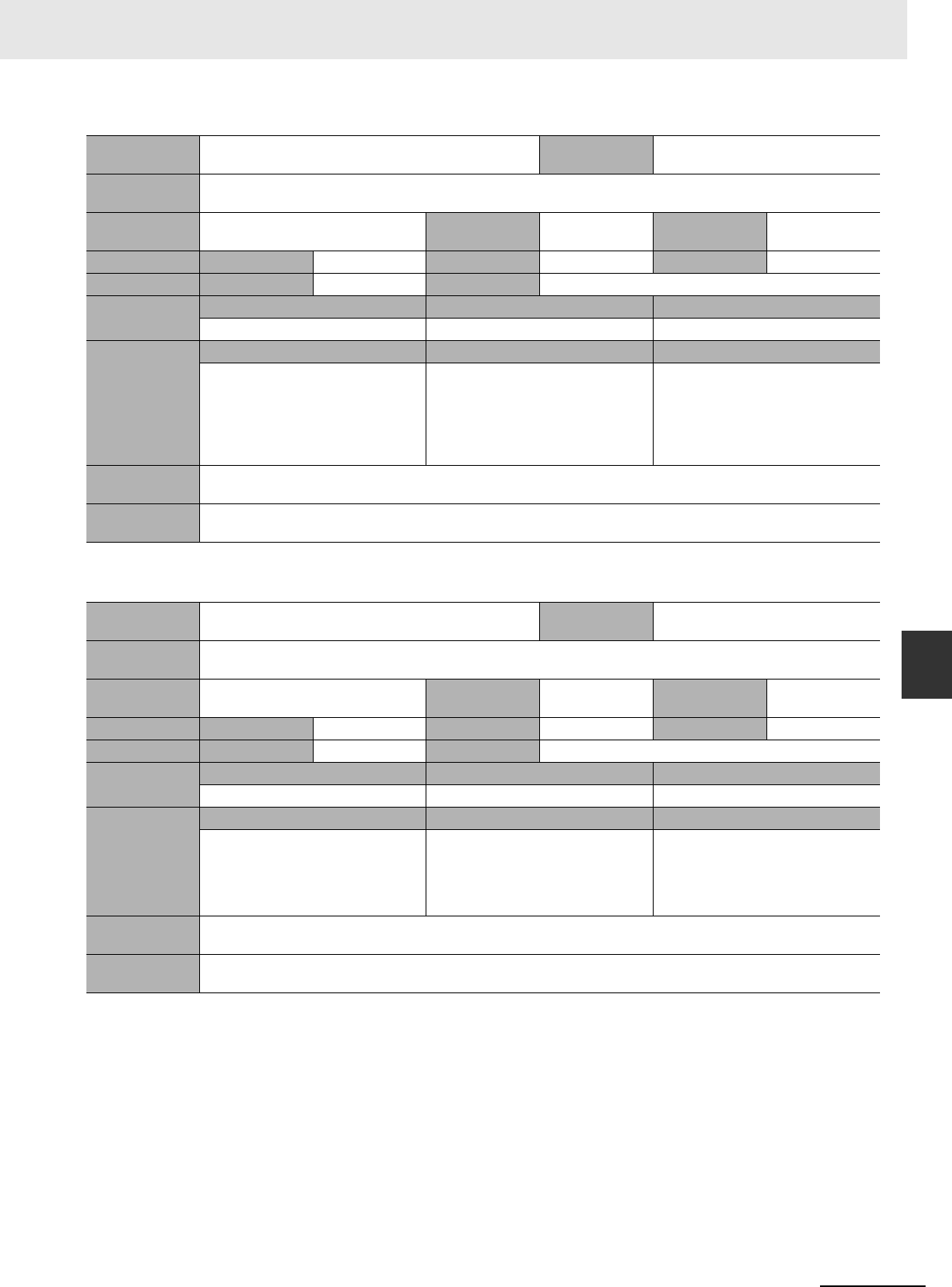

The following table provides the relevant manuals for the NJ/NX-series CPU Units.

Read all of the manuals that are relevant to your system configuration and application before you use

the NJ/NX-series CPU Unit.

Most operations are performed from the Sysmac Studio Automation Software. Refer to the Sysmac Stu-

dio Version 1 Operation Manual (Cat. No. W504) for information on the Sysmac Studio.

Purpose of use

Manual

Basic information

NX-series CPU Unit

Hardware User’s Manual

NX-series NX1P2 CPU Unit

Hardware User's Manual

NJ-series CPU Unit

Hardware User’s Manual

NJ/NX-series CPU Unit

Software User’s Manual

NX-series NX1P2 CPU Unit

Built-in I/O and Option Board User's Manual

NJ/NX-series

Instructions Reference Manual

NJ/NX-series CPU Unit

Motion Control User’s Manual

NJ/NX-series

Motion Control Instructions Reference Manual

NJ/NX-series CPU Unit

Built-in EtherCAT Port User’s Manual

NJ/NX-series CPU Unit

Built-in EtherNet/IP Port User’s Manual

NJ-series Database Connection CPU Units

User’s Manual

NJ-series SECS/GEM CPU Units

User’s Manual

NJ-series NJ Robotics

CPU Unit User’s Manual

NJ/NX-series

Troubleshooting Manual

Introduction to NX701 CPU Units

Introduction to NX1P2 CPU Units

Introduction to NJ-series Controllers

Setting devices and hardware

Using motion control

Using EtherCAT

Using EtherNet/IP

Software settings

Using motion control

Using EtherCAT

Using EtherNet/IP

Using the database connection service

Using the GEM Services

Using robot control

Using the NX1P2 CPU Unit functions

Writing the user program

Using motion control

Using EtherCAT

Using EtherNet/IP

Using the database connection service

Using the GEM Services

Using robot control

Programming error processing

Using the NX1P2 CPU Unit functions

3

Relevant Manuals

NJ/NX-series Motion Control Instructions Reference Manual (W508)

*1 Refer to the NJ/NX-series Troubleshooting Manual (Cat. No. W503) for the error management concepts and an overview

of the error items. Refer to the manuals that are indicated with triangles for details on errors for the corresponding Units.

Testing operation and debugging

Using motion control

Using EtherCAT

Using EtherNet/IP

Using the database connection service

Using the GEM Services

Using robot control

Using the NX1P2 CPU Unit functions

Learning about error management

and corrections

*1

Maintenance

Using motion control

Using EtherCAT

Using EtherNet/IP

Purpose of use

Manual

Basic information

NX-series CPU Unit

Hardware User’s Manual

NX-series NX1P2 CPU Unit

Hardware User's Manual

NJ-series CPU Unit

Hardware User’s Manual

NJ/NX-series CPU Unit

Software User’s Manual

NX-series NX1P2 CPU Unit

Built-in I/O and Option Board User's Manual

NJ/NX-series

Instructions Reference Manual

NJ/NX-series CPU Unit

Motion Control User’s Manual

NJ/NX-series

Motion Control Instructions Reference Manual

NJ/NX-series CPU Unit

Built-in EtherCAT Port User’s Manual

NJ/NX-series CPU Unit

Built-in EtherNet/IP Port User’s Manual

NJ-series Database Connection CPU Units

User’s Manual

NJ-series SECS/GEM CPU Units

User’s Manual

NJ-series NJ Robotics

CPU Unit User’s Manual

NJ/NX-series

Troubleshooting Manual

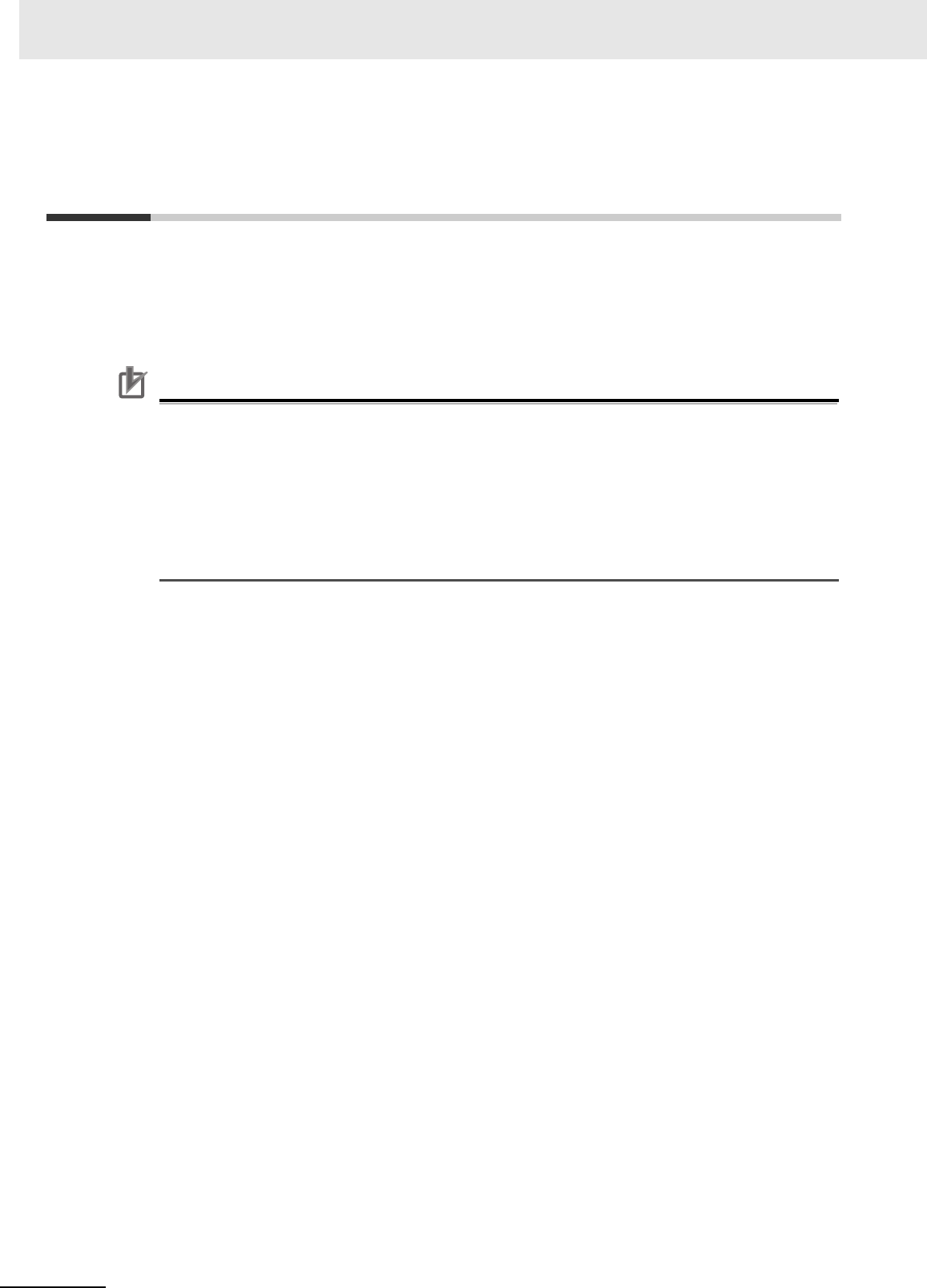

Manual Structure

4

NJ/NX-series Motion Control Instructions Reference Manual (W508)

Manual Structure

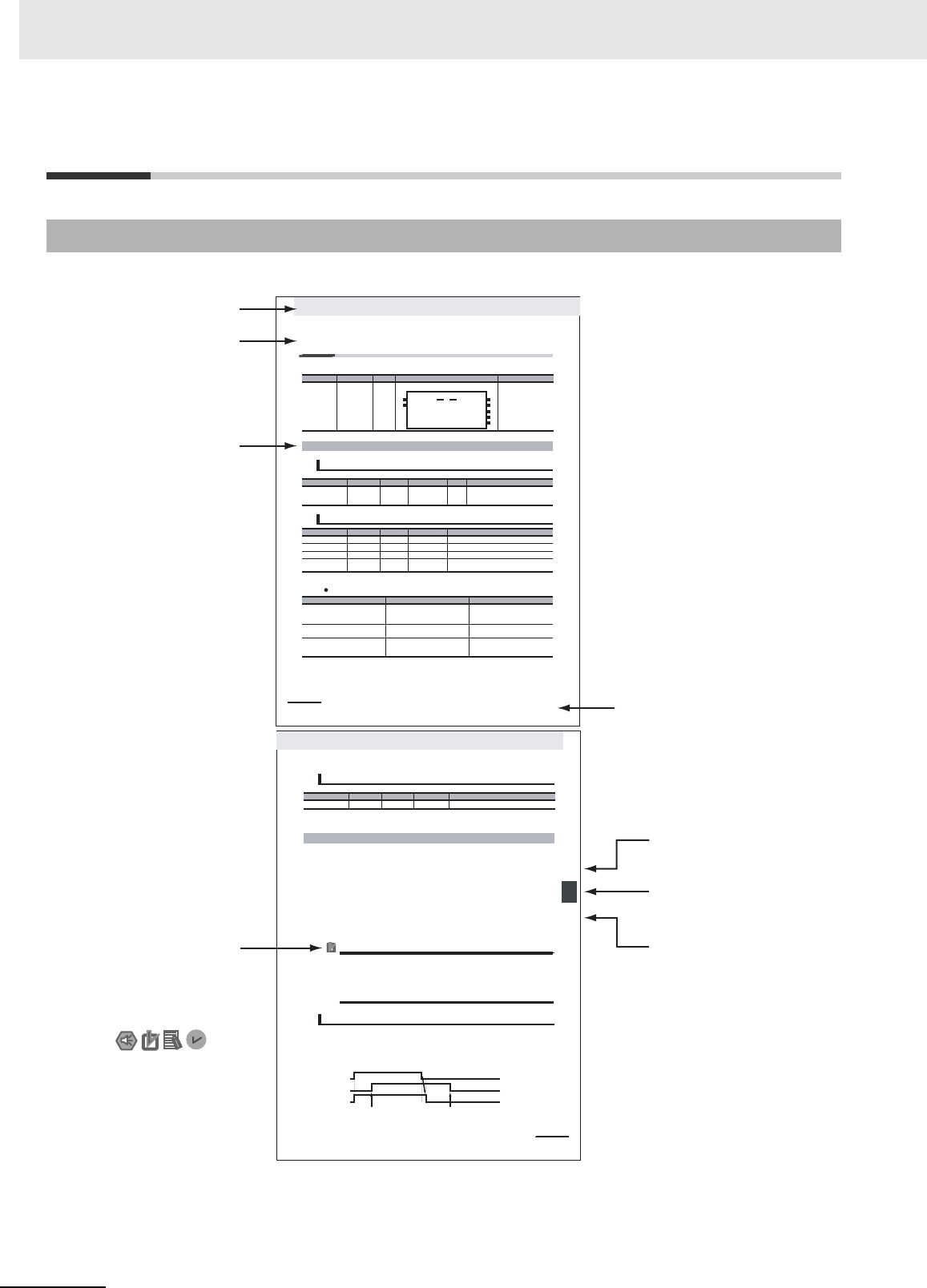

The following page structure is used in this manual.

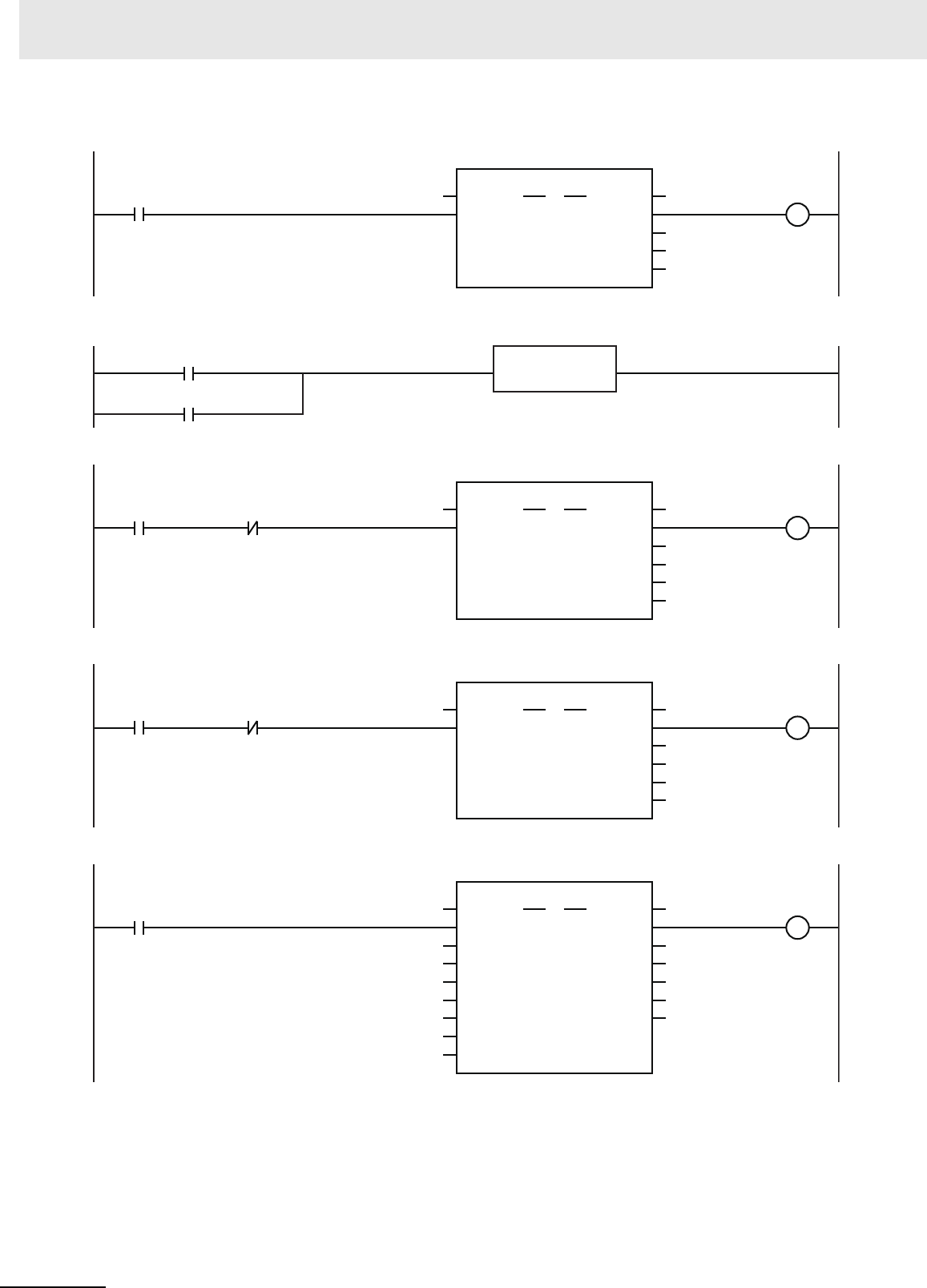

Page Structure

Manual name

Special information

Icons indicate

precautions, additional

information, or reference

information.

Note: This page is for illustration only. It does not represent a specific page in this manual.

Level-1 section heading

Level-2 section heading

Level-1 section number

Level-3 section heading

The level-1 section number

is given.

The level-2 section heading

is given.

The level-3 section heading

is given.

3 Axis Command Instructions

3-2

NJ-series Motion Control Instructions Reference Manual (W508)

MC_Power

The MC_Power instruction makes a Servo Drive ready to operate.

*Refer to A-1 Error Codes.

Output Variable Update Timing

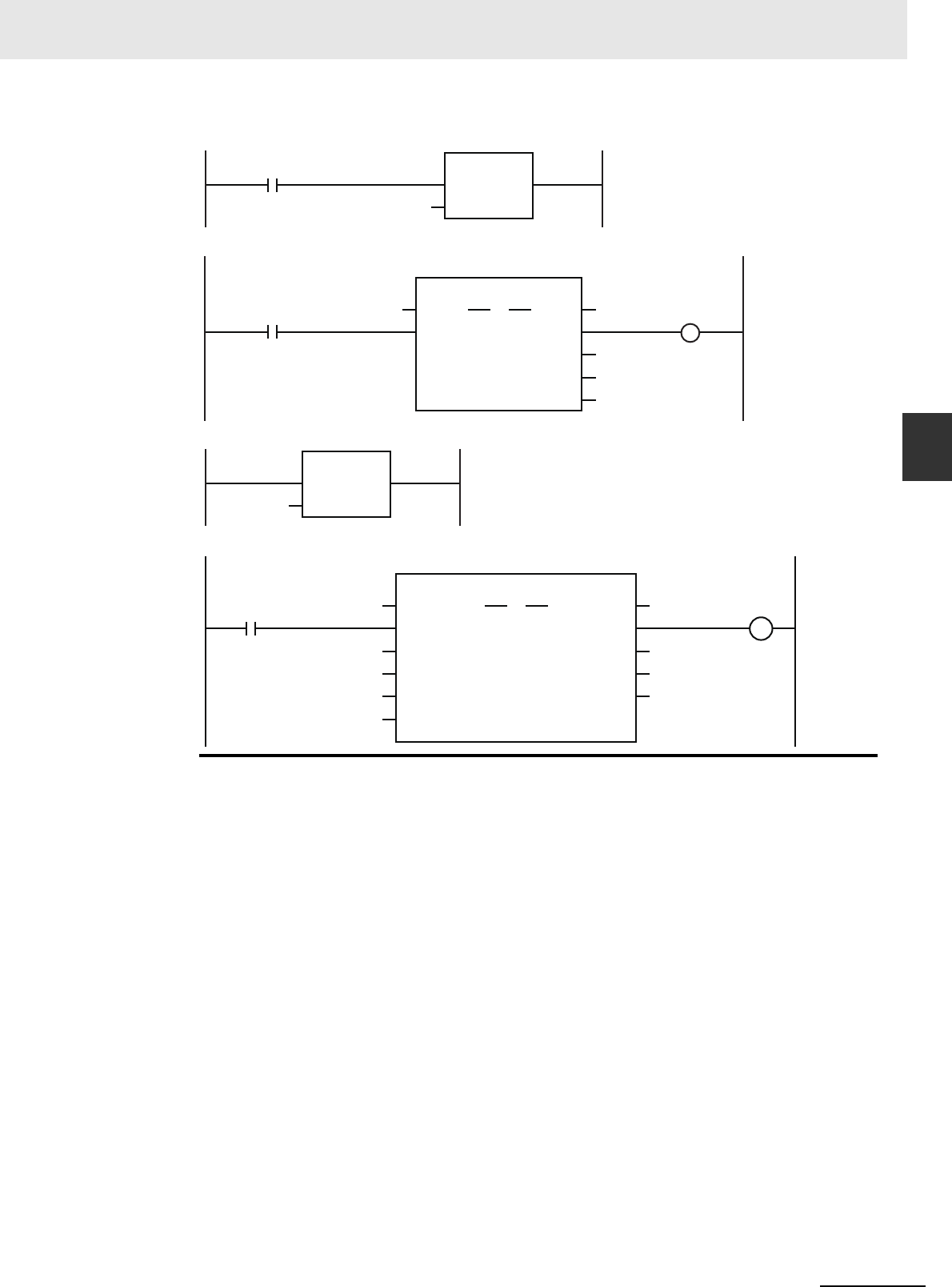

Instruction Name FB/FUN Graphic expression ST expression

MC_Power Power Servo FB MC_Power_instance (

Axis :=parameter,

Enable :=parameter,

Status =>parameter,

Busy =>parameter,

Error =>parameter,

ErrorID =>parameter

);

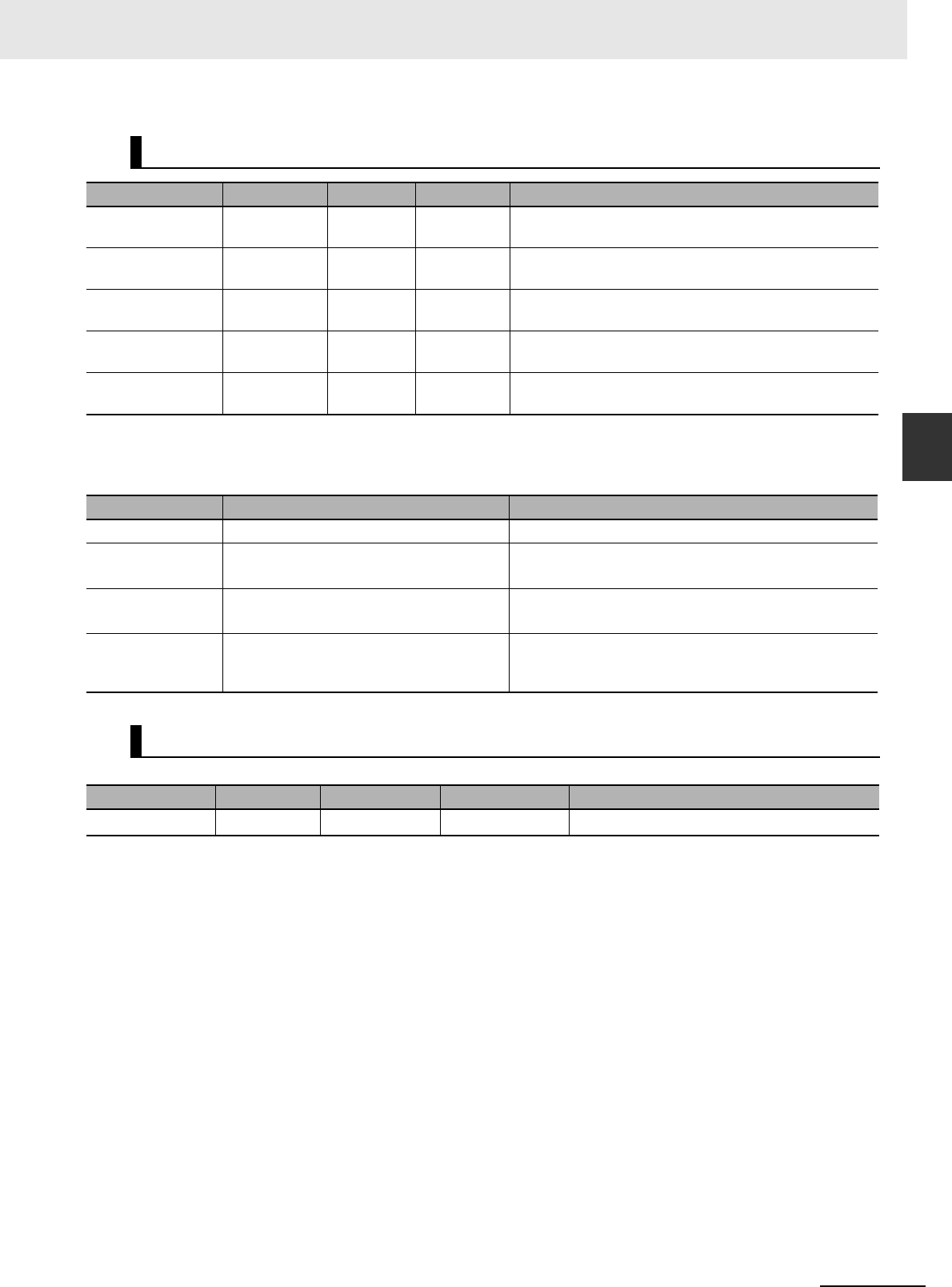

Variables

Input Variables

Name Meaning Data type Valid range Default Description

Enable Enable BOOL TRUE or FALSE FALSE The device is ready for operation when

Enable is TRUE, and not ready when it is

FAL SE.

Output Variables

Name Meaning Data type Valid range Description

Status Servo ON BOOL TRUE or FALSE TRUE when the device is ready for operation.

Busy Executing BOOL TRUE or FALSE TRUE when the instruction is acknowledged.

Error Error BOOL TRUE or FALSE TRUE while there is an error.

ErrorID Error Code WORD

*

Contains the error code when an error occurs.

A value of 16#0000 indicates normal execution.

Name Timing for changing to TRUE Timing for changing to FALSE

Status When the specified axis becomes

ready for operation.

• When operation ready status for the

specified axis is cleared.

• When Error changes to TRUE.

Busy When Enable changes to TRUE. • When Enable changes to FALSE.

• When Error changes to TRUE.

Error When there is an error in the execution

conditions or input parameters for the

instruction.

When the error is cleared.

MC_Power_instance

Error

Axis Axis

Enable Status

Busy

MC_Power

ErrorID

3-3

3 Axis Command Instructions

NJ-series Motion Control Instructions Reference Manual (W508)

rewoP_CM

3

noitcnuF

* Specify an Axis Variable that was created in the Axis Basic Settings of the Sysmac Studio. (The default axis variable names

are MC_Axis***.)

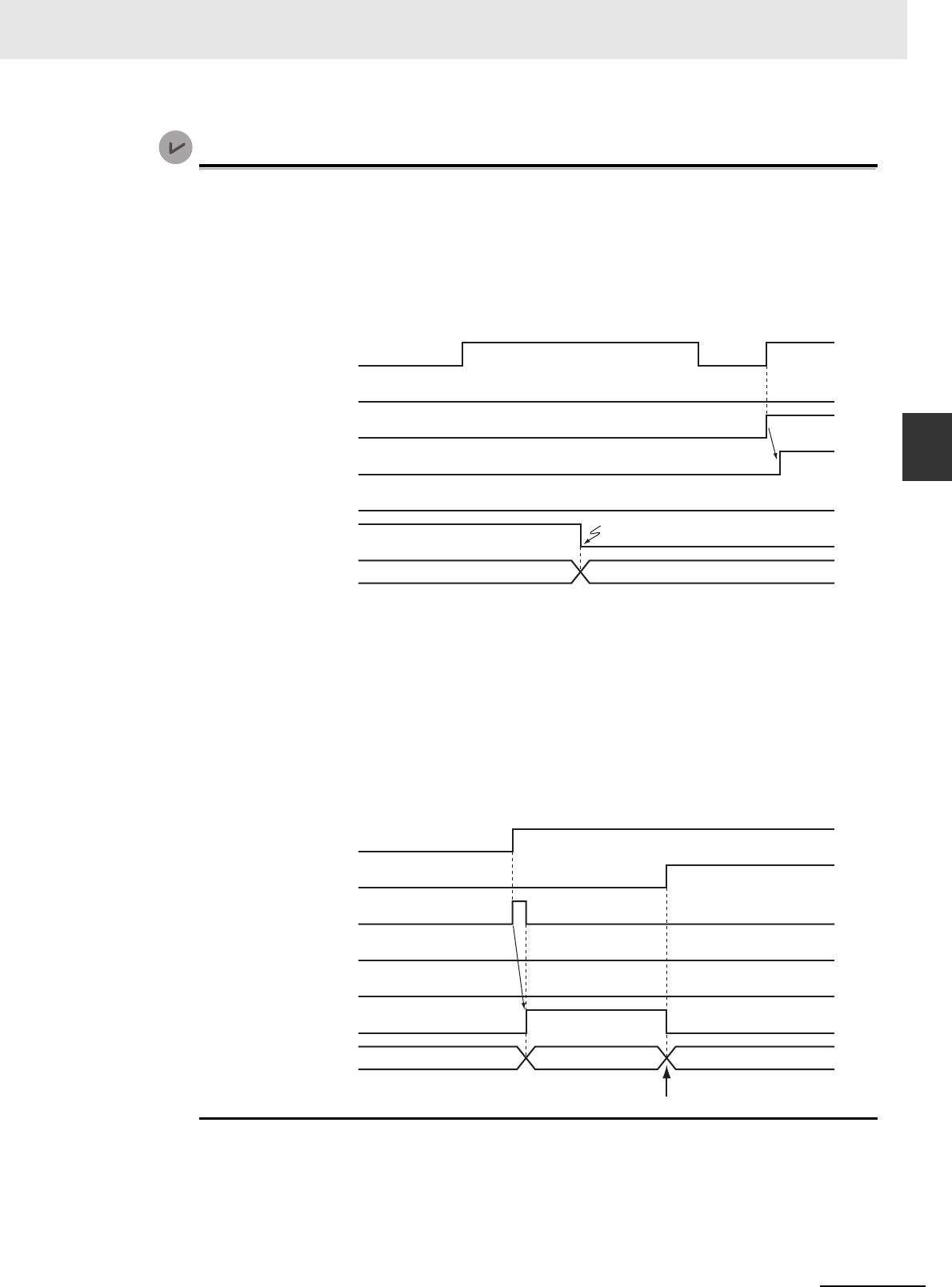

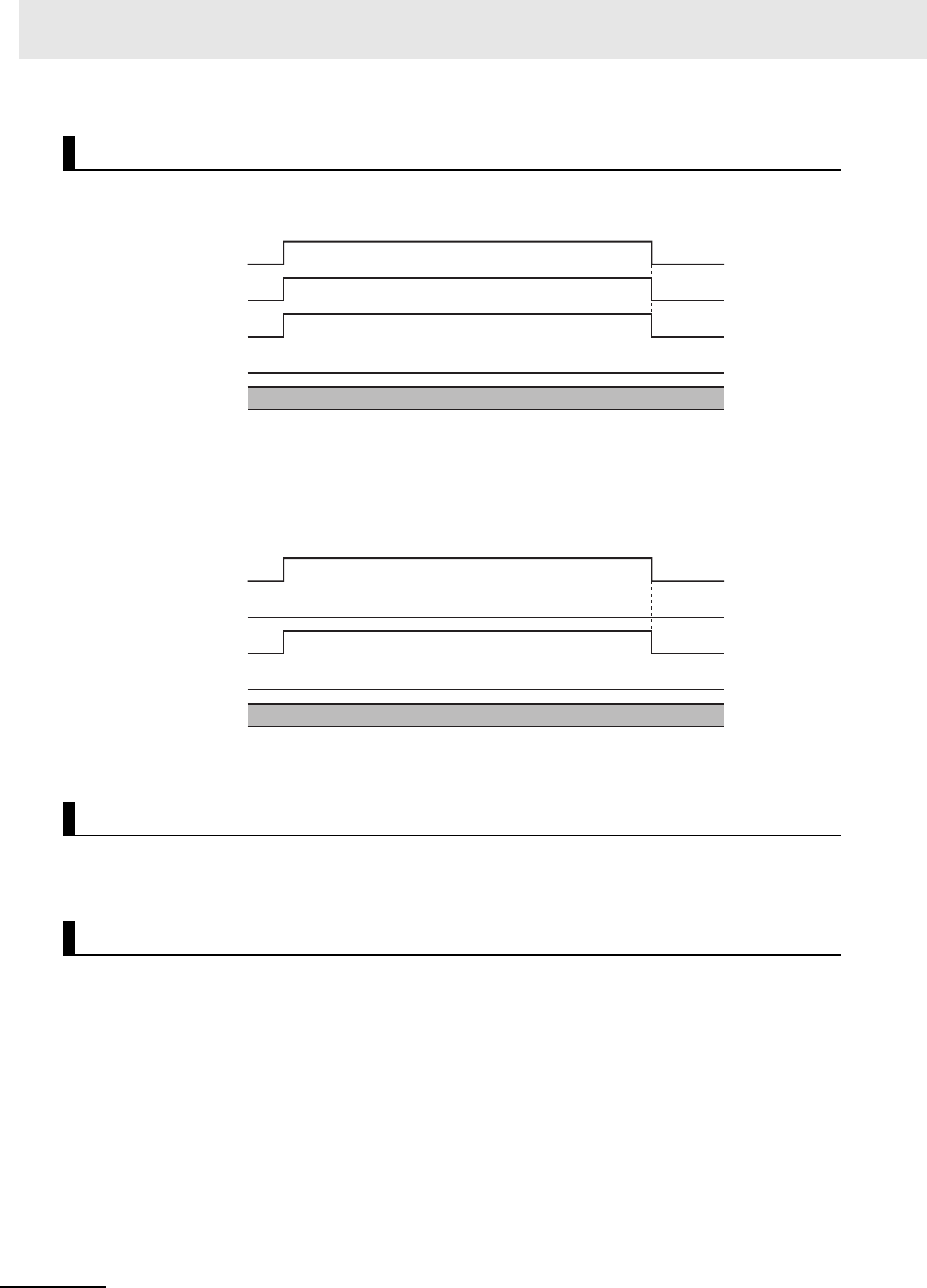

• When Enable changes to TRUE, the axis specified by Axis is made ready to operate.

You can control the axis when it is ready to operate.

• When Enable changes to FALSE, the ready status is cleared for the axis specified by Axis.

You cannot control the axis after the ready status is cleared because it will not acknowledge opera-

tion commands. Also, an error occurs if a motion command is executed for an axis for which the

ready status is cleared. You can execute the MC_Power (Power Servo) and MC_Reset (Reset Axis

Error) instructions even for axes that are not ready.

• You can use this instruction to disable the operation of axes while they are in motion. In this case,

CommandAborted will change to TRUE. Output of the operation command will stop and the axis will

not longer be ready for operation.

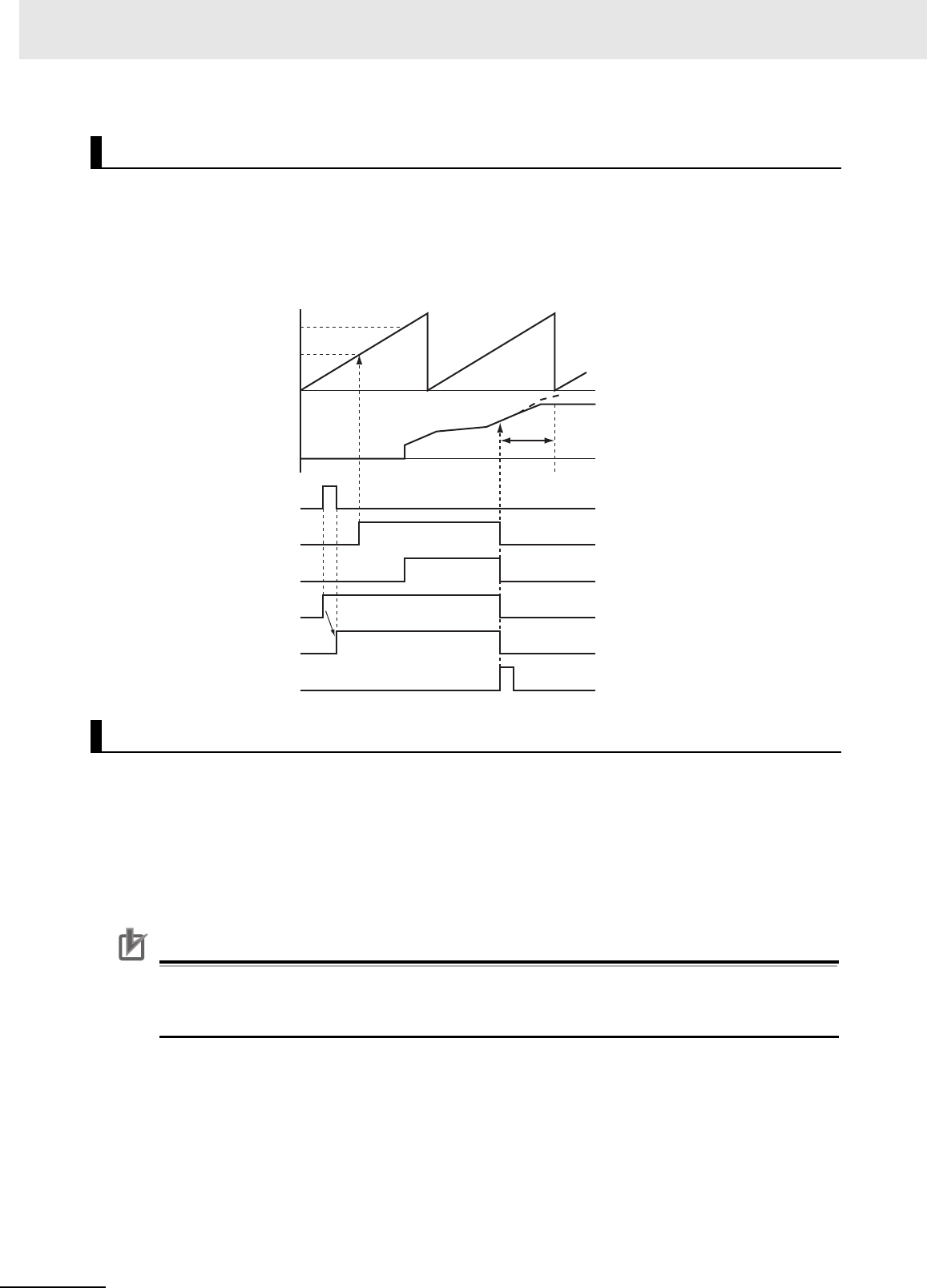

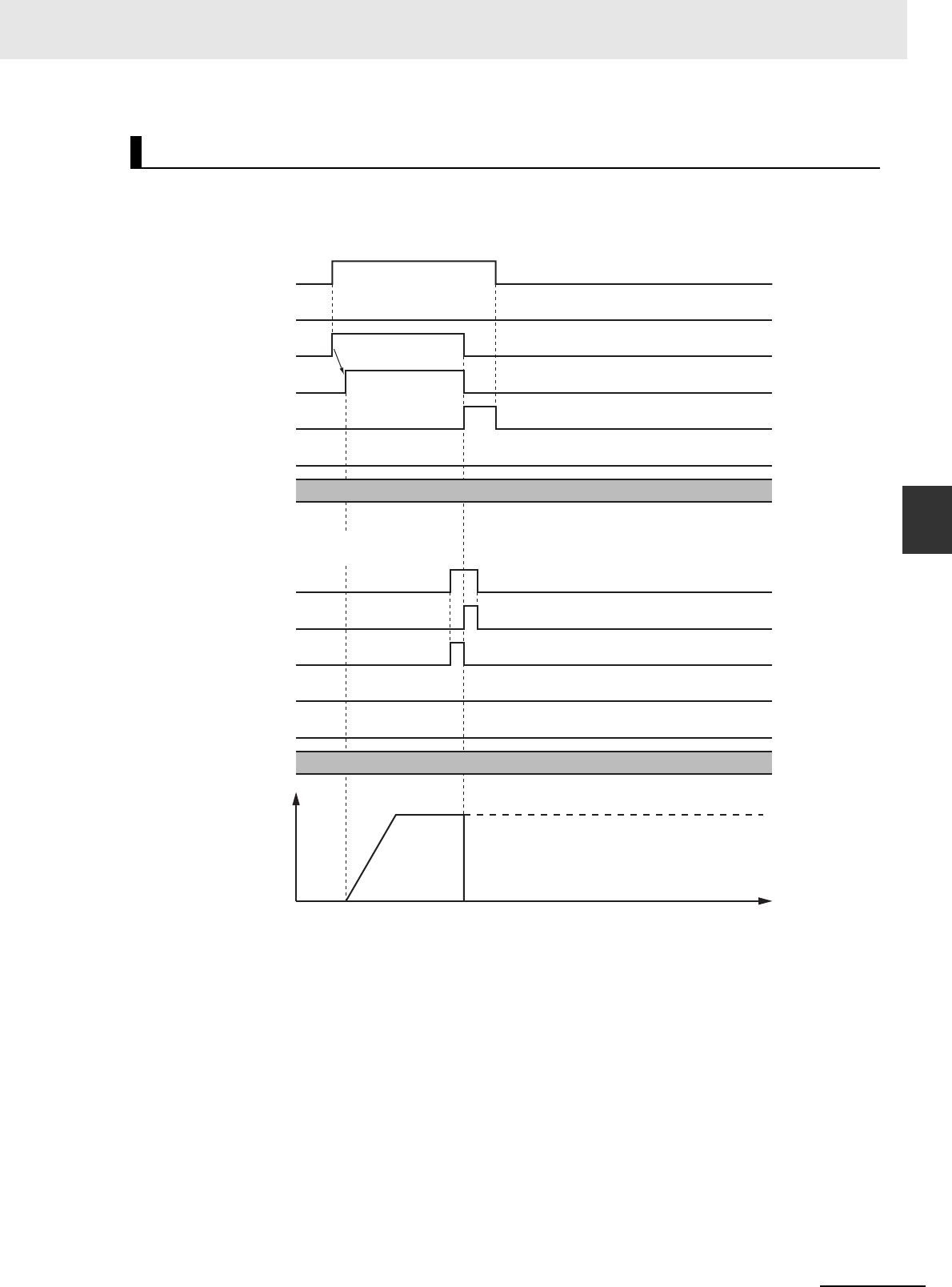

• If home is not defined for a Servomotor with an absolute encoder, compensation is performed using

the absolute encoder home offset to define home when the axis is ready to operate.

For details on the absolute encoder home offset, refer to the NJ-series CPU Unit Motion Control

User’s Manual (Cat. No. W507).

Precautions for Correct UsePrecautions for Correct Use

• You can use this instruction for servo axes and virtual servo axes. If the instruction is used for

encoder axes or virtual encoder axes, an error will occur.

• Executing this Instruction for the Master Axis of Synchronized Control

When master axis operation is disabled for a vertical axis, the position of the master axis may

change rapidly. This may cause the motion of the slave axis to change rapidly. Take suitable

measures to prevent the slave axis from moving rapidly, such as applying a brake to the mas-

ter axis or leaving master axis operation enabled until after synchronized control is completed.

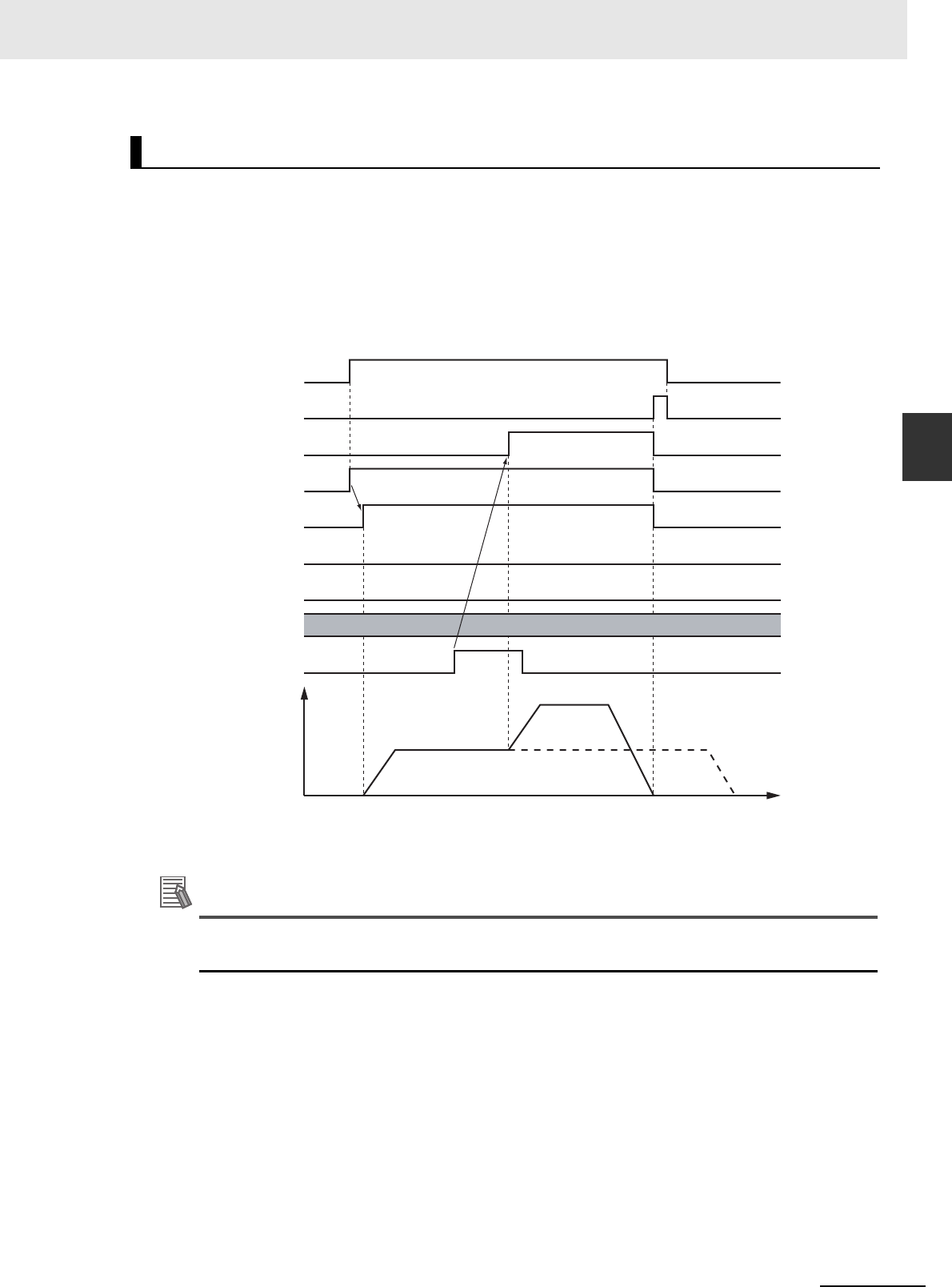

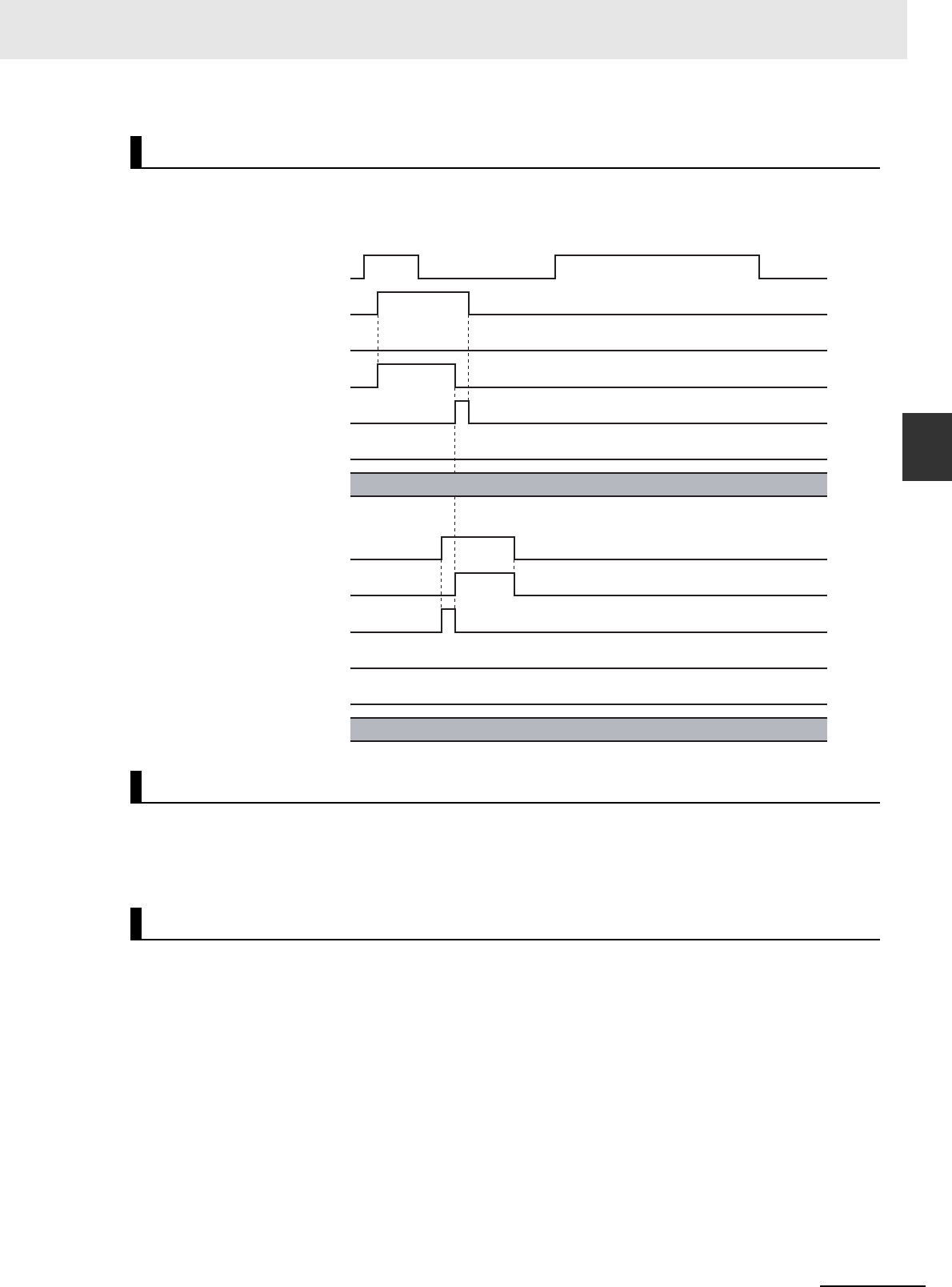

• When Enable changes to TRUE, Busy (Executing) changes to TRUE to indicate that the instruction

was acknowledged.

• After the axis becomes ready for operation, Status (Servo ON) changes to TRUE.

• When Enable changes to FALSE, Busy (Executing) changes to FALSE. Status (Servo ON) changes

to FALSE when ready status is cleared. Status (Servo ON) outputs the axis ready status regardless

of whether Enable is TRUE or FALSE.

In-Out Variables

Name Meaning Data type Valid range Description

Axis Axis _sAXIS_REF ---

Specify the axis.

*

Function

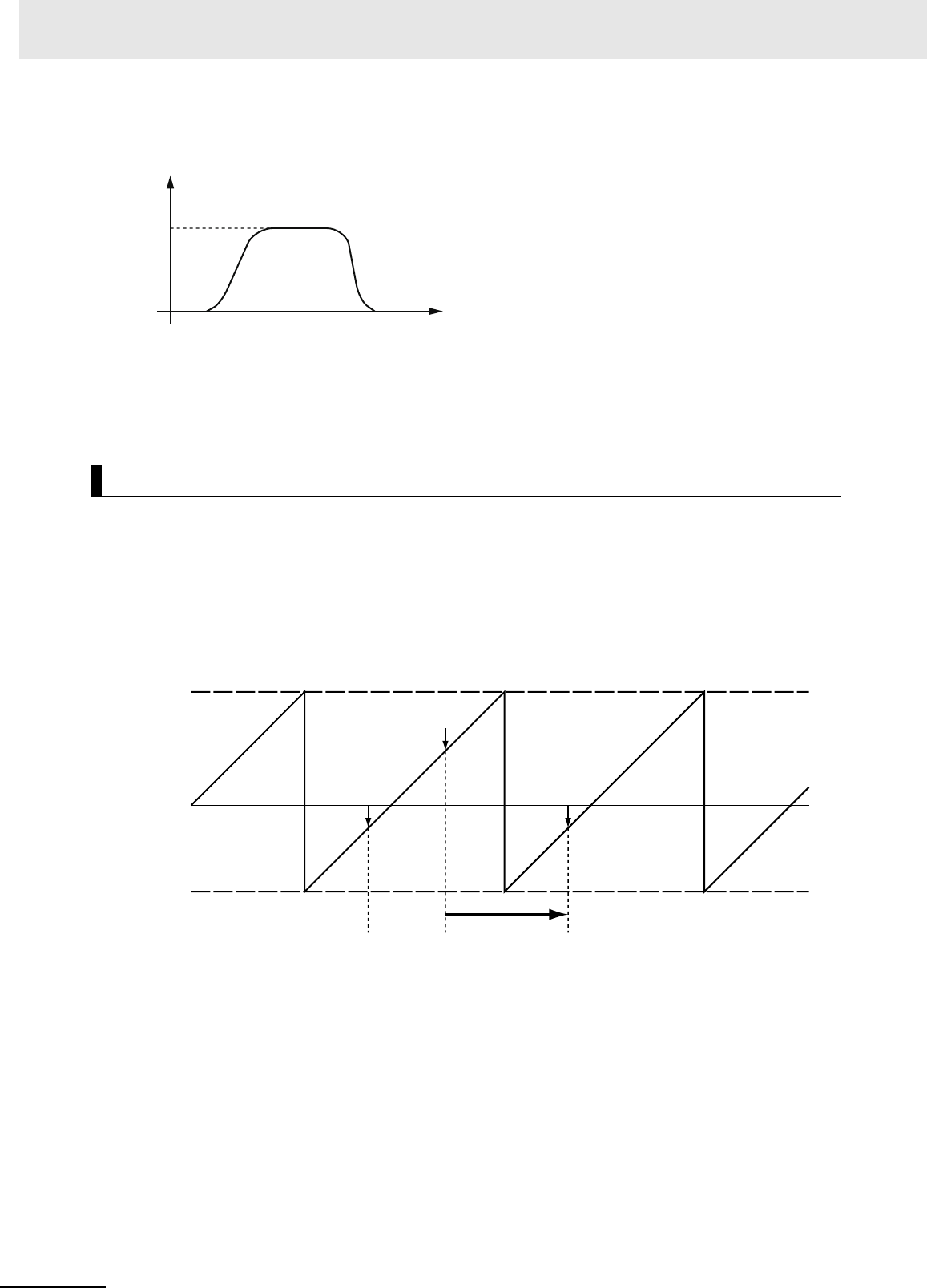

Timing Charts

Enable

Status

Busy

The specified axis becomes

ready for operation.

Ready status is cleared for the

specified axis.

Level-2 section heading

Level-3 section heading

5

Manual Structure

NJ/NX-series Motion Control Instructions Reference Manual (W508)

Special information in this manual is classified as follows:

Note References are provided to more detailed or related information.

Special Information

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Version Information

Information on differences in specifications and functionality for CPU Units with different unit versions

and for different versions of the Sysmac Studio are given.

Manual Structure

6

NJ/NX-series Motion Control Instructions Reference Manual (W508)

7

Sections in this Manual

NJ/NX-series Motion Control Instructions Reference Manual (W508)

Sections in this Manual

1

2

3

4

5

A

I

1

2

3

4

5

A

I

Introduction to Motion Control Instructions

Variables and Instructions

Axis Command Instructions

Axes Group Instructions

Common Command Instructions

Appendices

Index

Sections in this Manual

8

NJ/NX-series Motion Control Instructions Reference Manual (W508)

9

NJ/NX-series Motion Control Instructions Reference Manual (W508)

CONTENTS

CONTENTS

Introduction............................................................................................................... 1

Relevant Manuals...................................................................................................... 2

Manual Structure ...................................................................................................... 4

Sections in this Manual............................................................................................ 7

Terms and Conditions Agreement ........................................................................ 15

Safety Precautions ................................................................................................. 17

Precautions for Safe Use ....................................................................................... 18

Precautions for Correct Use .................................................................................. 19

Regulations and Standards ................................................................................... 20

Versions................................................................................................................... 22

Related Manuals ..................................................................................................... 26

Revision History ..................................................................................................... 29

Section 1 Introduction to Motion Control Instructions

1-1 Motion Control Instructions.................................................................................................... 1-2

Function Blocks for PLCopen® Motion Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Overview of Motion Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Precautions for Master and Auxiliary Axes in Synchronized Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-2 Basic Information on Motion Control Instructions............................................................... 1-8

Motion Control Instruction Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Languages for Motion Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Motion Control Instruction Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Multi-execution of Motion Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Online Editing of Motion Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Changes in the Operating Mode of the CPU Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Section 2 Variables and Instructions

2-1 Variables ................................................................................................................................... 2-2

MC Common Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Axis Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Axes Group Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Input Variables for Motion Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Output Variables for Motion Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

In-Out Variables for Motion Control Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

2-2 Instructions ............................................................................................................................ 2-31

Common Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Axis Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Axes Group Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

2-3 PDO Mapping ......................................................................................................................... 2-35

Required Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Objects Required for Specific Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

10

NJ/NX-series Motion Control Instructions Reference Manual (W508)

CONTENTS

Section 3 Axis Command Instructions

MC_Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

MC_MoveJog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

MC_Home . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

MC_HomeWithParameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

MC_Move . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

MC_MoveAbsolute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

Sample Programming 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-59

Sample Programming 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-67

MC_MoveRelative . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-76

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-76

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-78

MC_MoveVelocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-83

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-83

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-85

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-90

MC_MoveZeroPosition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-98

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-98

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-100

MC_MoveFeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-105

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-106

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-109

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-122

MC_Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-133

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-133

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-134

MC_ImmediateStop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-142

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-142

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-143

MC_SetPosition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-147

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-147

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-148

MC_SetOverride . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-153

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-153

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-154

MC_ResetFollowingError . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-158

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-158

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-159

MC_CamIn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-165

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-165

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-169

Sample Programming 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-192

Sample Programming 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-203

MC_CamOut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-219

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-219

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-220

MC_GearIn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-224

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-224

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-226

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-233

11

NJ/NX-series Motion Control Instructions Reference Manual (W508)

CONTENTS

MC_GearInPos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-243

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-243

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-246

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-254

MC_GearOut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-264

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-264

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-266

MC_MoveLink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-269

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-269

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-272

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-282

MC_CombineAxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-292

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-292

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-295

MC_Phasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-304

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-304

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-306

MC_TorqueControl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-312

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-312

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-314

MC_SetTorqueLimit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-323

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-323

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-324

MC_ZoneSwitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-330

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-330

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-332

MC_TouchProbe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-336

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-336

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-339

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-351

MC_AbortTrigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-358

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-358

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-360

MC_AxesObserve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-363

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-363

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-365

MC_SyncMoveVelocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-369

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-369

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-371

MC_SyncMoveAbsolute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-379

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-379

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-381

MC_Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-386

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-386

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-387

MC_ChangeAxisUse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-390

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-390

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-391

MC_DigitalCamSwitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-394

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-395

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-396

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-406

MC_TimeStampToPos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-413

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-413

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-414

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-417

MC_PeriodicSyncVariables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-425

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-425

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-426

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-430

MC_SyncOffsetPosition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-433

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-433

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-435

12

NJ/NX-series Motion Control Instructions Reference Manual (W508)

CONTENTS

Section 4 Axes Group Instructions

MC_GroupEnable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

MC_GroupDisable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

MC_MoveLinear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

MC_MoveLinearAbsolute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

MC_MoveLinearRelative . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

MC_MoveCircular2D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

MC_GroupStop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-68

MC_GroupImmediateStop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-75

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-75

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-76

MC_GroupSetOverride . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-79

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-79

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-80

MC_GroupReadPosition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-83

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-83

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-85

MC_ChangeAxesInGroup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-87

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-87

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-89

MC_GroupSyncMoveAbsolute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-91

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-91

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-93

MC_GroupReset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-97

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-97

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-98

Section 5 Common Command Instructions

MC_SetCamTableProperty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

MC_SaveCamTable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

MC_Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

MC_GenerateCamTable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Sample Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

MC_WriteAxisParameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-49

13

NJ/NX-series Motion Control Instructions Reference Manual (W508)

CONTENTS

MC_ReadAxisParameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-62

Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-62

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-64

Appendices

A-1 Error Codes..............................................................................................................................A-2

A-2 Error Code Details .................................................................................................................A-25

A-3 Instructions for Which Multi-execution Is Supported ......................................................A-108

A-3-1 Axis and Axes Group Status...................................................................................................A-109

A-3-2 State Transitions and Instructions for which Multi-execution Is Supported .............................A-111

A-4 Version Information .............................................................................................................A-117

Index

14

NJ/NX-series Motion Control Instructions Reference Manual (W508)

CONTENTS

15

Terms and Conditions Agreement

NJ/NX-series Motion Control Instructions Reference Manual (W508)

Terms and Conditions Agreement

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workman-

ship for a period of twelve months from the date of sale by Omron (or such other period expressed in

writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-com-

plying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be

responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of

any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies

shall not be liable for the suitability or unsuitability or the results from the use of Products in combi-

nation with any electrical or electronic components, circuits, system assemblies or any other materi-

als or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CON-

SEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

Warranty, Limitations of Liability

Warranties

Limitation on Liability; Etc

Terms and Conditions Agreement

16

NJ/NX-series Motion Control Instructions Reference Manual (W508)

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a com-

plete determination of the suitability of the Product in combination with the end product, machine, sys-

tem, or other application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system. Buyer shall take applica-

tion responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual perfor-

mance is subject to the Omron’s Warranty and Limitations of Liability.

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

Information presented by Omron Companies has been checked and is believed to be accurate; how-

ever, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

Application Considerations

Suitability of Use

Programmable Products

Disclaimers

Performance Data

Change in Specifications

Errors and Omissions

17

Safety Precautions

NJ/NX-series Motion Control Instructions Reference Manual (W508)

Safety Precautions

Refer to the following manuals for safety precautions.

• NX-series CPU Unit Hardware User’s Manual (Cat. No. W535)

• NX-series NX1P2 CPU Unit Hardware User’s Manual (Cat. No. W578)

• NJ-series CPU Unit Hardware User’s Manual (Cat. No. W500)

Precautions for Safe Use

18

NJ/NX-series Motion Control Instructions Reference Manual (W508)

Precautions for Safe Use

Refer to the following manuals for precautions for safe use.

• NX-series CPU Unit Hardware User’s Manual (Cat. No. W535)

• NX-series NX1P2 CPU Unit Hardware User’s Manual (Cat. No. W578)

• NJ-series CPU Unit Hardware User’s Manual (Cat. No. W500)

19

Precautions for Correct Use

NJ/NX-series Motion Control Instructions Reference Manual (W508)

Precautions for Correct Use

Refer to the following manuals for precautions for correct use.

• NX-series CPU Unit Hardware User’s Manual (Cat. No. W535)

• NX-series NX1P2 CPU Unit Hardware User’s Manual (Cat. No. W578)

• NJ-series CPU Unit Hardware User’s Manual (Cat. No. W500)

Regulations and Standards

20

NJ/NX-series Motion Control Instructions Reference Manual (W508)

Regulations and Standards

• EMC Directives

• Low Voltage Directive

EMC Directive

OMRON devices that comply with EU Directives also conform to the related EMC standards so that

they can be more easily built into other devices or the overall machine. The actual products have

been checked for conformity to EMC standards.*

Whether the products conform to the standards in the system used by the customer, however, must

be checked by the customer. EMC-related performance of the OMRON devices that comply with EU

Directives will vary depending on the configuration, wiring, and other conditions of the equipment or

control panel on which the OMRON devices are installed. The customer must, therefore, perform

the final check to confirm that devices and the overall machine conform to EMC standards.

* Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN 61131-2

EMI (Electromagnetic Interference): EN 61131-2 (Radiated emission: 10-m regulations)

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 VAC and 75 to 1,500 VDC meet the

required safety standards. The applicable directive is EN61010-2-201.

Conformance to EU Directives

The NJ/NX-series Controllers comply with EU Directives. To ensure that the machine or device in

which the NJ/NX-series Controller is used complies with EU Directives, the Controller must be

installed as follows:

• The NJ/NX-series Controller must be installed within a control panel.

• You must use the power supply in SELV specifications for the DC power supplies connected to

DC Power Supply Units and I/O Units.

• NJ/NX-series Controllers that comply with EU Directives also conform to the Common Emission

Standard (EN 61000-6-4). Radiated emission characteristics (10-m regulations) may vary

depending on the configuration of the control panel used, other devices connected to the control

panel, wiring, and other conditions.

You must therefore confirm that the overall machine or equipment complies with EU Directives.

Conformance to EU Directives

Applicable Directives

Concepts

21

Regulations and Standards

NJ/NX-series Motion Control Instructions Reference Manual (W508)

Observe the following precaution if you use NX-series Units in Korea.

Class A Device (Broadcasting Communications Device for Office Use)

This device obtained EMC registration for office use (Class A), and it is intended to be used in places

other than homes.

Sellers and/or users need to take note of this.

The NJ/NX-series Controllers comply with the following shipbuilding standards. Applicability to the

shipbuilding standards is based on certain usage conditions. It may not be possible to use the prod-

uct in some locations. Contact your OMRON representative before attempting to use a Controller on

a ship.

• The NJ/NX-series Controller must be installed within a control panel.

• Gaps in the door to the control panel must be completely filled or covered with gaskets or other

material.

• The following noise filter must be connected to the power supply line.

Noise Filter

This product incorporates certain third party software. The license and copyright information associ-

ated with this software is available at http://www.fa.omron.co.jp/nj_info_e/.

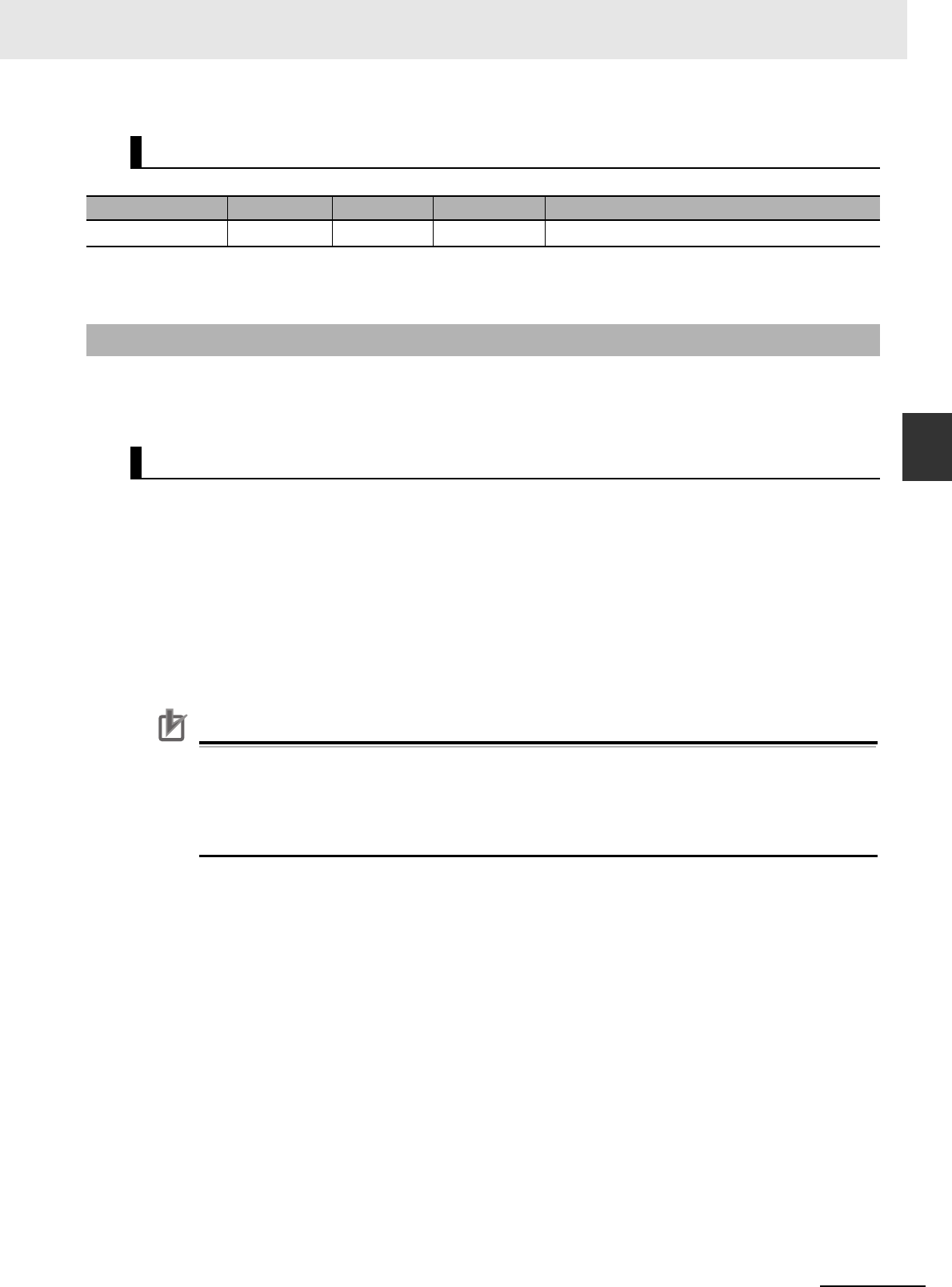

Conformance to KC Standards

Conformance to Shipbuilding Standards

Usage Conditions for NK and LR Shipbuilding Standards

Manufacturer Model

Cosel Co., Ltd. TAH-06-683

Software Licenses and Copyrights

Versions

22

NJ/NX-series Motion Control Instructions Reference Manual (W508)

Versions

Hardware revisions and unit versions are used to manage the hardware and software in NJ/NX-series

Units and EtherCAT slaves. The hardware revision or unit version is updated each time there is a

change in hardware or software specifications. Even when two Units or EtherCAT slaves have the

same model number, they will have functional or performance differences if they have different hard-

ware revisions or unit versions.

You can check versions on the ID information indications or with the Sysmac Studio.

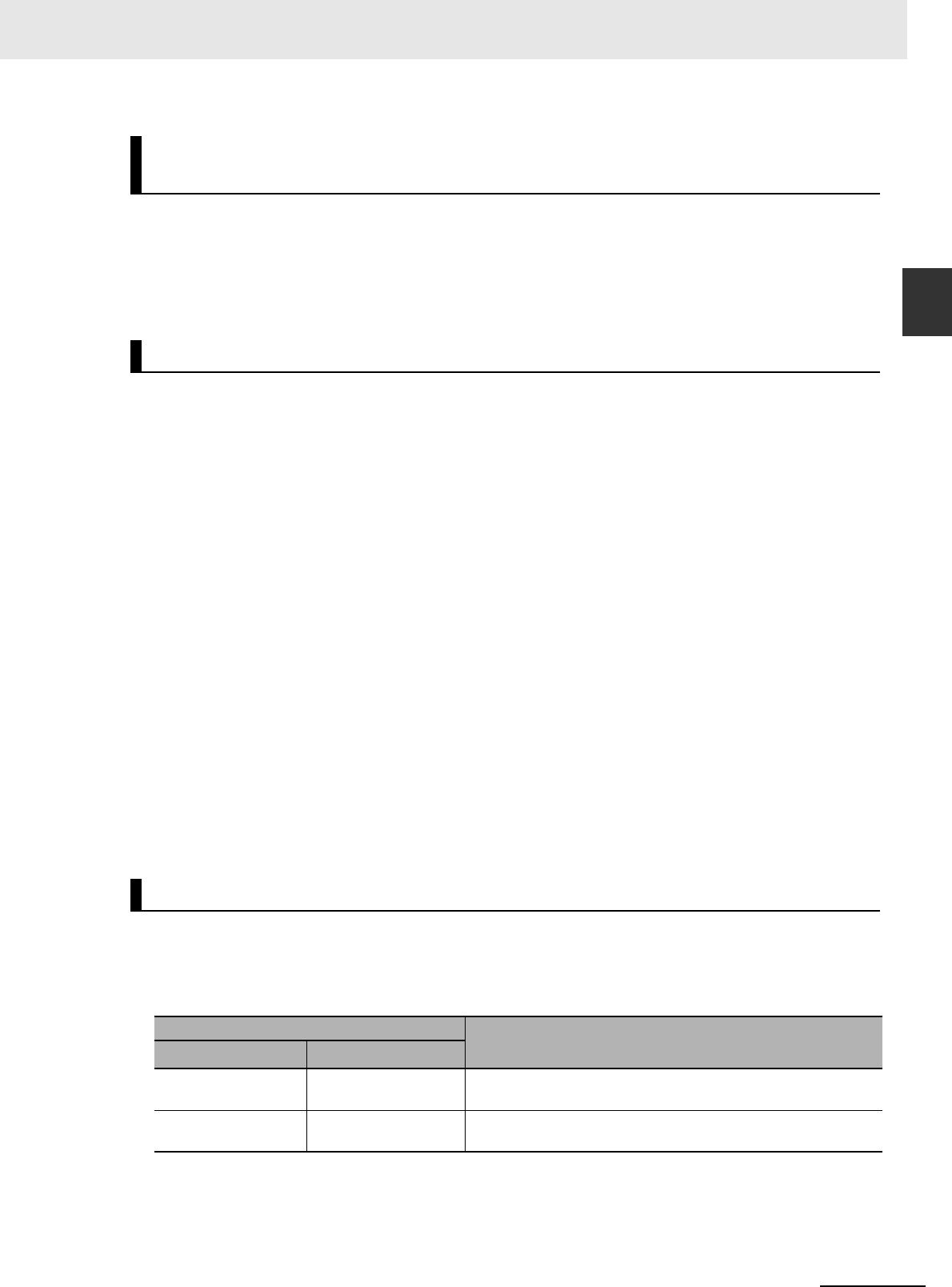

The unit version is given on the ID information indication on the side of the product.

The ID information on an NX-series NX701- CPU Unit is shown below.

Note The hardware revision is not displayed for the Unit that the hardware revision is in blank.

The ID information on an NX-series NX1P2- CPU Unit is shown below.

Note The hardware revision is not displayed for the Unit that the hardware revision is in blank.

Checking Versions

Checking Unit Versions on ID Information Indications

ID information indication

Lot number Serial number Unit version

MAC address Hardware revision

LOT No. DDMYY xxxx Ver.1.

PORT1 : HW Rev.

PORT2 :

PORT1 :

PORT2 :

Ver.1. HW Rev.

LOT No. DDMYY xxxx

ID information indication

Lot number Serial number

Unit version

MAC address

Hardware

revision

23

Versions

NJ/NX-series Motion Control Instructions Reference Manual (W508)

The ID information on an NJ-series NJ501- CPU Unit is shown below.

Note The hardware revision is not displayed for the Unit that the hardware revision is in blank.

You can use the Sysmac Studio to check unit versions. The procedure is different for Units and for Eth-

erCAT slaves.

Checking the Unit Version of an NX-series CPU Unit

You can use the Production Information while the Sysmac Studio is online to check the unit version

of a Unit. You can do this for the CPU Unit. For an NX1P2 CPU Unit, you can also check the unit

versions of the NX Units on the CPU Rack and Option Boards.

1 Right-click CPU Rack under Configurations and Setup − CPU/Expansion Racks in the

Multiview Explorer and select Production Information.

The Production Information Dialog Box is displayed.

Checking the Unit Version of an NJ-series CPU Unit

You can use the Production Information while the Sysmac Studio is online to check the unit version

of a Unit. You can do this for the CPU Unit, CJ-series Special I/O Units, and CJ-series CPU Bus

Units. You cannot check the unit versions of CJ-series Basic I/O Units with the Sysmac Studio.

Use the following procedure to check the unit version.

1 Double-click CPU/Expansion Racks under Configurations and Setup in the Multiview

Explorer. Or, right-click CPU/Expansion Racks under Configurations and Setup and select

Edit from the menu.

The Unit Editor is displayed.

2 Right-click any open space in the Unit Editor and select Production Information.

The Production Information Dialog Box is displayed.

Checking Unit Versions with the Sysmac Studio

ID information indication

Unit model

Lot number Serial number MAC address

Unit version Hardware revision

NJ501

-

Ver.1.

PORT1 MAC ADDRESS:

PORT2 MAC ADDRESS:

Lot No. DDMYY

xxxx

HW Rev.

Versions

24

NJ/NX-series Motion Control Instructions Reference Manual (W508)

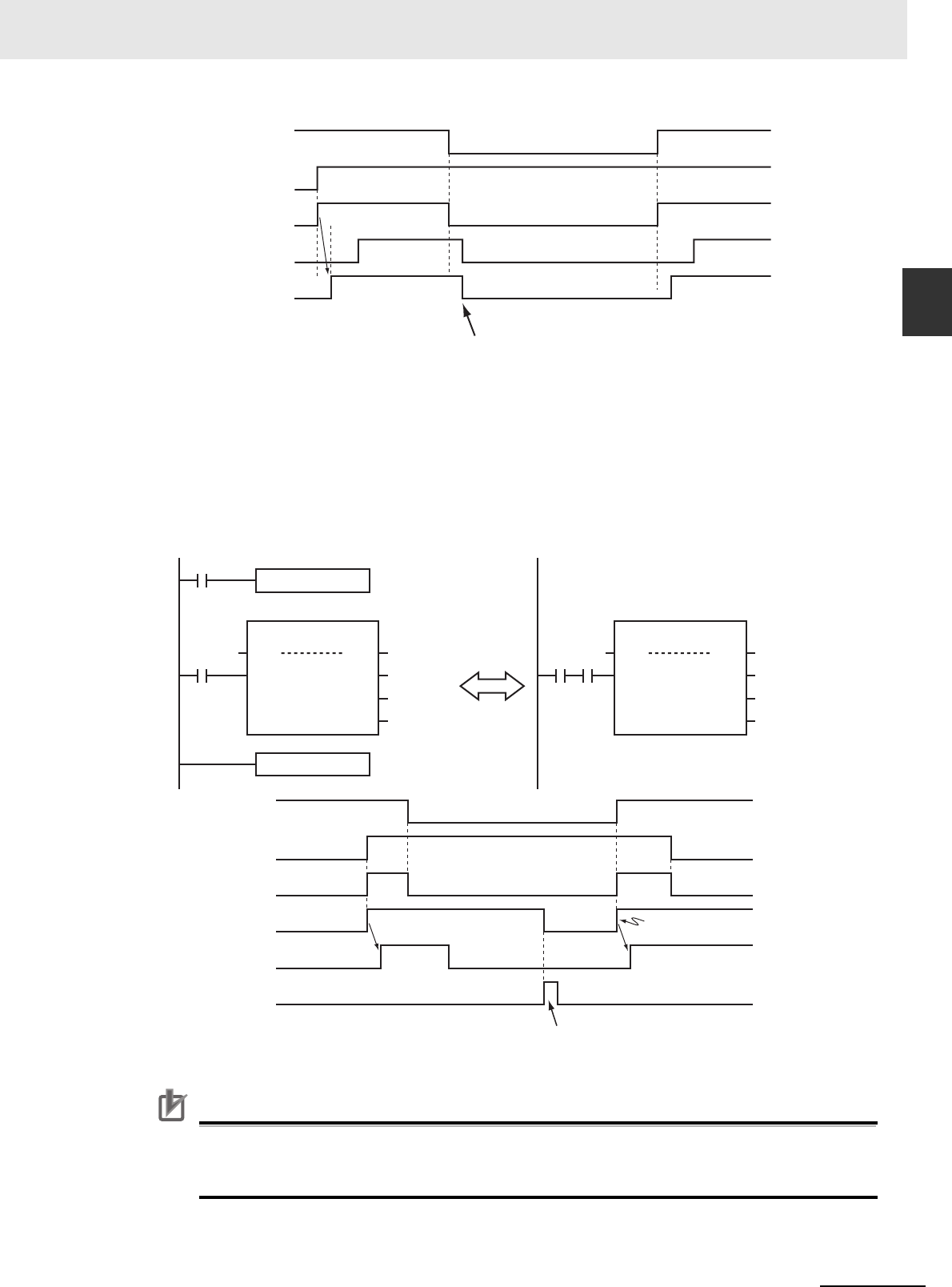

Changing Information Displayed in Production Information Dialog Box

1 Click the Show Detail or Show Outline Button at the lower right of the Production Information

Dialog Box.

The view will change between the production information details and outline.

The information that is displayed is different for the Outline View and Detail View. The Detail View

displays the unit version, hardware version, and software versions. The Outline View displays only

the unit version.

Note The hardware revision is separated by "/" and displayed on the right of the hardware version. The hardware

revision is not displayed for the Unit that the hardware revision is in blank.

Checking the Unit Version of an EtherCAT Slave

You can use the Production Information while the Sysmac Studio is online to check the unit version

of an EtherCAT slave. Use the following procedure to check the unit version.

1 Double-click EtherCAT under Configurations and Setup in the Multiview Explorer. Or, right-

click EtherCAT under Configurations and Setup and select Edit from the menu.

The EtherCAT Tab Page is displayed.

2 Right-click the master on the EtherCAT Tab Page and select Display Production Information.

The Production Information Dialog Box is displayed.

The unit version is displayed after “Rev.”

Changing Information Displayed in Production Information Dialog Box

Click the Show Detail or Show Outline Button at the lower right of the Production Information Dia-

log Box.

The view will change between the production information details and outline.

Outline View Detail View

25

Versions

NJ/NX-series Motion Control Instructions Reference Manual (W508)

The functions that are supported depend on the unit version of the NJ/NX-series CPU Unit. The version

of Sysmac Studio that supports the functions that were added for an upgrade is also required to use

those functions.

Refer to the NJ/NX-series CPU Unit Software User’s Manual (Cat. No. W501) for the relationship

between the unit versions of the CPU Units and the Sysmac Studio versions, and for the functions that

are supported by each unit version.

Outline View Detail View

Unit Versions of CPU Units and Sysmac Studio Versions

Related Manuals

26

NJ/NX-series Motion Control Instructions Reference Manual (W508)

Related Manuals

The followings are the manuals related to this manual. Use these manuals for reference.

Manual name Cat. No. Model numbers Application Description

NX-series CPU Unit

Hardware User’s Manual

W535 NX701- Learning the basic specifi-

cations of the NX701 CPU

Units, including introductory

information, designing,

installation, and mainte-

nance. Mainly hardware

information is provided.

An introduction to the entire NX701 system is pro-

vided along with the following information on the

CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

NX-series NX1P2 CPU

Unit Hardware User's

Manual

W578 NX1P2- Learning the basic specifi-

cations of the NX1P2 CPU

Units, including introductory

information, designing,

installation, and mainte-

nance.

Mainly hardware informa-

tion is provided.

An introduction to the entire NX1P2 system is pro-

vided along with the following information on the

CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

NJ-series CPU Unit

Hardware User’s Manual

W500 NJ501-

NJ301-

NJ101-

Learning the basic specifi-

cations of the NJ-series

CPU Units, including intro-

ductory information, design-

ing, installation, and

maintenance. Mainly hard-

ware information is pro-

vided.

An introduction to the entire NJ-series system is

provided along with the following information on

the CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

NJ/NX-series CPU Unit

Software User’s Manual

W501 NX701-

NX1P2-

NJ501-

NJ301-

NJ101-

Learning how to program

and set up an NJ/NX-series

CPU Unit. Mainly software

information is provided.

The following information is provided on an

NJ/NX-series CPU Unit.

• CPU Unit operation

• CPU Unit features

• Initial settings

• Programming based on IEC 61131-3 language

specifications

NX-series NX1P2 CPU

Unit Built-in I/O and

Option Board User's

Manual

W579 NX1P2- Learning about the details

of functions only for an NX-

series NX1P2 CPU Unit and

an introduction of functions

for an NJ/NX-series CPU

Unit.

Of the functions for an NX1P2 CPU Unit, the fol-

lowing information is provided.

• Built-in I/O

• Serial Communications Option Boards

• Analog I/O Option Boards

An introduction of following functions for an

NJ/NX-series CPU Unit is also provided.

• Motion control functions

• EtherNet/IP communications functions

• EtherCAT communications functions

NJ/NX-series Instructions

Reference Manual

W502 NX701-

NX1P2-

NJ501-

NJ301-

NJ101-

Learning detailed specifica-

tions on the basic instruc-

tions of an NJ/NX-series

CPU U

nit.

T

he instructions in the instruction set (IEC 61131-

3 specifications) are described.

NJ/NX-series CPU Unit

Motion Control User’s

Manual

W507 NX701-

NX1P2-

NJ501-

NJ301-

NJ101-

Learning about motion con-

trol settings and program-

ming concepts.

The settings and operation of the CPU Unit and

programming concepts for motion control are

described.

27

Related Manuals

NJ/NX-series Motion Control Instructions Reference Manual (W508)

NJ/NX-series Motion

Control Instructions Ref-

erence Manual

W508 NX701-

NX1P2-

NJ501-

NJ301-

NJ101-

Learning about the specifi-

cations of the motion control

instructions that are pro-

vided by OMRON.

The motion control instructions are described.

NJ/NX-series CPU Unit

Built-in EtherCAT® Port

User’s Manual

W505 NX701-

NX1P2-

NJ501-

NJ301-

NJ101-

Using the built-in EtherCAT

port on an NJ/NX-series

CPU Unit.

Information on the built-in EtherCAT port is pro-

vided. This manual provides an introduction and

provides information on the configuration, fea-

tures, and setup.

NJ/NX-series CPU Unit

Built-in EtherNet/IP

TM

Port User’s Manual

W506 NX701-

NX1P2-

NJ501-

NJ301-

NJ101-

Using the built-in Ether-

Net/IP port on an NJ/NX-

series CPU Unit.

Information on the built-in EtherNet/IP port is pro-

vided. Information is provided on the basic setup,

tag data links, and other features.

NJ-series Database Con-

nection CPU Units User’s

Manual

W527 NJ501-120

NJ101-20

Using the database connec-

tion service with NJ-series

Controllers

Describes the database connection service.

NJ-series SECS/GEM

CPU Unit User’s Manual

W528 NJ501-1340 Using the GEM Services

with NJ-series Controllers

Information is provided on the GEM Services.

NJ-series NJ Robotics

CPU Unit User’s Manual

W539 NJ501-4 Controlling robots with NJ-

series CPU Units.

Describes the functionality to control robots.

NJ/NX-series Trouble-

shooting Manual

W503 NX701-

NX1P2-

NJ501-

NJ301-

NJ101-

Learning about the errors

that may be detected in an

NJ/NX-series Controller.

Concepts on managing errors that may be

detected in an NJ/NX-series Controller and infor-

mation on individual errors are described.

Sysmac Studio Version 1

Operation Manual

W504 SYSMAC-

SE2

Learning about the operat-

ing procedures and func-

tions of the Sysmac Studio.

Describes the operating procedures of the Sys-

mac Studio.

NX-series EtherCAT®

Coupler Unit User’s Man-

ual

W519 NX-ECC Learning how to use an NX-

series EtherCAT Coupler

Unit and EtherCAT Slave

Terminals

The system and configuration of EtherCAT Slave

Terminals, which consist of an NX-series Ether-

CAT Coupler Unit and NX Units, are described

along with the hardware, setup, and functions of

the EtherCAT Coupler Unit that are required to

configure, control, and monitor NX Units through

EtherCAT.

NX-series Data

Reference Manual

W525 NX- Referencing lists of the data

that is required to configure

systems with NX-series

Units.

Lists of the power consumptions, weights, and

other NX Unit data that is required to configure

systems with NX-series Units are provided.

NX-series NX Units

User’s Manuals

W521 NX-ID

NX-IA

NX-OC

NX-OD

NX-MD

Learning how to use NX

Units

Describes the hardware, setup methods, and

functions of the NX Units.

Manuals are available for the following Units.

Digital I/O Units, Analog I/O Units, System Units,

Position Interface Units, Communications Inter-

face Units, Load Cell Input Units, and IO-Link

Master Units.

W522 NX-AD

NX-DA

W566 NX-TS

NX-HB

W523 NX-PD1

NX-PF0

NX-PC0

NX-TBX01

W524 NX-EC0

NX-ECS

NX-PG0

W540 NX-CIF

W565 NX-RS

W567 NX-ILM

Manual name Cat. No. Model numbers Application Description

Related Manuals

28

NJ/NX-series Motion Control Instructions Reference Manual (W508)

GX-series EtherCAT

Slave Units User's

Manual

W488 GX-ID

GX-OD

GX-OC

GX-MD

GX-AD

GX-DA

GX-EC

XWT-ID

XWT-OD

Learning how to use the

EtherCAT remote I/O

terminals.

Describes the hardware, setup methods, and

functions of the EtherCAT remote I/O terminals.

AC Servomotors/Servo

Drives 1S-series with

Built-in EtherCAT® Com-

munications User’s Man-

ual

I586 R88M-1

R88D-1SN-

ECT

Learning how to use the

Servomotors/Servo Drives

with built-in EtherCAT Com-

munications.

Describes the hardware, setup methods and func-

tions of the Servomotors/Servo Drives with built-in

EtherCAT Communications.

AC Servomotors/Servo

Drives G5-series with

Built-in EtherCAT® Com-

munications User’s Man-

ual

I573 R88M-K

R88D-KN

-ECT-

R

Learning how to use the AC

Servomotors/Servo Drives

with built-in EtherCAT Com-

munications.

Describes the hardware, setup methods and func-

tions of the AC Servomotors/Servo Drives with

built-in EtherCAT Communications.

The linear motor type model and the model dedi-

cated for position controls are available in

G5-series.

I576 R88M-K

R88D-KN-ECT

I577 R88L-EC-

R88D-KN

-ECT-L

Manual name Cat. No. Model numbers Application Description

29

Revision History

NJ/NX-series Motion Control Instructions Reference Manual (W508)

Revision History

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Revision code Date Revised content

01 July 2011 Original production

02 March 2012 Added the following axes group instructions

• MC_GroupReadPosition (Read Axes Group Position)

• MC_ChangeAxesInGroup (Change Axes in Group)

• MC_GroupSyncMoveAbsolute (Axes Group Cyclic Synchro-

nous Absolute Positioning)

Corrected mistakes.

03 May 2012 Made changes accompanying the upgrade to unit version 1.02

and corrected mistakes.

04 August 2012 Made changes accompanying release of unit version 1.03 of

the CPU Unit.

05 February 2013 Made changes accompanying release of unit version 1.04 of

the CPU Unit.

06 April 2013 Made changes accompanying release of unit version 1.05 of

the CPU Unit.

Corrected mistakes.

07 June 2013 Made changes accompanying release of unit version 1.06 of

the CPU Unit.

Corrected mistakes.

08 December 2013 Made changes accompanying release of unit version 1.08 of

the CPU Unit.

Corrected mistakes.

09 July 2014 Made changes accompanying release of unit version 1.09 of

the CPU Unit.

Corrected mistakes.

10 January 2015 Made changes accompanying release of unit version 1.10 of

the CPU Unit.

Corrected mistakes.

11 April 2015 Made changes accompanying the addition of NX-series

NX701- CPU Units and NJ-series NJ101-

CPU Units.

Corrected mistakes.

12 April 2016 Made changes accompanying release of unit version 1.11 of

the CPU Unit.

Corrected mistakes.

13 July 2016 Made changes accompanying release of unit version 1.12 of

the CPU Unit.

Corrected mistakes.

W508-E1-15

Revision code

Cat. No.

Revision History

30