Program name

BACHELOR OF ENGINEERING

(TEXTILE TECHNOLOGY)

Program code

619112

Department of Textile Engineering

Faculty of Technology and Engineering

The Maharaja Sayajirao University of Baroda

Vadodara

PSO for B.E. (Textile Technology)

PSO1: Graduates of the program will have the ability to apply knowledge of Basic science, engineering and Textile Technology in identifying

and providing appropriate solution for textile manufacturing industry.

PSO2: Graduates of the program will have the ability to design, optimize textile process and Textile machinery to develop quality and cost-

effective products.

PSO3: Graduates of the program will have successful career in design, development, manufacturing, production planning and process control of

textile machines for textile industry.

PSO4: Graduates of the program will have the continual learning ability and will be adapting to the constantly changing technology.

PSO5: Graduates of the program will have necessary skills to take up Entrepreneurial Venture.

PSO6: Graduates of the program will serve to the needs of Textile Industry and the Nation.

PSO7: Graduates of the program will be able enhance skill and other skill related issues for textile industry.

PSO8: Graduates of the program (especially female) will get platform to design & create prototypes with changing demands of the textile market

and fashion segment.

Bloom’s Taxonomy Levels: 1. Remember 2. Understand 3. Application 4. Analysis 5. Evaluation 6. Creation

Titles of Courses and Detailed Syllabi

w.e.f. 2019-20

(B.E. SEM-I [FSBE-I] & SEM-II [SSBE-I])

(B.E. SEM-I [FSBE-II] & SEM-II [SSBE-II])

(B.E. SEM-I [FSBE-III] & SEM-II [SSBE-III])

(B.E. SEM-I [FSBE-IV] & SEM-II [SSBE-IV])

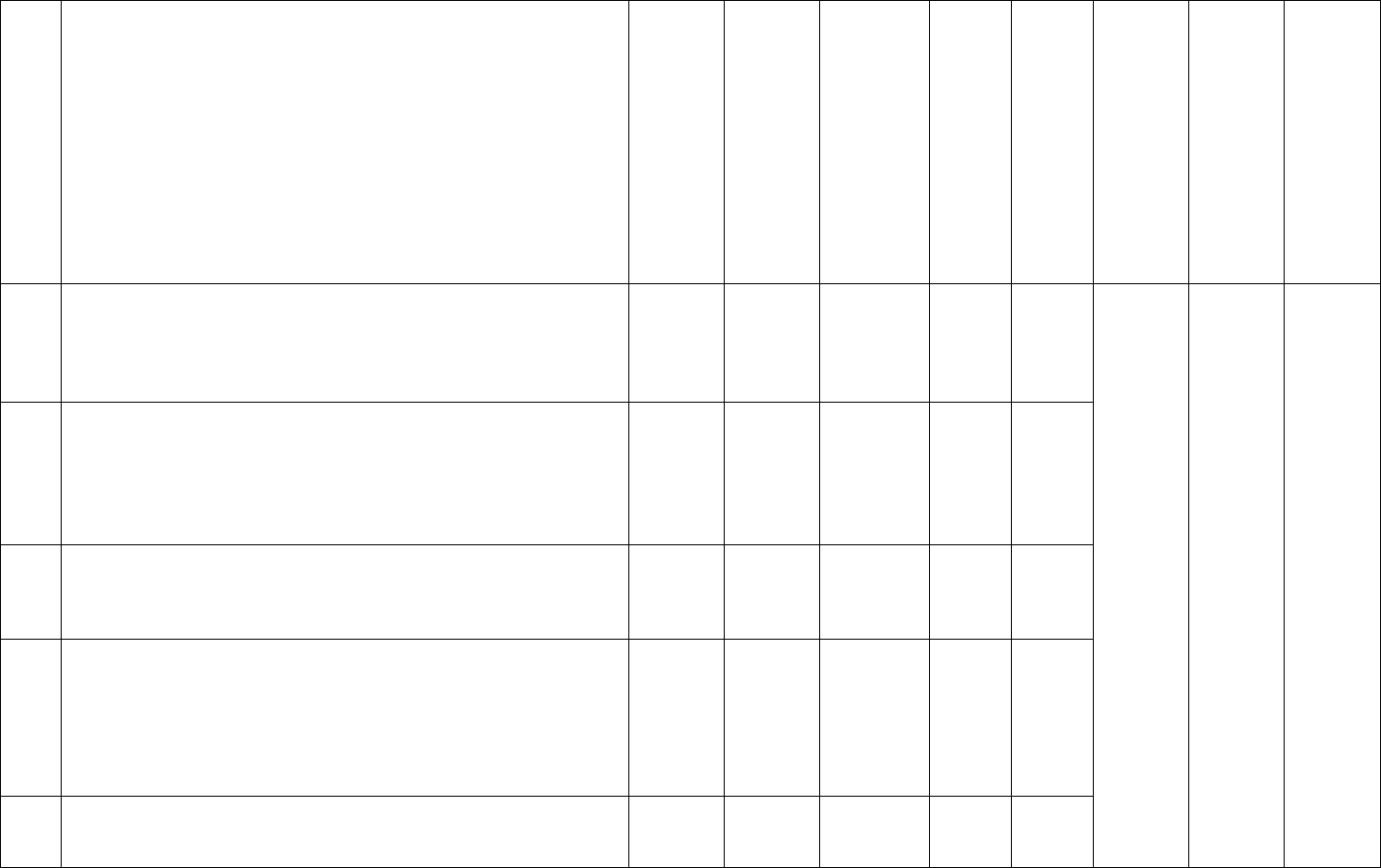

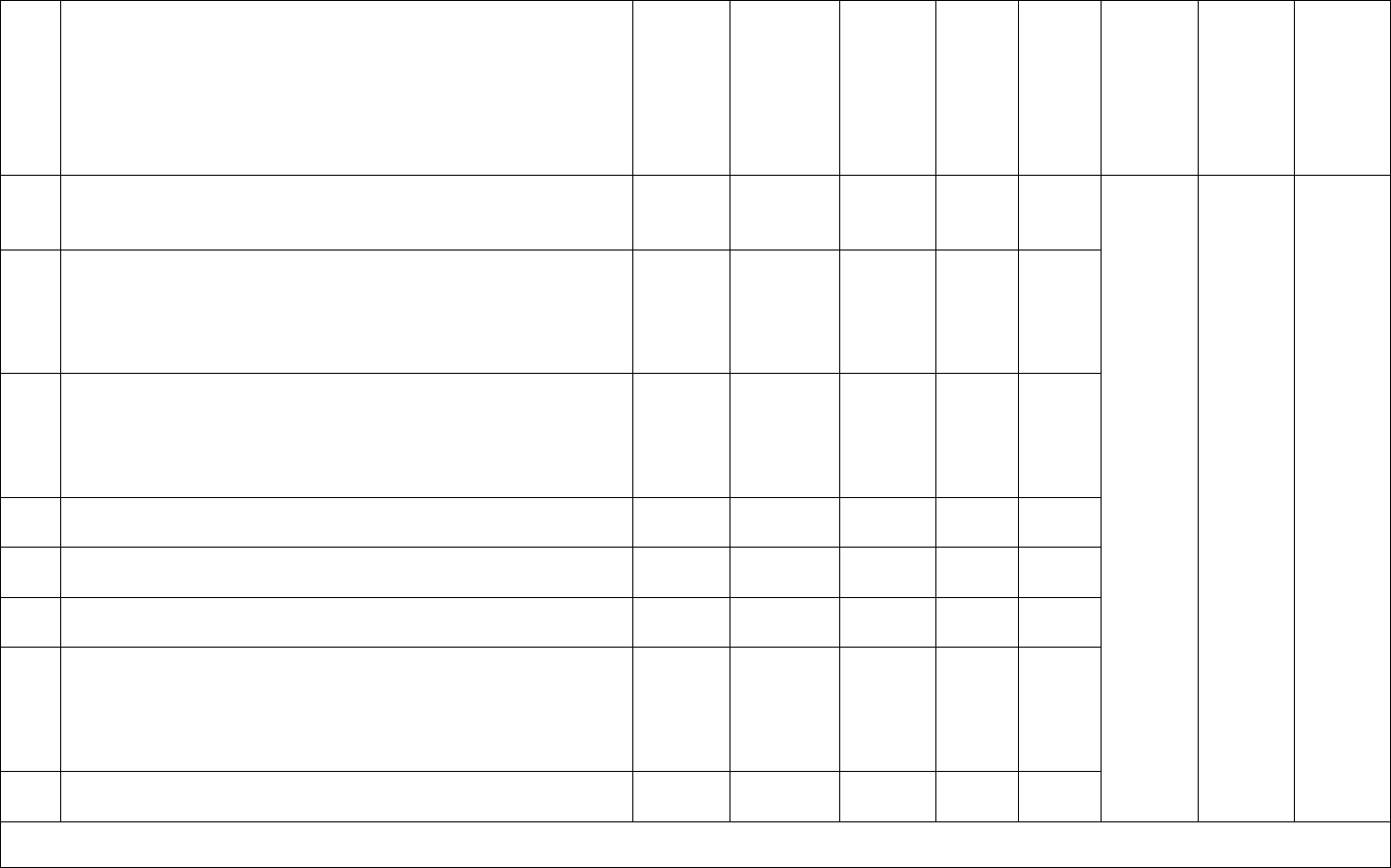

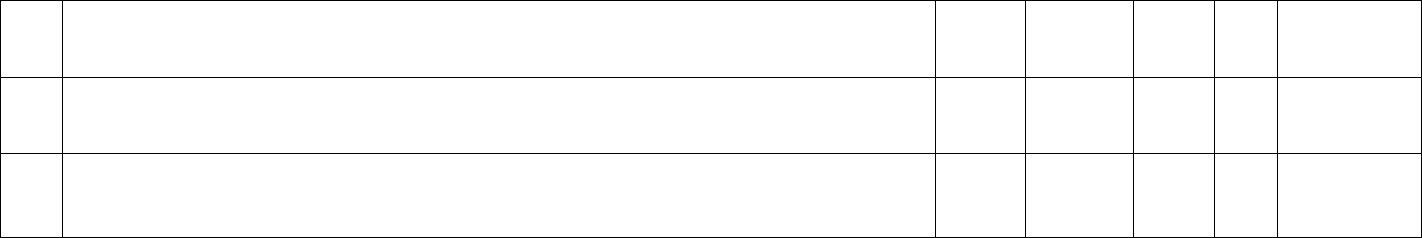

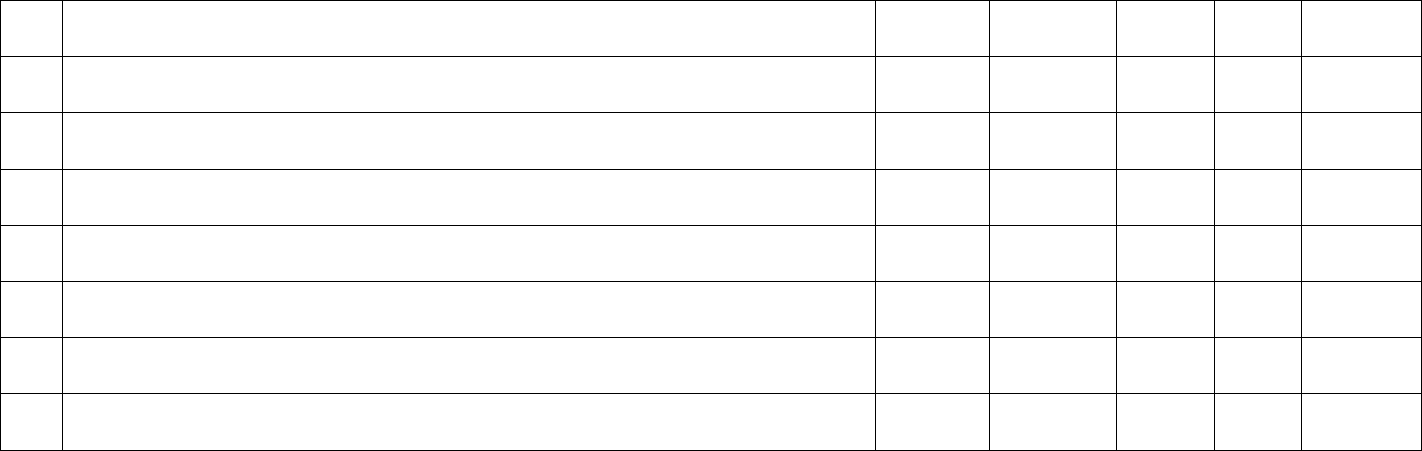

Sr. No

Subject Code

Subject Title

Page No.

F.S. B.E.-I

APH1101

Applied Physics-I

APH1101L

Applied Physics-I Lab

AMT1101

Applied Mathematics-I

MEC1101

Engineering Drawing-I

MEC1101L

Engineering Drawing-I Lab

MME1101

Material Science

CVL1104

Fundamentals of Civil Engineering and

Environmental Engineering

CVL1104L

Fundamentals of Civil Engineering and

Environmental Engineering Lab

MEC1102

Workshop Practice-I

S.S. B.E.-I

APH1201/APH1206

Applied Physics-II

APH1201L/APH1206L

Applied Physics-II Lab

AMT1202

Mathematics & Statistical Methods

AMT1202L

Mathematics & Statistical Methods Lab

TXC1203

Textile Chemical Processing-I

MEC1207

Mechanical Engineering

AMT1203

Introduction to Computer & Numerical Analysis

AMT1203L

Introduction to Computer & Numerical Analysis Lab

TXE1203

Principles of Textile Manufacturing

TXE1203L

Principles of Textile Manufacturing - TW/Practical

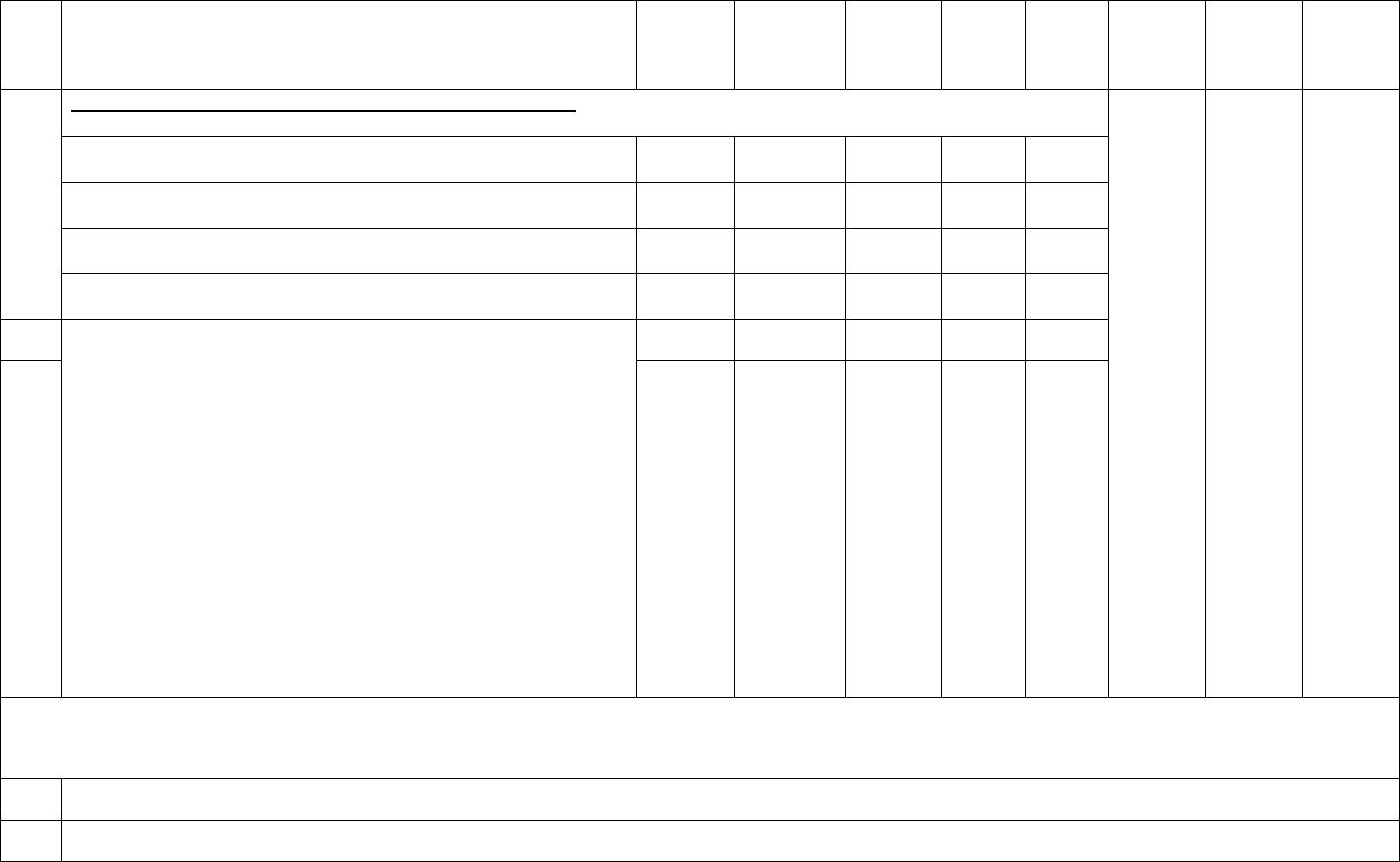

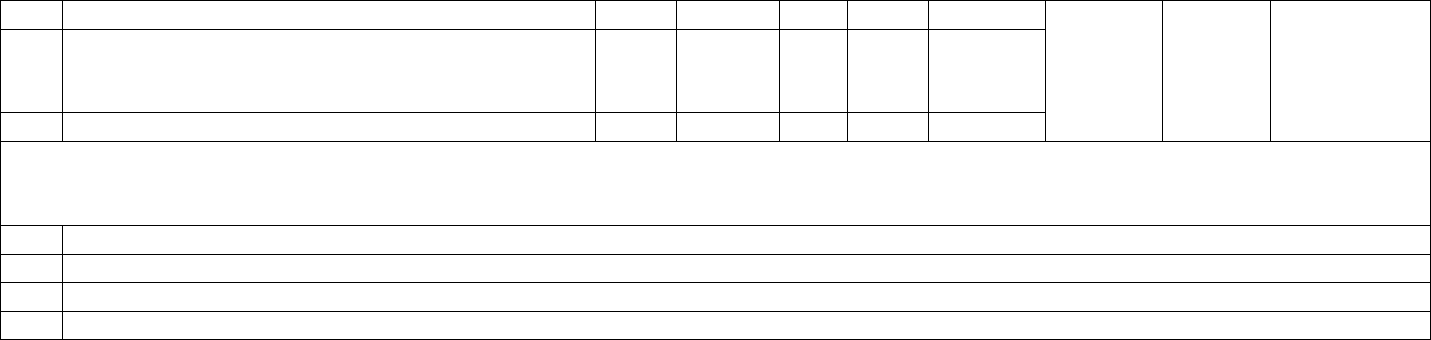

F.S. B.E.-II

APH1301

Fibre Science and Textile Physics

APM1302

Applied Mechanics

APM1302L

Applied Mechanics Lab

TXC1305

Textile Chemistry-I

TXC1305L

Textile Chemistry-I Lab

ACH1307

Chemistry

ACH1307L

Chemistry Lab

TXE1306

Principles of Yarn Manufacturing

S.S. B.E.-II

ACH1404

Applied Chemistry

ACH1404L

Applied Chemistry Lab

TXE1402

Spinning -I

TXE1402L

Spinning -I Lab

TXE1403

Weaving-I

TXE1403L

Weaving-I Lab

TXE1404

Yarn Preparation-I

TXE1404L

Yarn Preparation-I Lab

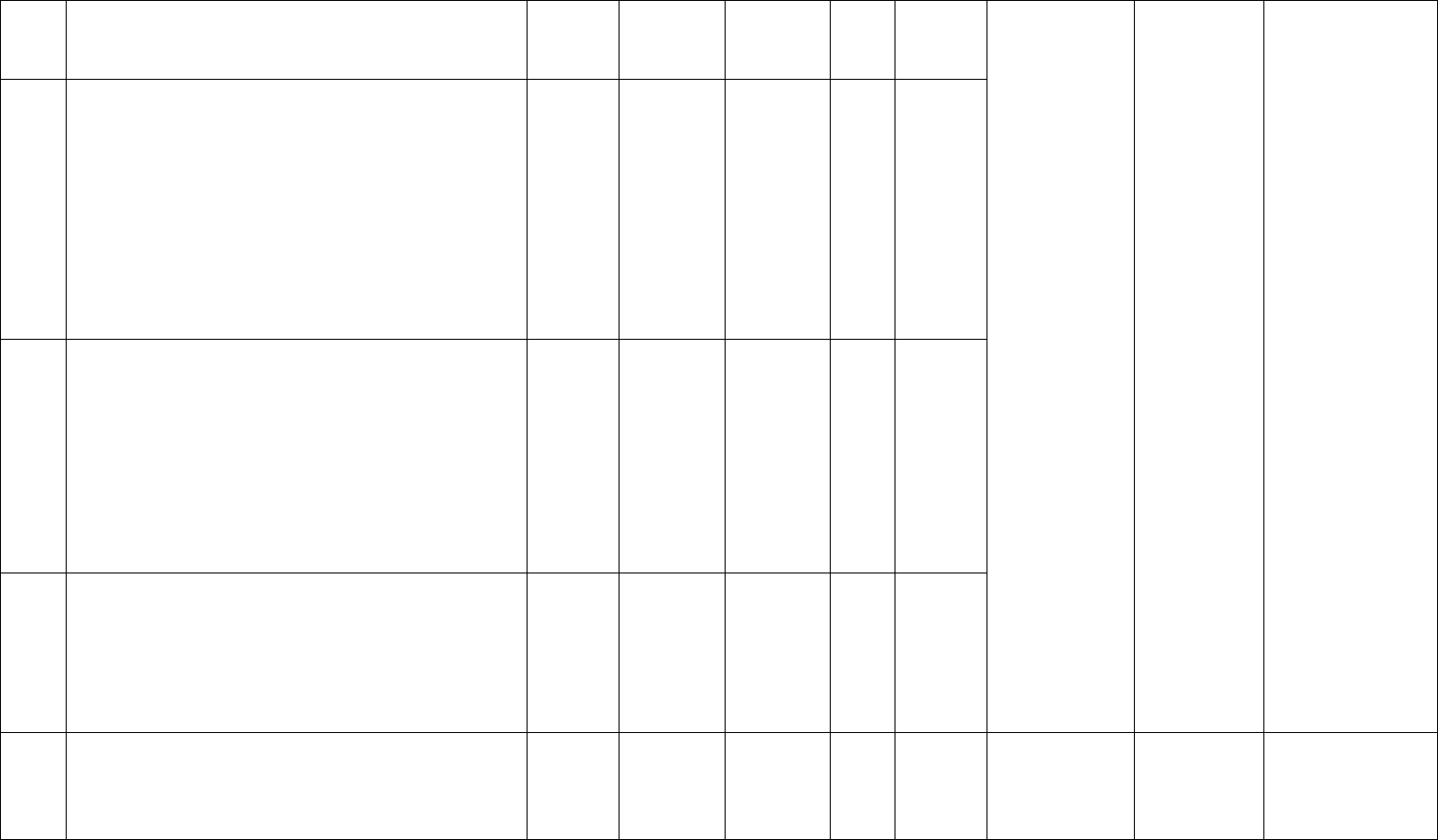

F.S. B.E.-III

ELE1511

Electrical Engineering Fundamental

ELE1511L

Electrical Engineering Fundamental Lab

CBM1501

Management Of Textile Unit

TXE1505

Textile Machine Control and Quality Management

TXE1507

Textile Testing-I

TXE1507L

Textile Testing-I Lab

TXE1508

Fabric Structure

TXE1508L

Fabric Structure Lab

S.S. B.E.-III

TXC1601

Textile Chemistry-II

TXC1601L

Textile Chemistry-II Lab

MEC1608

Industrial Engineering and Operation Research

TXE1606

Textile Testing -II

TXE1606L

Textile Testing -II Lab

TXE1607

Spinning-II

TXE1607L

Spinning-II Lab

TXE1608

Weaving-II

TXE1608L

Weaving-II Lab

F.S. B.E.-IV

TXE1701

Engineering of Textile Structure

TXE1702

Man Made Fibre Technology-I

TXE1703

Spinning-III

TXE1703L

Spinning-III Lab

TXE1704

Weaving-III

TXE1704L

Weaving-III Lab

TXE1706

Yarn Preparation-II

TXE1706L

Yarn Preparation-II Lab

S.S. B.E.-IV

TXE1801

Advance Fabric Structure,

TXE1803

Garment Technology

TXE1804

Knitting

TXE1805

Man Made Fibre Technology-II

TXE1805L

Man Made Fibre Technology-II Lab

TXE1806

Technical Textiles

TXE1807

Textile Production Management and Costing

TXE1807L

Textile Production Management and Costing Lab

TXE1808

Process Control and Modern Yarn Production

TXE1808L

Process Control and Modern Yarn Production Lab

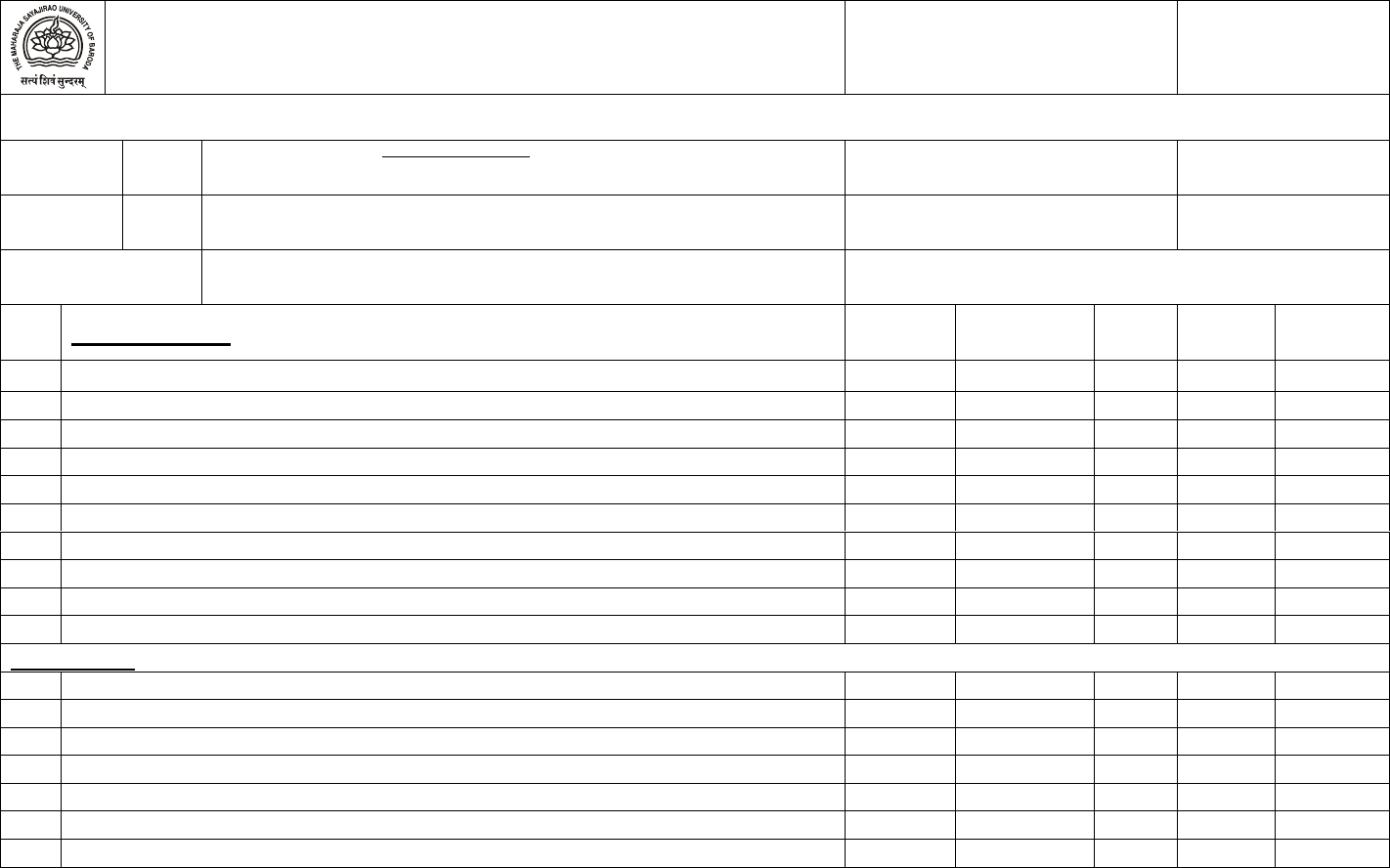

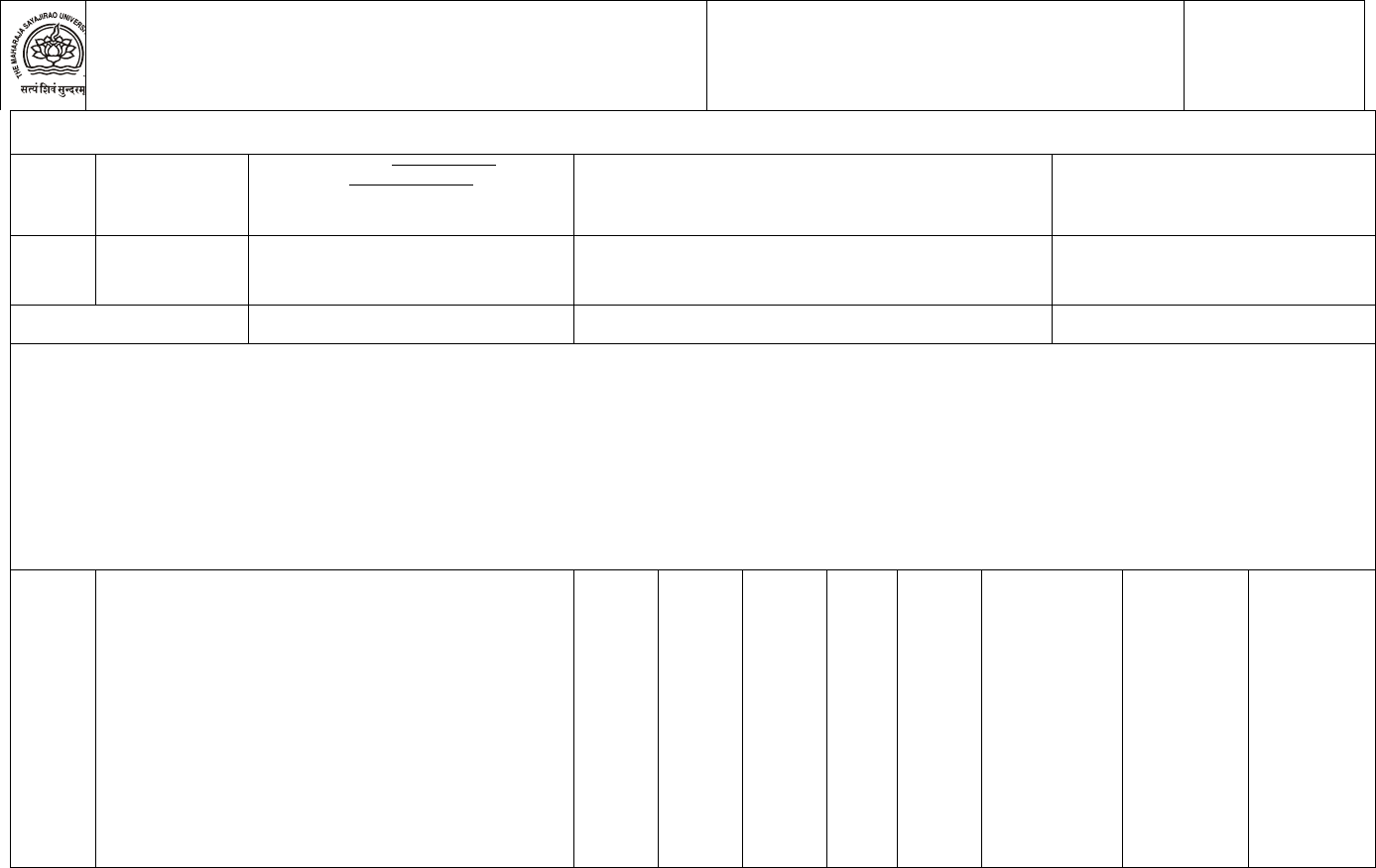

The Maharaja Sayajirao University of Baroda

Faculty Technology and Engineering

Department of Textile Engineering

Academic Year

2019-20

B.E. - Textile Technology: Regular Programme

Year

I

Core / Elective / Foundation

APH1101: Applied Physics I

Credits / Hours per week

04

Semester

I

Year of Introduction: 2007

Year of Syllabus Revision: 2012

Maximum Marks / Grade

100

Mode of

Transaction

Lectures and Tutorials

Course Outcome (CO) APH1101

CO1 Understand the basics of laws governing physical world.

CO2 Application of physical laws in various engineering applications

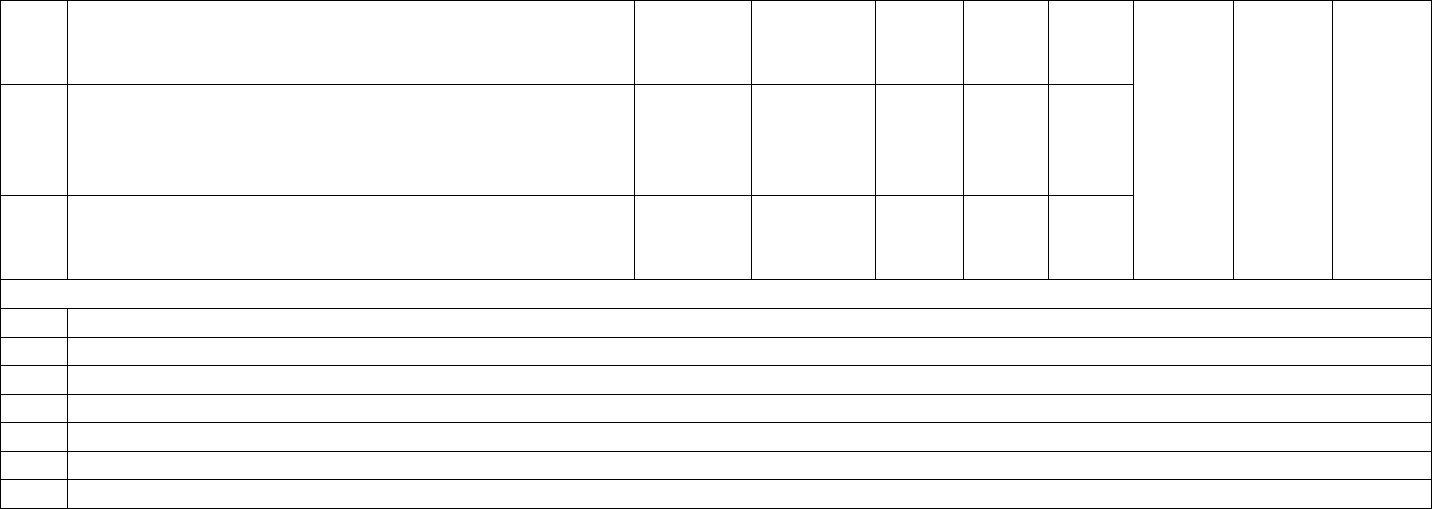

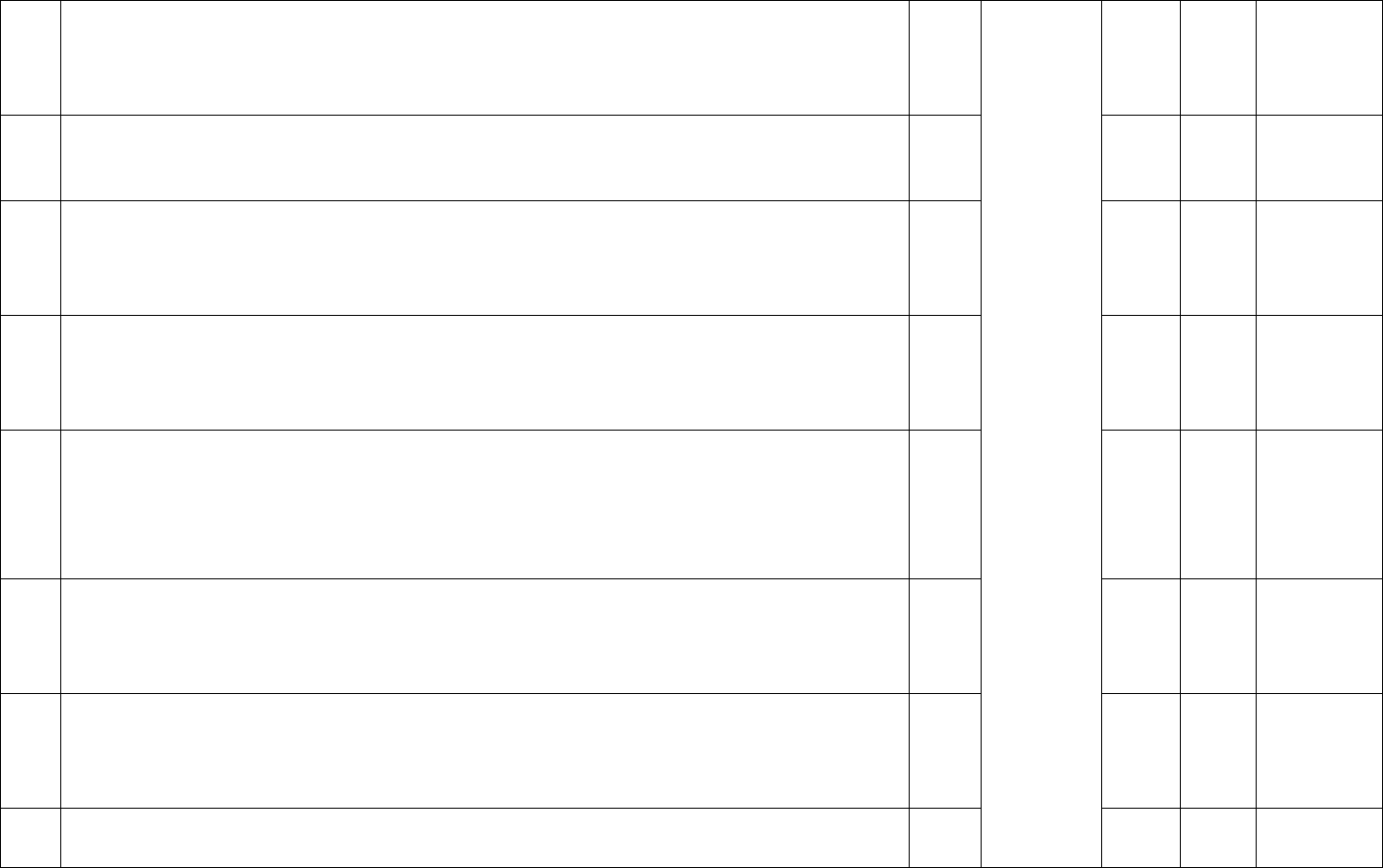

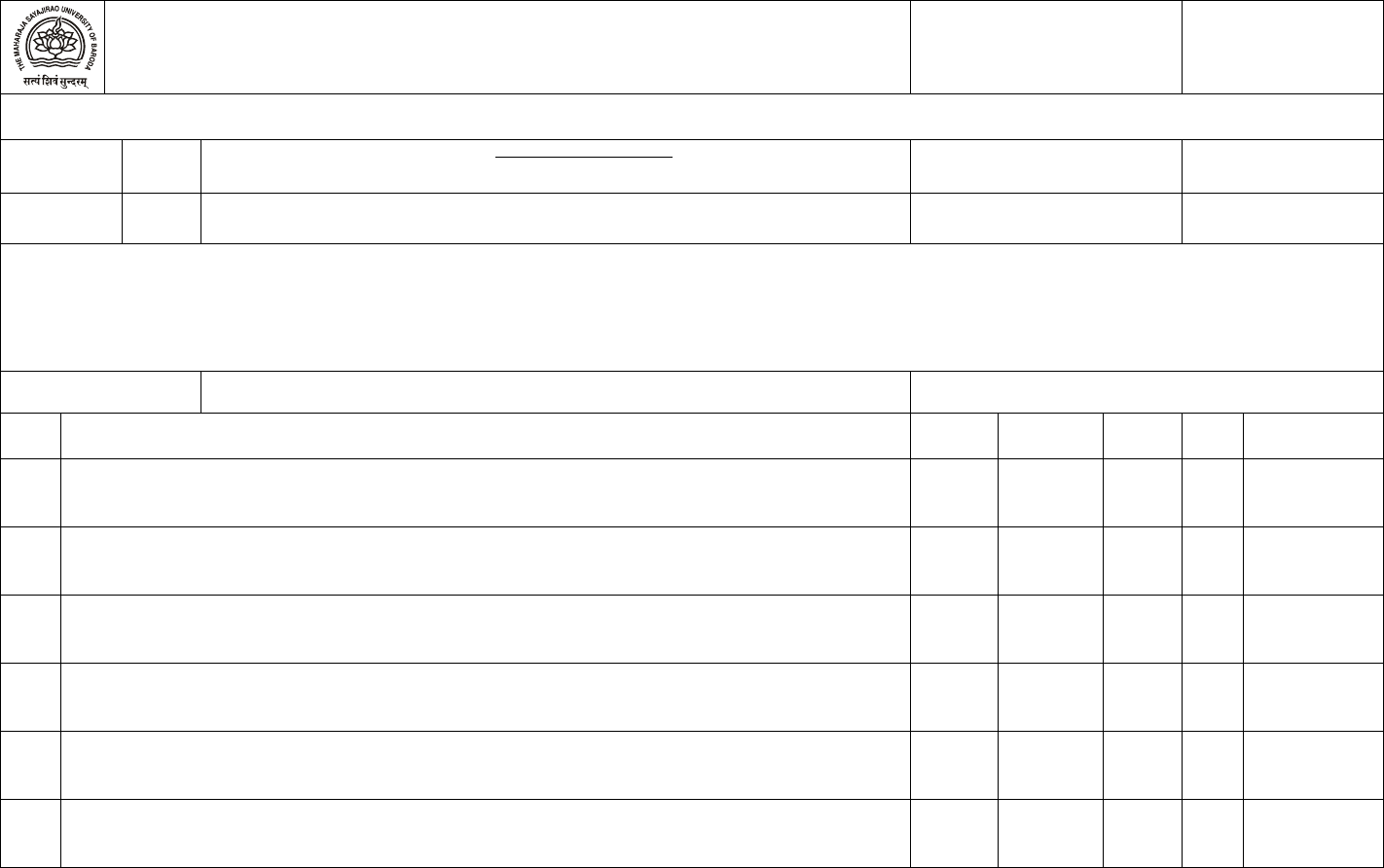

Unit

No.

Topic/Unit

Contact

Hours

Weightage

(%)

BT

Level

CO

PSO

Elements of

Employability

(Emp)/

Entrepreneurship

(Ent)/ Skill

Development

(SD)

Relevance to Local

(L)/ National (N)/

Regional(R)/Global

(G)

developmental needs

Relation to

Gender (G),

Environment

and

Sustainability

(ES), Human

Values

(HV)and

Professional

Ethics (PE)

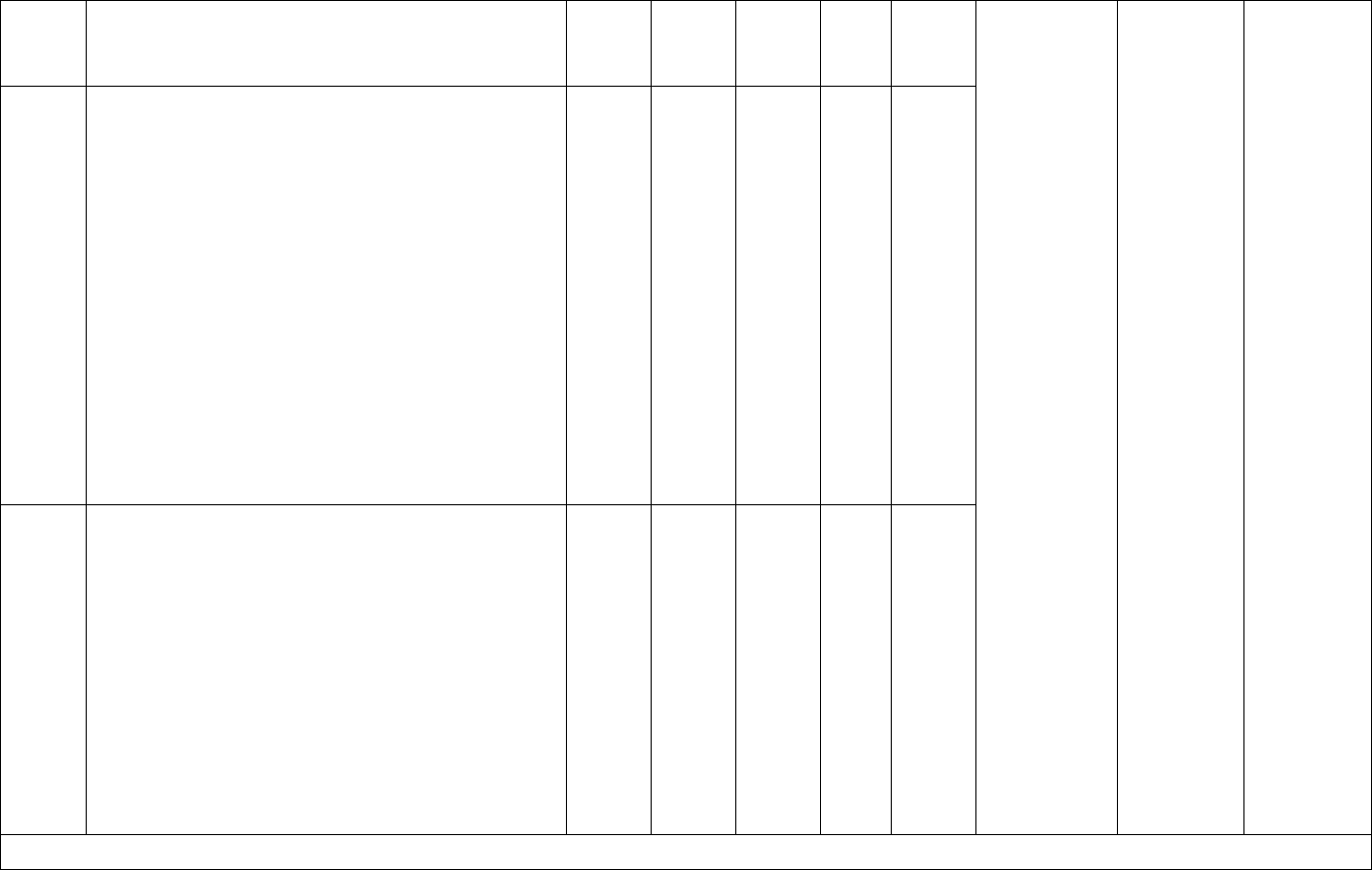

1

Interference:

• Types of interference. Fresnel's

biprism, White light fringes,

Determination of the thickness of

a thin sheet of transparent

material.

• Interference in thin films,

Wedge-shaped film, Necessity of

an extended source.

• Newton's rings, Determination

of wave-length of sodium light

using Newton’s rings,

Determination of refractive index

of a liquid, Newton s rings with

white light.

• Non-reflecting films,

Michelson interferometer, Types

of fringes, Uses of Michelson’s

interferometer, Standardization of

the meter.

• Fabry-Perot interferometer,

Interference filters.

06

10

1,2

CO1

CO2

PSO2

EMP, ENT, SD

N,R,G

ES, PE

2

Diffraction:

• Introduction, Two kinds of

diffraction, Difference between

interference and diffraction.

• Fraunhofer diffraction at a

circular aperture, Plane diffraction

06

10

1,2

CO1

CO2

PSO2

grating, Formation of multiple

spectra with grating, Maximum

number of orders available with a

grating.

• Absent spectra with a

diffraction grating, Effect of

increase in the width of niled

surface.

• Determination of wavelength,

dispersive power of grating.

3

Resolving Power of Optical

Instruments:

• Meaning of resolving power,

Rayleighs criterion of resolution.

• Resolving power of grating,

prism, telescope and microscope.

06

06

1,2

CO1

CO2

PSO6

4

Polarization:

• Geometry of calcite crystal,

double refraction, Nicol's prism,

Huygen's theory of double

refraction.

• Quarter-wave plate,

polarization by selective

absorption. Half-wave plate.

• Elliptically and circularly

polarized light, production of

circularly and elhptically polarized

04

10

1,2

CO1

CO2

PSO2

light, conversion of elliptically

polarized light into circularly

polarized light, analysis of

polarized light of different kinds.

• Ken effect. Optical activity,

specific rotation, Laurent's half

shade polarimeter. Photo

elasticity.

5

LASER:

• Lasers, spontaneous and

stimulated emission, population

inversion, pumping and active

system.

• The Ruby laser. Gas laser.

Semiconductor laser.

• CO2 laser, design of CO2

laser, mechanism of CO2 laser.

• Uses of lasers.

05

10

1,2,3,4

CO1

CO2

PSO2

6

Semiconductor Diode

Applications and Solar Cells:

• Rectifier, ripple factor,

capacitor filter.

• Types of Solar Cells, p-n

junction Solar Cells

Characteristics, Efficiency.

03

04

1,2,3,4

CO1

CO2

PSO2

PSO6

PSO7

7

Ultrasonics:

• Ultrasonic waves, production

of ultrasonic waves.

• Detection of ultrasonic,

properties of ultrasonic,

wavelength of ultrasonic waves.

• Applications of ultrasonic

waves.

08

10

2,3,4,5

CO1

CO2

PSO2

PSO6

8

Maxwell's equations and

electromagnetic waves:

• Vector field, Irrotational vector

field, rotational vector fields

(curl), source and sinks of vector

fields -divergence theorem.

• Basic laws of electricity and

magnetism- different forms.

• Lumped and distributed

elements -oscillations,

electromagnetic cavity oscillator.

• Charge conservation law —

continuity equation, displacement

current.

• Maxwell's equations,

electromagnetic waves in free

space.

08

10

CO1

CO2

PSO2

9

Waves and Particles:

08

10

CO1

PSO2

• Equation of motion of matter

waves, physical interpretation of

wave function

• Operators. Eigen functions and

Eigen values, momentum and

energy operators, properties of

wave functions

• Solution of Schrodinger

equation. Stationary state

solutions.

• The free particle, particle in a

box, energy levels of a particle

enclosed in one-dimensional

potential box of infinite height.

• The hydrogen atom

(qualitative). Barrier Tunneling,

STM, electron microscope.

CO2

10

Temperature and its

measurement:

• Liquid thermometers, mercury

thermometers, errors in mercury

thermometers.

• Bimetallic thermometers.

Platinum resistance

thermometers, thermoelectric

thermometers, Pyrometers, Fery's

total radiation pyrometer.

Disappearing filament optical

03

10

CO1

CO2

PSO2

pyrometer.

• Factors for the selection of a

thermometer for a particular use,

temperature range of various

thermometers.

11

Vacuum technology:

• Introduction, exhaust pump

and their characteristics, different

types of pumps.

• Rotary oil pumps. Diffusion

pump.

• Measurement of low pressure,

Pirani gauge.

03

10

CO1

CO2

PSO2

Reference Books

1.

Engineering Physics: by R. K. Gaur and S. L. Gupta, DhanpatRai Publications (P) Ltd. 8

th

Edition.

2.

Fundamentals of Physics: by D. Halliday, R Resnick and J. Walker, Asian Books Pvt. Ltd. 6

th

Edition

3.

Modem Engineering Physics: by A. S. Vasudeva, S. Chand and Company Ltd.

4.

A Textbook of Engineering Physics by MN Avadhanulu& PG Kshirsagar, S Chand Publishers

The Maharaja Sayajirao University of Baroda

Faculty Technology and Engineering

Department of Textile Engineering

Academic Year

2020-21

B.E. - Textile Technology: Regular Programme

Year

I

Core / Elective / Foundation

APH1101L : Applied Physics Laboratory

Practical

Credits / Hours per week

03

Semester

I

Year of Introduction: 2007

Year of Syllabus Revision: 2016

Maximum Marks / Grade

50

Mode of

Transaction

Laboratory Experiments,

discussion and viva

Course Outcome (CO) APH1101L

CO1 Understanding the optics

CO2 Understanding the physical properties through experiments

CO3 Methods to determine physical properties

CO4 Understanding of advances in instrumentation

CO5 Understanding the spectroscopy

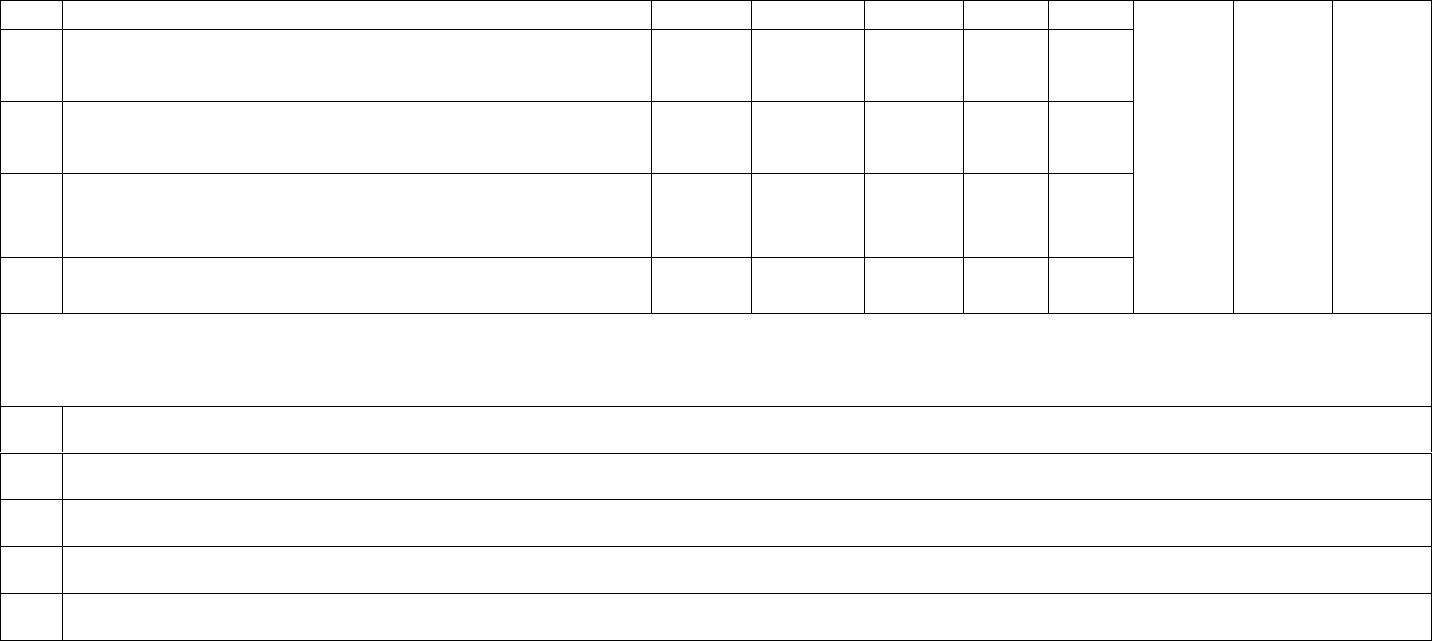

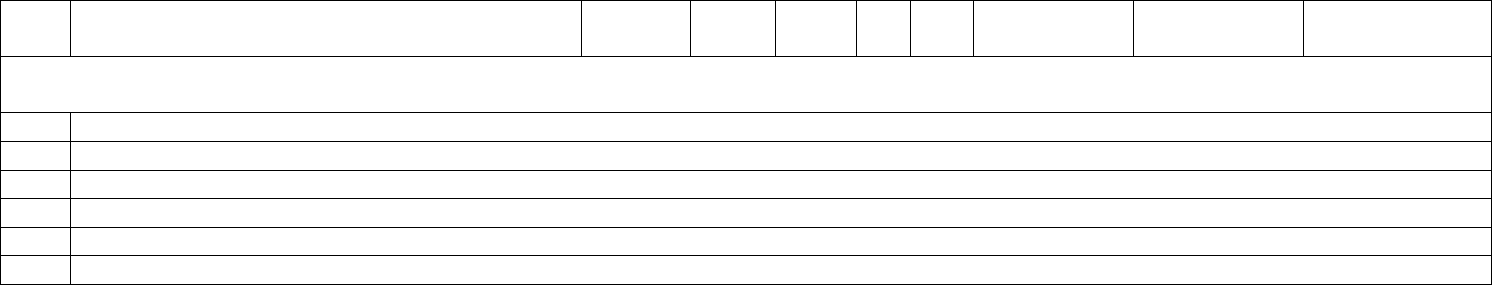

No.

Experiment

Hours

BT

Level

CO

PSO

Elements of

Employability

(Emp)/

Entrepreneurship

(Ent)/ Skill

Development

(SD)

Relevance to Local

(L)/ National (N)/

Regional(R)/Global

(G)

Relation to

Gender (G),

Environment

and

Sustainability

(ES), Human

Values

(HV)and

Professional

Ethics (PE)

1

Newton’s Rings: To Study the interference patterns

from single monochromatic source and find out the

Radius of Curvature of given Plano-Convex lens from

the obtain interference pattern.

06

1,2

CO1,

CO2

PSO1,

PSO2

SD

G

PE

2

Diffraction Grating: To study the diffraction pattern

from sodium vapor lamp and find out the wavelength

of this source by using diffraction pattern that obtain

with the help of Transmission Grating.

06

2

CO1

CO2

PSO1,

PSO2

3

Frequency of AC Mains: To determine the frequency

of A. C. Mains.

06

2,3

CO3

CO4

PSO1,

PSO2

4

Ultrasonic Waves: To determine the frequency of

Ultrasonic waves and find out the velocity of

Ultrasonic wave in air medium by using the

interference theory of longitudinal wave.

06

3,4

PSO1,

PSO3

5

Resolving Power of Telescope:- Comparative study

between resolving power of Travelling Microscope and

Telescope.

06

2,3

CO1

CO2

PSO1,

PSO4

6

Solar Cell: Study of various parameters of solar cell

06

2,3

PSO1,

PSO3

7

Dispersion of Light: Calculate the refractive index of

different wavelength associated with white light using

the prism.

06

3,4

PSO1,

PSO3

8

Laser Parameters: (1) To determine the full angular

divergence of the given gas laser. (2) To determine the

wavelength of the given laser source using diffraction

by grating.

06

3,4

CO5

PSO1,

PSO3

9

Polari meter: To determine the specific rotation of the

given optically active substance.

06

2,3,4

CO1

CO2

PSO1,

PSO3

10

Rectifier Circuits: To study the process of

rectification through half wave, full wave and bridge

rectifiers.

06

2,3,4

CO3

CO4

PSO1,

PSO4

The Maharaja Sayajirao University of Baroda

Faculty Technology and Engineering

Department of Textile Engineering

Academic Year

2020-21

B.E. - Textile Technology: Regular Programme

Year

I

Core / Elective / Foundation

AMT 1101: APPLIED MATHEMATICS-I

Credits / Hours per week

04

Semester

I

Year of Introduction: 2010

Year of Syllabus Revision: 2016

Maximum Marks / Grade

100

Mode of Transaction

Lecture

Course Outcome (CO) (AMT1101)

CO1 Evaluate successive differentiation of given function and solve identities involving higher order derivatives, evaluate radius of curvature, obtain

Taylor & Maclaurin series expansion of function of single variable. Evaluate limits of indeterminate forms.

CO2 Test for convergence sequences and positive term series using various tests like comparison test, ratio test. Also find the convergence, absolute and

conditional convergence for alternating series.

CO3 Understand the requirement of complex numbers their various representations, Demovier’s theorem and its applications. Logarithm of complex

numbers. Evaluate and use circular functions, hyperbolic functions.

CO4 Classify the differential equations with respect to their order and linearity, explain the meaning of different types of solutions of a differential

equation.

CO5 Identify and solve the 1

st

order differential equations.

CO6 Apply the method of undetermined coefficients to solve the non-homogeneous linear differential equations with constant coefficients.

CO7 Apply the method "variations of parameters" to find to solution of higher-order linear differential equations with variable coefficients.

CO8 Solve the Cauchy-Euler equations and systems of linear differential equations .

CO9 Analyze real-world problems in field of Engineering like problems related to bending of beams, mixtures, growth and decay, heating and cooling,

electric circuits, Spring-mass system etc.

CO10 Find series solutions of Bessel differential equation and Legendre’s differential equations and make use of the properties of Bessel’s functions and

Legendre polynomials to study and analyze the solution.

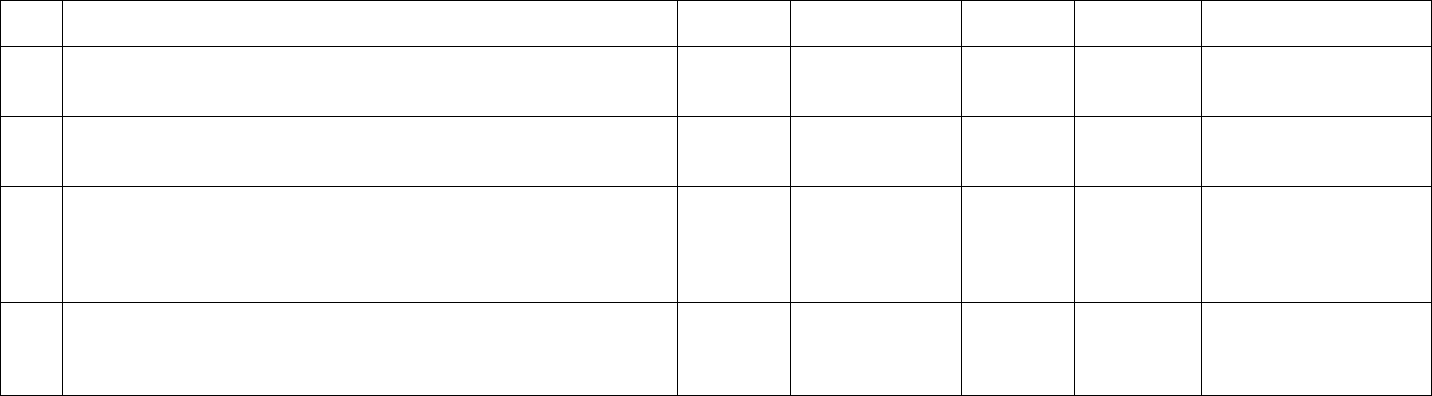

Unit

No.

Topic

Contact

Hours

Weightage

(%)

BT

Level

CO

PSO

Elements

of

Employa

bility

Relevanc

e to

Local (L)/

National

Relation

to

Gender

(G),

(Emp)/

Entrepre

neurship

(Ent)/

Skill

Develop

ment

(SD)

(N)/

Regional(

R)/Global

(G)

Environ

ment

and

Sustaina

bility

(ES),

Human

Values

(HV)and

Professio

nal Ethics

(PE)

1

Calculus:

Reorientation, Functions of one variable Application of derivatives,

Curvature, Successive differentiation, Partial derivatives, Leibnitz rule

for the nth order derivative of a function, Techniques of partial

derivatives.

8

16.67

1,2,3,5

CO1

Emp, SD

G

PE

2

Infinite Series:

Sequence and their convergence , convergence and divergence of

infinite series, Geometric series, P – Series ,Necessary condition for

convergence, Comparison test, ratio test Absolute convergence and

conditional convergence of alternating series, Maclauarin’s & Taylor’s

expansion with reminder form, Indeterminate forms L’Hospital’s rule

8

16.67

1,2,3,4

CO2

3

Complex Numbers:

Complex numbers & their geometrical representation, Complex

numbers in polar form, Demoivre’s theorem and its applications,

Exponential, logarithmic, trigonometric & hyperbolic functions.

8

16.67

1,2,3,4

CO3

4

Differential Equations

Reorientation, Modeling of engineering systems pertaining to

first order differential equations, Exact differential equations,

integrating factors, Unified approach to first order ordinary

differential equations, Equations of first order and higher

degree.

8

16.67

1,2,3,5

CO4

CO5

CO9

5

Linear differential equations of higher order with constant

coefficients and with variable coefficients

Models of higher order differential equations, Method of variation of

10

20.83

1,2,3,5

CO6

CO7

CO8

parameters, Simultaneous linear differential equations

Method of solution in series

CO9

6

Bessel and Legendre’s equations, Properties of Bessel functions

Introduction to Legendre polynomials

6

12.5

1,4,5

CO10

The Maharaja Sayajirao University of Baroda

Faculty Technology and Engineering

Department of Textile Engineering

Academic Year

2020-21

B.E. - Textile Technology: Regular Programme

Year

I

Core / Elective / Foundation

MEC 1101: Engineering Drawing I

Credits / Hours per week

Lectures: 04

Practical-: 04

Semester

I

Year of Introduction: 2016

Year of Syllabus Revision: ----

Maximum Marks / Grade

Theory: 100

PR/TW/VIVA: 50

Mode of

Transaction

Lectures

Course Outcome (CO) MEC 1101

CO 1

Use the drawing instruments effectively and how to use the dimensioning methods.

CO 2

Observe, analyse and correlate two-dimensional (Orthographic view) and three dimensional (Isometric view)

CO 3

Construct and application of various engineering curves in engineering practice

CO 4

Apply the knowledge of Projection of points, Lines and Planes in engineering

CO 5

Create freehand sketches of basic machine components

Unit

No.

Topic/Unit

Contac

t

Hours

Weightag

e

(%)

BT

Level

CO

PSO

Elements of

Employabilit

y (Emp)/

Entrepreneurs

hip (Ent)/

Skill

Development

(SD)

Relevance

to

Local (L)/

National

(N)/

Regional(R

)/

Global (G)

developme

ntal needs

Relation to

Gender (G),

Environment

and

Sustainability

(ES), Human

Values (HV)and

Professional

Ethics (PE)

1.

Introduction to Engineering Curves:

Introduction to conic sections, types of conic

sections, eccentricity, construction of conic

sections( parabola, ellipse , hyperbola) by

different methods, Construction of involutes,

08

20

1,2,6

CO3

PSO1,2

,3

Emp, Ent, SD

L,N,R,G

G, ES, HV, PE

construction of cycloid, epicycloid and

hypocycloid, construction of spiral, construction

of normal and tangent to all curves.

2.

Free hand sketches:

Parts of screw thread and its types, conventional

representation of threads, screwed fastening-

types of nuts, bolts, set screws, locking

arrangement of nuts, foundation bolts, riveted

and welded joints, forms and proportions of

rivet heads, representation of welded joints,

shaft keys and couplings- types of keys, cotter

joint, knuckle joint, double cotter/sleeve joint,

types of couplings.

08

10

1,2,6

CO5

PSO1,2

,3

3.

Projection of Point and Line

Introduction to principal planes of projections,

projections of points located with respect to

reference planes (in different quadrants),

Projection of Lines, Line parallel to reference

planes, Line parallel to one reference plane and

inclined to other reference plane, Line inclined

to both the reference planes, Application of all

variants

08

20

3,4,6

CO4

PSO1,2

,3

4.

Projection of Planes

Projection of Planes (Polygons, circle, semi-

circle, ellipse etc.). Plane parallel to one

reference plane and inclined to other, Plane

inclined to both the reference plane, Concept of

auxiliary plane method for projection of plane.

08

10

1,2,4

CO4

PSO1,2

,3

5.

Orthographic projection

Fundamental of projection along with

classification, Projections from the pictorial

view of the object on the principal planes for

10

20

2,3,5

CO2

PSO1,2

,3

view from front, top and sides using first angle

projection method and third angle projection

method, full sectional view

6

Isometric Projections and Isometric View or

Drawing:

Isometric Scale, Conversion of orthographic

views into isometric projection, isometric view

or drawing of objects

10

20

2,4,5

CO2

PSO1,2

,3

Reference book

1.

Bhatt, N.D., ‘Engineering Drawing’,

2.

Shah, P. J., ‘Engineering Drawing’,

3.

Bhatt, N.D., ‘Machine Drawing’,

4.

Dhawan, R.K., ‘A Textbook of Engineering Drawing’,

5.

Venugopal, K., ‘Engineering Drawing and Graphics’

6.

M. Raja Roy, B.V.R. Gupta, ‘Engineering Drawing with AutoCAD’,

The Maharaja Sayajirao University of Baroda

Faculty Technology and Engineering

Department of Textile Engineering

Academic Year

2019-20

B.E. - Textile Technology: Regular Programme

Year

I

Core / Elective / Foundation

MEC1101L Engineering Drawing-I

(Practical/TW/Viva)

Credits / Hours per week

02

Semester

I

Year of Introduction:1954

Year of Syllabus Revision: NA

Maximum Marks / Grade

50

Mode of

Transaction

Term work, Practical and viva

No.

Experiment

Contact

hours

Weightage

(%)

BT

Level

CO

PSO

1

Different types of Engineering Curves:

08

20

1,2,6

CO3

PSO1,2,3

2

Free hand sketches:

08

10

1,2,6

CO5

PSO1,2,3

3

Projection of Point and Line

08

20

3,4,6

CO4

PSO1,2,3

4

Projection of Planes

08

10

1,2,4

CO4

PSO1,2,3

5

Orthographic projection

10

20

2,3,5

CO2

PSO1,2,3

6

Isometric Projections and Isometric View or Drawing:

10

20

2,4,5

CO2

PSO1,2,3

The Maharaja Sayajirao University of Baroda

Faculty of Technology and Engineering

Department of Textile Engineering

Academic Year

2020-2021

B.E. - Textile Technology: Regular Programme

Year

I

Core / Elective / Foundation :

MME1101 Materials Science

Credits / Hours per Week

04 (Theory)

Semester

I

Year of Introduction :

Maximum Marks / Grade

100 (Theory)

Mode of Transactions

Lectures and Tutorials

Course Outcome (CO) / MET 1101

CO-1: Understanding of materials and their classification

CO-2: Study about crystals and lattices parameters

CO-4: Studies of phase important with their diagrams and materials defects

CO-5: Learning about ceramics and glasses materials

CO-6: Understanding briefly causes and types of corrosions and their protection methods

CO-7: Study about electronics and electrical materials

CO-8: Learn about some advanced materials and their uses

Unit

No.

Topic/Unit

Contact

Hours

Weightage

(%)

[1]

BT

Level

CO

PSO

[2]

Elements of

EMP/ENT/SD

[3]

Relevance

to L/R/N/G

[4]

Relation to

GN/ES/HV/PE

1

Introduction of Engineering

02

10%

1/2/3/4

CO1

SD

G

ES

Materials

Metalica Materials, Ceramic Material,

Polymers, Composite and Nano-

materials.

2

Crystal Structure

Crystallography, Atomic structure

and; Structure of crystalline solids;

Lattices, unit cells; Crystal systems,

Bravais lattices; Indexing of directions

and planes, notations, Inter-planar

spacings and angles, co-ordination

number, packing factors stacking

sequence in BCC, FCC and HCP.

06

15%

1/2/3/5

CO2

SD

G

ES

3

Mechanical Properties of Materials

Concepts of stress and strain,

Stress-Strain diagrams; Properties

obtained from the tensile test; Elastic

deformation, Plastic deformation.

Impact Testing & toughness

behavior. Hardness of materials.

08

15%

1/2/3

CO3

SD

G

ES

4

Phase diagram

Gibbs phase rule, Binary phase

08

15%

1/2/3

CO4

SD

G

ES

diagram its types, solid solution –

Hume Rothery Rules. Imperfections:

Point defects, Line defects and

surface defects – grain boundary, tilt

boundary and twin boundary, Grain,

Grain size number. Burgers vector

and its representation.

5

Ceramic Materials

Introduction, ceramic structures,

silicate structures, Processing of

ceramics; Properties, glasses;

Composite Materials- Introduction,

classification, metal-matrix, ceramic–

matrix and polymer matrix

composites.

05

10%

1/2

CO5

SD

G

ES

6

Corrosion

Types of corrosion – Dry and Wet

corrosion, Electro chemical and

oxidation (Chemical) corrosion.

Corrosion prevention – anodic and

cathodic protection & coatings

06

15%

1/2/3

CO6

SD

G

ES

7

Electrical & Electronic Materials

Intrinsic and Extrinsic Semi

conductivity, Dielectric material,

05

10%

1/2

CO7

SD

G

ES

Piezo-electric materials. Magnetic

Materials: Introduction, classification

of magnetic materials, soft & hard

magnetic materials.

8

Advanced Materials

Nano Materials & its application,

Metallic glasses, Super conducting

material, optic fibers, smart materials.

05

10%

1/2

CO8

SD

G

ES

45

100%

Text Books or Reference Books:

1.

Askeland D.R., & P. P. Fullay (2007), The Science and Engineering of Materials –4th Cengage Learning Publishers

2.

William D. Callister, Jr (2008), Callister’s Materials Science and Engineering, (Adopted by R. Balasubramaniam) Wiley-Eastern

3.

A.S. Edelstein and R.C. Cammarata Ed. (1998), Nano Materials: Synthesis, Properties and Applications, Inst. Of Physics Publishing,

UK

4.

Raghavan V (2007), Materials Science and Engineering - A First Course, Prentice Hall, India

5.

James F. Shackelford (1996), Introduction to Materials Science for Engineers, Prentice Hall, India

The Maharaja Sayajirao University of Baroda

Faculty Technology and Engineering

Department of Textile Engineering

Academic Year

2019-20

B.E. Textile Technology: Regular Programme

Year

I

Core / Elective / Foundation

CVL 1104 : FUNDAMENTALS OF CIVIL AND ENVIRONMENTAL ENGINEERING

(NEW COURSE)

Credits / Hours

per week

04

Semester

I

Year of Introduction: 2019

Year of Syllabus Revision:

Maximum Marks / Grade

100

Mode of Transaction

Lectures

Course Outcome (CO) CVL

CO1 To impart brief fundamental concept related to various materials and their use in building construction

CO2 To study environmental pollution comprehensively and

CO3 Students will know concept of linear and angular measurements

CO4 Students will be aware of various constructional practices

Uni

t

No.

Topic

Contac

t

Hours

Weighta

ge

(%)

BT

Level

CO

PSO

Elemen

ts of

Employ

ability

(Emp)/

Entrepr

eneursh

ip

(Ent)/

Skill

Develo

pment

(SD)

Releva

nce to

Local

(L)/

Nationa

l (N)/

Region

al(R)/G

lobal

(G)

Relatio

n to

Gender

(G),

Enviro

nment

and

Sustain

ability

(ES),

Human

Values

(HV)an

d

Profess

ional

Ethics

(PE)

1

Building Material

Stone - Introduction to stone – Uses of stone –

Characteristics of good building stone – Availability,

suitability and properties of different stone. Bricks -

Comparison between stone work and brick work –

Advantages of bricks – Characteristics of good brick –

Standard test for brick along with field test for brick. Lime

- Classification of Lime, Precautions in handling Lime.

Cement - Basic ingredient of ordinary cement – Physical

properties of cement – Field examinations of cement –

Storing of cement and its uses. Timber - Introduction to

timber – Importance of seasoning – Wood base product.

Steel - Introduction – Use of different form of steel –

Marketable forms of steel. Aggregates. Bitumen. FRP.

Optical fiber. Plastic - Properties of plastics – Types and

uses of plastic.

14 hrs

27

2,3

CO1

PSO3

(Emp),

(Ent),

(SD)

(L),

(N),

(R), (G)

(ES),

(PE)

2

Environmental Science and Sustainable Development

Introductory Environmental Engineering Terminology––

Introduction to various types of pollution- Water and land

pollution and remedial measures for control, water and

wastewater quality criteria – Disposal of wastes – Air

pollution and remedial for control – Ecology,

Environmental Protection and legislation. Hydrologic

cycle, Rain water harvesting, Green building, Solid waste

management, Environment Impact Assessment, Basic

environmental chemistry, Sustainable development – clean

development mechanism, Global warming, Ozone layer

12 hrs

23

2,3

CO2

PSO2

depletion, Acid rain, and Climate change.

3

Surveying and Leveling

Surveying - Introduction – Principle – Object of survey –

Classification – Basic instruments of linear and angular

measurements – chain, tape, Offsetting, Types of offsets,

Ranging methods. Prismatic compass, Types of meridians,

Types of bearings. Traverse survey: open and closed

Examples based on compass. Leveling – Definitions –

Computation of reduced levels– Introduction to contour,

Methods of leveling and Examples on Level. Modern

tools: Introduction to Theodolite, Total station –

Introduction to GPS, GIS, Remote sensing.

14 hrs

27

2, 3, 4

CO3

PSO1

PSO2

PSO3

4

Building Construction

Building Construction & Infrastructures: Types of

constructions – roads, pipelines, transmission lines –

Typical details of load bearing and framed structures –

Brief discussion and illustrational sketches of typical

important building components – Foundation – Functions,

Types of foundations such as Spread footing, Stepped

footing, Isolated and Combined column footing, Raft, and

Grillage foundation. Lintels – Function, Types of lintel.

Flooring, Roofing. Mortar and concrete specifications –

Ingredients for mortar and concrete – classification of

mortar and concrete – selection of mortar and its uses –

precaution in using mortar – Pre-stressed concrete –

grades of concrete, Internet of things for buildings,

Hydropower plants.

12 hrs

23

1, 2, 3

CO4

PSO1

PSO3

Reference Books

1

Arora S.P. and Bindra S.P. (2012), A text book of Building Construction, Dhanpatai and Sons, Publishers.

2

Rangwala S.C. (2012), A text book of Building Construction, Charotar Publishing House, India.

3

Gilbert M Masters, (2006), Introduction to Environmental Engineering & Science, Prentice Hall of India Pvt. Ltd. New Delhi

4

Deshpande P.D., (2009) Basic Civil Engineering, Nirali Prakashan Pune.

5

G.S.Birdie, Water supply & Sanitary Engg., Dhanpatrai & Sons.

6

S.C.Rangwala, Engg. Materials, Charotar Books Staff, Anand.

7

Janardan Jha Building Material

8

Surendra Singh, Building Material, Vikas Pub. Pvt. New Delhi.

9

D.N.Ghose, Material of Construction, Tata McGraw Hill Pub. Co. Ltd. New Delhi

10

Surveying & Levelling – Kanetkar & Kulkarni Vol-I A.V.G. Prakashan, Puna.

11

Elementary Survey – B.C.Punmia Vol-I. Laxmi Pub. Dariya Gunj, New Delhi.

12

Surveying & Levelling – S.C.Rangwala, Charotar Pub. House, Anand.

The Maharaja Sayajirao University of Baroda

Faculty Technology and Engineering

Department of Textile Engineering

Academic Year

2019-20

B.E. Textile Technology: Regular Programme

Year

I

Core / Elective / Foundation

CVL 1104L : FUNDAMENTALS OF CIVIL AND

ENVIRONMENTAL ENGINEERING (NEW COURSE) : Field

Practical

Credits / Hours per week

02

Semester

I

Year of Introduction: 2019

Year of Syllabus Revision:

Maximum Marks /

Grade

50

Course Outcome (CO) CVL

CO1 To impart brief fundamental concept related to various materials and their use in building construction

CO2 To study environmental pollution comprehensively and

CO3 Students will know concept of linear and angular measurements

CO4 Students will be aware of various constructional practices

Mode of

Transaction

Practical’s, discussion and viva

PSO1 is common for all experiments

No.

Experiment

Conta

ct

Hours

Course

Code

BT

Level

CO

PSO

1

Conventional signs and symbols, scale, topographic-sheet

2

CVL110

4L

1,2,3

CO

3

PSO1

2

Linear measurements: tape, ranging, offsets

4

CVL110

4L

2,3

CO

3

PSO1

3

Compass: Introduction, Bearings

2

CVL110

4L

2,3,4

CO

3

PSO1

4

Auto level: Introduction, HI, Rise and fall

6

CVL110

2,3,4,

5

CO

3

PSO1

4L

5

GPS : Introduction, and demonstration

2

CVL110

4L

2,3,4

CO

3

PSO1

6

Theodolite and Total Station demonstration

6

CVL110

4L

2,3,4,

5

CO

3

PSO1

7

Any other term-work based on syllabus

4

CVL110

4L

1,2

CO

1C

O4

PSO1,

PSO3

The Maharaja Sayajirao University of Baroda

Faculty Technology and Engineering

Department of Textile Engineering

Academic Year

2020-21

B. E. (Mechanical Engineering): Regular Programme

Workshop Practice I

Year

I MECH

Core

MEC 1102

Credits / Hours per week

Lectures: 00

Practical-: 03

Semester

I

Year of Introduction:

Year of Syllabus Revision: 2018

Maximum Marks / Grade

Theory: NILL

PR/TW/VIVA: 50

Mode of Transaction: Lectures and Practical

Course Outcome (CO) MEC 1102

CO1 Understand carpentry shop work ,different tools ,use of tools and hand on practices of subject.

CO2 Understand Smithy workshop related tools and learning forging operation in workshop .

Unit

No.

Topic

Contac

t

Hours

Weightage

(%)

BT

Level

CO

PO

Elements

of

Employabili

ty (Emp)/

Entreprene

urship

(Ent)/ Skill

Developme

nt (SD)

Relevance

to Local

(L)/

National

(N)/

Regional(

R)/Global

(G)

Relation to

Gender (G),

Environment

and

Sustainability

(ES), Human

Values (HV)and

Professional

Ethics (PE)

1

Carpentry: Name, use and setting of hand tools, Construction

of halved single mortise and tenon joints, dovetail joint, bridle

joint, oblique mortise and tenon joint and rafter joint.

20

50

1,2,3,

4,5,6

Co1

Po 2,3,4

All

All

All

2

Smithy: Tools used for preparing simple jobs in hand forging.

19

50

1,2,3,

4,5,6

Co2

Po 2,3,4,5

39

100

Reference Books

1.

Workshop Technology-I. W.A. J. Chapman Taylor & Francis

2.

Comprehensive Workshop Technology (Manufacturing Processes). S.K. Garg Laxmi publications

3.

Workshop practice manual. K.Venkata Reddy B.S.Publications.

4.

Workshop Technology-I. Hazra and Chaudhary Media promoters & Publisher private limited

The Maharaja Sayajirao University of Baroda

Faculty Technology and Engineering

Department of Textile Engineering

Academic Year

2020-21

B.E. (Textile Technology) : Regular Programme

Year

I

Core / Elective / Foundation

APH1201/APH1206: Applied

Physics-II

Credits / Hours per week

04

Semester

II

Year of Introduction: 2003

Year of Syllabus Revision: 2012

Maximum Marks / Grade

100

Mode of Transaction

Lectures, Tutorials and

Practical/TW/Viva

Course Outcome (CO) APH1201

CO1 Understanding the fibres

CO2 Understanding the physical properties of fibres

CO3 Methods to determine physical properties

CO4 Understanding of instrumentation

CO5 Analysis of color

CO6 Applications of fibres

Unit

No.

Topic/Unit

Contact

Hours

Weightage

(%)

BT

Level

CO

PSO

Elemen

ts of

Emplo

yability

(Emp)/

Entrep

reneur

ship

(Ent)/

Skill

Develo

pment

(SD)

Releva

nce to

Local

(L)/

Nation

al (N)/

Region

al(R)/G

lobal

(G)

develo

pmenta

l needs

Relatio

n to

Gende

r (G),

Enviro

nment

and

Sustain

ability

(ES),

Huma

n

Values

(HV)a

nd

Profess

ional

Ethics

(PE)

1

Introduction to Fibres

Classification of fibers, Natural and Manmade fibers

and their general properties, Growth of fiber, Effect of

external parameters i.e. Radiation, Temperature,

Pressure and other on fiber

04

06

1

CO1

PSO1

SD

L, N

PE

2

Humidity, Regain and Moisture Content

Humidity and relative Humidity, Hygrometers, Regain

and Moisture Content, measurement of regain, relation

between regain and relative humidity, influence of

temperature and stress

07

11

1,2

CO2

CO3

PSO1

3

Colorimetry

Science of colors, additive color mixture, three color

mixture, spectrophotometry, dominant wavelength and

purity, subtractive method of color mixing, the color of

paint and inks, subtractive primaries

07

11

1,2, 3,

6

CO5

PSO1

PSO5

PSO7

4

Microscopy

Eye pieces, Principles and working of compound

microscope, oil immersion microscope, polarization

microscope, electron microscope and their use in

studying surface and structure of fiber,

07

11

2, 3,4

CO4

CO6

PSO1

PSO5

5

Spectroscopy

Beer’s law, Lambert’s law, Principles and working of

spectrophotometer and interpretation of UV, visible

and IR spectra, sample preparation

07

11

2, 3,4

CO4

CO6

PSO1

PSO5

6

Tensile Properties of Fibers

Factors determining the results of Tensile experiments,

12

20

2,3

CO2

CO3

PSO1

PSO7

Stress, specific stress, tensile strain, strength, work of

rapture, Elongation at break, initial, modulus, work

factor, yield point and crimp, The effect of moisture &

Temperature, Pierce’s, Spencers Smith’s and weak

link theories.

7

Elastic Recovery

Introduction, Definition, Experimental methods& their

results, change of Properties as a result of straining,

Swelling recovery, Simple recovery model, Recovery,

work of rupture and durability,

08

10

2,3

CO2

CO3

PSO1

PSO5

PSO7

8

Fiber Friction

Technological Effects, Measurements of Friction,

Bewden and Leben’s Apparatus, Static and Dynamic

Capston Method, Bucide and Pollitt’s Technique and

Measurement of inter-fiber Friction, Static and Kinetic

Friction and State of the Surface, The nature of Fiber

Friction and it’s applications to Fiber Friction,The

Friction of Wool, Theory of directional friction.

12

20

1, 2,3

CO2

CO3

PSO1

PSO5

PSO7

Reference Books

1.

Physical properties of Textile fibers by W.E. Morton and J.W.S. Hearle, Woodhead Publishers, UK

2.

Optics by F.W. Sears, Addison-Wesley Publishing Co. Inc.

3.

A textbook of Optics, S.L.Kakani, K.C. Bhandari, S. Chand & Sons

4.

Modern Concepts of Color and Appearance, A.K. Roy Choudhury, Oxford& IBH Publishing Co. Pvt. Ltd.

5.

Organic Spectroscopy, Y.R. Sharma, S. Chand Publishers

6.

Fibre Science & Technology by P. Ghosh

7.

A Text Book of Fibre Science by S.P.Mishra (TS 1540 M4T3)

The Maharaja Sayajirao University of Baroda

Faculty Technology and Engineering

Department of Textile Engineering

Academic Year

2020-21

B.E. (Textile Technology): Regular Programme

Year

I

Core / Elective / Foundation

APH1201L/ APH1206L : Applied Physics-II (Practical/TW/Viva)

Credits / Hours per week

03

Semester

II

Year of Introduction: 2003

Year of Syllabus Revision: 2012

Maximum Marks / Grade

50

Mode of

Transaction

Laboratory Experiments, TW/Viva

No.

Experiment

Contact

hrs

Course

Code

BT

Level

CO

PSO

1

Determine the Planck’s constant (h)using different LEDs. Use at least 4 LEDs.

APH120

1TX

3,4

CO

4

PSO1

PSO5

2

Determine the diameter of the given textile yarn using diffraction of light.

Wavelength of the laser = 632.9 nm

APH120

1TX

3,5

CO

3

PSO1

3

Demonstrate the exponential decay law using the given statistical board set up. Plot

the necessary graphs and determine the decay constant.

APH120

1TX

3,4,6

CO

3

PSO1,

PSO7

4

Obtain the V-I characteristic of the given Zener diode in forward and reverse bias

conditions. Plot the necessary graphs.

APH120

1TX

3,4

CO

4

PSO1,

PSO5

5

Determine the energy band-gap of a given semiconductor using the Four-probe

method. Plot the necessary graph.Distance between two neighboring probes = 2.0

mm,Thickness of the semiconductor crystal = 0.5 mm

APH120

1TX

3,6

CO

4

PSO1,

PSO5

6

Determine the friction coefficient for the given system of wood cart and the glass

floor.

APH120

1TX

3,4,5

CO

3

PSO1,

PSO7

7

Determine the Young’s modulus of the given material (wood) using the method of

bending of a beam. Plot the necessary graphs.

APH120

1TX

3,4,6

CO

3

PSO1,

PSO7

8

Determine the molar extinction coefficient (ε) for the given KMnO

4

(0.05N)solution.

Plot the necessary graph using at least 8 points and obtain ε.

APH120

1TX

3,5

CO

4

PSO1,

PSO7

9

Obtain the load-elongation curve for the given yarn. Determine the following from the

load-elongation curve: (1) work of rupture (2) work factor (3) Initial modulus (4) yield

point, Length of the yarn = 40 cm; Linear density of the yarn(pink) = 26.88 g/km

APH120

1TX

3,6

CO

3

PSO1,

PSO5

10

Study the moisture content (M) and regain (R) of the given cotton specimen at

constant temperature. Determine the equilibrium state. Plot the necessary graphs.

APH120

1TX

3,4,5

CO

3

PSO1,

PSO5

The Maharaja Sayajirao University of Baroda

Faculty Technology and Engineering

Department of Applied Physics

Academic Year

2020-21

B.E.-I (Textile Engineering/Textile Technology): Regular Programme

Year

I

Core / Elective / Foundation

AMT1202: Mathematics and Statistical

Methods

Credits / Hours per week

04

Semester

II

Year of Introduction:

Year of Syllabus Revision:

Maximum Marks / Grade

100

Mode of Transaction

Lectures and Tutorials

Course Outcome (CO)

CO1 Understand and Evaluate the domain, range, limit, continuity, differentiability of multivariable functions, and apply it to various applications like estimating the

Taylor series expansion, maxima and minima of functions of several variables, Tangent plane and Normal line to the given surface.

CO2 Understanding and evaluating gradient, curl, divergence of scalar and vector functions, and to determine the directional derivatives for scalar point function.

CO3 Understands the concept of different types of line integrals with evaluation techniques.

CO4 Understands the Double, Triple integrations and can apply it appropriately, to evaluate Volume, Mass, Area, C.G. and M.I.

CO5 Understands the relation between double and line integrals as a Green’s Theorem and can apply the concept of line integral to find out Work done, Mass, Length

of curve, Area etc.

CO6 Able to analysis, classify and interpret data to answer questions about the real world problem, and able to demonstrate the ability to analyze data by

appropriately

fitting, assessing, and interpreting a variety of statistical models.

CO7 Understands the basic probability theories well, and be familiar with discrete and continuous random variables and implement it to translate uncertainty

problems

into probability models with application to the areas related to Textile sector.

CO8 Understands data description, statistical inference, hypothesis testing, analysis of association and variance.

CO9 Implement a proficiency in collection, organization, design, and drawing inferences from data using appropriate statistical methodology and problem solving skill.

CO10 Able to analysis, classify and interpret data to answer questions about the real world problem.

Unit

No.

Topic

Contact

Hours

Weightage

(%)

BT

Level

CO

PSO

Elements

of

Relevanc

e to

Relation

to

Employa

bility

(Emp)/

Entrepre

neurship

(Ent)/

Skill

Develop

ment

(SD)

Local (L)/

National

(N)/

Regional(

R)/Global

(G)

Gender

(G),

Environ

ment

and

Sustaina

bility

(ES),

Human

Values

(HV)and

Professio

nal Ethics

(PE)

1

Partial Differentiation:

Function of two variables, limit, continuity and partial

derivatives, Chain rule, Euler’s theorem, implicit function

differentiation. Applications of partial derivatives, tangent

planes and normal lines to above surfaces (by calculus

method).

09

19

1,2,3

CO1

PSO1

Emp /

Ent

N /

G

PE

2

Vector Calculus:

Scalar and vector fields, gradient of a scalar function,

directional derivatives, divergence and curl of a vector field

and their applications. Line integrals and its Applications,

Green’s Theorem.

07

14.5

1,2,3

CO2

CO3

CO5

PSO1

3

Multiple Integration:

Double integral, Change of order of integration, Triple

integration, Change of variables in double and triple integrals,

Applications of double and triple integration

07

14.5

2, 3, 4,5

CO4

PSO1

PSO4

4

Statistics:

Reorientation of basic concepts: by taking examples related

to Textile Engineering.

Curve fitting (least square approximation), Correlation

analysis, Regression analysis.

07

14.5

1, 2, 3,5

CO6

PSO1

PSO2

5

Probability:

Reorientation and problems pertaining to Textile Engineering,

Random Variables and Probability Distributions (Discrete and

Continuous), Binomial probability distribution, Poisson

distribution, Normal probability distribution. General idea of

sampling, methods to draw a random sample, Confidence

interval for mean for large and small samples.

10

21

1,2,3,4,5

CO7

CO9

PSO1

PSO2

6

Testing of Data:

General idea for testing of hypothesis, One-tailed and Two-

tailed tests, Large and small sample tests, Test using p-values,

Control charts for variables and attributes , chi-square test of

goodness of fit, contingency tables. Analysis of Variance

(ANOVA).

08

16.5

2,3,4,6

CO8

CO9

CO10

PSO1

PSO2

PSO3

Reference Books

1.

Erwin Kreyszig: Advanced Engineering Mathematics, (6th edition) John-Wiley & Sons.

2.

Wilfrad Kaplan: Advanced Calculus, Addison-Wesley Publ. Company, Inc

3.

C.R.Wylie: Advanced Engineering Mathematics, Mc. Graw– Hill, Inc.

4.

A.Richard: Probability and Statistics for Engineers, Johanson, PHI, 1996

5.

S.P.Gordon & F.S.Gordon: Contemporary Statistics, Mc – Graw Hill Inc, 1994.

6.

J.E.Booth: Textile Mathematics (Vol.I, II, III), The Textile Institute, Manchester, 1975.

7.

J.E.Booth: Principles of Textile Testing, CBS Publishers & Distributors, 1996.

8.

E.B.Grover & D. S. Hamby: Handbook of Textile Testing & Quality Control, Wiley India Pvt. Ltd.

9

B.V.Ramana: Higher Engineering Mathematics, Tata Mc. Graw-Hill. (Core Engineering Series).

The Maharaja Sayajirao University of Baroda

Faculty Technology and Engineering

Department of Applied Mathematics

Academic Year

2019-20

Bachler of Textile Engineering and Textile Technology

Year

I

Core / Elective / Foundation

AMT 1202L : Mathematics & Statistical Methods-TW/Practical

Credits / Hours per week

02

Semester

II

Year of Introduction:

Year of Syllabus Revision:

Maximum Marks / Grade

50

Mode of Transaction

Term Work, Practical and Viva

Course Outcome (CO)

CO1 Understands and be able to apply Mathematical software towards the problem solving.

CO2 Able to analysis, classify and interpret data using computer algorithms.

CO3 Able to demonstrate the ability to analyze data by appropriately fitting, assessing, and interpreting a variety of statistical tools.

CO4 Able to apply the appropriate software programs towards the basic probability theories with application to the areas related to Textile sector.

CO5 Understands and implement the appropriate software programs related to data description, statistical inference, and control charts.

No.

Experiment

Course

Code

BT

Level

CO

PSO

1

Introduction to Mathematical Software.

AMT1202L

1,2

CO1

PSO1

PSO4

2

Basic inbuilt commands and functions of vectors in Mathematical Software.

1,2,3,4

CO1

CO2

PSO1

PSO4

3

Basic inbuilt commands and functions of matrices in Mathematical Software.

1, 2, 3,

4

CO1

CO2

PSO1

PSO4

4

a. Basic command for 2D – plotting using Mathematical Software.

b. Presentation of frequency distribution into graphs using Mathematical Software. (Histogram, bar, pie,

etc.)

1, 2,

3,4,5

CO2

CO3

PSO1

PSO4

5

Measure of central Tendency

(1) Mean

(2) Median

(3) Mode

1,2,3,4

,5

CO2

CO3

PSO1

PSO2

PSO4

6

(a) Measure of Dispersion: Standard Deviation and Variance

(b) Relative Measure: Coefficient of variation

(c) Skewness

1, 2,

3,4,5

CO2

CO3

PSO1

PSO2

PSO4

7

Correlation Analysis

1, 2,

3,4,5

CO2

CO3

PSO1

PSO2

PSO4

PSO5

8

Regression Analysis

(1) Regression line y on x

(2) Regression line x on y

1, 2,

3,4,5

CO1

PSO1

PSO2

PSO4

PSO5

9

Curve fitting

(1) Straight line( or )

(2) Parabola

(3) Exponential (

)

(4) Power function(

and

)

1, 2,

3,4,5

CO1

CO2

PSO1

PSO2

PSO4

10

Probability Distribution

(1) Binomial Distribution

(2) Poisson Distribution28

Normal Distribution

1, 2,

3,4,5

CO1

CO2

PSO1

PSO2

PSO4

PSO5

11

Hypothesis Testing

1, 2,

3,4,5

CO2

CO3

PSO1

PSO2

PSO4

PSO5

12

Control Charts

1, 2,

3,4,5

CO2

CO3

PSO1

PSO2

PSO4

PSO5

The Maharaja Sayajirao University of Baroda

Faculty Technology and Engineering

Department of Textile Engineering

Academic Year

2019-20

B.E. (Textile Technology): Regular Programme

Year

I

Core / Elective / Foundation

Textile Chemical Processing - I

TXC1203

Credits / Hours per week

04

Semester

II

Year of Introduction:2020

Year of Syllabus Revision: NA

Maximum Marks / Grade

100

Mode of

Transaction

Lectures

Course Outcome (CO) TXCXXXX

CO 1

Learning various pre-treatment processes for various textile fibres.

CO 2

Understanding the importance of the pre-treatment.

CO 3

Learning method of application of different pre-treatment.

CO 4

Understanding chemistry & mechanism of different pre-treatment.

CO 5

Understanding working principle of various machines used for pre-treatment.

CO 6

Learning basic concept of dyes and dyeing.

CO 7

Understanding theory and mechanism of dyeing.

CO 8

Learning method of application of various dyes on cellulosic, protein and man-made fibres.

CO 9

Understanding chemistry of dyeing of cellulosic, protein and man-made fibres.

CO10

Understanding various fastness properties of dyeing.

CO11

Learning various dyeing machines used for dyeing of textiles.

CO12

Understanding working principle of different dyeing machines.

Unit

No.

Topic/Unit

Contact

Hours

Weightage

(%)

BT

Level

CO

PSO

Elements of

Employability

(Emp)/

Entrepreneurship

(Ent)/ Skill

Development

(SD)

Relevance to

Local (L)/

National (N)/

Regional(R)/

Global (G)

developmental

needs

Relation to

Gender (G),

Environment

and

Sustainability

(ES), Human

Values (HV)

and

Professional

Ethics (PE)

1.

Brief introduction to various preparatory

processes like Singeing, Desizing, Scouring,

15

25

1,2,3,4,5

1,2,3,4

1,2,3,4,5,6,7,8

Emp, Ent, SD

L, N, R, G

G, ES, HV,

PE

Bleaching, Mercerising for various natural and

man-made fibers.

2.

Brief introduction to different machines involved

in pre-treatment processes of textiles

15

25

1,2,3,4,5

5

1,2,3,4,5,6,7,8

Emp, Ent, SD

L, N, R, G

G, ES, HV,

PE

3.

Classification of dyes.

Brief information on different classes of dyes and

their methods of application of cellulosic, protein

and synthetic fibers.

15

25

1,2,3,4,5

6,7,8,9

1,2,3,4,5,6,7,8

Emp, Ent, SD

L, N, R, G

G, ES, HV,

PE

4.

Basic fundamentals for the evaluation of colour

fastness of dyed materials towards various

agencies.

05

08

1,2,3,4,5

10

1,2,3,4,5,6,7,8

Emp, Ent, SD

L, N, R, G

G, ES, HV,

PE

5.

Brief description of various dyeing machines used

for dyeing cellulosic, protein and synthetic fibers.

10

17

1,2,3,4,5

11,12

1,2,3,4,5,6,7,8

Emp, Ent, SD

L, N, R, G

G, ES, HV,

PE

Reference Books

1.

V. A. Shenai: Technology of Bleaching (Vol – 3), Sevak Publication Mumbai.

2.

V. A. Shenai: Technology of Dyeing (Vol – 6), Sevak Publication Mumbai.

3.

F. Sadov: Chemical Technology of Fibrous Materials.

4.

E. R. Trotmann: Dyeing & Chemical Technology of Textile Fibers, Griffins, London

5.

S. R. Karmarkar: Chemical Technology in the pre-treatment processes of Textiles: Elservier Publication.

The Maharaja Sayajirao University of Baroda

Faculty Technology and Engineering

Department of Textile Engineering

Academic Year

2020-21

B. E. (Textile Technology): Regular Programme

Year

I Text

Techno

Core mechanical engineering

MEC :1207

Credits / Hours per week

Lectures: 04

Practical-: nill

Semester

II

Year of Introduction:

Year of Syllabus Revision: 2018

Maximum Marks / Grade

Theory: 100

PR/TW/VIVA:

Mode of Transaction: Lectures

Course Outcome (CO) MEC 1207

CO1 Understand basic laws of thermodynamics.

CO2 Understand basic of second law of thermodynamic and it's working analysis.

CO3 Understand basic of Reciprocating air compressor and it's analysis.

CO4 Understand basic of Internal combustion engine and it's analysis.

CO5 Understand basic of Gas producers.

CO6 Study of theory of machine principal with various mechanism.

CO7 Understand the power transmission drive and application.

Unit

No.

Topic

Conta

ct

Hours

Weightage

(%)

BT

Level

CO

PO

Elements

of

Employabil

ity (Emp)/

Entreprene

urship

(Ent)/ Skill

Developme

nt (SD)

Relevanc

e to Local

(L)/

National

(N)/

Regional(

R)/Global

(G)

Relation to

Gender (G),

Environment and

Sustainability

(ES), Human

Values (HV)and

Professional

Ethics (PE)

1

Theory of machines, kinematics of motion, graphical and

analytical methods of finding velocity and acceleration of

various links in mechanisms

10

25

1

Co6

Po2

All

All

All

2

. Belts, ropes, gears, flywheel and cams

15

25

1,3

Co7

Po2,3

3

. Heat engineering: Gas laws - air cycles, I.C. engines, steam

engine performances and maintenance, etc

15

25

3,5

Co

1,2,3

Po 3,5

4

Steam cycles. Boiler study with reference to working and

12

25

2,6

Co1,2,

Po4

maintenance.

3,4,5

52

100

Reference Books

1.

Mechanical design : R S Khurmi

2.

Thermal engineering : p k nag

3.

Rattan, S. S., ‘Theory of Machines’, Tata McGraw Hill

The Maharaja Sayajirao University of Baroda

Faculty Technology and Engineering

Department of Textile Engineering

Academic Year

2019-20

B.E (Textile Technology): Regular Programme

Year

I

Core / Elective / Foundation

AMT1203 Introduction to Computer and

Numerical Analysis

Credits / Hours per week

04

Semester

II

Year of Introduction:

Year of Syllabus Revision:

Maximum Marks / Grade

100

Mode of Transaction

Lectures

Course Outcome (CO)

CO1 Learn about the flowchart and design an algorithm for a given problem and to develop simple C – programs using operators.

CO2 Study about Conditional and Iterative statements which are available in C – language.

CO3 Learned about the importance and use of Arrays and Functions in C – language.

CO4 Learned about Strings, Pointers, Structures, Unions and Command Line Arguments.

CO5 Understand the concepts like File Handling in C-language.

CO6 Understanding of common numerical methods and how they are used to obtain an approximate solution the given problem.

CO7 To understand the concepts of interpolation with equal and unequal intervals.

CO8 To understand the concepts of numerical integral by various methods.

CO9 To solve algebraic, transcendental and system of linear equations by using various techniques.

CO10 To solve the ordinary differential equations with initial condition by numerical techniques.

CO11 Analyze and evaluate the accuracy of common numerical method.

CO12 Implementation of numerical schemes into C-Program.

Unit

No.

Topic

Contact

Hours

Weightage

(%)

BT

Level

CO

PSO

Element

s of

Employa

bility

(Emp)/

Entrepre

neurship

(Ent)/

Skill

Develop

ment

Relevan

ce to

Local

(L)/

National

(N)/

Regional

(R)/Glob

al (G)

Relation

to Gender

(G),

Environm

ent and

Sustainab

ility (ES),

Human

Values

(HV)and

Professio

(SD)

nal Ethics

(PE)

1

Programming tools and C preliminaries

Introduction, Algorithms, effective procedures in problem solving,

flowcharts, pseudo-code, Data types, constants, variables, type

specification statements, operators and expressions, library functions,

simple C programs

06

12%

1,2,5

CO1

PSO1,

PSO4,

PSO7

SD

G

PE

2

Control Structures in ‘C’

Importance and types of control structures, structured programming, if

– else, switch structure, go to, while, do – while, for continue and

break statement.

09

19%

1,2,3,5

CO2

PSO1,

PSO4,

PSO7

3

Advance Concepts in ‘C’

Arrays, Functions, Structure and pointers.

09

19%

1,2,3,5

CO3,

CO4,

CO5

PSO1,

PSO4,

PSO7

4

Interpolation and Numerical Integration

Finite differences: Backward, Forward, Central Differences

Newton’s Forward and Backward Interpolation formulae

Lagrange’s formula, Newton Divided difference Interpolation

formula.

Numerical Integration: Trapezoidal rule, Simpson’s 1/3

rd

rule,

Simpson’s 3/8

th

rule.

09

19%

1,2,3,4,5

CO6,

CO7,

CO8,

CO11,

CO12

PSO1,

PSO4,

PSO7

5

Solution of Algebraic and Transcendental Equations

Solution of equations of one variable: Bisection method. Regula –

falsi, Newton – Raphson method

Introduction to matrix algebra:

Rank of matrix, Consistency of system of equations, Solution of

system of linear equations, Gauss – elimination methods

Gauss – Seidel, Jacobi, LU Factorization method

09

19%

1,2,3,4,5

CO6,

CO9,

CO11,

CO12

PSO1,

PSO4,

PSO7

6

Numerical solution of Ordinary Differential Equations

Euler’s method, Modified Euler method, Runge – Kutta method,

Finite difference methods for ordinary differential equations.

Applications oriented examples related to Textile engineering / Textile

06

12%

1,2,3,4,5

CO6,

CO10,

CO11,

CO12

PSO1,

PSO4,

PSO7

Technology.

The Maharaja Sayajirao University of Baroda

Faculty Technology and Engineering

Department of Textile Engineering

Academic Year

2019-20

B.E (Textile Technology): Regular Programme

Year

I

Core / Elective / Foundation

AMT1203L- Introduction to Computer and Numerical Analysis

Credits / Hours per week

02

Semester

II

Year of Introduction:

Year of Syllabus Revision:

Maximum Marks / Grade

50

Mode of Transaction

Term Work, Practical and Viva

Course Outcome (CO)

CO1 Learn about the flowchart and design an algorithm for a given problem and to develop simple C – programs using operators.

CO2 Study about Conditional and Iterative statements which are available in C – language.

CO3 Learned about the importance and use of Arrays and Functions in C – language.

CO4 Learned about Strings, Pointers, Structures, Unions and Command Line Arguments.

CO5 Understand the concepts like File Handling in C-language.

CO6 Able to write C- program to find integration numerically.

CO7 Able to write C-program to find solution of algebraic, transcendental and system of linear equations.

CO8 Able to write C- program to solve ordinary differential equations with initial condition by numerical techniques.

No.

Experiment

Course

Code

BT

Level

CO

PSO

1

Programs on printf(),

AMT1203L

1,2,3,

5,6

CO1

PSO1,

PSO4,

PSO7

2

Programs on and scanf()

CO1

3

Programs on Conditional Statements like if, if- else, nested if-else.

CO2

4

Programs on Conditional Statements like switch-case, continue, break, go-to

.

CO2

5

Programs on Looping Statements like for-loop, while-loop and do-while loop.

CO2

6

Programs related to Arrays.

CO3

7

Programs related to Functions.

CO3

8

Programs on Character and Strings

CO4

9

Programs on Pointers and Structures

CO4

10

Programs on File Handling and Macros

CO5

11

Program to find Numerical Integration.

CO6

12

Programming on Solution of Algebraic and Transcendental functions.

CO7

13

Program to find the solution of system of linear equations.

CO7

14

Programming on Solution of Ordinary differential equations.

CO8

The Maharaja Sayajirao University of Baroda

Faculty Technology and Engineering

Department of Textile Engineering

Academic Year

2019-20

B.E. (Textile Technology): Regular Programme

Year

I

Core / Elective / Foundation

TXE 1203:

Principles of Textile Manufacturing

Credits / Hours per week

04 (theory)

Semester

II

Year of Introduction: 2020

Maximum Marks / Grade

100 (theory)

Mode of

Transaction

Lectures & Tutorials

Course Outcome (CO) TXE 1701

CO1 Understanding the basic textile concepts including processes and machinery.

CO2 Concept of fundamental spinning operations.

CO3 Learning different spinning technologies and systems.

CO4 Study of inter relationship between fibres and yarn properties.

CO5 Knowledge about garment manufacturing process

CO6 Understanding fabrics manufacturing techniques and concept of yarn preparation

CO7 Knowledge of post weaving processes

Unit

No.

Topic/Unit

Contact

Hours

Weightage

(%)

BT

Level

CO

PSO

Elements of

Employability

(Emp)/

Entrepreneurship

(Ent)/ Skill

Development

(SD)

Relevance to Local

(L)/ National (N)/

Regional(R)/Global

(G)

developmental

needs

Relation to

Gender (G),

Environment

and

Sustainability

(ES), Human

Values

(HV)and

Professional

Ethics (PE)

1

Introduction to basics of textile, Classification of textile

fibres and properties of fibres, Yarn classification and

functional properties, Passage of material and flow chart

of different machines used in spinning.

06

15%

1,2

CO1

PSO1

EMP, SD

R,N,G

ES

2

Fundamental spinning operations;

Essential: 1) Opening, cleaning and mixing, 2) Sliver

06

15%

1,2,3

CO2

formation, 3) Attenuation, 4) Twisting, 5) Package

formation, Optional: 1) Combing, 2) Doubling

3

Yarn numbering system. Concept of spinnability,

Concept of blending and its significance, Different

spinning technologies. Impurities and cleaning of natural

fibres. Types of spinning systems. Yarn properties and

it’s inter relationship with fibre properties.

08

20%

2, 3,4

CO2,

CO3,

CO4

4

Introduction to Garment manufacturing process.

Different types of fabrics and their properties.

06

15%

1,2

CO5

5

Introduction to different types of fabric manufacturing

method.

08

20%

1,2,3

CO6

6

Different types of yarn preparation process and their

importance. Introduction to different types of chemical

process.

06

15%

1,2,3

CO6,

CO7

Reference Books:

1.

Fibre to Fabric by Bernard P. Corbman, published by McGraw-Hill, 1983.

2.

Weaving: Conversion of Yarn to Fabric by Peter Reeves Lord, Mansour H. Mohamed, published by Woodhead Publishing, 1982.

3.

Introduction to Textile Fibres by H V Sreenivasa Murthy, published by The textile association India, 1987

4.

Textile Yarns by B. C. Goswami, published by Wiley, 1977.

5.

Spun yarn technology by Eric Oxtoby, published by Elsevier Science, 2013.

6.

Motivation series Textiles by Andrea Wynne, published by Macmillan Education, 1997.

7.

Principles of textile testing by J. E. Booth, published by CBS publishers and distributors, 1996

8.

General Technology of cotton manufacturing by P. T. Bukayev, published by MIR Publishers, 1984.

The Maharaja Sayajirao University of Baroda

Faculty Technology and Engineering

Department of Textile Engineering

Academic Year

2019-20

B.E.(Textile Technology) Regular Programme

Year

I

Core / Elective / Foundation

TXE 1203L: Principles of Textile Manufacturing (Practical/TW/Viva)

Credits / Hours per week

02

Semester

II

Year of Introduction: 2020

Maximum Marks / Grade

50

Mode of

Transaction

Laboratory Experiments, discussion, drawing, term work and viva

No.

Experiment

Contact

hrs.

%Weightage

BT

Level

CO

PSO

1

Introduction to spinning. Outline of spinning laboratory. Collection of different fibre samples

2

8.33%

1,2

CO1

PSO1

2

Passage of material through Blow room and Card with flowcharts. Study of different beaters of Blow

room

2

8.33%

1,2,3,4

CO2

3

Passage of material through Draw frame and Speed frame with flowcharts

2

8.33%

1,2,3,4

CO2

4

Passage of material through lap former and Comber with flowcharts

2

8.33%

1,2,3,4

CO2

5