232

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

233

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

Transformers

5

Transformers

5.1 Introduction 234

5.1.1 Overview 234

5.2 Reliability and Project Performance 236

5.3 Transformer Loss Evaluation 238

5.4 Power Transformers 240

5.4.1 Large Power Transformers 240

5.4.2 Medium Power Transformers 241

5.4.3 Small Power Transformers 241

5.5 Reactors 242

5.6 Special Transformers

for Industrial Applications 243

5.7 Phase-Shifting Transformers 245

5.8 HVDC Transformers 246

5.9 Distribution Transformers 247

5.9.1 Liquid-immersed Distribution Transformers

for European/US/Canadian Standard 247

5.9.2 Voltage Regulators 248

5.9.3 GEAFOL Cast-Resin Transformers 249

5.9.4 GEAFOL Special Transformers 254

5.10 Traction Transformers 256

5.11 Transformer Lifecycle Management 257

234

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

5 Transformers

5.1 Introduction

5.1.1 Overview

Whether in infrastructure systems, industry or households,

transformers always play a key role in the reliable transmission

and distribution of power. The construction, rated power,

voltage level and scope of the application are all key factors that

determine the transformer’s design.

Siemens provides the right transformer for every need – from

compact distribution transformers to large power transformers

with ratings far above 1,000 MVA. The Siemens product range

covers all mainstream requirements like UHV DC applications,

low noise emission and environmentally friendly products with

alternative insulation liquids, also embedded in a complete

power system from generation via transmission to distribution

networks. The long-term reliability of a transformer begins with

its initial high quality. Then transformer lifecycle management

measures maintain that quality throughout the transformer’s

entire life.

Fig. 5.1-1 and table 5.1-1 are an overview of how various trans-

formers can be used in a network.

Global Footprint

Emerging countries are not just “extended workbenches” for

producing goods. First and foremost, they are important future

markets. Through its own local production and sales locations,

Siemens provides service to customers in the most important

global markets. The local presence of Siemens in many coun-

tries also ensures that customers have better access to Siemens

services and that they benefit from an efficient and effective

distribution of Siemens resources as part of a global network.

As Siemens factories around the world develop and produce

their products, Siemens also encourages them to share their

expertise.

Siemens meets the growing global demand for transformers in

a variety of ways: by further optimization of value-added steps

in the worldwide network, by use of approaches such as vertical

integration and by the pursuit of programs for boosting produc-

tivity.

For further information:

www.siemens.com/energy/transformers

235

Transformers

5.1 Introduction

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

Fig. 5.1-1: Product range of Siemens transformers

Table 5.1-1: Product range of Siemens transformers

Generator and System

Transformers

Above 2.5 MVA up to more than 1,000 MVA, above 30 kV up to 1,500 kV (system and system

interconnecting transformers, with separate windings or auto-connected), with on-load tap

changers or off-circuit tap changers, of 3-phase or 1-phase design

Phase Shifters

To control the amount of active power by changing the effective phase displacement

Reactors

Liquid-immersed shunt and current-limiting reactors up to the highest rated powers

Reactors for HVDC transmission systems

HVDC Transformers

Transformers and smoothing reactors for bulk power transmission systems up to 800 kV DC

Transformers for DC coupling of different AC networks

Cast-Resin Distribution and

Power Transformers GEAFOL

100 kVA to more than 40 MVA, highest voltage for equipment up to 36 kV, of 3-phase or 1-phase

design, GEAFOL-SL substations

Liquid-immersed Distribution

Transformers

50 to 2,500 kVA, highest voltage for equipment up to 36 kV, with copper or aluminum windings,

hermetically sealed or with conservator of 3- or 1-phase design

pole mounted transformers and distribution transformers acc. to IEC with amorphous cores

Special Transformers for

Industry

Electric arc furnace transformers

Electric arc furnace series reactors

DC electric arc furnace transformers

Rectifier transformers

Converter transformers for large drives

Traction Transformers

Traction transformers mounted on rolling stock

Transformer Lifecycle

Management

Condition assessment & diagnostics

Online monitoring

Consulting & expertise

Maintenance & lifecycle extension

Spare parts & accessories

Repair & retrofit

Transport, installation & comissioning

236

Transformers

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

5.2 Reliability and Project

Performance

The quality strategy in the transformer business is based on the

three cornerstones of product, people and process quality

(fig. 5.2-1). The objective is to achieve the greatest customer

satisfaction with cost-efficient processes. This is only possible if

all employees are involved in the processes have a profound

understanding of the customer needs and specific requirements

in the transformer business.

The strategy is implemented in the form of mandatory elements.

These elements cover product and service quality, which is visible

to customers; personnel quality, which is achieved by training

and ongoing education; and process quality in all processes used.

Business and process-specific indicators must be used to ensure

that each single element is measurable and transparent.

Nine mandatory elements are defined:

tȋ Customer integration

tȋ Embedded quality in processes and projects

tȋ Consequent supplier management

tȋ Business-driven quality planning

tȋ Focused quality reporting

tȋ Qualification of employees on quality issues

tȋ Continuous improvement

tȋ Management commitment

tȋ Control and support role of quality manager

Elements of quality (mandatory elements)

Customer integration

Customer integration depends on the consistent use of:

tȋ Analysis tools for customer requirements and market studies

tȋ Analysis of customer satisfaction

tȋ Professional management of feedback from and to the

customer

tȋ Complaint management

Customer requirements need to be precisely defined in a specifi-

cation. And the specification must be continuously updated

throughout the definition phase of a transformer project. The

actual requirements must also be available to all responsible

employees.

Rapid feedback loops – in both directions – are essential in order

to increase customer trust and satisfaction.

Siemens resolves customer complaints to the customer’s satis-

faction in a timely manner through its complaint management

system.

Embedded quality in processes and projects

The quality of the processes used to produce a product has a

significant impact on the quality of the product that is actually

produced. Process discipline and process stability can be

Product/Service

quality

Process

quality

Greatest possible

customer

satisfaction …

... combined with

efficient processes

results in the best

cost position

Personnel

quality

Quality

strategy

... and best trained

and motivated employees …

Fig. 5.2-1: Cornerstones of quality strategy

achieved by a high degree of process standardization. All pro-

cesses should be standardized for all employees based on simple

procedures. If this condition is met, it is possible to implement

clearly defined work instructions (fig. 5.2-2).

Quality gates are placed at points in the process at which

quality-relevant decisions are necessary. The following quality

gates are mandatory for the power transformer business.

tȋ Bid approval

tȋ Entry order clarified

tȋ Release of design

tȋ Release of fully assembled transformer

tȋ Evaluation of project

For each quality gate, there is a clear definition of participants,

preconditions, results (traffic light) and the escalation process, if

necessary. If the result is not acceptable, the process must be

stopped until all requirements are fulfilled.

Supplier management

The quality of the product depends not only on the quality of the

own processes but also on that of the suppliers. Problems and

costs caused by inadequate supplier quality can only be reduced

by a systematic supplier management process that includes:

tȋ Selection

tȋ Assessment

tȋ Classification

tȋ Development

tȋ Phasing out of suppliers as well as the support process Supplier

Qualification

237

Transformers

5.2 Reliability and Project Perfomance

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

A further condition for a high level of supplier quality is close

cooperation with the suppliers. Joint development of require-

ments for suppliers and processes leads to continuous improve-

ments in quality. In this context, supplier know-how can also be

used to create innovations. This aspect of the relationship with

suppliers is becoming more and more important, especially in

the transformer business.

Business-driven quality planning

Planning quality means analyzing possible future scenarios and

anticipated problems and taking preventive steps to solve those

problems. It is crucial that both current and future critical busi-

ness factors are considered in planning. That means that quality

is based on business-driven planning and specific objectives,

activities and quantitative indicators.

Focused quality reporting

Reporting is based on:

tȋ Focused key performance indicators such as non-conformance

costs, external failure rate, internal failure rate and on-time

delivery

tȋ Concrete quality incidents

tȋ Root cause analysis of quality problems including definition of

corrective and preventive measures

For customers, the reliability of transformers is of special impor-

tance. ANSI C57.117 has made an attempt to define failures.

Based on this definition, statistics on in-service failures and

reliability values can be derived. An example for power trans-

formers appears in table 5.2-1.

Qualification of employees on quality issues

People are the decisive factor influencing quality. Therefore, all

employees involved in the processes must have the skills and

abilities appropriate to the quality aspects of the process steps

they perform. Any qualification measures that may be necessary

must be determined on the basis of a careful analysis of existing

deficits.

TPD

2.01.02

Page 1/6 Page 1/6

Core assembly – stacking core

laminates

SIEMENS

PEQ

Drawn up by: Matthes Checked/approved: Dr. Knorr As of date: 2004-02

The passing on as well as the duplication of this document. use and communication of its contents is not permitted. nor may the contents be expressed. Offenders are liable to pay damages. All rights

reserved. in particular for the case of patent granting or GM-entry

1. Purpose/objective

Process description for the manufacture of transformer core

within the tolerances which are laid down

2. Scope/application

applies to all the core forms of the power transformers

does not apply to the cores of compensating reactors

3. Process overview/description

Stack of core laminations – dimensions checked by the supplier to

ensure that they agree with the drawing

Frame parts – dimensions checked by the supplier to ensure that they

agree with the drawing

Insulating parts – dimensions checked by the supplier (internal ore

external )to ensure that they agree with the drawing

washers, small accessories Job – related core drawings

Process report TPD 2.01.01

INPUTINPUT

Stacking

core

laminates

Tools

Assembly area with special support beams for fixing the core

laminations which have been put on into position

Integrated slewing mechanism for mounting the finished core

Process owner

Staff trained in core assembly

Completed core with clamping frame also completely mounted

Process report TPD 2.01.02

References/guidelines, recommendations

Stack height tolerances as in drawing N00 08 792

Arrangement of the cooling duct shims as in drawing N10 11 100

Locking the screwed connections in accordance with TPD 3.036.01

Measurement of insulation resistance with TUQ 1634

OUTPUT

TPD

2.01.02

Core assembly–stacking core

laminates

SIEMENS

PEQ

Drawn up by: Matthes Checked/approved: Dr. Knorr As of date: 2004-02

The passing on as well as the duplication of this document. use and communication of its contents is not permitted. nor may the contents be expressed. Offenders are liable to pay damages. All rights

reserved. in particular for the case of patent granting or GM-entry

Adjusting

the support

trestles

Adjusting

the support

trestles

> Setting the clearance of the support

trestles (on the support beams) for

the core-limb laminations

> The position of support trestles are to be

placed in the middle between the single

bandages

> The position and clearance of the

bandages are defined in the core

drawing

2501,200 to 1,500

3001,000 to 1,200

350800 to 1,000

450650 to 800

550< 650

Middle distance

support trestles

Max. sheet width

B

S

4. Process sequence

> Setting the middle distance of the support beams to one

another in accordance with the drawing guideline

> Tolerance +/–5 mm to the desired size

Subprocess 1:

Setting up the construction devices and limit stops

Adjusting the

construction

supports

The following clearances

apply to cores without

single bandages (e.g.

wound bandage cylinders)

:

Measure -

ment

Measure-

ment

Clearance support trestles

Measure -

ment

Measure-

ment

Fig. 5.2-2: Example of standardized working instruction

Table 5.2-1: In-service failure statistic

E T TR In-Service Failure Statistic 2000 – 2009 for Power Transformers

based on ANSI C 57.117

E T TR Plant

1

Plant

2

Plant

3

Plant

4

Plant

5

Plant

6

Plant

7*

Plant

8

Plant

9

Plant

10

Plant

11

Plant

12

Plant

13*

Plant

14**

Plant

15

N 11,278 572 1,704 755 793 774 534 – 735 1,076 705 649 994 – 1007 980

SY 51,429 2,358 7,479 3,858 3 4,326 1,996 – 3,341 4,561 4,17 2,889 4,899 – 3,781 4,771

n

F

91 9 7 10 11 1 11 – 3 6 2 7 8 – 3 13

FRe (%) 0.18 0.38 0.09 0.26 0.37 0.02 0.55 – 0.09 0.13 0.05 0.24 0.16 – 0.08 0.27

MTBF (yrs) 565 262 1068 386 273 4,326 181 – 1,114 760 2,085 413 612 – 1,26 367

* Plant 7 & 13: new plants; ** Plant 14: 9 years 2001 – 2009

N = No. of units in service

SY = No. of service years

n

F

= No. of units failed

FRe (%) = Failure rate = n

F

×

100/SY

MTBF (yrs) = Mean time between failures = 100/FRe

FRe ≤ 0.5 % excellent

0.5 % < FRe ≤ 1.0 % good

1.0 % < FRe ≤ 1.5 % satisfactory

1.5 % < FRe ≤ 2.0 % acceptable

FRe > 2.0 % not acceptable

Continuous improvement

Because “there is nothing that cannot be improved”, continuous

improvement must be an integral part in all processes.

The objective is to continue optimizing each process step. This is

also the purpose of improvement teams. Appropriate coaching

of these teams should make it possible to reach almost all

employees.

238

Transformers

5.2 Reliability and Project Perfomance

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

Methods like, Kaizen, 5S and methods and tools from Six Sigma

e.g. DMAIC circle, FMEA, IPO are helpful in supporting this

continuous improvement process (fi g. 5.2-3).

Management commitment

Every manager in a company also bears responsibility for quality.

Thus, each manager’s actions must be characterized by a high

level of quality awareness.

The level of commitment shown by all levels of management in

the event of quality problems, the establishment of quality

demands and the creation of targeted quality controls in day-to-

day work together produce a culture in which there is a high

level of quality.

Control and support role of the quality manager

The role of the quality manager is of fundamental importance

for well-running processes. The quality manager combines a

supporting role with that of a neutral controller. Quality man-

agement must be directly involved in processes and projects.

The independence of the quality department and individual

quality managers in the processes and projects must be guaran-

teed and agreed by top management.

Conclusion

The quality of a transformer is based on the quality of all pro-

cesses that are necessary – from project acquisition to project

closing. The quality of the processes depends essentially on

people. Only well-trained and motivated employees are able to

guarantee that a process will be performed with a high degree

of quality.

NCC

140

120

100

DpMO

PONC x 1000 RMB

NCC

0

1000

2000

3000

4000

5000

6000

7000

DpMO

Check

Define

Measure

Analyze

Improve

DMAIC

circle

Our process

should be like this

How far are we

from the goal

What is preventing

us to fulfill the

requirements

What must be done

in order to achieve

the goal

Are we

improving?

Fig. 5.2-3: DMAIC circle

ANSI Standard C57.117, 1986,

Guide for Reporting Failure Data for Power Transformers

and Shunt Reactors on Electric Utility Power Systems.

5.3 Transformer Loss

Evaluation

The sharply increased cost of electrical energy has made it

almost mandatory for buyers of electrical machinery to carefully

evaluate the inherent losses of these items. For distribution and

power transformers, which operate continuously and most

frequently in loaded condition, this consideration is especially

important. As an example, the added cost of loss-optimized

transformers can in most cases be recovered via savings in

energy use in less than three years.

Low-loss transformers use more and better materials for their

construction and are thus intially more expensive than low-cost

transformers. By stipulating loss evaluation fi gures in the trans-

former inquiry, the manufacturer receives the necessary incen-

tive to provide a loss-optimized transformer rather than the

low-cost model. Detailed loss evaluation methods for trans-

formers have been developed and are described accurately in

the literature. These methods take the project-specifi c evalua-

tion factors of a given customer into account.

A simplifi ed method for a quick evaluation of different quoted

transformer losses makes the following assumptions:

tȋ The transformers are operated continuously.

tȋ The transformers operate at partial load, but this partial load is

constant.

tȋ Additional cost and infl ation factors are not considered.

tȋ Demand charges are based on 100 % load.

The total cost of owning and operating a transformer for one

year is thus defi ned as follows:

tȋ Capital cost (C

C

), taking into account the purchase price (C

p

),

the interest rate (p) and the depreciation period (n)

tȋ Cost of no-load loss (C

P0

) based on the no-load loss (P

0

) and

energy cost (C

e

)

tȋ Cost of load loss (C

Pk

) based on the load loss (P

k

), the

equivalent annual load factor (a) and energy cost (C

e

)

tȋ Cost resulting from demand charges (C

d

) based on the amount

set by the utility and the total kW of connected load (fi g. 5.3-1)

The following examples show the difference between a low-cost

transformer and a loss-optimized transformer (fi g. 5.3-2).

Note that the lowest purchase price is unlike the total cost of

ownership.

239

Transformers

5.3 Transformer Loss Evaluation

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

A. Low-cost transformer

B. Loss-optimized transformer

Depreciation period

Interest rate

Energy charge

Demand charge

Equivalent annual load factor

n

p

C

e

C

d

_

= 20 years

= 12 % p.

a.

= 0.25 €

/ kWh

= 350 €

/ (kW

.

year)

= 0.8

P

0

= 19 kW

P

k

= 167 kW

C

p

= € 521, 000

P

0

= 16 kW

P

k

= 124 kW

C

p

= € 585, 000

no-load loss

load loss

purchase price

no-load loss

load loss

purchase price

C

c

521, 000

.

13.39

100

€ 69, 762 / year

C

P0

0.2

.

8,760

.

19

€ 33,

288 / year

=

=

=

=

C

Pk

0.2

.

8,760

.

0.64

.

167

€ 187,

254 / year

=

=

C

D

350 · (19 + 167)

€ 65,100

/ year

=

=

Total cost of owning and

operating this transformer

is thus:

€ 355,

404 / year

C

c

585, 000

.

13.39

100

€ 78, 332 / year

C

P0

0.2 · 8,760 · 16

€ 28,

032 / year

=

=

=

=

C

Pk

0.2 · 8,760 · 0.64 · 124

€ 139,

039 / year

=

=

C

D

350 · (16 + 124)

€ 49,

000 / year

=

=

Total cost of owning and

operating this transformer

is thus:

€ 294,

403 / year

The energy saving of the optimized distribution transformer of

€ 61,

001 per year pays for the increased purchase price in less

than one year.

Example: Distribution transformer

Depreciation

factor r = 13.39

Fig. 5.3-2: Example for cost saving with optimized distribution

transformer

Capital cost

taking into account the purchase price C

p

, the interest rate p,

and the depreciation period n

C

c

=C

p

· r

/

100 [amount

/

year]

C

p

= purchase price

= p

.

q

n

/

(q

n

–1)r = depreciation factor

q = p

/

100 + 1 = interest factor

= interest rate in % p.ap

n = depreciation period in years

C

P0

=C

e

· 8,760 h

/

year

.

P

0

= energy charges [amount

/

kWh]

C

Cost of no-load loss

based on the no-load loss P

0

, and energy cost C

e

C

e

P

0

= no-load loss [kW]

C

D

=C

d

(P

0

+ P

k

)

Cost resulting from demand charges

based on the no-load loss P

0

, and energy cost C

e

C

d

Pk

=C

e

· 8,760 h

/

year a

2

P

k

Cost of load loss

based on the load loss P

k

, the equivalent anual load factor a,

and energy cost C

e

a = constant opperation load

/

rated load

P

k

= copper loss [kW]

= demand charges [amount

/

(kW

.

year)]

Fig. 5.3-1: Calculation of the individual operation cost of a

transformer in one year

240

Transformers

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

5.4 Power Transformers

5.4.1 Large Power Transformers

In the power range above 250 MVA, generator and network

intertie transformers with off-load or on-load tap changers, or a

combination of both, are recommended. Depending on the on-site

requirements, they can be designed as multiwinding transformers

or autotransformers, in 3-phase or 1-phase versions. Even with

ratings of more than 1,000 MVA and voltages up to 1,200 kV

(800 kV), the feasibility limits have not yet been reached. We

manufacture these units according to IEC 60076 as well as other

international and national standards (e.g., ANSI/IEEE), (fig. 5.4-1).

Generator step-up (GSU) transformers

GSU units transform the voltage up from the generator voltage

level to the transmission voltage level, which may be as high as

1,200 kV system voltage. Such transformers are usually YNd-con-

nected.

In order to make an inquiry regarding a GSU power transformer,

the technical data for the items in this section are required.

Step-down transformers

Step-down transformers transform the voltage down from the

transmission voltage level to an appropriate distribution voltage

level. The power rating of step-down transformers may range up

to the power rating of the transmission line.

Fig. 5.4-1: Large power transformer

System interconnecting transformers

System interconnecting transformers connect transmission

systems with different voltages together so that active as well as

reactive power can be exchanged between the systems.

Main specification data

tȋ Standard

tȋ Installation – indoor/outdoor

tȋ Max. ambient air temperature

tȋ Rated frequency f

tȋ Vector group

tȋ Rated power S

tȋ Primary rated voltage U

rHV

tȋ Tapping range/taps

tȋ Voltage regulation

tȋ Secondary rated voltage U

rLV

tȋ Impedance u

k

at S

r

and U

r

tȋ Max. sound power level L

WA

tȋ Insulation level HV-Ph – U

m

/AC/LI

tȋ Insulation level HV-N – U

m

/AC/LI

tȋ Insulation level LV-Ph – U

m

/AC/LI

tȋ Type of cooling

tȋ HV connection technique

tȋ LV connection technique

tȋ Transportation medium

tȋ Losses

241

Transformers

5.4 Power Transformers

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

5.4.2 Medium Power Transformers

Medium power transformers with a power range from 30 to

250 MVA and a voltage of over 72.5 kV are used as network and

generator step-up transformers (fig. 5.4-2).

Specific items

tȋ Transformer design according to national and international

standards (IEC/ANSI) with or without voltage regulation

tȋ 3-phase or 1-phase

tȋ Tank-attached radiators or separate radiator banks

Main specification data

tȋ Number of systems (HV, LV, TV)

tȋ Voltage and MVA rating

tȋ Regulation range and type

tȋ Vector group

tȋ Frequency

tȋ Losses or capitalization

tȋ Impedances

tȋ Type of cooling

tȋ Connection systems (bushing, cable)

tȋ Noise requirements (no-load, load and/or total noise)

tȋ Special insulation fluid

tȋ Application of high temperature/extra small size operation

5.4.3 Small Power Transformers

Small power transformers are distribution transformers from 5 to

30 MVA with a maximum service voltage of 145 kV. They are used

as network transformers in distribution networks (fig. 5.4-3).

This type of transformer is normally a 3-phase application and

designed according to national and international standards. The

low-voltage windings should be designed as foil or layer wind-

ings. The high-voltage windings should use layer or disc execu-

tion, including transposed conductors. Normally, the cooling

type is ONAN (oil-natural, air-natural) or ONAF (oil-natural,

air-forced). The tapping can be designed with off-circuit or

on-load tap changers (OCTC or OLTC).

Main specification data

tȋ Voltage and MVA rating

tȋ Frequency

tȋ Regulation range and type

tȋ Vector group

tȋ Losses or capitalization

tȋ Impedances

tȋ Noise requirements

tȋ Connection systems (bushing, cable)

tȋ Weight limits

tȋ Dimensions

tȋ Information about the place of installation

tȋ Special insulation fluid

tȋ Application of high temperature/extra small size operation

tȋ Type of cooling

Fig. 5.4-2: Medium power transformer with natural oil based

insulation fluid

Fig. 5.4-3: Small power transformer

242

Transformers

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

5.5 Reactors

In AC networks, shunt reactors and series reactors are widely

used in the system to limit the overvoltage or to limit the short-

circuit current. With more high-voltage overhead lines with long

transmission distance and increasing network capacity, both

types of reactors play an important role in the modern network

system.

Made for every requirements

Oil filled reactors are manufactured in two versions:

tȋ With an iron core divided by air gaps

tȋ Without an iron core, with a magnetic return circuit

Oil filled reactors offer individual solutions: They satisfy all the

specified requirements regarding voltage, rating, type of opera-

tion, low-noise and low loss and type of cooling, as well as trans-

portation and installation.

The windings, insulation tank monitoring devices and connec-

tion method are practically the same as those found in the

construction of transformers.

Shunt reactors

For extra-high-voltage (EHV) transmission lines, due to the long

distance, the space between the overhead line and the ground

naturally forms a capacitor parallel to the transmission line,

which causes an increase of voltage along the distance.

Depending on the distance, the profile of the line and the power

being transmitted, a shunt reactor is necessary either at the line

terminals or in the middle. An liquid-immersed shunt reactor is a

solution. The advanced design and production technology will

ensure the product has low loss and low noise level.

Shunt reactors also can be built as adjustable shunt reactors.

This offers the possibility in fine tuning the system voltage and

also the reduction of high voltage equipment by substitution of

several unregulated reactors by a regulated one.

Series reactors

When the network becomes larger, sometimes the short-circuit

current on a transmission line will exceed the short-circuit

current rating of the equipment. Upgrading of system voltage,

upgrading of equipment rating or employing high-impedance

transformers are far more expensive than installing liquid-

immersed series reactors in the line. The liquid-immersed design

can also significantly save space in the substation.

Specification

Typically, 3-phase or 1-phase reactors should be considered first.

Apart from the insulation level of the reactor, the vector group,

overall loss level, noise level and temperature rise should be

considered as main data for the shunt reactor.

Although the above data are also necessary for series reactors,

the rated current, impedance and thermal/dynamic stability

current should also be specified.

Fig. 5.5-1: Reactor

5

Transformers

243

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5.6 Special Transformers for

Industrial Applications

A number of industry applications require specific industrial

transformers due to the usage of power (current) as a major

resource for production. Electric arc furnaces (EAF), ladle fur-

naces (LF) and high-current rectifiers need a specific design to

supply the necessary power at a low voltage level. These trans-

former types, as well as transformers with direct connection to a

rectifier are called special-purpose or industrial transformers,

whose design is tailor-made for high-current solutions for

industry applications.

Electric arc furnace transformers

EAF and LF transformers are required for many different furnace

processes and applications. They are built for steel furnaces,

ladle furnaces and ferroalloy furnaces, and are similar to short or

submerged arc furnace transformers (fig. 5.6-1).

EAF transformers operate under very severe conditions with

regard to frequent overcurrents and overvoltages generated by

short-circuit in the furnace and the operation of the HV circuit-

breaker. The loading is cyclic. For long-arc steel furnace opera-

tion, additional series reactance is normally required to stabilize

the arc and optimize the operation of the furnace application

process.

Specific items

EAF transformers are rigidly designed to withstand repeated

short-circuit conditions and high thermal stress, and to be

protected against operational overvoltages resulting from the

arc processes. The Siemens EAF reactors are built as 3-phase

type with an iron core, with or without magnetic return circuits.

Design options

tȋ Direct or indirect regulation

tȋ On-load or no-load tap changer (OLTC/NLTC)

tȋ Built-in reactor for long arc stability

tȋ Secondary bushing arrangements and designs

tȋ Air or water-cooled

tȋ Internal secondary phase closure (internal delta)

Main specification data

tȋ Rated power, frequency and rated voltage

tȋ Regulation range and maximum secondary current

tȋ Impedance and vector group

tȋ Type of cooling and temperature of the cooling medium

tȋ Series reactor and regulation range and type (OLTC/NLTC)

DC electric arc furnace transformers

Direct-current electric arc furnace (DC EAF) transformers are

required for many different furnace processes and applications.

They are built for steel furnaces with a Thyristor rectifier. DC EAF

transformers operate under very severe conditions, like rectifier

transformers in general but using rectifier transformers for

furnace operation. The loading is cyclic.

Fig. 5.6-1: Electric arc furnace transformer

5.6 Special Transformers for Industrial Applications

5

Transformers

244

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

Rectifier transformers

Rectifier transformers are combined with a diode or Thyristor

rectifier. The applications range from very large aluminum

electrolysis to various medium-size operations. The transformers

may have a built-in or a separate voltage regulation unit. Due to

a large variety of applications, they can have various designs up

to a combination of voltage regulation, rectifier transformers in

double-stack configuration, phase-shifting, interphase reactors,

transductors and filter-winding (fig. 5.6-2).

Specific items

Thyristor rectifiers require voltage regulation with a no-load tap

changer, if any. A diode rectifier will, in comparison, have a

longer range and a higher number of small voltage steps than an

on-load tap changer. Additionally, an auto-connected regulating

transformer can be built in the same tank (depending on trans-

port and site limitations).

Design options

tȋ Thyristor or diode rectifier

tȋ On-load or no-load tap changer (OLTC/NLTC)/filter winding

tȋ Numerous different vector groups and phase shifts possible

tȋ Interphase reactor, transductors

tȋ Secondary bushing arrangements and designs

tȋ Air or water-cooled

Main specification data

tȋ Rated power, frequency and rated voltage

tȋ Regulation range and number of steps

tȋ Impedance and vector group, shift angle

tȋ Type of cooling and temperature of the cooling medium

tȋ Bridge or interphase connection

tȋ Number of pulses of the transformer and system

tȋ Harmonics spectrum or control angle of the rectifier

tȋ Secondary bushing arrangement

Converter transformers

Converter transformers are used for large drive application, static

voltage compensation (SVC) and static frequency change (SFC).

Specific items

Converter transformers are mostly built as double-tier, with two

secondary windings, allowing a 12-pulse rectifier operation.

Such transformers normally have an additional winding as a

filter to take out harmonics. Different vector groups and phase

shifts are possible.

Main specification data

tȋ Rated power, frequency and rated voltage

tȋ Impedance and vector group, shift angle

tȋ Type of cooling and temperature of the cooling medium

tȋ Number of pulses of the transformer and system

tȋ Harmonics spectrum or control angle of the rectifier

Line Feeder

This kind of transformer realizes the connection between the

power network and the power supply for the train. Transformer

is operating in specific critical short circuit condition and over-

load condition in very high frequencies per year, higher reli-

ability is required to secure the train running in safety.

Main specification data

tȋ Rated power, frequency and rated voltage

tȋ Impedance and vector group

tȋ Overload conditions

tȋ Type of cooling and temperature of the cooling medium

tȋ Harmonics spectrum or control angle of the rectifier

Design options

tȋ Direct connection between transmission network and railway

overheadcontactline

tȋ Frequence change via DC transformation

(e.g. 50 Hz – 16,67 Hz)

tȋ Thyristor or diode rectifier

tȋ On-load or no-load tap changer (OLTC/NLTC)/filter winding

tȋ Secondary bushing arrangements and designs

tȋ Air or water-cooled

Fig. 5.6-2: Rectifier transformer for an aluminum plant

245

Transformers

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

5.7 Phase-Shifting

Transformers

A phase-shifting transformer is a device for controlling the

power flow through specific lines in a complex power transmis-

sion network.The basic function of a phase-shifting transformer

is to change the effective phase displacement between the input

voltage and the output voltage of a transmission line, thus

controlling the amount of active power that can flow in the line.

Guidance on necessary information

Beside the general information for transformers, the following

specific data are of interest (fig. 5.7-1):

tȋ Rated MVA

The apparent power at rated voltage for which the phase-

shifting transformer is designed.

tȋ Rated voltage

The phase-to-phase voltage to which operating and

performance characteristics are referred to – at no-load.

tȋ Rated phase angle

Phase angle achieved when the phase-shifting transformer

is operated under no-load condition, or if stated at full load, at

which power factor.

tȋ Phase shift direction

In one or both directions. Changeover from and to under load

or no-load condition.

tȋ Tap positions

Minimum and/or maximum number of tap positions.

tȋ Impedance

Rated impedance at rated voltage, rated MVA and zero phase

shift connection as well as permissible change in impedance

with voltage and phase angle regulation.

tȋ System short-circuit capability

When the system short-circuit level is critical to the design of

phase-shifting transformers, the maximum short-circuit fault

level shall be specified.

tȋ BIL

Basic impulse level (BIL) of source, load and neutral terminals.

tȋ Special design tests

Besides the standard lightning impulse tests at all terminals, it

has to be considered that the lightning impulse might occur

simultaneously at the source and the load terminal in case of

closed bypass breaker. If such a condition is likely to appear

during normal operation, a BIL test with source and load

terminals connected might be useful to ensure that the phase-

shifting transformer can withstand the stresses of lightning

strokes in this situation.

tȋ Special overload condition

The required overload condition and the kind of operation

(advance or retard phase angle) should be clearly stated.

Especially for the retard phase angle operation, the overload

requirements may greatly influence the cost of the phase-

shifting transformer.

tȋ Operation of phase-shifting transformer

Operation with other phase-shifting transformers in parallel or

series.

tȋ Single or dual-tank design

In most cases, a dual-core design requires a dual-tank design

as well.

tȋ Symmetric or non-symmetric type

Symmetric means that under a no-load condition the voltage

magnitude at the load side is equal to that of the source side.

For non-symmetric phase-shifting transformers, the

permissible variation in percent of rated voltage at maximum

phase angle must be stated.

tȋ Quadrature or non-quadrature type

A quadrature-type phase-shifting transformer is a unit where

the boost voltage, which creates the phase shift between

source and load terminals, is perpendicular to the line voltage

on one terminal.

tȋ Internal varistors

It has to be clarified whether internal metal oxide varistors are

allowed or not.

Fig. 5.7-1: Phase-shifting transformer

246

Transformers

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

5.8 HVDC Transformers

HVDC transformers are key components of HVDC stations. HVDC

converter and inverter stations terminate long-distance DC

transmission lines or DC sea cables. This type of transformer

provides the interface between AC grids and high power recti-

fiers and are used to control the load flow over the DC transmis-

sion lines. These actors adapt the AC grid voltage to an adequate

level which is suitable for feeding the valve system of DC con-

verter and inverter.

Design options

The design concept of HVDC transformers is mainly influenced

by the rated voltage, rated power and transportation require-

ments like dimensions, weight and mode of transportation.

Many large power HVDC converter station are located in rural

areas of low infrastructure. Frequently, special geometrical

profiles have to be fulfilled in order to move such transformers

by railway.

Typically, HVDC transformers are single phase units containing

2 winding limbs. This concept can include either 2 parallel valve

windings (two for delta or two for wye system, fig. 5.8-1) or two

different valve windings (one for delta and one for wye, fig. 5.8-

2). In order to reduce the total transportation height frequently

the core assembly includes 2 return limbs. Due to redundancy

requirements in HVDC stations 3 phase units are quite

uncommon.

The valve windings are exposed to AC and DC dielectric stress

and therefore a special insulation assembly is necessary. Further-

more, special lead systems connecting the turrets and windings

have to be installed in order to withstand the DC voltage of

rectifier. Additionally, the load current contains harmonic com-

ponents of considerable energy resulting in higher losses and

increased noise. Above all, special bushings are necessary for

the valve side to access upper and lower winding terminals of

each system from outside. Conclusively, two identical bushings

are installed for star or delta system.

For approving the proper design and quality of manufacturing

special applied DC and DC polarity reversal tests have to be

carried out. The test bay has to be equipped with DC test appa-

ratus accordingly and needs to provide adequate geometry to

withstand the DC test voltage.

Technical items

In addition to the standard parameters of power transformers,

special performance requirements have to be known for the

design of HVDC transformers. These parameters are jointly

defined by designers of the HVDC station and transformer design

engineers in order to reach a cost-effective design for the entire

equipment.

Special parameters are:

tȋ Test levels: DC applied, DC polarity reversal and long-time AC

defines the insulation assembly of the transformer

tȋ Harmonic spectrum of the load current and phase relation

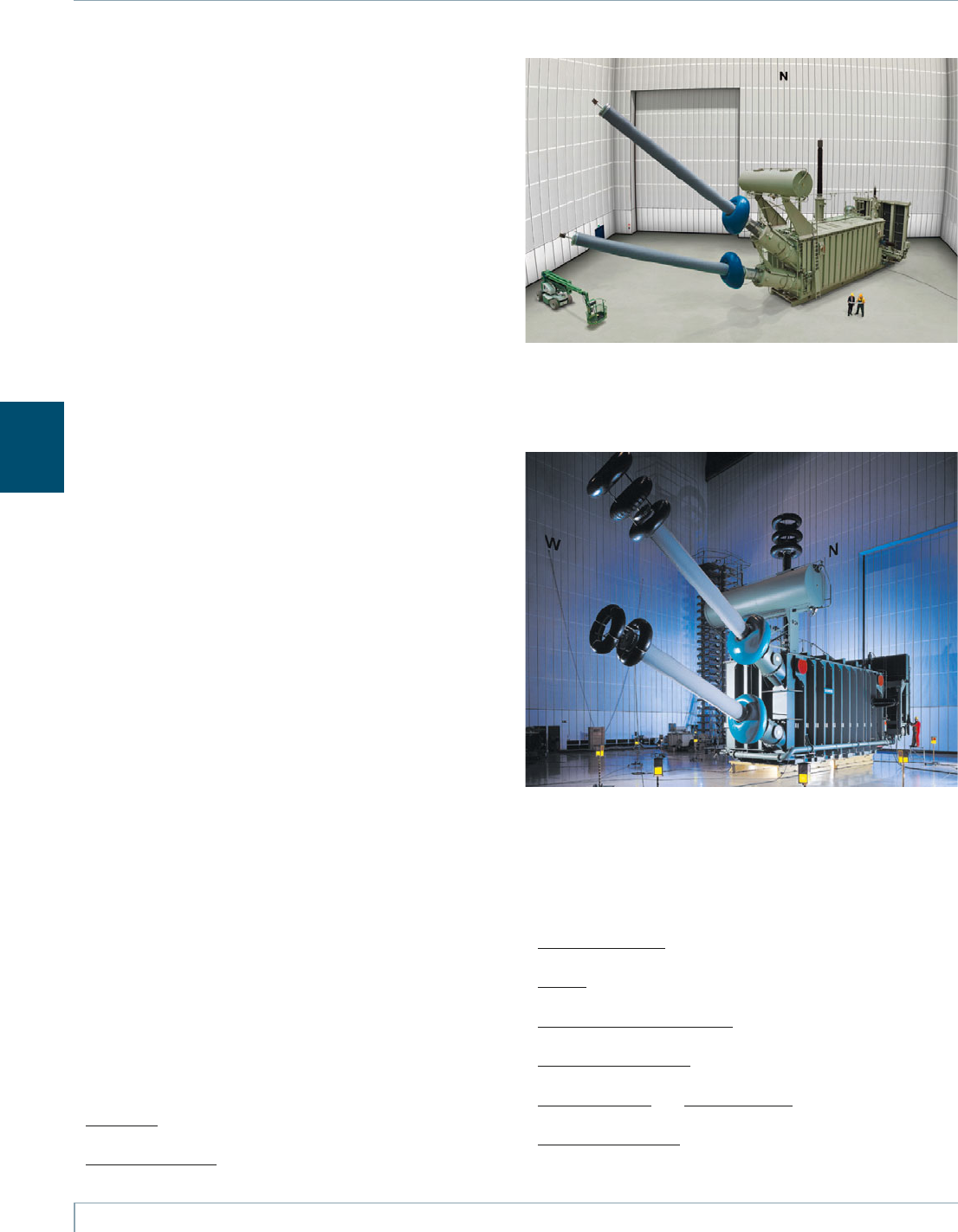

Fig. 5.8-1: Converter transformer for UHVDC bipolar transmission

system ± 800 kVDC, 6,400 MW; 2,071 km: single phase;

550 kVAC, 816 kVDC; 321 MVA; high pulse wye system

feeding

Fig. 5.8-2: Converter transformer for HVDC bipolar transmission

system ± 500 kVDC; 2,500 MW: single phase; 420 kVAC;

515 kVDC; 397 MVA; wye system (left side of figure) and

delta system (right side of figure)

generate additional losses, which have to compensated by the

cooling circuit

tȋ Voltage impedance impacting the dimensions of windings and

the total height of the transformer

tȋ DC bias in load and current and transformer-neutral have to be

considered for no-load noise and no-load losses

tȋ Derivative of the load current (di/dt) is a key parameter for the

on-load tap changer

tȋ Overload requirements have to be considered for cooling

circuit and capacity of coolers

tȋ Regulation range and number of steps influence the voltage

per turn which is a key design parameter

tȋ Seismic requirements have to be considered for mechanical

strength of turrets, outlets and bushings

247

Transformers

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

5.9 Distribution

Transformers

5.9.1 Liquid-immersed Distribution

Transformers for

European/US/Canadian Standard

On the last transformation step from the power station to the

consumer, distribution transformers (DT) provide the necessary

power for systems and buildings. Accordingly, their operation

must be reliable, efficient and, at the same time, silent.

Distribution transformers are used to convert electrical energy

of higher voltage, usually up to 36 kV, to a lower voltage,

usually 250 up to 435 V, with an identical frequency before and

after the transformation. Application of the product is mainly

within suburban areas, public supply authorities and industrial

customers. Distribution transformers are usually the last item in

the chain of electrical energy supply to households and indus-

trial enterprises.

Distribution transformers are fail-safe, economical and have a

long life expectancy. These fluid-immersed transformers can be

1-phase or 3-phase. During operation, the windings can be

exposed to high electrical stress by external overloads and high

mechanical stress by short-circuits. They are made of copper or

aluminum. Low-voltage windings are made of strip or flat wire,

and the high-voltage windings are manufactured from round

wire or flat wire.

Three product classes – standard, special and renewable –

are available, as follows:

tȋ Standard distribution transformers:

ȋ– Pole mounted (fig. 5.9-1), wound core or stacked

core technology distribution transformer

(≤ 2,500 kVA, U

m

≤ 36 kV)

ȋ– Wound core or stacked core technology medium distribution

transformer (> 2,500 ≤ 6,300 kVA, U

m

≤ 36 kV)

ȋ– Large distribution transformer

(> 6.3 – 30.0 MVA, U

m

≤ 72.5 kV)

ȋ– Voltage regulator (fig. 5.9-2)

tȋ Special distribution transformers:

ȋ– Special application: self-protected DT, regulating DT (OLTC),

electronic regulate DT, low-emission DT or others

(autotransformer, transformer for converters, double-tier,

multiwinding transformer, earthing transformer)

ȋ– Environmental focus: amorphous core DT with significant

low no-load losses, DT with special low load-loss design,

low-emission DT in regard of noise and/or electromagnetic

field emissions, DT with natural or synthetic ester where

higher fire-resistance and/or biodegradability is required

tȋ Renewable distribution transformers:

ȋ– Used in wind power stations, solar power plants or sea flow/

generator power plants

Fig. 5.9-1: Pole mounted, Canada

Fig. 5.9-2: Liquid-immersed distribution transformer

248

Transformers

5.9 Distribution Transformers

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

5.9.2 Voltage Regulators

Siemens invented the voltage regulator in 1932 and pioneered

its use in the United States. Voltage Regulators are tapped step

autotransformers used to ensure that a desired level of voltage

is maintained at all times. A voltage regulator comprises a

tapped autotransformer and a tap changer. The standard

voltage regulator provides ± 10 % adjustment in thirty-two

0.625 % steps. Voltage Regulators with ± 15 % and ± 20 %

regulation are available for some designs.

Voltage regulators are liquid-immersed and can be 1-phase or

3-phase. They may be self-cooled or forced air-cooled. Available

at 50 or 60 Hz and with 55 or 65 °C temperature rise, they can

be used in any electrical system to improve voltage quality.

Voltage regulator ratings are based on the percent of regulation

(i.e., 10 %). For example, a set of three 1-phase 333 kVA regula-

tors would be used with a 10 MVA transformer (e.g., 10 MVA

t

0.10/3 = 333 kVA). 1-phase voltage regulators are available in

ratings ranging from 2.5 kV to 19.9 kV and from 38.1 kVA to

889 kVA (fig. 5.9-3). 3-phase voltage regulators are available at

13.2 kV or 34.5 kV and from 500 kVA to 4,000 kVA.

Voltage regulators can be partially or completely untanked for

inspection and maintenance without disconnecting any internal

electrical or mechanical connections. After the unit is untanked,

it is possible to operate the voltage regulator mechanism and

test the control panel from an external voltage source without

any reconnections between the control and the regulator.

Standard external accessories

The standard accessories are as follows:

tȋ External metal-oxide varistor (MOV) bypass arrester

tȋ Cover-mounted terminal block with a removable gasketed

cover. It allows easy potential transformer reconnections

for operation at different voltages

tȋ Oil sampling valve

tȋ Two laser-etched nameplates

tȋ External oil sight gauge that indicates oil level at 25 °C

ambient air temperature and oil color

tȋ External position indicator that shows the tap changer position

tȋ Mounting bosses for the addition of lightning arresters to the

source (S), load (L) and source-load (SL) bushings. They shall

be fully welded around their circumference.

Accessories and options

Remote mounting kit

Extra-long control cable shall be provided for remote mounting

of the control cabinet at the base of the pole.

Sub-bases

To raise the voltage regulator to meet safe operating clearances

from the ground to the lowest live part.

Auxiliary PT

Operation at different voltages.

Testing

All voltage regulators shall be tested in accordance with the

latest ANSI C57.15 standards.

Standard tests include:

tȋ Resistance measurements of all windings

tȋ Ratio tests on all tap locations

tȋ Polarity test

tȋ No-load loss at rated voltage and rated frequency

tȋ Excitation current at rated voltage and rated frequency

tȋ Impedance and load loss at rated current and rated frequency

tȋ Applied potential

tȋ Induced potential

tȋ Insulation power factor test

tȋ Impulse test

tȋ Insulation resistance

Fig. 5.9-3: 1-phase voltage

regulator, JFR

249

Transformers

5.9 Distribution Transformers

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

5.9.3 GEAFOL Cast-Resin Transformers

GEAFOL transformers have been in successful service since

1965. Many licenses have been granted to major manufacturers

throughout the world since then. Over 100,000 units have

proven themselves in power distribution or converter operation

all around the globe.

Advantages and applications

GEAFOL distribution and power transformers in ratings from 100

to approximately 50,000 kVA and lightning impulse (LI) values

up to 250 kV are full substitutes for liquid-immersed trans-

formers with comparable electrical and mechanical data. They

are designed for indoor installation close to their point of use at

the center of the major load consumers. The exclusive use of

flame-retardant insulating materials frees these transformers

from all restrictions that apply to oil-filled electrical equipment,

such as the need for oil collecting pits, fire walls, fire extin-

guishing equipment. For outdoor use, specially designed sheet

metal enclosures are available.

GEAFOL transformers are installed wherever oil-filled units

cannot be used or where use of liquid-immersed transformers

would require major constructive efforts such as inside build-

ings, in tunnels, on ships, cranes and offshore platforms, inside

wind turbines, in groundwater catchment areas and in food

processing plants. For outdoor use, specially designed sheet

metal enclosures are available.

Often these transformers are combined with their primary and

secondary switchgear and distribution boards into compact

substations that are installed directly at their point of use.

When used as static converter transformers for variable speed

drives, they can be installed together with the converters at the

drive location. This reduces construction requirements, cable

costs, transmission losses and installation costs.

GEAFOL transformers are fully LI-rated. Their noise levels are

comparable to oil-filled transformers. Taking into account the

indirect cost reductions just mentioned, they are also mostly

Fig. 5.9-4: GEAFOL cast-resin dry-type transfomer properties

* on-load tap changers on request

HV winding

Consisting of vacuum-potted

single foil-type aluminum coils.

See enlarged detail

in fig. 5.9-5

HV terminals

Variable arrangements,

for optimal station design.

HV tapping links for

adjustment to system

conditions, reconnectable

in de-energized state*

Resilient spacers

To insulate core and

windings from mechanical

vibrations, resulting in low

noise emissions

LV winding

Made of aluminum strip.

Turns firmly glued together

by means of insulating sheet

wrapper material

Temperature monitoring

By PTC or Pt 100 thermistor

detectors in the LV winding

Paint finish

on steel parts

Thick layer coating,

RAL 5009. On request:

Two-component varnish

(for aggressive

environments

or high humidity)

Clamping frame and truck

Rollers can be swung

around for lengthways

or sideways travel

Insulation

Mixture of epoxy resin

and quartz powder

makes the transformer

practically maintenance-

free, moisture-proof,

tropicalized, flame-resistant

and self-extinguishing

LV terminals

Normal arrangement:

Top, rear

Special version:

Bottom, available on

request at extra charge

Ambient class E2

Climatic category C2

(If the transformer is installed

outdoors, degree of protection

IP23 must be assured)

Three-leg core

Made of grain-oriented,

low-loss electrolaminations

insulated on both sides

Fire class F1

250

Transformers

5.9 Distribution Transformers

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

U

U

2 3 4 5 6 7 8

1 2 3 4 5 6 7

2 4 6 8

1 3 5 7

Foil winding

The interlayer voltage is equal

to the interturn voltage

Round-wire winding

The interturn voltages can add up

to twice the interlayer voltage

Fig. 5.9-5: High-voltage encapsulated winding design of

GEAFOL cast-resin transformer and voltage stress of a

conventional round-wire winding (above) and the foil

winding (below)

cost-competitive. By virtue of their design, GEAFOL transformers

are practically maintenance-free.

Standards and regulations

GEAFOL cast-resin dry-type transformers comply with

IEC 60076-11, EN 60076-11 and EN 50541-1.

Characteristic properties (fig. 5.9-4)

HV winding

The high-voltage windings are wound from aluminum foil

interleaved with high-grade insulating foils. The assembled and

connected individual coils are placed in a heated mold and are

potted in a vacuum furnace with a mixture of pure silica (quartz

sand) and specially blended epoxy resins. The only connections

to the outside are casted brass nuts that are internally

bonded to the aluminum winding connections.

The external delta connections are made of

insulated copper or aluminum connectors to

guarantee an optimal installation design. The resulting high-

voltage windings are fire-resistant, moisture-proof and corro-

sion-proof, and they show excellent aging properties under all

operating conditions.

The foil windings combine a simple winding technique with a

high degree of electrical safety. The insulation is subjected to

less electrical stress than in other types of windings. In a conven-

tional round-wire winding, the interturn voltages can add up to

twice the interlayer voltage. In a foil winding, it never exceeds

the voltage per turn, because a layer consists of only one

winding turn. This results in high AC voltage and impulse

voltage withstand capacity.

Aluminum is used because the thermal expansion coefficients of

aluminum and cast resin are so similar that thermal stresses

resulting from load changes are kept to a minimum (fig. 5.9-5).

LV winding

The standard low-voltage winding with its considerably reduced

dielectric stresses is wound from single aluminum sheets with

interleaved cast-resin impregnated fiberglass fabric (prepreg).

The assembled coils are then oven-cured to form uniformly

bonded solid cylinders that are impervious to moisture. Through

the single-sheet winding design, excellent dynamic stability

under short-circuit conditions is achieved. Connections are

submerged arc-welded to the aluminum sheets and are

extended either as aluminum or copper bars to the secondary

terminals.

Fire safety

GEAFOL transformers use only flame-retardant and self-extin-

guishing materials in their construction. No additional sub-

stances, such as aluminum oxide trihydrate, which could nega-

tively influence the mechanical stability of the cast-resin

molding material, are used. Internal arcing from electrical faults

and externally applied flames do not cause the transformers to

251

Transformers

5.9 Distribution Transformers

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

burst or burn. After the source of ignition is removed, the trans-

former is self-extinguishing. This design has been approved by

fire officials in many countries for installation in populated

buildings and other structures. The environmental safety of the

combustion residues has been proven in many tests (fig. 5.9-6).

Categorization of cast-resin transformers

Dry-type transformers have to be classified under the categories

listed below:

tȋ Environmental category

tȋ Climatic category

tȋ Fire category

These categories have to be shown on the rating plate of each

dry-type transformer.

The properties laid down in the standards for ratings within the

category relating to environment (humidity), climate and fire

behavior have to be demonstrated by means of tests.

These tests are described for the environmental category

(code numbers E0, E1 and E2) and for the climatic category

(code numbers C1 and C2) in IEC 60076-11. According to this

standard, the tests are to be carried out on complete trans-

formers. The tests of fire behavior (fire category code numbers

F0 and F1) are limited to tests on a duplicate of a complete

transformer that consists of a core leg, a low-voltage winding

and a high-voltage winding.

GEAFOL cast-resin transformers meet the requirements of the

highest defined protection classes:

tȋ Environmental category E2 (optional for GEAFOL-BASIC)

tȋ Climatic category C2

tȋ Fire category F1

Insulation class and temperature rise

The high-voltage winding and the low-voltage winding utilize

class F insulating materials with a mean temperature rise of

100 K (standard design).

Overload capability

GEAFOL transformers can be overloaded permanently up to 50 %

(with a corresponding increase in impedance voltage and load

losses) if additional radial cooling fans are installed (dimensions

can increase by approximately 100 mm in length and width.)

Short-time overloads are uncritical as long as the maximum

winding temperatures are not exceeded for extended periods of

time (depending on initial load and ambient air temperature).

Temperature monitoring

Each GEAFOL transformer is fitted with three temperature

sensors installed in the LV winding, and a solid-state tripping

device with relay output. The PTC thermistors used for sensing

are selected for the applicable maximum hot-spot winding

temperature.

Additional sets of sensors can be installed, e.g. for fan control

purposes. Alternatively, Pt100 sensors are available. For oper-

Fig. 5.9-6: Flammability test of cast-resin transformer

Fig. 5.9-7: Radial cooling fans on GEAFOL transformer for AF cooling

Table 5.9-1: Standard insulation levels of GEAFOL

U

m

(kV) LI (kV) AC (kV)

1.1 – 3

12 75 28

24 95* 50

36 145* 70

* other levels upon request

ating voltages of the LV winding of 3.6 kV and higher, special

temperature measuring equipment can be provided.

Auxiliary wiring is run in a protective conduit and terminated in

a central LV terminal box (optional). Each wire and terminal is

identified, and a wiring diagram is permanently attached to the

inside cover of this terminal box.

252

Transformers

5.9 Distribution Transformers

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

Installation and enclosures

Indoor installation in electrical operating rooms or in various

sheet metal enclosures is the preferred method of installation.

The transformers need to be protected only against access to the

terminals or the winding surfaces, against direct sunlight and

against water. Unless sufficient ventilation is provided by the

installation location or the enclosure, forced-air cooling must be

specified or provided by others (fig. 5.9-7).

Instead of the standard open terminals, plug-type elbow con-

nectors can be supplied for the high-voltage side with LI ratings

up to 170 kV. Primary cables are usually fed to the transformer

from trenches below but can also be connected from above

(fig. 5.9-8).

Secondary connections can be made by multiple insulated

cables, or by connecting bars from either below or above.

Secondary terminals are made of aluminum (copper upon

request).

A variety of indoor and outdoor enclosures in different protec-

tion classes are available for the transformers alone, or for

indoor compact substations in conjunction with high-voltage

and low-voltage switchgear panels. PEHLA-tested housings are

also available (fig. 5.9-9).

Cost-effective recycling

The oldest of the GEAFOL cast-resin transformers that entered

production in the mid-1960s are approaching the end of their

service life. Much experience has been gathered over the years

with the processing of faulty or damaged coils from such trans-

formers. The metal materials and resin used in GEAFOL cast-resin

transformers, that is, approximately 95 % of their total mass, can

be recyled. The process used is non-polluting. Given the value of

secondary raw materials, the procedure is often cost-effective,

even with the small amounts currently being processed.

Fig. 5.9-9: GEAFOL transformer in protective housing to IP20/40

Fig. 5.9-8: GEAFOL transformer with plug-type cable connections

The GEAFOL Basic – a true GEAFOL and more

The GEAFOL Basic is based on more than 45 years of proven

GEAFOL technology and quality, but it offers numerous innova-

tions that has allowed Siemens to provide it with several very

special characteristics. For example, the GEAFOL Basic distribu-

tion transformer with a maximum rated power of 3.15 MVA and

a maximum medium voltage of 36 kV is almost ten percent

lighter than a comparable model from the proven GEAFOL series.

And this “slimming down” also positively affects the dimensions.

This could be achieved by a considerably improved heat dissipa-

tion because of the new, patented design.

Of course all GEAFOL Basic distribution transformers meet the

specifications of IEC 60076-11, EN 60076-11 and EN 50541-1.

They meet the highest requirements for safe installation in

residential and work environments with Climatic Class C2, Envi-

ronmental Class E2 (standard model meets E1; E2 is available as

option at additional costs) and Fire Classification F1. With fewer

horizontal surfaces, less dust is deposited, which leads to a

further reduction in the already minimal time and effort needed

for maintenance and also increases operational reliability.

Optimum compromise

The GEAFOL Basic distribution transformer represents an

optimum compromise between performance, safety and small

dimensions. In addition, the high degree of standardization

ensures the best possible cost-benefit ratio. Thanks to their

compact shape and comprehensive safety certification, GEAFOL

Basic distribution transformers can be used in almost every

environment.

253

Transformers

5.9 Distribution Transformers

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

9

6

1

4

2

3

5

8

7

A new design for your success –

the r

eliable, space-saving GEAFOL Basic

1

Three-limb core

Made of grain-oriented, low-loss

electric sheet steel that is insulated

on both sides

2

Low-voltage winding

Made of aluminum strip; turns are

permanently bonded with insulating sheet

3

High-voltage winding

Made of individual aluminum coils using

foil technology and vacuum casting

4

Low-voltage connectors (facing up)

5

Lifting eyes

Integrated into the upper core frame

for simple transport

6

Delta connection tubes with

HV terminals

7

Clamping frame and truck

Convertible rollers for longitudinal

and transverse travel (rollers optional)

8

Insulation made of an epoxy resin/

quartz powder mixture

Makes the transformer extensively

maintenance-free, moisture-proof

and suitable for the tropics, fire-

resistant and self-extinguishing

9

High-voltage taps ±2 x 2.5 %

(on the high-voltage connector side)

to adapt to the respective network

conditions; reconnectable off load

Temperature monitoring

With PTC thermistor detector in limb V

of the low-voltage winding (in all three

phases upon request)

Painting of steel parts

High-build coating, RAL 5015:

two-component coating upon request

(for particularly aggressive environments)

Structure made of individual components

For example, windings can be individually

assembled and replaced on site

254

Transformers

5.9 Distribution Transformers

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

5.9.4 GEAFOL Special Transformers

GEAFOL cast-resin transformers with oil-free

on-load tap changers

The voltage-regulating cast-resin transformers connected on the

load side of the medium-voltage power supply system feed the

plant-side distribution transformers. The on-load tap changer

controlled transformers used in these medium-voltage systems

need to have appropriately high ratings.

Siemens offers suitable transformers in its GEAFOL design

(fig. 5.9-10), which has proved successful over many years and

is available in ratings of up to 50 MVA. The range of rated

voltage extends to 36 kV, and the maximum impulse voltage is

200 kV (250 kV). The main applications of this type of trans-

former are in modern industrial plants, hospitals, office and

apartment blocks and shopping centers.

Linking 1-pole tap changer modules together by means of

insulating shafts produces a 3-pole on-load tap changer for

regulating the output voltage of 3-phase GEAFOL transformers.

In its nine operating positions, this type of tap changer has a

rated current of 500 A and a rated voltage of 900 V per step.

This allows voltage fluctuations of up to 7,200 V to be kept

under control. However, the maximum control range utilizes

only 20 % of the rated voltage.

Transformers for static converters

These are special liquid-immersed or cast-resin power trans-

formers that are designed for the special demands of thyristor

converter or diode rectifier operation.

The effects of such conversion equipment on transformers and

additional construction requirements are as follows:

tȋ Increased load by harmonic currents

tȋ Balancing of phase currents in multiple winding systems

(e.g., 12-pulse systems)

tȋ Overload capability

tȋ Types for 12-pulse systems, if required

Siemens supplies oil-filled converter transformers of all ratings

and configurations known today, and dry-type cast-resin con-

verter transformers up to 50 MVA and 250 kV LI (fig. 5.9-11).

To define and quote for such transformers, it is necessary to

know considerable details on the converter to be supplied and

Fig. 5.9-10: 16/22-MVA GEAFOL cast-resin transformer with oil-free on-load tap changer

255

Transformers

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

on the existing harmonics. These transformers are almost exclu-

sively inquired together with the respective drive or rectifier

system and are always custom-engineered for the given applica-

tion.

Neutral earthing transformers

When a neutral earthing reactor or earth-fault neutralizer is

required in a 3-phase system and no suitable neutral is available,

a neutral earthing must be provided by using a neutral earthing

transformer.

Neutral earthing transformers are available for continuous

operation or short-time operation. The zero impedance is

normally low. The standard vector groups are zigzag or wye/

delta. Some other vector groups are also possible.

Neutral earthing transformers can be built by Siemens in all

common power ratings in liquid-immersed design and in cast-

resin design.

Transformers for Silicon-reactor power feeding

These special transformers are an important component in

plants for producing polycrystalline silicon, which is needed

particularly by the solar industry for the manufacture of collec-

tors.

What’s special about these transformers is that they have to

provide five or more secondary voltages for the voltage supply

of the special thyristor controllers. The load is highly unbalanced

and is subject to harmonics that are generated by the con-

verters. Special geafol cast resin transformers with open sec-

ondary circuit have been developed for this purpose. The rated

power can be up to round about 10 MVA, and the current can

exceed an intensity of 5,000 amps depending on the reactor

type and operating mode. Depending on the reactor control

system two-winding or multi-winding transformers will be used

(fig. 5.9-12).

Fig. 5.9-11: 23-MVA GEAFOL cast resin transformer 10 kV/Dd0Dy11

Fig. 5.9-12: 4771 kVA GEAFOL converter transformer with

5 secondary tappings 10/0.33 – 2.4 kV

For further information:

Fax: ++49 (0) 70 21-5 08-4 95

www.siemens.com/energy/transformers

256

Transformers

Siemens Energy Sector t Power Engineering Guide t Edition 7.0

5

5.10 Traction Transformers

Siemens produces transformers for railway applications called

traction transformers. These transformers are installed in electric

cars such as high-speed trains, electric multiple units (EMUs)

and electric locomotives. Their main purpose is transform the

overhead contact line voltage, which range mainly from 15 kV

up to 25 kV, to voltages suitable for traction converters

(between 0.7 kV and 1.5 kV) (fig. 5.10-1).

Siemens develops and produces traction transformers for rolling

stock applications of all relevant ratings, voltage levels and

customer-specific requirements.

All products are optimized with regard to individual customer

requirements such as:

tȋ Frequency, rating and voltage

tȋ Required dimensions and weights

tȋ Losses and impedance voltage characteristics

tȋ Operational cycles and frequency response behavior

tȋ Environmental requirements

Characterization

Technically, traction transformers are in general characterized as

follows:

tȋ 1-phase transformers

tȋ Ratings up to 10 MVA and above

tȋ Operating frequencies from 16⅔ to 60 Hz

tȋ Voltages: 1.5 kV DC, 3 kV DC, 15 kV, 25 kV, 11.5 kV

or other specific solutions

tȋ Weight: < 15 t

tȋ Auxiliary windings and/or heater windings according to

customer specification

tȋ Single or multiple system operation

tȋ Under floor, machine room or roof assembly

tȋ Traction windings to be used as line filters

tȋ Integrated absorption circuit reactors

tȋ Various cooling media for all ratings: mineral oil, silicone or

ester fluid for highest environmental compatibility

In case of customer request:

tȋ With cooling plant – integrated in one frame together with the

transformer or stand-alone solution